Wood Life Copper Coat is a popular wood preservative known for its ability to protect wood from rot, insects, and weathering while providing a distinctive copper-colored finish. One of the most common questions among users is regarding its durability: how long does Wood Life Copper Coat last? Typically, when applied correctly and maintained properly, it can provide effective protection for 5 to 10 years, depending on environmental factors such as exposure to moisture, sunlight, and temperature fluctuations. Regular inspections and reapplication in high-wear areas can extend its lifespan, making it a reliable choice for decks, fences, and outdoor wooden structures.

| Characteristics | Values |

|---|---|

| Expected Lifespan | 10-15 years (varies based on exposure and maintenance) |

| Resistance to UV Degradation | High (copper coating provides UV protection) |

| Moisture Resistance | Excellent (prevents rot and decay) |

| Insect and Pest Resistance | High (copper acts as a natural repellent) |

| Maintenance Required | Minimal (periodic cleaning and reapplication after 10-15 years) |

| Environmental Impact | Low toxicity (copper is environmentally friendly in small quantities) |

| Application Surface | Suitable for exterior wood surfaces (decks, fences, siding) |

| Drying Time | 24-48 hours (depending on humidity and temperature) |

| Color Change Over Time | Patina formation (natural aging to greenish hue) |

| Cost-Effectiveness | Moderate (initial cost offset by long-term durability) |

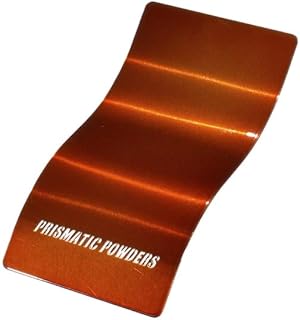

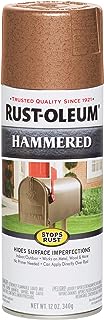

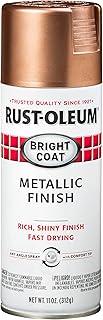

Explore related products

What You'll Learn

- Application methods and durability factors affecting Copper Coat's lifespan on wood surfaces

- Environmental conditions impacting how long wood life Copper Coat lasts outdoors

- Maintenance tips to extend the longevity of Copper Coat on treated wood

- Comparative analysis: Copper Coat vs. other wood preservatives in terms of lifespan

- Expected lifespan of Copper Coat in different climates and wood types

Application methods and durability factors affecting Copper Coat's lifespan on wood surfaces

Copper Coat's longevity on wood surfaces hinges on both application precision and environmental exposure. Proper preparation is paramount: wood must be clean, dry, and free of contaminants. Sanding to a smooth finish (120-180 grit) ensures optimal adhesion. Apply the Copper Coat in thin, even layers, allowing each coat to dry fully (typically 2-4 hours, depending on humidity) before adding the next. Overloading the brush or roller can lead to uneven coverage and reduced durability. For best results, use a synthetic bristle brush or airless sprayer, maintaining a consistent 6-8 inch distance from the surface when spraying.

Environmental factors play a critical role in Copper Coat’s lifespan. UV exposure, moisture, and temperature fluctuations accelerate degradation. In coastal or humid regions, expect a lifespan of 5-7 years, while drier, inland areas may see up to 10-12 years. To enhance durability, apply a UV-resistant topcoat annually, particularly in high-sunlight areas. Additionally, wood treated with Copper Coat should be inspected biannually for signs of wear, such as chalking or peeling, and re-coated as needed. Proper maintenance can extend the product’s effectiveness by 20-30%.

The wood species itself influences Copper Coat’s performance. Dense hardwoods like oak or cedar absorb the coating more effectively, providing a longer-lasting barrier against decay. Softwoods like pine or fir, while more porous, may require additional coats or a wood preservative pretreatment to achieve comparable durability. For structural applications, such as fence posts or decking, consider pressure-treating the wood before applying Copper Coat to maximize resistance to rot and insect damage.

Application timing matters as much as technique. Avoid coating wood during rainy seasons or in temperatures below 50°F (10°C), as improper curing can compromise adhesion. For large projects, work in sections, ensuring each area is shielded from moisture until fully cured (48-72 hours). If applying over existing finishes, strip or sand the surface thoroughly to remove any sealants or paints that could prevent bonding. Following these guidelines can double the expected lifespan of Copper Coat, making it a cost-effective solution for wood preservation.

Wood-Fired Hot Tub Heating Time: What to Expect

You may want to see also

Explore related products

Environmental conditions impacting how long wood life Copper Coat lasts outdoors

Wood life Copper Coat, a popular wood preservative, boasts impressive longevity, but its outdoor lifespan is significantly influenced by environmental conditions. Understanding these factors is crucial for maximizing its effectiveness and ensuring your wood projects endure the elements.

Sunlight Exposure: Ultraviolet (UV) rays from the sun are a primary culprit in Copper Coat degradation. Prolonged exposure leads to fading, cracking, and a breakdown of the protective barrier. South-facing surfaces, receiving the most direct sunlight, will require more frequent reapplication compared to shaded areas. Consider using UV-resistant topcoats or strategically placing structures to minimize sun exposure.

Moisture Levels: While Copper Coat is water-repellent, excessive moisture can still accelerate its deterioration. In humid climates or areas prone to frequent rain, the coating may require more frequent maintenance. Ensure proper drainage around treated wood to prevent standing water, which can lead to rot and compromise the Copper Coat's integrity.

Temperature Fluctuations: Extreme temperature swings, common in many regions, can cause the wood to expand and contract, potentially cracking the Copper Coat layer. This allows moisture to penetrate, accelerating deterioration. In areas with harsh winters and hot summers, consider using a more flexible Copper Coat formulation or applying a thicker coat to compensate for potential movement.

Air Pollution: Industrial areas or regions with high levels of air pollution can deposit corrosive particles on the wood surface, hastening the breakdown of Copper Coat. Regular cleaning with a mild detergent solution can help remove these deposits and extend the coating's life.

Biological Threats: Even with Copper Coat's fungicidal properties, certain fungi and algae can still pose a threat, especially in damp, shaded areas. Regular inspection and prompt removal of any visible growth are essential. For particularly susceptible areas, consider using a Copper Coat product with added biocides for enhanced protection.

By carefully considering these environmental factors and implementing appropriate mitigation strategies, you can significantly extend the lifespan of Wood life Copper Coat outdoors, ensuring your wood projects remain protected and beautiful for years to come.

Phantom Wood Growth Timeline: Understanding Its Development and Duration

You may want to see also

Explore related products

Maintenance tips to extend the longevity of Copper Coat on treated wood

Copper Coat, a preservative treatment for wood, is renowned for its durability, often lasting 40 years or more when properly maintained. However, environmental factors like moisture, UV exposure, and physical wear can accelerate degradation. To maximize its lifespan, proactive maintenance is essential.

Inspection and Cleaning: Begin with biannual inspections, ideally in spring and fall. Use a soft-bristle brush or compressed air to remove dirt, debris, and organic growth like algae or mildew. For stubborn stains, a mild detergent solution (1 cup detergent per gallon of water) applied with a sponge works effectively. Avoid pressure washers, as they can strip the Copper Coat layer.

Reapplication and Touch-Ups: Every 5–7 years, assess the wood’s condition. If the surface appears chalky or faded, lightly sand the area with 120-grit sandpaper to restore adhesion, then apply a fresh coat of Copper Coat following the manufacturer’s instructions (typically 1 gallon covers 150–200 sq. ft.). For small scratches or exposed areas, use a brush to spot-treat, ensuring even coverage.

Moisture Management: Copper Coat’s primary threat is prolonged moisture exposure. Ensure treated wood is sealed at all ends with a compatible wood sealer to prevent water absorption. For decks or horizontal surfaces, incorporate a slight slope (1/4 inch per foot) during installation to facilitate water runoff. In humid climates, consider annual applications of a water-repellent preservative to enhance moisture resistance.

UV Protection and Physical Care: UV rays can degrade Copper Coat over time, particularly in sun-exposed areas. Apply a UV-resistant wood finish every 2–3 years to mitigate fading and surface erosion. Additionally, minimize physical damage by using furniture pads, avoiding dragging heavy objects, and trimming nearby vegetation to prevent abrasion.

By adhering to these targeted maintenance practices, you can significantly extend the life of Copper Coat, ensuring treated wood remains protected and aesthetically pleasing for decades. Consistency is key—small, regular efforts yield far greater results than sporadic interventions.

How Long Blood Stains Last in Wood: A Comprehensive Guide

You may want to see also

Explore related products

Comparative analysis: Copper Coat vs. other wood preservatives in terms of lifespan

Wood preservatives are essential for extending the lifespan of wooden structures, but their effectiveness varies widely. Copper Coat, a popular choice, is known for its durability, typically lasting 15 to 20 years when applied correctly. This longevity stems from its copper-based formula, which resists decay, insects, and fungal growth. However, its performance isn’t unmatched—other preservatives like creosote, ACQ (Alkaline Copper Quaternary), and borate treatments offer distinct lifespans and application methods. Understanding these differences is crucial for selecting the right product for specific needs.

Creosote, a traditional wood preservative, boasts a lifespan of 20 to 30 years, making it one of the longest-lasting options. It’s highly effective against rot and pests but requires careful handling due to its toxicity and oily residue. In contrast, ACQ, a water-based treatment, lasts 10 to 15 years and is safer for the environment and users. Its copper content provides robust protection, though it may leach over time, reducing efficacy. Borate treatments, often used indoors, offer a 10 to 15-year lifespan but are less effective in wet conditions, limiting their outdoor applications.

Application methods further differentiate these preservatives. Copper Coat requires a clean, dry surface and is typically applied with a brush or sprayer, with a recommended dosage of 1 gallon per 150 to 200 square feet. Creosote is applied by dipping or brushing, but its strong odor and messy application make it less user-friendly. ACQ is pressure-treated, ensuring deep penetration but requiring professional equipment. Borates are dissolved in water and applied by spraying or dipping, making them easy to use but less effective on dense woods.

For outdoor projects, Copper Coat and creosote are top contenders due to their resistance to moisture and pests. However, Copper Coat’s lower toxicity and easier application give it an edge in residential settings. ACQ is ideal for decks and fences, while borates excel in dry, indoor environments like attic framing or furniture. Practical tips include reapplying Copper Coat every 15 years for optimal protection and avoiding creosote for structures in contact with soil or water due to leaching risks.

In summary, Copper Coat’s 15 to 20-year lifespan positions it as a reliable mid-range option, outperforming ACQ and borates but falling slightly behind creosote. Its balance of durability, ease of use, and safety makes it a versatile choice for various applications. By comparing these preservatives, users can make informed decisions tailored to their project’s specific demands, ensuring long-term protection and value.

Ringworm Survival in Wood: Understanding Its Lifespan and Risks

You may want to see also

Explore related products

Expected lifespan of Copper Coat in different climates and wood types

Copper Coat, a popular wood preservative, boasts impressive longevity, but its lifespan isn't a one-size-fits-all scenario. Climate and wood type play a crucial role in determining how long this protective barrier will endure.

In arid, dry climates with minimal rainfall and low humidity, Copper Coat can last upwards of 10-15 years. The lack of moisture significantly reduces the risk of fungal growth and wood rot, allowing the copper to remain effective for extended periods. Conversely, in humid, tropical climates with frequent rainfall, the lifespan decreases to around 5-8 years. Constant moisture exposure accelerates the leaching of copper from the wood, diminishing its protective properties.

Wood type also significantly influences Copper Coat's longevity. Dense, hardwoods like cedar and redwood, naturally resistant to decay, provide an ideal substrate for Copper Coat. The preservative penetrates deeply, forming a robust barrier that can last 8-12 years, even in moderately humid climates. Softer woods like pine and fir, more susceptible to rot, offer less inherent protection. Copper Coat on these woods may only last 4-7 years, especially in harsher climates.

For optimal results, consider these factors:

- Climate: Choose a Copper Coat formulation specifically designed for your climate. Some formulations contain additional additives to enhance durability in humid environments.

- Wood Type: Select a wood species naturally resistant to decay for maximum lifespan.

- Application: Ensure proper surface preparation and apply the recommended dosage of Copper Coat. Multiple thin coats are generally more effective than a single thick application.

- Maintenance: Regularly inspect treated wood for signs of wear and tear. Reapply Copper Coat as needed, typically every 5-7 years in moderate climates, to maintain protection.

By understanding the interplay between climate, wood type, and proper application, you can maximize the lifespan of Copper Coat and ensure your wood structures remain protected for years to come.

Durability of Wooden Posts Submerged Underwater: Lifespan and Factors

You may want to see also

Frequently asked questions

Woodlife Copper Coat can last up to 10–15 years on outdoor wood structures when properly applied and maintained, depending on exposure to weather and environmental conditions.

Yes, the durability can vary. Harder, more dense woods like cedar or redwood may retain the coating longer compared to softer woods like pine, which may require more frequent reapplication.

Prolonged exposure to direct sunlight and moisture can degrade the coating faster. In areas with high UV exposure or frequent rain, the lifespan may be reduced to 5–8 years without proper maintenance.

Yes, it can be reapplied every 5–7 years to extend its lifespan. Ensure the surface is clean and dry before reapplication for best results.

Regularly inspect the wood for signs of wear, clean the surface annually, and reapply the coating as needed. Avoid harsh chemicals and ensure proper ventilation during application.