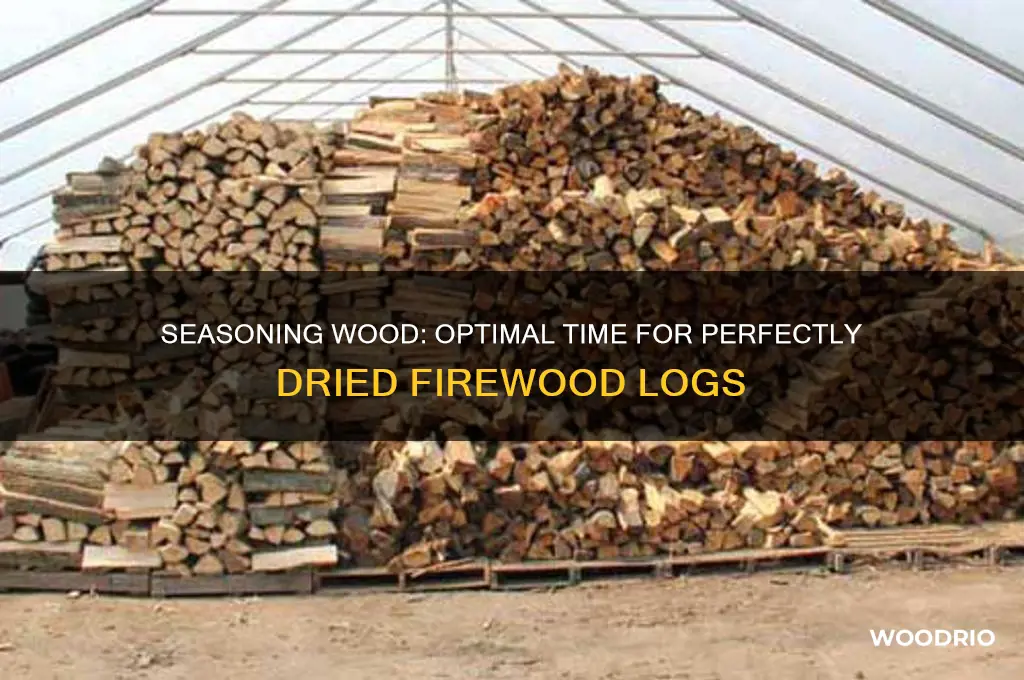

Seasoning wood is a crucial process for ensuring it burns efficiently and safely in fireplaces, stoves, or wood-burning appliances. The time required for wood to be properly seasoned depends on various factors, including the type of wood, its initial moisture content, and the environmental conditions in which it is stored. Generally, hardwoods like oak or maple take longer to season, typically requiring 6 to 12 months, while softer woods like pine may only need 3 to 6 months. Proper seasoning involves stacking the wood in a dry, well-ventilated area, protected from rain and snow, and allowing it to air-dry until its moisture content drops to around 20%. This process not only improves combustion but also reduces creosote buildup, minimizing the risk of chimney fires.

| Characteristics | Values |

|---|---|

| Ideal Seasoning Time | 6 months to 2 years, depending on wood type and climate conditions |

| Minimum Seasoning Time | 6 months for softer woods (e.g., pine); 12 months for harder woods (e.g., oak) |

| Moisture Content Goal | 20% or less for optimal burning efficiency |

| Stacking Method | Split and stacked in a dry, well-ventilated area, off the ground |

| Wood Type Influence | Softwoods season faster (6–12 months); hardwoods take longer (12–24 months) |

| Climate Impact | Warmer, drier climates speed up seasoning; humid climates slow it down |

| Split Wood vs. Whole Logs | Split wood seasons faster due to increased surface area |

| Covering Requirements | Cover the top of the stack to protect from rain; leave sides open for airflow |

| Seasoning Indicators | Cracks in the ends, lighter weight, and a dull appearance |

| Indoor vs. Outdoor Seasoning | Outdoor seasoning is more common; indoor requires controlled humidity |

| Tools for Monitoring | Moisture meter to check wood moisture content |

Explore related products

What You'll Learn

- Ideal Drying Time: 6-12 months for hardwood, 3-6 months for softwood, depending on climate

- Moisture Content Goal: Aim for 20% or less moisture content for optimal seasoning

- Stacking Methods: Split and stack wood in a dry, sunny area with airflow

- Seasoning Indicators: Check for cracks, lighter weight, and a dull appearance

- Accelerating Seasoning: Use kilns or covered storage to speed up drying time

Ideal Drying Time: 6-12 months for hardwood, 3-6 months for softwood, depending on climate

The drying time for wood to be properly seasoned varies significantly between hardwood and softwood, primarily due to their cellular structures. Hardwoods, like oak or maple, have denser fibers that retain moisture more stubbornly, requiring 6 to 12 months of air-drying to reach optimal moisture levels (below 20%). Softwoods, such as pine or cedar, have larger, less dense cells that release moisture faster, typically seasoning in 3 to 6 months. These timelines are not arbitrary—they’re rooted in the wood’s biology and its interaction with environmental conditions.

Climate plays a critical role in these timelines. In dry, sunny regions with low humidity, wood dries faster, potentially shaving weeks off the seasoning process. Conversely, humid or rainy climates slow moisture evaporation, often extending the drying period. For instance, hardwood in a humid coastal area might need closer to 12 months, while the same wood in a desert climate could be ready in 8. Softwoods, though quicker to dry, still follow this pattern—a pine log in a damp forest might take the full 6 months, whereas one in a dry prairie could be seasoned in 4.

To maximize efficiency, stack wood in a single row, allowing air to circulate freely on all sides. Cover the pile with a tarp, but leave the sides open to prevent moisture buildup. For hardwood, split logs into smaller pieces (4–6 inches in diameter) to expose more surface area, accelerating drying. Softwoods, already quicker to season, benefit from being stacked off the ground on pallets to avoid moisture absorption from the soil. Regularly check moisture levels with a wood moisture meter—seasoned hardwood should read 15–20%, while softwood should be 10–15%.

A common mistake is underestimating the impact of stacking density. Overcrowded piles trap moisture, leading to mold or rot. For hardwood, maintain at least 2 inches of space between logs; for softwood, 1 inch suffices. If time is a constraint, consider kiln-drying, which reduces hardwood seasoning time to weeks, though it’s costly and less accessible for casual users. Ultimately, patience and attention to environmental cues are key—rushing the process compromises the wood’s quality, while respecting its natural timeline ensures a durable, efficient fuel source.

Drying Tree Wood: Essential Timeframes for Optimal Results Explained

You may want to see also

Explore related products

Moisture Content Goal: Aim for 20% or less moisture content for optimal seasoning

Achieving a moisture content of 20% or less is the gold standard for seasoned firewood. This threshold ensures the wood burns efficiently, producing more heat and less smoke. But why 20%? Freshly cut wood, or "green" wood, can contain moisture levels upwards of 50%, which not only hinders combustion but also increases creosote buildup in chimneys, posing a fire hazard. By reducing moisture content to 20% or below, you maximize the wood’s energy output while minimizing safety risks.

To measure moisture content accurately, invest in a wood moisture meter, a tool that pierces the wood and provides a percentage reading. These meters are affordable and indispensable for anyone serious about seasoning wood. Test multiple pieces from different parts of the stack, as moisture levels can vary. Aim for consistent readings below 20% across the pile before considering the wood fully seasoned.

The time required to reach this goal depends on several factors: wood species, initial moisture content, splitting size, and environmental conditions. Hardwoods like oak or maple naturally dry more slowly than softwoods like pine. Splitting logs into smaller pieces exposes more surface area to air, accelerating drying. Stack wood in a sunny, well-ventilated area, protected from rain, to optimize conditions. In ideal scenarios, wood can season to 20% moisture in 6–12 months, but denser hardwoods may take up to 2 years.

If you’re in a rush, kiln-drying is an alternative method that can reduce moisture content to 20% in days, not months. However, this process requires specialized equipment and is typically used by commercial suppliers. For most homeowners, patience and proper stacking techniques are the most practical approach. Remember, wood with moisture content above 20% will burn inefficiently, so resist the temptation to use it prematurely.

Finally, seasoned wood with 20% or less moisture content is lighter in weight, has cracks at the ends, and makes a hollow sound when two pieces are knocked together. These visual and auditory cues, combined with meter readings, confirm you’ve achieved the goal. Properly seasoned wood not only enhances your fires but also extends the life of your fireplace or wood stove, making the wait well worth it.

Wood Oil Drying Time: Factors Affecting Cure and Finish Duration

You may want to see also

Explore related products

Stacking Methods: Split and stack wood in a dry, sunny area with airflow

Proper stacking is a cornerstone of seasoning wood effectively. Split logs into pieces no longer than 18 inches and no thicker than 4 inches to maximize surface area for moisture evaporation. Arrange these in rows, ensuring each piece is supported by the one below it to prevent collapse. Leave a minimum of 6 inches between rows to promote airflow, which accelerates drying. Position the stack in a south-facing location to capitalize on sunlight, which acts as a natural dehumidifier. Elevate the woodpile slightly using pallets or railroad ties to prevent ground moisture absorption, a common culprit of rot and mold.

While stacking, consider the wood’s density and initial moisture content. Hardwoods like oak or hickory, with moisture levels around 60-80%, require 12-24 months to season properly. Softer woods like pine, starting at 30-50% moisture, may dry in 6-12 months. Use a moisture meter to monitor progress; seasoned wood should read 20% or less. Stack denser woods in looser configurations to compensate for slower drying rates, and softer woods in tighter arrangements to balance airflow and stability.

A persuasive argument for meticulous stacking lies in its long-term benefits. Properly seasoned wood burns hotter, cleaner, and more efficiently, reducing creosote buildup in chimneys and minimizing environmental impact. Poorly stacked wood not only takes longer to dry but also risks decay, insect infestation, and mold growth, rendering it unusable. Investing time in strategic stacking saves both effort and resources, ensuring a reliable fuel source for years to come.

For those new to wood stacking, start small. Begin with a single row, mastering the technique before scaling up. Use stakes or braces to stabilize larger piles, especially in windy areas. Cover the top of the stack with a tarp, securing it only on the sides to allow airflow while shielding the wood from rain. Regularly inspect the pile for signs of moisture accumulation or pests, adjusting as needed. With patience and precision, stacking becomes less of a chore and more of a craft, yielding wood that’s ready to fuel warmth and comfort when the time comes.

Drying Persimmon Wood: Timeframe and Best Practices for Optimal Results

You may want to see also

Explore related products

Seasoning Indicators: Check for cracks, lighter weight, and a dull appearance

Wood seasoning is a process that transforms freshly cut timber into a stable, efficient fuel source, but how do you know when it’s truly ready? Beyond the general guideline of 6 to 12 months for hardwoods and 3 to 6 months for softwoods, there are tangible indicators that signal readiness. Among these, cracks, lighter weight, and a dull appearance stand out as reliable markers. These signs aren’t just superficial changes; they reflect the wood’s internal transformation as moisture content drops from 50% or more to an ideal 20% or less.

Cracks, particularly end checks or radial splits, are a telltale sign of proper seasoning. As wood dries, the outer layers shrink faster than the inner core, causing stress that manifests as cracks. While this might seem counterintuitive, these fissures indicate that moisture is escaping, a critical step in the seasoning process. However, excessive cracking or deep splits could signal overexposure or improper stacking, so monitor closely. For firewood, small surface cracks are ideal; for woodworking, minimal cracking is preferable.

Lighter weight is another definitive indicator. Freshly cut wood is heavy due to its high moisture content. As it seasons, water evaporates, reducing weight significantly. A simple test: compare a seasoned piece to a freshly cut one of the same size. The difference can be as much as 20-30% in weight. For practical purposes, if you can easily carry an armload of split logs that once felt cumbersome, it’s likely seasoned. A moisture meter can confirm this, with readings ideally between 15-20% for optimal use.

A dull appearance completes the trio of seasoning indicators. Fresh wood often has a vibrant, almost glossy surface due to moisture just beneath the bark. As it dries, the surface becomes matte and loses its sheen. This change is particularly noticeable in hardwoods like oak or maple. However, dullness alone isn’t conclusive; combine it with the other indicators for accuracy. For instance, if the wood feels lighter, shows minor cracks, and appears dull, it’s likely seasoned.

In practice, these indicators work best in tandem. For example, if you notice cracks but the wood still feels heavy, it’s not fully seasoned. Similarly, a dull appearance without weight loss could indicate surface drying only. Patience is key; rushing the process can lead to inefficient burning or warped wood. By observing these signs, you ensure the wood is not just dry, but properly seasoned for its intended use, whether for a cozy fireplace or a finely crafted piece of furniture.

Black Walnut Wood Oxidation: Understanding the Aging Process and Timeline

You may want to see also

Explore related products

Accelerating Seasoning: Use kilns or covered storage to speed up drying time

Wood seasoning typically requires 6 to 24 months of air drying, depending on factors like wood type, climate, and storage conditions. However, for those who need seasoned wood faster, kilns and covered storage offer viable solutions. Kiln drying, a method widely used in commercial settings, can reduce drying time to just a few days to a few weeks. By controlling temperature, humidity, and airflow, kilns extract moisture efficiently, ensuring wood reaches optimal seasoning levels swiftly. Covered storage, while slower than kiln drying, still accelerates the process compared to open-air seasoning. It protects wood from rain and snow, allowing for more consistent drying even in humid climates.

To implement kiln drying, start by selecting a kiln suitable for your scale of operation—small kilns are available for homeowners, while larger models cater to commercial needs. Load the wood in a way that maximizes airflow, stacking it loosely to avoid trapping moisture. Set the kiln to a temperature between 120°F and 160°F (49°C to 71°C), depending on the wood species. Hardwoods like oak may require higher temperatures and longer drying times than softwoods like pine. Monitor moisture levels regularly using a wood moisture meter, aiming for a final moisture content of 15–20% for optimal seasoning. Be cautious not to over-dry the wood, as this can lead to cracking or warping.

Covered storage, while less precise than kiln drying, is a cost-effective alternative. Construct a simple shelter with a roof and open sides to allow airflow while protecting the wood from precipitation. Stack the wood off the ground using pallets or sticks to prevent moisture absorption from the soil. Arrange the logs in a crisscross pattern to promote air circulation. For best results, cover the pile with a breathable tarp, securing it on the sides to shield from rain while allowing moisture to escape. This method can reduce seasoning time by 30–50% compared to open-air drying, though it still depends on local climate conditions.

Comparing the two methods, kiln drying is faster and more reliable but requires an initial investment in equipment and energy costs. Covered storage, on the other hand, is budget-friendly and accessible but demands patience and strategic planning. For those with immediate needs, kilns are the clear choice. For hobbyists or those with time to spare, covered storage offers a practical middle ground. Regardless of the method, both approaches significantly outperform traditional air drying, making them essential tools for anyone looking to accelerate wood seasoning.

Maximizing Flavor: Understanding the Lifespan of Smoker Wood Chips

You may want to see also

Frequently asked questions

Wood typically needs to sit for 6 to 12 months to be properly seasoned, depending on factors like the type of wood, moisture content, and climate conditions.

Yes, wood can be seasoned faster by splitting it into smaller pieces, stacking it in a dry, well-ventilated area, and covering it to protect from rain while allowing airflow.

Seasoned wood feels lighter, has cracks or checks in the ends, and makes a sharp, hollow sound when two pieces are knocked together. A moisture meter can also confirm it’s below 20% moisture content.