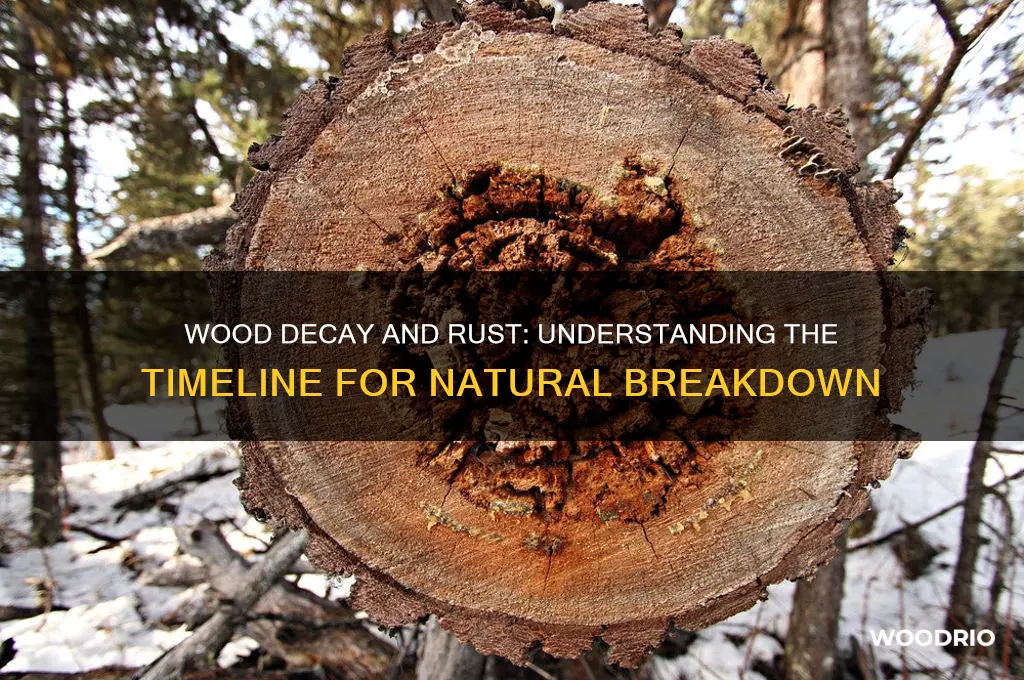

Wood decay and rust are two distinct processes, but they can both be influenced by environmental factors such as moisture, temperature, and exposure to elements. While rust specifically refers to the oxidation of iron or steel, wood decay is the breakdown of wood caused by fungi, bacteria, or insects. The time it takes for wood to decay varies widely, depending on factors like the type of wood, moisture levels, and the presence of decay agents. Hardwoods like oak or teak can take decades to decompose, whereas softer woods like pine may decay within a few years under favorable conditions. Rust, on the other hand, can form on metal surfaces within days or weeks in humid environments, but its progression slows significantly in dry conditions. Understanding these processes is crucial for preserving structures and materials in various settings.

| Characteristics | Values |

|---|---|

| Type of Wood | Hardwoods (e.g., oak, teak) decay slower than softwoods (e.g., pine). |

| Moisture Content | High moisture accelerates decay; dry wood lasts longer. |

| Oxygen Exposure | Decay is faster in aerobic conditions (with oxygen). |

| Temperature | Warmer temperatures (20-35°C) speed up decay. |

| Soil Contact | Direct soil contact increases decay rate due to moisture and microbes. |

| Microbial Activity | Fungi and bacteria are primary agents of wood decay. |

| Preservative Treatment | Treated wood (e.g., pressure-treated) lasts significantly longer. |

| pH Level | Acidic environments (pH < 5) can accelerate decay. |

| Rust Impact | Rust itself does not directly cause wood decay but indicates moisture. |

| Average Decay Time (Untreated) | 5-10 years in humid, warm conditions; up to 50+ years in dry climates. |

| Average Decay Time (Treated) | 20-40+ years depending on treatment and conditions. |

Explore related products

What You'll Learn

Factors Affecting Decay Rate

Wood decay in the presence of rust is a complex process influenced by multiple environmental and material factors. Moisture content, for instance, is a primary driver. Wood exposed to consistent moisture, such as in damp soil or humid environments, decays significantly faster than dry wood. Rust, an iron oxide formed through oxidation, accelerates this process by retaining moisture and creating conditions conducive to fungal growth. Studies show that wood in contact with rusty metal can decay up to 50% faster than wood in dry conditions. To mitigate this, ensure wood is treated with water-repellent preservatives and kept away from metal surfaces prone to rusting.

Temperature and humidity play critical roles in decay rates as well. In tropical climates, where temperatures average 25–30°C and humidity exceeds 70%, wood decay can occur within 5–10 years. Conversely, in arid regions with temperatures below 15°C and low humidity, decay may take 20–30 years or longer. Fungi, the primary agents of wood decay, thrive in warm, humid conditions. For outdoor structures, consider using naturally rot-resistant woods like cedar or redwood, and apply fungicides annually to inhibit fungal growth.

The type of wood and its density also affect decay resistance. Softwoods, such as pine, decay faster than hardwoods like oak due to their lower density and higher resin content. However, even hardwoods are not immune if exposed to prolonged moisture and rust. For example, oak posts buried in soil with rusty metal fasteners can show signs of decay within 15 years. To enhance durability, use pressure-treated wood, which is infused with preservatives like chromated copper arsenate (CCA), proven to extend lifespan by 2–3 times in harsh conditions.

Microbial activity is another key factor. Bacteria and fungi, particularly brown rot and white rot fungi, break down cellulose and lignin in wood. Rusty metal surfaces provide a habitat for these microorganisms by leaching iron ions, which act as nutrients. Regular inspection and removal of rust from metal components can slow this process. Additionally, applying borate-based treatments to wood can inhibit microbial growth, as borates are toxic to fungi and insects at concentrations as low as 1–2%.

Finally, physical stress and exposure to elements accelerate decay. Wood subjected to frequent wetting and drying cycles, such as in coastal areas with saltwater exposure, degrades faster due to osmotic pressure and salt crystallization. Rusty nails or screws exacerbate this by creating entry points for moisture and fungi. To combat this, use stainless steel or galvanized fasteners, which resist rust, and seal wood ends with epoxy to prevent water absorption. Periodic maintenance, including re-sealing and rust removal, can extend the life of wooden structures by decades.

Old English Drying Time: How Long on Wood Surfaces?

You may want to see also

Explore related products

Wood Type and Durability

Wood decay is a natural process influenced by factors like moisture, fungi, and wood type. Not all woods succumb to rot at the same rate; some species possess inherent qualities that make them more resistant to decay. For instance, teak and cedar are renowned for their durability, often lasting decades without treatment, while pine and spruce may show signs of decay within a few years when exposed to harsh conditions. Understanding these differences is crucial for anyone looking to use wood in outdoor or damp environments.

Consider the environment where the wood will be used. In areas with high humidity or frequent rainfall, choosing a naturally rot-resistant wood like redwood or cypress can save time and money on maintenance. These woods contain natural oils and tannins that deter fungi and insects, slowing the decay process significantly. For less demanding applications, pressure-treated pine offers a cost-effective alternative, though it typically lasts 15–20 years before showing signs of deterioration.

If you’re working with less durable wood, preventive measures can extend its lifespan. Applying a wood preservative or sealant creates a barrier against moisture, the primary catalyst for decay. For example, a copper-based preservative can add 5–10 years to the life of a wooden structure. Regular maintenance, such as reapplying sealant every 2–3 years and ensuring proper drainage, is equally important. Even the most durable woods benefit from these practices, especially in extreme climates.

Comparing wood types reveals a clear hierarchy of durability. Tropical hardwoods like ipe and mahogany are at the top, often lasting 40 years or more without treatment. Softwoods like fir and hemlock fall at the bottom, typically lasting 5–10 years in harsh conditions. Engineered woods, such as acetylated wood, offer a middle ground, combining the workability of natural wood with enhanced resistance to decay. Choosing the right wood for the job isn’t just about aesthetics—it’s about ensuring longevity and reducing long-term costs.

Finally, consider the role of sustainability in your choice. While durable woods like teak are excellent for longevity, they often come from slow-growing trees, raising environmental concerns. Opting for fast-growing, treated softwoods or recycled wood products can strike a balance between durability and ecological responsibility. By weighing these factors, you can make an informed decision that aligns with both practical needs and environmental values.

Boiling Palo Azul Wood Chips: Optimal Time for Best Results

You may want to see also

Explore related products

Environmental Conditions Impact

Wood decay in the presence of rust is a complex process influenced heavily by environmental conditions. Moisture levels, temperature, oxygen availability, and microbial activity collectively dictate the pace of degradation. For instance, wood submerged in waterlogged soil can decay within 5–10 years due to constant moisture and anaerobic bacteria, while wood in arid climates may persist for decades, even centuries, with minimal microbial activity. Rust, a byproduct of iron oxidation, accelerates decay by weakening wood fibers through chemical interaction, but its impact is amplified or mitigated by the surrounding environment.

Consider the role of humidity and temperature as a dynamic duo. In tropical regions with 80–90% humidity and temperatures above 25°C, fungi like *Serpula lacrymans* thrive, reducing untreated wood lifespan to 5–15 years. Conversely, in deserts with humidity below 30% and temperatures exceeding 40°C, wood decay slows dramatically, often preserving structures for 50+ years. Practical tip: In humid areas, elevate wooden structures 6–12 inches above ground and apply borate-based preservatives to inhibit fungal growth.

Oxygen availability is another critical factor. Wood buried in oxygen-depleted environments, such as wetlands or deep soil, decays slower due to anaerobic conditions, which hinder most wood-decaying fungi. However, anaerobic bacteria can still cause decay, albeit at a reduced rate. In contrast, well-ventilated environments expose wood to aerobic fungi and insects, accelerating decay. For example, a wooden post in a breezy coastal area may deteriorate in 10–15 years, while a similarly treated post buried in clay soil could last 20–30 years.

Microbial activity, particularly fungi and bacteria, is the primary driver of wood decay, but their effectiveness depends on environmental pH and nutrient availability. Acidic soil (pH <5.5) enhances fungal activity, while alkaline soil (pH >7.5) suppresses it. Adding lime to acidic soil can raise pH, slowing decay. Additionally, wood in nutrient-rich environments, like compost or manure, decays faster due to increased microbial populations. Caution: Avoid placing wood near organic matter or fertilizer to extend its lifespan.

Finally, sunlight and UV radiation play a dual role. While UV rays degrade wood’s lignin, making it brittle, they also inhibit surface fungal growth by drying the wood. In sunny environments, untreated wood may last 10–20 years due to reduced fungal activity, but it becomes structurally weaker over time. In shaded areas, moisture retention increases fungal colonization, shortening lifespan to 5–10 years. Practical tip: Apply UV-resistant sealants to wooden surfaces in sunny climates to balance moisture protection and fungal inhibition.

Understanding these environmental interactions allows for strategic interventions to prolong wood’s life. Whether through site selection, chemical treatments, or design modifications, managing moisture, temperature, oxygen, and microbial factors can significantly delay decay, even in the presence of rust.

Dreamlight Valley Tropical Wood Respawn Time: What to Expect

You may want to see also

Explore related products

Preventing Rust on Metal Parts

Wood decay is a natural process influenced by moisture, fungi, and environmental conditions, but its role in rust formation on metal parts is often misunderstood. While wood itself doesn’t directly cause rust, its decay can create conditions that accelerate corrosion. For instance, rotting wood can trap moisture against metal surfaces, fostering the oxidation process. Understanding this interplay is crucial for preventing rust, especially in structures where wood and metal are in close contact, like fences, bridges, or outdoor furniture.

To prevent rust on metal parts, start by isolating metal from direct contact with wood. Use non-conductive materials like plastic or rubber washers and spacers between the two. For example, when attaching metal brackets to wooden posts, insert a layer of neoprene to minimize moisture transfer. Additionally, ensure proper ventilation around metal components to reduce humidity buildup. In high-moisture environments, consider treating wood with preservatives like copper azole or borates, which inhibit fungal growth and slow decay while also creating a less corrosive environment for adjacent metal.

Another effective strategy is applying protective coatings to metal surfaces. Zinc-rich primers, such as galvanizing compounds, provide a sacrificial layer that corrodes instead of the metal. For smaller parts, immersion in a rust-inhibiting solution containing phosphates or silicates can create a protective barrier. Regularly inspect and reapply coatings, especially in areas prone to wood decay. For instance, metal fasteners in wooden decks should be coated annually with a rust-preventive spray containing VCI (vapor corrosion inhibitors) to penetrate tight spaces.

Comparing preventive methods reveals trade-offs. While galvanization offers long-term protection, it’s costly and labor-intensive. Powder coating, on the other hand, is more affordable but less durable in harsh conditions. For DIY enthusiasts, a simple yet effective approach is using a mixture of boiled linseed oil and mineral spirits (1:1 ratio) to seal metal surfaces. This natural method not only repels moisture but also enhances the metal’s appearance. Pairing this with regular wood maintenance ensures both materials age gracefully without compromising structural integrity.

Finally, monitor environmental factors that accelerate both wood decay and rust. Keep metal parts at least 6 inches above ground to prevent water wicking, and slope surrounding soil away from structures to improve drainage. In coastal areas, where salt accelerates corrosion, rinse metal components monthly with fresh water and apply marine-grade rust inhibitors. By addressing the root causes of moisture retention and decay, you can significantly extend the lifespan of metal parts, even in wood-heavy applications.

How Long Does Smoking Wood Last: A Comprehensive Guide

You may want to see also

Explore related products

Accelerated Decay Methods

Wood decay in the presence of rust is a natural process, but it can be accelerated through targeted methods that exploit environmental and chemical factors. One effective approach is increasing moisture exposure, as wood in constant contact with water decays 50–100% faster than dry wood. For controlled experiments or artistic projects, submerging wood in water mixed with iron filings (100g per 5L) mimics a rust-rich environment, speeding up degradation. This method is particularly useful for creating weathered textures in woodworking or studying material breakdown.

Another technique involves applying hydrogen peroxide (3–6% concentration) directly to the wood’s surface. This oxidizing agent breaks down cellulose fibers while reacting with iron oxides in rust, accelerating decay. Apply the solution evenly using a spray bottle, reapplying every 48 hours for consistent results. Caution: wear gloves and work in a ventilated area to avoid skin irritation or inhalation risks. This method is ideal for small-scale projects but may not be practical for large structures due to cost and labor.

For larger applications, such as landscaping or outdoor installations, burying wood in soil with high iron content (e.g., clay-rich earth) can expedite decay. The soil’s moisture and iron oxides create an ideal environment for fungi like *Serpula lacrymans*, which thrive in damp, mineral-rich conditions. To enhance this, mix 5–10% iron sulfate into the soil before burial. Monitor the wood’s progress monthly, as this method can reduce decay time from decades to 3–5 years, depending on climate and wood type.

Comparatively, heat treatment offers a contrasting approach by weakening wood’s structural integrity before exposing it to rust. Heating wood to 180–220°C for 2–4 hours makes it more susceptible to fungal and bacterial invasion. Once treated, place the wood in a humid environment with rusted metal objects to accelerate decay. This two-step process is labor-intensive but yields predictable results, making it suitable for scientific studies or controlled artistic decay.

In summary, accelerated decay methods range from simple moisture manipulation to complex chemical treatments, each with unique advantages and limitations. By understanding these techniques, practitioners can tailor their approach to specific needs, whether for research, art, or practical applications. Always prioritize safety and environmental considerations when experimenting with these methods.

Perfect Timing: When to Use Wood After Placing It in Your Wber

You may want to see also

Frequently asked questions

The decay time for wood in Rust depends on its type and environmental factors, but typically ranges from 3 to 7 days without maintenance.

Yes, exposure to rain and other weather conditions accelerates wood decay in Rust, reducing its lifespan significantly.

Yes, applying a tool cupboard or using building privileges can prevent decay, and maintaining the structure regularly slows it down.

Fully decayed wood structures collapse, leaving behind any items or components placed within them, which can be looted.

No, in Rust, all wood types decay at the same rate; the game does not differentiate between different wood materials.