When considering the longevity of a wood haul boat, several factors come into play, including the type of wood used, the quality of construction, maintenance practices, and environmental conditions. Typically, a well-built and properly maintained wooden boat can last for several decades, with some even enduring for over a century. Hardwoods like oak, mahogany, and teak are favored for their durability and resistance to decay, while regular maintenance, such as sealing, painting, and addressing any signs of wear, significantly extends the boat's lifespan. However, exposure to harsh weather, saltwater, and neglect can accelerate deterioration, making consistent care essential for maximizing the boat's longevity.

| Characteristics | Values |

|---|---|

| Average Lifespan | 10–30 years (varies based on maintenance, wood type, and usage) |

| Wood Type Influence | Teak, oak, and cedar last longer (20–30+ years); pine lasts 10–15 years |

| Maintenance Impact | Regular maintenance (sealing, varnishing) extends lifespan by 5–10 years |

| Environmental Factors | Freshwater boats last longer than saltwater boats (due to corrosion) |

| Usage Frequency | Light use: 20–30 years; heavy use: 10–15 years |

| Rot and Decay Resistance | Teak and cedar are highly resistant; pine is less resistant |

| Repairability | Wood boats are highly repairable, extending lifespan with proper care |

| Cost of Maintenance | Annual maintenance costs $500–$2,000, depending on boat size and condition |

| Storage Conditions | Covered, dry storage extends lifespan by 5–10 years |

| Restoration Potential | Proper restoration can add 10–15 years to lifespan |

Explore related products

What You'll Learn

Factors Affecting Boat Lifespan

Wooden boats, when properly maintained, can last for decades, even centuries. However, their lifespan is influenced by a myriad of factors that go beyond the material itself. Understanding these factors is crucial for boat owners who aim to preserve their vessels for as long as possible. One of the most significant determinants is the type of wood used. Hardwoods like teak, oak, and mahogany are more durable and resistant to rot compared to softer woods such as pine or cedar. The choice of wood not only affects the boat’s structural integrity but also its ability to withstand environmental stressors over time.

Environmental conditions play a pivotal role in a wooden boat’s longevity. Prolonged exposure to saltwater, for instance, accelerates corrosion and wood degradation, necessitating regular maintenance and protective coatings. Freshwater environments are less harsh but still require vigilance against moisture absorption, which can lead to rot and fungal growth. UV radiation from sunlight is another silent adversary, causing wood to dry out, crack, and weaken over time. Boat owners in sunny climates should invest in UV-resistant finishes and consider storing their boats under cover when not in use.

Maintenance practices are the cornerstone of extending a wooden boat’s lifespan. Regular inspections for cracks, leaks, and signs of rot are essential, as early detection can prevent minor issues from escalating. Applying marine-grade sealants and varnishes at least once a year helps protect the wood from moisture and UV damage. Additionally, proper cleaning routines, including removing algae and barnacles, are vital to prevent surface degradation. For those in colder climates, winterization is critical—draining water systems and storing the boat in a dry, temperature-controlled environment prevents freeze-thaw damage.

Usage patterns also significantly impact a wooden boat’s durability. Frequent, heavy use in rough waters subjects the boat to greater stress, increasing the likelihood of structural damage. Conversely, boats used sparingly and in calm conditions tend to last longer, as they experience less wear and tear. Regardless of usage, adhering to the manufacturer’s guidelines for load capacity and operational limits is essential to avoid overstressing the hull. Customizing storage and handling practices to match the boat’s usage profile can further mitigate risks and prolong its life.

Finally, the craftsmanship and design of the boat itself are non-negotiable factors in its longevity. A well-built wooden boat with precise joinery, proper caulking, and thoughtful design will inherently outlast a poorly constructed one. Investing in a skilled shipwright for repairs or restorations ensures that the boat’s structural integrity is maintained. Modern advancements, such as epoxy resins and composite materials, can also be integrated into traditional wooden boats to enhance durability without compromising their classic appeal. By addressing these factors holistically, wooden boat owners can maximize their vessel’s lifespan and enjoy it for generations.

Mastering Wood Chip Soaking: Optimal Time for Perfect Smoking Results

You may want to see also

Explore related products

$42.21 $51.49

Maintenance Tips for Durability

Wooden haul boats, with their timeless charm and craftsmanship, can endure for decades, even centuries, when properly maintained. However, their longevity hinges on consistent care tailored to their unique material properties. Exposure to moisture, sunlight, and marine organisms poses the greatest threats, accelerating decay and structural compromise.

Preventative Measures: The Foundation of Durability

The cornerstone of wooden boat preservation lies in proactive measures. Regular cleaning is paramount, removing salt, grime, and organic matter that foster rot and attract pests. After each outing, rinse the hull thoroughly with fresh water, paying particular attention to crevices and areas prone to water pooling. For stubborn stains, use mild, marine-safe cleaners, avoiding harsh chemicals that can damage the wood's natural oils.

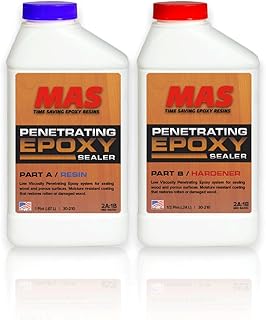

Every six months, inspect the boat meticulously for signs of wear and tear. Look for cracks, splintering, loose fasteners, and areas where the wood feels soft or spongy, indicating rot. Address these issues promptly, replacing damaged sections and reinforcing weak points with marine-grade epoxy or fiberglass.

Protective Coatings: A Shield Against the Elements

A well-applied protective coating acts as a barrier against moisture infiltration and UV damage. Choose a high-quality marine varnish or epoxy specifically formulated for wooden boats. Apply multiple thin coats, allowing each layer to dry completely before proceeding. Reapply the coating annually or as recommended by the manufacturer, ensuring continuous protection. For added UV resistance, consider incorporating a UV-inhibiting additive into the final coat.

In humid climates or for boats stored in water, consider using a moisture-resistant primer before applying the topcoat. This extra layer provides an additional barrier against water penetration, further safeguarding the wood.

Storage Strategies: Minimizing Environmental Stress

Proper storage significantly extends a wooden boat's lifespan. Whenever possible, store the boat out of direct sunlight and under cover. A dry, well-ventilated shed or boathouse is ideal. If outdoor storage is necessary, use a breathable boat cover to protect against rain and debris while allowing moisture to escape.

For long-term storage, consider blocking the boat off the ground using stands or cradles. This prevents the hull from resting directly on a damp surface, reducing the risk of rot. Periodically inspect the boat during storage, checking for signs of moisture accumulation or pest infestation.

Beyond the Basics: Advanced Care Techniques

For older wooden boats or those with historical significance, more specialized care may be required. Consult with a professional boatwright for guidance on restoration techniques, such as steam bending, scarfing, and traditional caulking methods. Regularly monitor the boat's structural integrity, addressing any issues promptly to prevent further deterioration.

By implementing these maintenance practices, wooden haul boats can be cherished for generations, their beauty and functionality enduring as a testament to the enduring appeal of this timeless craft. Remember, consistent care is the key to unlocking the full potential of these maritime treasures.

The Rise and Fall of Bretton Woods: A 27-Year Legacy

You may want to see also

Explore related products

$11.99

Wood Types and Longevity

The lifespan of a wooden haul boat hinges largely on the type of wood used in its construction. Different woods possess varying levels of durability, resistance to rot, and ability to withstand the harsh marine environment.

Understanding these characteristics is crucial for anyone considering building or maintaining a wooden boat.

Hardwoods: The Champions of Longevity

Hardwoods, derived from deciduous trees, are renowned for their density and strength. Teak, a premium choice for boatbuilding, boasts exceptional durability due to its natural oils that resist rot, insects, and warping. Boats constructed from teak can easily last for decades, even centuries, with proper care. Mahogany, another popular hardwood, offers good durability and a beautiful grain pattern, though it requires more maintenance than teak.

Softwoods: A Balancing Act

Softwoods, from coniferous trees, are generally less dense than hardwoods but offer advantages in terms of weight and workability. Cedar, known for its natural resistance to rot and insects, is a popular choice for boatbuilding, particularly for smaller vessels. Pine, while more susceptible to rot, is readily available and affordable, making it suitable for boats with shorter expected lifespans or those intended for freshwater use.

Beyond the Wood: Maintenance is Key

Regardless of wood type, proper maintenance is paramount to maximizing a wooden boat's lifespan. Regular cleaning, varnishing, and inspection for signs of rot or damage are essential. Keeping the boat out of the water when not in use and storing it in a dry, covered area significantly extends its life.

Choosing the Right Wood:

The ideal wood for a haul boat depends on factors like intended use, budget, and desired aesthetics. For a long-lasting, low-maintenance vessel, teak is the undisputed champion. For a more budget-friendly option with acceptable durability, cedar is a good choice. Pine, while less durable, can be suitable for occasional use or freshwater environments.

Maximizing Wood Mizer Blade Lifespan: Durability and Maintenance Tips

You may want to see also

Explore related products

Environmental Impact on Boats

Wooden boats, when properly maintained, can last for decades, even centuries, as evidenced by historic vessels still afloat today. However, their longevity is deeply intertwined with environmental factors that can either preserve or accelerate their deterioration. Sunlight, moisture, temperature fluctuations, and marine organisms all play critical roles in determining a wooden boat’s lifespan. For instance, prolonged exposure to UV rays can degrade wood fibers, while saltwater immersion fosters rot and corrosion of fasteners. Understanding these impacts is essential for boat owners aiming to maximize durability while minimizing ecological harm.

One of the most effective strategies to mitigate environmental damage is through proactive maintenance. Applying marine-grade sealants and UV-resistant varnishes can shield wood from sunlight and moisture, extending the boat’s life by 5–10 years. Regular inspections for cracks, blisters, or signs of marine borer infestation are equally vital. For example, replacing damaged planks promptly can prevent water intrusion, which, if left unchecked, can lead to structural failure within 2–3 years. Additionally, storing the boat in a covered area or using breathable tarps reduces exposure to harsh weather, further preserving its integrity.

The choice of materials and construction techniques also significantly influences a wooden boat’s environmental resilience. Traditional methods like carvel or clinker planking, when combined with modern preservatives like epoxy resins, can enhance durability without compromising authenticity. For instance, epoxy-coated wooden boats have been shown to withstand saltwater environments for up to 30 years with minimal degradation. Conversely, using untreated wood or inferior fasteners can halve this lifespan, leading to frequent repairs and increased waste.

Beyond maintenance and materials, the environmental impact of wooden boats extends to their ecological footprint. Unlike fiberglass or aluminum vessels, wooden boats are biodegradable and often built from renewable resources, making them a more sustainable option. However, the use of toxic preservatives like creosote or copper-based antifouling paints can harm marine ecosystems. Opting for eco-friendly alternatives, such as natural oils or non-toxic antifouling coatings, reduces pollution while maintaining performance. Boat owners can also contribute by participating in local marine conservation efforts, ensuring their vessel’s legacy aligns with environmental stewardship.

Finally, the cultural and historical value of wooden boats adds another layer to their environmental impact. Preserving these vessels not only honors maritime heritage but also reduces the demand for new, resource-intensive boats. Restoration projects, when done responsibly, can breathe new life into aging structures while minimizing waste. For example, reusing salvaged wood or repurposing old boats as floating gardens or educational exhibits demonstrates creativity and sustainability. By balancing preservation with innovation, wooden boat enthusiasts can ensure these crafts remain both environmentally and culturally significant for generations to come.

Wood County Ohio Affidavit Retention Period: What You Need to Know

You may want to see also

Explore related products

Signs of Aging and Repair

Wooden haul boats, with their timeless appeal and craftsmanship, are marvels of maritime tradition. Yet, like all vessels, they succumb to the relentless forces of nature and time. Recognizing the signs of aging is crucial for preserving their integrity and ensuring longevity. One of the earliest indicators is surface cracking, particularly along the gunwales and hull seams. These fissures, often hairline at first, signal drying and shrinking of the wood due to prolonged sun exposure and moisture fluctuations. Left unattended, they can deepen, compromising structural strength and allowing water intrusion.

Another telltale sign is rot, which manifests as soft, discolored, or spongy wood, especially in areas prone to moisture accumulation, such as the bilge or around fasteners. Rot is a silent destroyer, often hidden beneath paint or varnish, and requires immediate attention. To detect it, gently probe suspect areas with a screwdriver; if the wood gives way easily, rot has set in. Repair involves removing the damaged wood and replacing it with properly treated or matched timber, ensuring a seamless integration to maintain both aesthetics and functionality.

Fastener corrosion is a less obvious but equally critical issue. Wooden boats rely on metal screws, bolts, and nails to hold planks and frames together. Over time, saltwater exposure causes these fasteners to rust, expanding and splitting the surrounding wood. Regular inspection of exposed fasteners and their surrounding areas is essential. Replacing corroded hardware with stainless steel or galvanized alternatives, and sealing the holes with marine-grade epoxy, can prevent further damage.

Finally, warping and twisting of planks or frames are signs of prolonged stress, often caused by improper storage, uneven weight distribution, or inadequate support during dry-docking. These deformations not only affect the boat’s appearance but also its seaworthiness. Corrective measures may include re-fastening loose planks, adding temporary braces, or, in severe cases, steam-bending replacement wood to match the original curvature. Periodic inspection and proactive maintenance are key to addressing these issues before they escalate.

By staying vigilant for these signs of aging and addressing them promptly, owners can extend the life of their wooden haul boats, preserving their beauty and functionality for generations to come.

Wood Ducks Nesting Duration: Understanding Their Breeding Cycle

You may want to see also

Frequently asked questions

A well-maintained wood haul boat can last 30 to 50 years or more, depending on the type of wood, construction quality, and environmental conditions.

Factors include the type of wood used (e.g., teak or cedar are more durable), exposure to water and weather, maintenance frequency, and the boat's usage intensity.

Regular maintenance, such as cleaning, sealing, and repairing any damage promptly, can significantly extend its lifespan. Storing the boat in a dry, covered area when not in use also helps.