Wood putty is a versatile material commonly used to fill gaps, cracks, and imperfections in wood surfaces, providing a smooth and seamless finish. One of the most frequently asked questions by DIY enthusiasts and professionals alike is, How long does wood putty take to dry before sanding? The drying time for wood putty can vary significantly depending on factors such as the type of putty, environmental conditions, and the thickness of the application. Generally, water-based wood putties dry faster, often within 1 to 2 hours, while oil-based or solvent-based putties may take anywhere from 4 to 24 hours to fully cure. Humidity, temperature, and ventilation also play crucial roles, with warmer and drier conditions accelerating the drying process. It’s essential to allow the putty to dry completely before sanding to ensure a smooth, durable finish and avoid damaging the repaired area. Always refer to the manufacturer’s instructions for specific drying times and recommendations.

| Characteristics | Values |

|---|---|

| Drying Time Before Sanding | Typically 2-4 hours, depending on brand, humidity, and temperature. |

| Factors Affecting Drying Time | Humidity, temperature, thickness of application, and type of wood putty. |

| Optimal Conditions for Drying | Low humidity (below 60%), room temperature (65-75°F or 18-24°C). |

| Sanding Readiness Indicator | Putty is dry when it feels hard to the touch and does not indent easily. |

| Recommended Sanding Grit | Start with 120-150 grit sandpaper for initial smoothing. |

| Curing Time for Full Hardness | 24-48 hours for most wood putties, but check manufacturer instructions. |

| Accelerating Drying Time | Use a hairdryer on low heat or place in a well-ventilated, warm area. |

| Common Brands and Drying Times | DAP Plastic Wood (2-4 hours), Minwax High-Performance Wood Filler (2-4 hours), Elmer’s Carpenter’s Wood Filler (2-4 hours). |

| Avoid Sanding Prematurely | Sanding too early can smear or damage the putty. |

| Post-Sanding Finishing | After sanding, wipe clean and apply stain, paint, or sealant as needed. |

Explore related products

What You'll Learn

Factors Affecting Drying Time

Wood putty drying time is not a one-size-fits-all scenario. Several factors interplay, influencing how long you'll wait before sanding. Understanding these variables empowers you to plan your project effectively and achieve a smooth, professional finish.

Let's delve into the key players:

The Putty Itself: Different wood putty formulations boast varying drying times. Oil-based putties, known for their durability, typically take longer to dry, often requiring 24 hours or more. Water-based putties, on the other hand, are quicker, drying within 2-4 hours. Consider the manufacturer's instructions for specific drying time estimates.

Some putties even offer "fast-drying" variants, ideal for time-sensitive projects.

- Environmental Conditions: Think of your workspace as a drying chamber. Humidity acts as a drying inhibitor, slowing the process significantly. Aim for a humidity level below 50% for optimal drying. Temperature plays a crucial role too. Warmer temperatures accelerate drying, while cooler temperatures prolong it. Ideally, maintain a temperature range of 65-80°F (18-27°C) for best results.

- Application Thickness: A thin layer of putty dries faster than a thick glob. Apply putty sparingly, using a putty knife to achieve a smooth, even layer. For deeper imperfections, consider applying multiple thin layers, allowing each layer to dry completely before adding the next.

- Wood Type: The porosity of the wood itself can influence drying time. Softwoods, like pine, tend to absorb moisture more readily, potentially slowing drying. Hardwoods, like oak, are less absorbent and may allow for faster drying.

Practical Tips for Faster Drying:

- Ventilation: Ensure good airflow in your workspace by opening windows or using a fan.

- Heat Source: If possible, position your project near a gentle heat source, like a space heater, but avoid direct heat which can cause cracking.

- Hair Dryer: For small areas, a hair dryer on low heat setting can expedite drying, but exercise caution to avoid overheating the putty.

By considering these factors and implementing these tips, you can effectively manage wood putty drying time, ensuring a smooth and efficient sanding process. Remember, patience is key – rushing the drying process can lead to unsatisfactory results.

Wood-Fired Hot Tub Heating Time: What to Expect

You may want to see also

Explore related products

Recommended Drying Times

Wood putty drying times vary significantly based on factors like brand, environmental conditions, and application thickness. Most water-based wood putties dry to the touch within 30 minutes to 2 hours, but achieving a hardness suitable for sanding typically requires 2 to 4 hours. Oil-based putties take longer, often needing 4 to 8 hours before they’re ready for light sanding. Always check the manufacturer’s instructions, as these times can differ. For instance, Elmer’s Wood Filler claims a 15-minute drying time for light sanding, while Minwax High-Performance Wood Filler recommends waiting 2 hours.

Environmental conditions play a critical role in drying times. Humidity levels above 60% can double drying time, while temperatures below 60°F (15°C) slow the process significantly. In ideal conditions—65°F to 75°F (18°C to 24°C) with 40-50% humidity—putty dries most efficiently. To expedite drying, use a fan or heater, but avoid direct heat sources that can cause cracking. Conversely, cold or damp environments require patience; rushing the process risks sanding a putty that’s still soft, leading to uneven surfaces or residue on sandpaper.

Thicker applications of wood putty demand extended drying times. A thin layer filling small cracks may be ready for sanding in 2 hours, but a ¼-inch or deeper fill could require 8 hours or overnight drying. Test readiness by pressing lightly with a fingernail; if the putty indents, it’s not fully cured. Sanding prematurely not only ruins the repair but also clogs sandpaper, wasting materials. For deep fills, consider applying putty in layers, sanding between applications to ensure each layer is fully hardened before adding more.

Professionals often use a "tack-free" test to determine if putty is ready for sanding. Once the surface no longer feels sticky to the touch, wait an additional 30 minutes to 1 hour before sanding. This ensures the putty has hardened sufficiently beneath the surface. For fine sanding, especially before staining or finishing, allow an extra 24 hours for the putty to fully cure. This prevents shrinkage or softening under the finish, ensuring a seamless repair. Always sand with progressively finer grits (e.g., 120 to 220) to achieve a smooth, professional result.

In summary, recommended drying times for wood putty before sanding range from 2 to 8 hours, depending on type, thickness, and environment. Water-based putties dry faster than oil-based, but both require careful monitoring to avoid sanding too soon. Ideal conditions accelerate drying, while thicker applications demand patience. Always test for hardness and allow extra curing time for deep fills or fine finishing work. Following these guidelines ensures a durable, flawless repair that blends seamlessly with the surrounding wood.

Understanding Wood Tick Season: Duration and Prevention Tips

You may want to see also

Explore related products

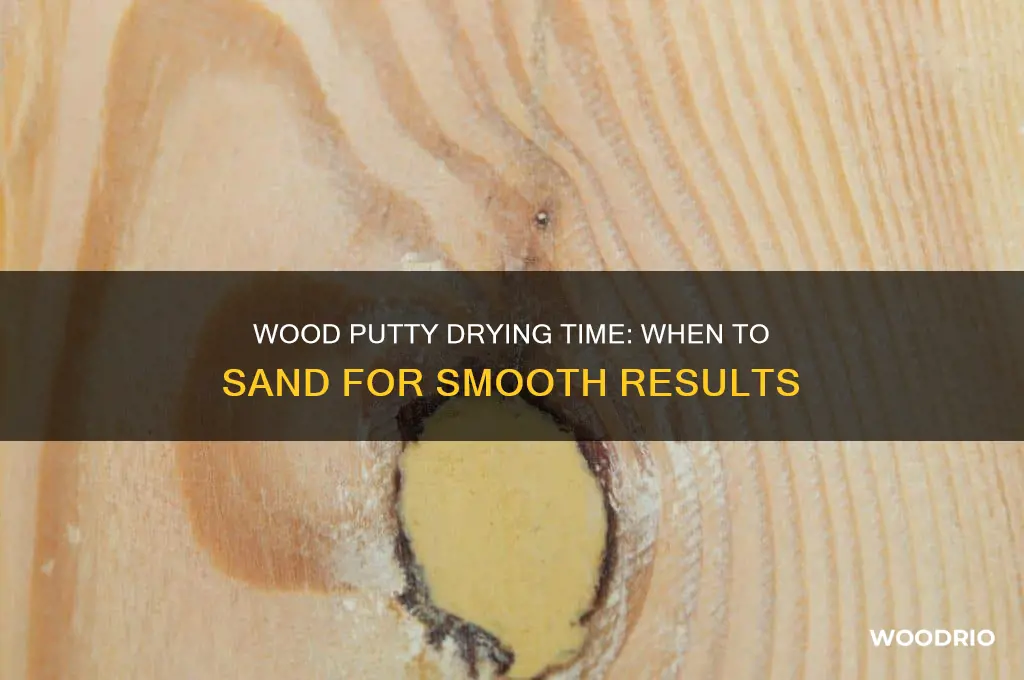

Testing for Dryness

Wood putty drying times vary widely—from 2 hours to 24 hours—depending on brand, environmental conditions, and application thickness. Testing for dryness isn't just about waiting; it's about ensuring the putty is ready for sanding without damaging the repair. A premature sanding attempt can smear the putty, undoing your work and leaving an uneven surface. Understanding how to accurately test for dryness saves time and ensures a professional finish.

Step-by-Step Testing Method: Begin by visually inspecting the putty. Most wood putties change color as they dry, shifting from a darker, wet appearance to a lighter, matte finish. Once the color stabilizes, press your fingernail gently into the surface. If the putty feels hard and doesn't indent, it’s likely dry enough for sanding. For thicker applications, test with a toothpick—insert it into the putty and wait 5 minutes. If the toothpick comes out clean and dry, the putty is ready. Avoid relying solely on touch, as some putties remain slightly tacky even when fully cured.

Environmental Factors to Consider: Humidity and temperature significantly impact drying time. In high-humidity environments (above 60%), drying can take up to 24 hours, while low-humidity conditions (below 30%) may accelerate drying to as little as 2–4 hours. Optimal drying occurs at room temperature (68–72°F). If you’re working in a cold or damp space, consider using a fan or heater to expedite the process, but avoid direct heat sources, which can cause uneven drying or cracking.

Comparative Testing Techniques: For precision, use a moisture meter designed for wood. While not specifically for putty, it can detect residual moisture in the surrounding wood, indicating whether the putty has dried sufficiently. Alternatively, compare the putty’s texture to a known dry sample. Apply a small amount of putty to a scrap piece of wood and let it dry completely. Use this as a benchmark to assess the dryness of your project. This method is particularly useful for large-scale repairs or when working with unfamiliar putty brands.

Practical Tips for Success: Always follow the manufacturer’s guidelines, as drying times vary by product. For example, epoxy-based putties often dry faster than water-based ones. If in doubt, err on the side of caution and allow extra time. Lightly sanding a small, inconspicuous area can confirm readiness without risking the entire repair. Remember, sanding too soon can ruin the putty, while waiting too long can lead to over-drying, making it harder to sand smoothly. Patience and methodical testing ensure a flawless finish.

Lepage Wood Glue Drying Time: Quick Guide for Woodworkers

You may want to see also

Explore related products

Sanding Techniques After Drying

Wood putty typically takes 2 to 4 hours to dry to the touch, but waiting 24 hours ensures it’s fully cured before sanding. Rushing this step risks smearing the putty or damaging the surface. Once dry, sanding becomes the critical next phase to achieve a seamless finish. The technique you use depends on the type of putty, the wood’s grain, and the desired outcome. Start with a medium-grit sandpaper (120-150 grit) to level the putty with the surrounding wood, applying even pressure to avoid gouging.

Transitioning to finer grits (220-320) is essential for blending the putty into the wood’s natural texture. Circular or diagonal strokes work best to mimic the grain pattern, while linear strokes can create unnatural scratches. For water-based putties, lightly dampening the sandpaper can reduce dust and improve smoothing. However, oil-based putties require dry sanding to prevent clumping. Always sand in the direction of the grain to maintain the wood’s integrity.

A common mistake is over-sanding, which can wear down the surrounding wood or expose the putty again. To avoid this, periodically wipe the area with a damp cloth to check progress. If the putty feels soft or lifts, it’s not fully cured—stop sanding and allow more drying time. For intricate areas, switch to a sanding sponge or folded sandpaper for better control. Patience and gradual progression are key to achieving a professional finish.

For stubborn imperfections, consider using a power sander with a fine-grit pad, but exercise caution. Hand sanding offers more precision and reduces the risk of over-aggression. Once the putty is flush and smooth, finish with a tack cloth to remove dust before applying stain or sealant. Proper sanding not only hides repairs but also ensures the wood’s surface is ready for its next layer, whether it’s paint, varnish, or oil.

In summary, sanding after drying is a blend of technique and timing. Start with medium grit, progress to fine, and always respect the wood’s grain. Avoid rushing or overdoing it, and use tools suited to the task. Done correctly, sanding transforms a patched area into an invisible repair, ready for the final touch.

Pittsburgh Paramount Cedar Wood Siding Finish Durability: Lifespan Explained

You may want to see also

Explore related products

Accelerating Drying Process

Wood putty typically takes 2 to 4 hours to dry to the touch, but achieving a hardness suitable for sanding can require 8 to 24 hours, depending on factors like humidity, temperature, and product type. Accelerating this process can save time and improve workflow efficiency, especially in professional settings or when working on multiple projects. By understanding the science behind drying and applying targeted methods, you can significantly reduce drying time without compromising the putty’s integrity.

Environmental Control is the most straightforward way to speed up drying. Increasing the ambient temperature to 70–80°F (21–27°C) and reducing humidity below 50% creates optimal conditions for evaporation. A portable heater or dehumidifier can be used in enclosed spaces, while placing the workpiece near a fan or in direct sunlight (if feasible) enhances air circulation. Avoid excessive heat, as it can cause the putty to crack or shrink. For small repairs, a hairdryer set on low heat can be gently applied from a distance of 6–8 inches, but monitor closely to prevent overheating.

Chemical Accelerants offer a more active approach. Some wood putties are compatible with solvents or accelerators designed to expedite curing. For example, adding 5–10 drops of mineral spirits per ounce of oil-based putty can reduce drying time by up to 30%, but always check the manufacturer’s guidelines to avoid damaging the product. Epoxy-based putties may benefit from mixing in a small amount of hardener beyond the recommended ratio, though this requires precision to prevent brittleness. Always test on a scrap piece first to ensure compatibility.

Application Techniques can also influence drying speed. Applying thin layers of putty rather than a single thick coat allows for faster moisture evaporation. Sanding the surrounding wood lightly before application creates a rough surface for better adhesion, reducing the risk of shrinkage during drying. For larger areas, consider using a putty knife to spread the product evenly, minimizing air pockets that can prolong curing. Pre-warming the putty to room temperature before use can further enhance its responsiveness to drying conditions.

While accelerating the drying process is advantageous, caution is essential to avoid compromising the repair. Over-accelerated drying can lead to surface cracking, adhesion failure, or uneven texture, necessitating reapplication. Always follow the manufacturer’s recommended drying times as a baseline and adjust methods incrementally. For critical projects, allow the putty to cure naturally for the first 6 hours before applying acceleration techniques. By balancing speed with precision, you can achieve a sandable surface faster without sacrificing quality.

Composite Decking vs. Wood: Which Lasts Longer and Why?

You may want to see also

Frequently asked questions

Wood putty usually takes 2 to 4 hours to dry enough for sanding, depending on the brand, humidity, and temperature.

Yes, you can speed up drying by using a hairdryer on low heat, increasing ventilation, or applying a thin layer of putty.

Wood putty is dry when it feels hard to the touch, no longer dents under pressure, and appears matte rather than glossy.

No, sanding prematurely can smear or damage the putty. Always wait until it’s fully hardened to avoid issues.

Yes, drying times can vary. Always check the manufacturer’s instructions for specific drying times and recommendations.