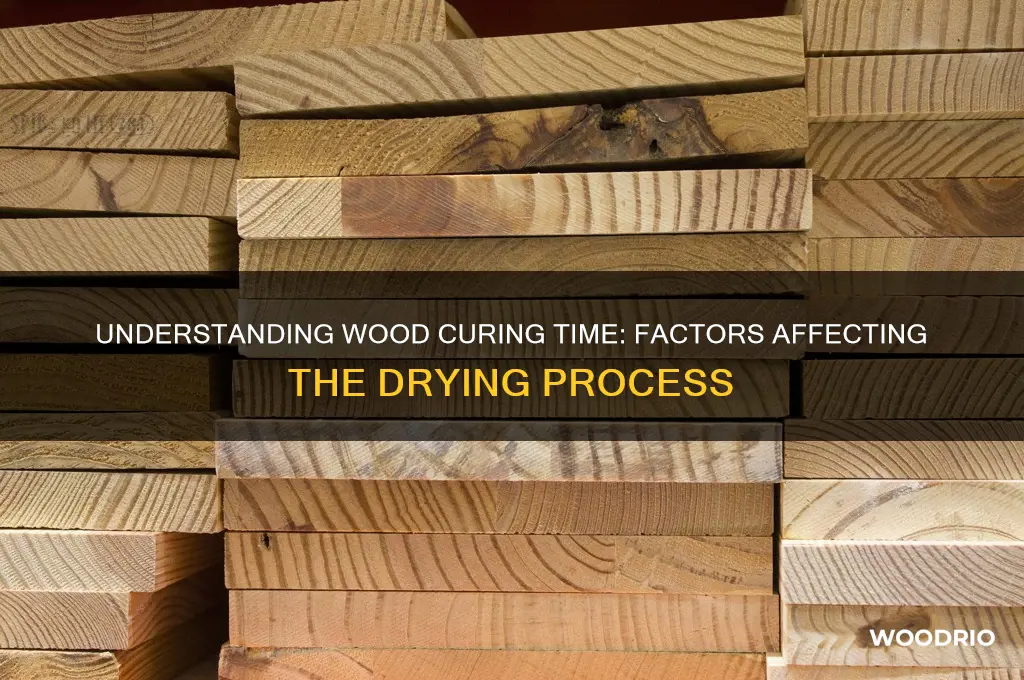

Curing wood is a crucial process that involves drying it to reduce moisture content, ensuring stability, durability, and resistance to warping or cracking. The time it takes for wood to cure depends on several factors, including the wood species, initial moisture level, environmental conditions, and the method used for drying. Softwoods like pine typically cure faster, often within 6 to 12 months, while hardwoods such as oak or maple can take 1 to 2 years or more. Air-drying, the most common method, relies on natural conditions and can be slow, whereas kiln-drying accelerates the process to weeks or months by using controlled heat and humidity. Proper curing is essential for woodworking, construction, and crafting, as it directly impacts the wood’s performance and longevity.

| Characteristics | Values |

|---|---|

| Air Drying Time (Softwoods) | 1-2 years per inch of thickness |

| Air Drying Time (Hardwoods) | 2-3 years per inch of thickness |

| Kiln Drying Time (Softwoods) | 2-10 days depending on thickness and species |

| Kiln Drying Time (Hardwoods) | 4-14 days depending on thickness and species |

| Moisture Content Goal | 6-8% for indoor use, 12-15% for outdoor use |

| Factors Affecting Drying Time | Wood species, thickness, humidity, temperature, airflow |

| Initial Moisture Content | 30-200% depending on wood species and freshness |

| Shrinkage During Drying | 4-10% tangential, 2-6% radial (varies by species) |

| Optimal Drying Conditions | Relative humidity: 50-70%, Temperature: 70-90°F (21-32°C) |

| Risk of Improper Drying | Warping, cracking, splitting, mold, insect infestation |

| Seasoning Methods | Air drying, kiln drying, solar drying, dehumidification kiln drying |

| Minimum Curing Time (General) | 6 months for thin pieces, up to 5 years for thick hardwood logs |

| Testing Moisture Content | Use a moisture meter (ideal range: 6-12% for most applications) |

Explore related products

What You'll Learn

Green Wood Curing Time

The curing time for green wood is a critical factor in woodworking, as it directly impacts the material's stability, durability, and workability. Freshly cut wood, or green wood, contains a high moisture content, typically ranging from 30% to 200%, depending on the species and environmental conditions. This moisture must be reduced to a suitable level, usually between 8% and 12%, for the wood to be considered properly cured and ready for use in furniture, construction, or other applications. The process of curing green wood involves allowing it to air dry naturally or using kiln-drying methods to expedite the process. Understanding the variables that affect curing time—such as wood species, thickness, humidity, and temperature—is essential for achieving optimal results.

Analytical Perspective:

Different wood species cure at varying rates due to their unique cellular structures and densities. For instance, softwoods like pine or cedar generally dry faster than hardwoods like oak or maple. A 1-inch thick board of pine might take 6 to 12 months to air dry, while the same thickness of oak could require 12 to 24 months. Kiln-drying reduces these times significantly, often curing wood in days or weeks, but it requires precise control to avoid cracking or warping. The thickness of the wood is another critical factor; a 4-inch thick log can take 2 to 4 years to air dry, whereas a 1-inch board may cure in under a year. Calculating the moisture loss rate—typically 4% to 8% per inch of thickness per year for air drying—helps predict curing timelines accurately.

Instructive Approach:

To cure green wood effectively, start by cutting the wood to the desired thickness and stacking it in a well-ventilated area. Stickers—small pieces of wood placed between layers—promote airflow and prevent warping. Cover the stack with a waterproof roof to shield it from rain while allowing air circulation. Monitor the moisture content using a moisture meter, aiming for a reading between 8% and 12%. For kiln-drying, follow manufacturer guidelines for temperature and humidity settings, gradually increasing heat to avoid stress on the wood. Always acclimate cured wood to its intended environment for at least two weeks before use to prevent shrinkage or expansion.

Comparative Insight:

Air drying is cost-effective and environmentally friendly but requires patience and space. Kiln-drying, while faster, is more expensive and energy-intensive. For hobbyists, air drying is often the preferred method, whereas commercial operations favor kiln-drying for its efficiency. Another alternative is solar drying, which uses solar-powered kilns to combine speed with sustainability. Each method has trade-offs: air drying risks fungal growth if not managed properly, while kiln-drying can lead to case hardening if not controlled meticulously. Choosing the right method depends on the scale of the project, available resources, and desired turnaround time.

Descriptive Takeaway:

Imagine a stack of freshly cut oak boards, their rich green hue gradually fading to a warm brown as moisture escapes. The air around them carries a faint earthy scent, a testament to the natural process unfolding. Over months, the wood transforms, becoming lighter, harder, and more resilient. Each crackle and shift in the stack signals progress, a reminder of the patience required to master the art of curing. Whether for a handcrafted table or a structural beam, properly cured green wood ensures longevity and beauty, making the wait well worth it.

Practical Tips:

- Seal the ends of logs or boards with wax or paint to slow moisture loss from these areas, reducing the risk of splits.

- Rotate stacks periodically to ensure even drying and prevent sticking.

- Avoid stacking wood directly on the ground; use pallets or planks to elevate it and improve airflow.

- For kiln-drying, maintain a humidity gradient, starting at 90% and gradually reducing it to 40% over several days to prevent surface checking.

- Store cured wood in a controlled environment to maintain its moisture content until it’s ready for use.

By understanding and respecting the curing process, woodworkers can transform raw, green wood into a stable, versatile material that stands the test of time.

Heat-Treated Wood Durability: Longevity and Outdoor Performance Explained

You may want to see also

Explore related products

$26.99 $29.99

Air Drying vs. Kiln Drying

The curing time for wood depends heavily on the method chosen: air drying or kiln drying. Air drying, a traditional approach, relies on natural conditions—temperature, humidity, and airflow—to gradually reduce moisture content. This process can take anywhere from 6 months to 2 years, depending on the wood species and environmental factors. For instance, hardwoods like oak or maple may require closer to 2 years, while softer woods like pine dry faster. Kiln drying, on the other hand, accelerates this process using controlled heat and humidity in a specialized chamber. It typically takes 2 to 14 days, making it significantly faster but more resource-intensive.

Analytical Perspective:

The choice between air drying and kiln drying hinges on cost, time, and quality. Air drying is cost-effective and environmentally friendly, as it requires minimal energy. However, it’s unpredictable—weather fluctuations can lead to uneven drying or mold growth. Kiln drying ensures uniformity and precision, reducing the risk of defects like warping or splitting. For commercial operations or projects with tight deadlines, kiln drying is often the preferred option despite its higher cost.

Instructive Steps:

To air dry wood effectively, stack lumber in a well-ventilated area, ensuring stickers (spacers) are placed between boards to allow airflow. Cover the stack with a roof to protect from rain while permitting air circulation. Rotate the stack periodically to ensure even drying. For kiln drying, load the wood into a kiln, set the desired moisture content (typically 6–12%), and monitor temperature and humidity levels. Follow manufacturer guidelines for specific wood species to avoid overheating or drying too quickly.

Comparative Takeaway:

While air drying is ideal for hobbyists or small-scale projects, kiln drying suits large-scale production or time-sensitive applications. Air-dried wood often retains a more natural appearance and stability over time, whereas kiln-dried wood is immediately ready for use but may lack the same long-term resilience. Consider the end use—furniture makers might prefer air-dried wood for its character, while construction projects benefit from kiln-dried wood’s consistency.

Practical Tip:

For those without access to a kiln, a hybrid approach can be effective. Air dry wood for several months to reduce moisture content, then finish drying in a homemade kiln (e.g., a shed with heaters and fans). This balances time and cost while achieving satisfactory results. Always measure moisture content with a wood moisture meter to ensure it’s below 15% for indoor use or 19% for outdoor applications.

Mastering Propane Smoking: Wood Chip Burn Time Explained

You may want to see also

Explore related products

Moisture Content Goals

Wood curing is fundamentally about managing moisture content, a process that varies widely depending on species, thickness, and environmental conditions. For instance, softwoods like pine can reach equilibrium moisture content (EMC) in 6–12 months, while denser hardwoods such as oak may require 1–2 years. The goal isn’t to eliminate moisture entirely but to stabilize it at a level that prevents warping, cracking, or decay. In most cases, wood for indoor use should aim for 6–8% moisture content, aligning with typical indoor humidity levels of 30–50%. Achieving this balance ensures durability and structural integrity, making moisture content the cornerstone of effective wood curing.

To set realistic moisture content goals, start by understanding the wood’s intended use. Outdoor projects, like decking or fencing, should target 12–15% moisture content to withstand weather fluctuations. Indoor furniture or flooring, however, demands stricter control at 6–8%. Tools like moisture meters are essential for monitoring progress, providing precise readings to guide decision-making. For example, if a hardwood plank reads 18% moisture, it’s far from ready for indoor use. Regular testing every 2–3 weeks helps track drying rates and adjust storage conditions, such as increasing airflow or using dehumidifiers, to meet specific targets.

Persuasive arguments for strict moisture control abound, particularly in preventing costly mistakes. Wood with excessive moisture content (above 19%) is prone to mold, rot, and dimensional instability, rendering it unusable. Conversely, overly dry wood (below 5%) becomes brittle and susceptible to cracking. Builders and craftsmen must prioritize moisture management to avoid project failures. Investing in proper curing techniques—such as kiln drying or air drying in a controlled environment—pays dividends in material quality and longevity. Ignoring moisture content goals is akin to building on quicksand; the foundation will inevitably fail.

Comparing natural air drying to kiln drying highlights the trade-offs in achieving moisture content goals. Air drying, while cost-effective, relies on ambient conditions and can take 1–3 years for thick hardwoods. Kiln drying accelerates the process to weeks but requires specialized equipment and energy expenditure. For hobbyists, air drying in a well-ventilated shed with stacked and stickered wood is practical, though slower. Professionals often opt for kiln drying to meet tight deadlines without compromising quality. Both methods demand vigilance, but the choice hinges on time constraints, resources, and desired precision in moisture control.

Descriptive examples illustrate the impact of moisture content on wood behavior. Imagine a freshly cut oak beam with 50% moisture content—heavy, pliable, and prone to distortion. As it dries to 12%, it hardens, lightens, and stabilizes, ready for outdoor construction. Further reduction to 7% transforms it into a prime candidate for fine cabinetry, its grains tight and resistant to shrinkage. Each percentage point reflects a tangible change in texture, weight, and workability. Observing these transformations underscores why moisture content goals aren’t arbitrary but critical benchmarks in the art and science of wood curing.

Understanding Wood Lovers Paralysis Duration: Symptoms, Recovery, and Treatment

You may want to see also

Explore related products

Species-Specific Curing Rates

The curing time of wood varies dramatically across species, influenced by factors like density, moisture content, and cellular structure. Hardwoods like oak and maple, with their dense fibers, can take 1-2 years per inch of thickness to cure properly. In contrast, softwoods such as pine or cedar, with lower density and more porous structures, often cure in 6-12 months per inch. This disparity underscores the importance of species-specific knowledge when planning woodworking projects.

Consider the example of walnut, a prized hardwood known for its rich color and durability. Its high natural oils slow moisture release, requiring 1.5-2 years per inch of curing time. Failure to account for this can lead to warping or cracking in finished pieces. Conversely, balsa wood, one of the lightest species, cures rapidly—often within 3-6 months per inch—due to its low density and minimal moisture retention. These examples highlight how species-specific traits dictate curing timelines, demanding tailored approaches for optimal results.

For those working with exotic species, understanding regional variations is critical. Teak, native to Southeast Asia, cures in 1-1.5 years per inch due to its natural oils and resins, which resist moisture absorption. However, African mahogany, despite being a hardwood, cures slightly faster—around 1 year per inch—thanks to its more open grain structure. Such nuances emphasize the need for research or consultation with experts when working with less common woods.

Practical tips can streamline the curing process for specific species. For instance, air-drying oak in a well-ventilated, shaded area with stickers between boards promotes even moisture loss. For faster-curing softwoods like cedar, kiln-drying at 120°F for 3-5 days can expedite the process, though this method risks over-drying if not monitored. Always measure moisture content with a wood moisture meter, aiming for 6-8% for indoor use, to ensure the wood is fully cured and stable.

In conclusion, species-specific curing rates are not one-size-fits-all. By understanding the unique properties of each wood type—density, natural oils, and grain structure—craftsmen can avoid common pitfalls like warping or splitting. Whether air-drying hardwoods over years or kiln-drying softwoods in days, precision and patience are key to harnessing the full potential of each species.

Wood Glue Drying Time: Factors Affecting Cure Speed and Strength

You may want to see also

Explore related products

$26.99 $30.54

Environmental Factors Impact

Wood curing times are not set in stone; they're a delicate dance influenced heavily by the environment. Humidity, the amount of moisture in the air, is a key player. In regions with high humidity, like tropical climates, wood curing can take significantly longer. The excess moisture in the air slows down the evaporation process, delaying the wood's drying. For instance, oak lumber might take 1-2 years to air-dry in a humid coastal area, compared to 6-9 months in a drier inland region.

Temperature plays a crucial role as well. Warmer temperatures accelerate evaporation, speeding up curing. However, extreme heat can cause cracks and warping. Ideally, wood should cure in a temperature range of 60-80°F (15-27°C). Airflow is another critical factor. Good ventilation allows moisture to escape efficiently. Stacking wood with spacers between boards and ensuring proper air circulation in the storage area can significantly reduce curing time.

Imagine two stacks of freshly cut pine planks. One is left in a damp, poorly ventilated basement, while the other is stored in a well-ventilated shed with controlled humidity and temperature. The shed-stored wood will likely be ready for use in half the time, showcasing the dramatic impact of environmental control.

Sunlight exposure can be a double-edged sword. While it can aid in drying, direct sunlight can cause uneven drying, leading to warping and discoloration. Rain and snow are obvious enemies of curing wood. Exposure to precipitation can reintroduce moisture, setting back the curing process and potentially leading to rot.

To optimize curing time and quality, consider these practical tips:

- Choose the right location: Opt for a dry, well-ventilated area with controlled temperature and humidity.

- Stack wood properly: Use stickers (spacers) between boards to allow airflow and prevent warping.

- Monitor moisture levels: Use a moisture meter to track the wood's moisture content, aiming for a target range of 6-8% for most indoor applications.

- Protect from the elements: Cover wood piles with a breathable tarp to shield them from rain and snow while allowing airflow.

By understanding and manipulating these environmental factors, woodworkers and enthusiasts can significantly influence the curing process, ensuring stronger, more stable, and longer-lasting wood for their projects.

Optimal Wood Drying Time for Efficient Splitting and Burning

You may want to see also

Frequently asked questions

The curing time for wood varies depending on the species and environmental conditions, but it generally takes 6 to 12 months for wood to air-dry to a moisture content suitable for most uses.

Yes, hardwoods typically take longer to cure than softwoods due to their denser structure. Hardwoods may require 1 to 2 years, while softwoods can cure in 6 to 12 months.

Yes, kiln-drying can significantly reduce curing time, often taking just a few days to a few weeks, depending on the wood species and kiln settings, compared to months for air-drying.