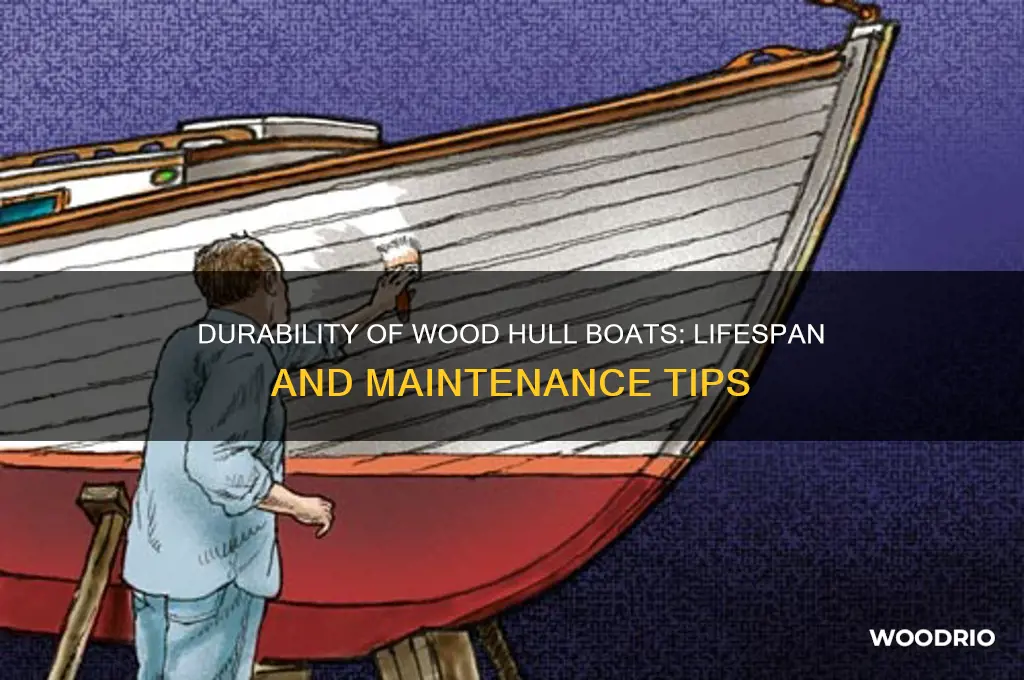

Wooden hull boats, when properly maintained, can last for several decades, with some well-cared-for vessels enduring for over a century. The longevity of a wood hull boat depends on factors such as the type of wood used, construction quality, environmental exposure, and regular maintenance practices. Hardwoods like teak, oak, and mahogany are more durable and resistant to decay, while softer woods require more frequent treatment. Protecting the hull from moisture, UV rays, and marine organisms through varnishes, paints, and antifouling coatings is crucial. Additionally, routine inspections for rot, cracks, and damage, along with timely repairs, significantly extend the boat’s lifespan. With diligent care, a wooden hull boat can remain seaworthy and aesthetically pleasing for generations.

| Characteristics | Values |

|---|---|

| Average Lifespan | 20-50 years (with proper maintenance) |

| Primary Factors Affecting Lifespan | Maintenance, environmental conditions, wood type, construction quality |

| Wood Type (Durability) | Teak, mahogany, oak (high durability); pine, cedar (moderate durability) |

| Maintenance Frequency | Annual inspections, regular varnishing, moisture control |

| Environmental Impact | Freshwater (longer lifespan); saltwater (shorter lifespan due to corrosion) |

| Common Issues | Rot, insect damage, delamination, cracks |

| Restoration Potential | High, with skilled craftsmanship and timely intervention |

| Cost of Maintenance | $500-$2,000 annually (varies by size and condition) |

| Lifespan with Neglect | 5-15 years |

| Comparative Lifespan (Fiberglass) | 30-50 years (generally lower maintenance) |

| Comparative Lifespan (Aluminum) | 40-60 years (more durable in harsh conditions) |

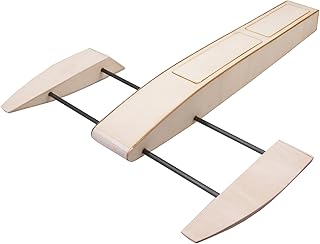

Explore related products

What You'll Learn

Maintenance impact on longevity

Wooden boats, when properly maintained, can outlast their fiberglass counterparts by decades, with some historic vessels still sailing after a century or more. The key to their longevity lies in consistent, proactive maintenance that addresses both visible and hidden threats. Water intrusion, UV exposure, and biological growth are the primary enemies of wood, but each can be mitigated with a structured care regimen. For instance, annual inspections should focus on caulking, seams, and fastenings, as these areas are prone to wear and can allow moisture to penetrate the hull. Applying a high-quality marine varnish or epoxy every 1-2 years not only enhances appearance but also creates a protective barrier against the elements.

The frequency and depth of maintenance directly correlate to a wooden boat’s lifespan. Neglecting routine tasks like cleaning and drying the hull after use can lead to rot, which often goes unnoticed until structural damage occurs. For example, freshwater rinsing after saltwater exposure prevents salt crystallization, a common cause of wood degradation. Similarly, storing the boat in a covered, dry environment reduces UV damage and minimizes the risk of fungal growth. Owners should also consider seasonal maintenance schedules: spring preparations might include sanding and re-coating, while winterization involves thorough cleaning and protective covering.

A persuasive argument for meticulous maintenance is the cost-effectiveness of prevention over repair. Replacing rotted planks or rebuilding a compromised frame can cost thousands, whereas regular upkeep requires minimal investment in materials and time. For instance, using a moisture meter to detect dampness in hidden areas allows for early intervention before rot spreads. Additionally, investing in professional inspections every 3-5 years can identify issues that untrained eyes might miss. This proactive approach not only extends the boat’s life but also preserves its value and historical integrity.

Comparing maintenance practices across different wooden boat types reveals tailored strategies for longevity. Traditional carvel-built boats, with their overlapping planks, require careful caulking and regular checks for seam integrity. In contrast, strip-planked or cold-molded boats benefit from epoxy saturation, which enhances durability but demands periodic inspections for cracks or delamination. Regardless of construction, all wooden boats thrive on a philosophy of "little and often"—small, consistent efforts that prevent major issues. For example, wiping down brightwork weekly prevents varnish breakdown, while monthly bilge inspections catch leaks early.

Descriptive accounts of well-maintained wooden boats underscore the rewards of diligence. A 1920s mahogany runabout, meticulously cared for by its owner, remains seaworthy and stunning, its hull gleaming with multiple layers of varnish applied over decades. Conversely, a neglected classic yacht, left exposed to the elements, succumbed to rot within 20 years, despite its initial robust construction. These examples illustrate that maintenance is not just about preservation but also about honoring the craftsmanship and heritage of wooden boats. By treating maintenance as a labor of love rather than a chore, owners ensure their vessels endure for generations.

Eric Rudolph's Survival: Years Hidden in the Appalachian Wilderness

You may want to see also

Explore related products

Environmental factors affecting durability

Wooden boats, when properly maintained, can endure for decades, even centuries. However, their longevity is significantly influenced by environmental factors that can either preserve or accelerate their deterioration. Understanding these factors is crucial for boat owners seeking to maximize the lifespan of their wooden vessels.

Moisture: The Arch-Nemesis of Wood

Moisture is the primary environmental threat to wooden hulls. Prolonged exposure to water, whether from immersion, rain, or humidity, can lead to rot, a process where fungi break down the wood's cellular structure. This is particularly problematic in areas with high rainfall or for boats frequently used in saltwater environments. Saltwater, due to its corrosive nature, can exacerbate the issue by accelerating the breakdown of wood fibers. To mitigate moisture damage, regular inspection and maintenance are essential. Applying high-quality marine-grade sealants and varnishes can create a protective barrier, reducing water absorption. Additionally, ensuring proper drainage and ventilation within the boat's interior can prevent moisture buildup.

Sunlight and Temperature Extremes: Silent Degraders

While less immediate than moisture, sunlight and temperature fluctuations also play a significant role in wood degradation. Ultraviolet (UV) rays from the sun can cause wood to fade, crack, and become brittle over time. This is especially noticeable in tropical regions with intense sunlight. Prolonged exposure to high temperatures can also dry out the wood, making it more susceptible to cracking and warping. Conversely, extreme cold can cause wood to contract, leading to potential structural issues. Boat owners in regions with harsh weather conditions should consider using UV-protective covers and storing their boats in shaded areas or indoor facilities during extended periods of non-use.

Marine Organisms: Unseen Attackers

The marine environment is teeming with life, some of which can pose a threat to wooden hulls. Marine borers, such as teredo worms and shipworms, are small mollusks that feed on wood, creating tunnels and weakening the hull's structure. These organisms are particularly prevalent in warm, shallow waters. To combat this, traditional methods like copper sheathing or modern anti-fouling paints can be applied to the hull, creating a barrier against these wood-boring creatures. Regular inspection and cleaning of the hull are also vital to detect and remove any early signs of infestation.

Air Quality and Pollution: Hidden Dangers

The quality of the air surrounding a wooden boat can also impact its durability. In industrial areas or regions with high air pollution, acidic rain and airborne chemicals can accelerate wood deterioration. Acid rain, caused by industrial emissions, can corrode wood surfaces, while pollutants like sulfur dioxide and nitrogen oxides can contribute to wood decay. Boat owners in such environments should consider more frequent cleaning and the use of protective coatings to minimize the impact of these pollutants.

In summary, the durability of a wooden hull boat is a complex interplay of various environmental factors. By understanding and addressing these factors through proactive maintenance, protective measures, and regular inspections, boat owners can significantly extend the lifespan of their wooden vessels, ensuring they remain seaworthy for generations to come. This knowledge empowers owners to make informed decisions, preserving the beauty and functionality of their wooden boats in the face of environmental challenges.

Smoking Wood Chips and Pesticides: How Long Do Residues Last?

You may want to see also

Explore related products

Wood type and lifespan

The choice of wood significantly influences the lifespan of a wooden hull boat, with some species offering decades of durability when properly maintained. Hardwoods like teak, oak, and mahogany are renowned for their natural resistance to decay, insects, and moisture, making them ideal for boat construction. Teak, for instance, contains natural oils that repel water and resist rot, often lasting 50 to 80 years or more in marine environments. In contrast, softer woods like pine or cedar require additional treatments such as epoxy coatings or fiberglass sheathing to extend their lifespan, typically ranging from 20 to 40 years. Understanding the inherent properties of each wood type is crucial for predicting and maximizing a boat’s longevity.

Selecting the right wood type involves balancing cost, availability, and desired lifespan. For example, while teak is exceptionally durable, its high cost and scarcity may lead builders to opt for more affordable alternatives like white oak or Douglas fir. White oak, with its tight grain and natural tannins, offers excellent rot resistance and can last 40 to 60 years with proper care. Douglas fir, though less rot-resistant, is strong and lightweight, making it suitable for larger vessels when treated with preservatives. A practical tip is to consult marine wood suppliers or boatbuilders to match wood type to the intended use and environmental conditions, ensuring the best long-term performance.

Maintenance plays a pivotal role in extending the lifespan of any wooden hull, regardless of wood type. Regular inspection for cracks, leaks, or signs of rot is essential, as is prompt repair of any damage. Applying marine-grade varnish, epoxy, or paint every 1–2 years helps seal the wood and protect it from UV rays and moisture. For softer woods, consider reinforcing vulnerable areas with fiberglass or Kevlar for added durability. A proactive maintenance schedule can add 10–20 years to a boat’s life, making it a worthwhile investment for wooden hull owners.

Comparing wood types reveals that longevity is not solely determined by the wood itself but also by its application and care. For instance, a well-maintained pine hull with epoxy encapsulation can outlast a neglected teak hull. Similarly, boats in freshwater environments generally experience less wear than those in saltwater, where corrosion and marine organisms accelerate deterioration. By combining the right wood type with appropriate treatments and maintenance, even less durable species can achieve impressive lifespans, challenging the notion that only premium woods are suitable for long-term use.

Instructively, the lifespan of a wooden hull boat can be optimized by following a few key steps. First, choose a wood species suited to your climate and boating conditions—teak or oak for harsh marine environments, or cedar for freshwater use. Second, invest in professional-grade preservatives and coatings during construction to create a robust barrier against moisture and pests. Third, establish a routine maintenance plan, including annual inspections and refinishing. Finally, store the boat in a dry, covered area when not in use to minimize exposure to the elements. By adhering to these guidelines, wooden hull boats can remain seaworthy and beautiful for generations.

Wood Patio Lifespan: Factors Affecting Durability and Longevity

You may want to see also

Explore related products

Rot prevention techniques

Wooden boats, when properly maintained, can endure for decades, even centuries. However, their longevity hinges on effective rot prevention, a battle against moisture, fungi, and marine organisms. The key lies in understanding the enemy and deploying a multi-pronged defense.

Moisture Control: The Foundation of Preservation

The primary culprit behind wood rot is moisture. Denying it access to the wood is paramount. This begins with meticulous sealing. Epoxy resins, applied liberally and meticulously, create a waterproof barrier, particularly crucial in areas prone to splashing or immersion. Pay special attention to joints, seams, and fastenings, where water can infiltrate. Regular inspections are vital; promptly address any cracks, splits, or worn sealant to prevent moisture intrusion.

Additionally, proper ventilation is essential. Allow air to circulate within the hull, preventing condensation buildup, a breeding ground for rot. Consider installing vents or using desiccants in enclosed spaces.

Biocides: Waging War on Microorganisms

Even with diligent moisture control, microorganisms can still pose a threat. Biocides, substances that kill or inhibit the growth of organisms, are powerful allies. Copper-based preservatives, like copper naphthenate, are commonly used due to their effectiveness against fungi and marine borers. Application methods vary; brushing, spraying, or pressure-treating the wood are all viable options. Follow manufacturer instructions carefully, ensuring proper dosage and safety precautions.

Remember, biocides are not a one-time solution. Regular reapplication is necessary, typically every 2-5 years, depending on the product and environmental conditions.

Traditional Wisdom: Tried and True Techniques

Before the advent of modern chemicals, shipwrights relied on traditional methods to combat rot. Creosote, a tar-based preservative, was widely used for its effectiveness against fungi and insects. While effective, its strong odor and potential environmental concerns have led to its decline in popularity.

Another traditional technique involves using naturally rot-resistant woods like teak, cedar, or oak. These woods possess natural oils and resins that deter decay. While more expensive, they offer a long-lasting, low-maintenance solution.

Proactive Maintenance: The Key to Longevity

Ultimately, the lifespan of a wooden boat hinges on proactive maintenance. Regular inspections, prompt repairs, and consistent application of preservatives are essential. By understanding the causes of rot and employing a combination of modern and traditional techniques, you can ensure your wooden vessel graces the waters for generations to come.

Effective Wood Cleaner: Spider Elimination Timeframe Explained

You may want to see also

Explore related products

$43.85 $58.95

Repair vs. replacement timing

Wooden boats, when meticulously maintained, can endure for decades, even centuries. However, the decision to repair or replace a wood hull hinges on a delicate balance of factors, primarily the extent of damage, the boat's age, and the owner's commitment to preservation.

A superficial crack in a newer boat, for instance, might warrant a straightforward repair using epoxy resins and fiberglass cloth, a process that, when done correctly, can restore structural integrity and extend the boat's life by years.

The age of the boat introduces a layer of complexity. Older vessels, particularly those nearing the half-century mark, may exhibit systemic issues like rot, delamination, or compromised fastenings. Here, a patchwork repair might only be a temporary solution, delaying the inevitable need for more extensive work or even replacement. A 50-year-old boat with widespread rot in the keel and frames, for example, would likely require a complete rebuild, a costly and time-consuming endeavor that might not be financially viable compared to investing in a newer vessel.

Consequently, a critical assessment of the boat's overall condition, considering factors like the extent of damage, the availability of replacement parts, and the owner's skill level and resources, is crucial in determining the most prudent course of action.

While the allure of preserving a classic wooden boat is undeniable, practicality must prevail. A boat that requires constant, costly repairs due to its age and deteriorating condition may ultimately be a financial drain. Conversely, a well-maintained boat with localized damage can be a worthwhile investment, as repairs can significantly extend its lifespan and preserve its historical and aesthetic value.

Ultimately, the decision to repair or replace a wood hull boat is a deeply personal one, requiring a careful weighing of emotional attachment, financial considerations, and the boat's overall health.

Cedar Wood Moth Balls Lifespan: How Long Do They Last?

You may want to see also

Frequently asked questions

With proper maintenance, a wood hull boat can last 50 years or more. Regular care, including varnishing, sealing, and addressing rot or damage promptly, is essential to extend its lifespan.

Factors include the type of wood used, exposure to water and weather, maintenance frequency, and storage conditions. Boats stored indoors or in dry environments tend to last longer than those left outdoors.

Yes, a wood hull boat can last as long as a fiberglass boat if properly maintained. Fiberglass boats may require less upkeep, but wood boats can endure for decades with consistent care and attention to detail.

![[1 Galllon] Instant Boat Hull Cleaner - Made in USA - Powerful Dual Acid Formula Easily Removes Scum Lines, Rust Stains, Hard Waterlines, & More from Fiberglass, Gelcoat & Painted Boat Surfaces](https://m.media-amazon.com/images/I/71zvQLQ7Q3L._AC_UL320_.jpg)