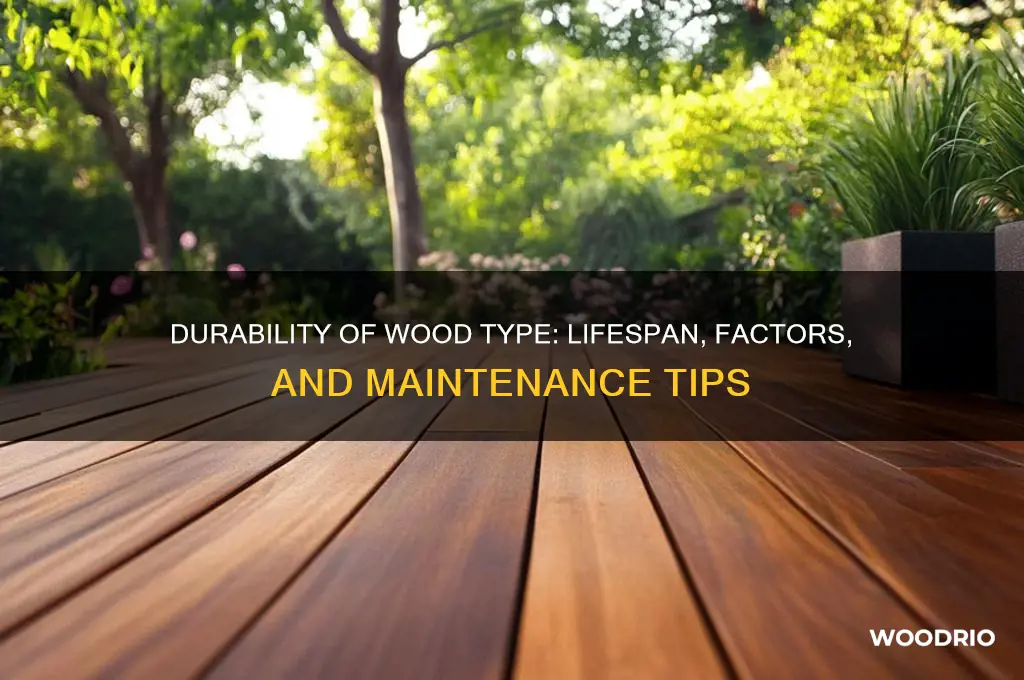

Wood type, a traditional method of printing using individual wooden letters and characters, has a lifespan that varies significantly depending on factors such as the type of wood used, environmental conditions, and maintenance. Typically, wood type made from durable hardwoods like maple or cherry can last for decades, even centuries, when stored in a controlled environment with stable humidity and temperature levels. However, softer woods or those exposed to moisture, pests, or frequent handling may degrade more quickly, leading to warping, cracking, or ink residue buildup. Proper care, such as regular cleaning and protective storage, can extend the longevity of wood type, ensuring its continued use in both historical preservation and modern artistic applications.

Explore related products

What You'll Learn

Climate Impact on Durability

Wood's longevity is significantly influenced by its exposure to varying climatic conditions, which can either preserve or accelerate its deterioration. In regions with high humidity, such as tropical climates, wood is prone to moisture absorption, leading to warping, cracking, and fungal growth. For instance, untreated pine in a humid environment may show signs of decay within 5–10 years, whereas in drier climates, it can last up to 40 years with minimal maintenance. To mitigate this, apply a moisture-resistant sealant or opt for naturally rot-resistant species like teak or cedar, which contain natural oils that repel water.

Temperature fluctuations also play a critical role in wood durability. Extreme cold can cause wood to contract, while heat induces expansion, both of which weaken structural integrity over time. In areas with freezing winters, such as the northern United States, wood structures may require annual inspections to detect and repair micro-fractures. Conversely, in hot, arid climates like the southwestern U.S., UV radiation can degrade wood surfaces, necessitating the use of UV-protective finishes. For outdoor applications, consider thermally modified wood, which undergoes a heat treatment process to enhance dimensional stability and resistance to temperature-induced stress.

Precipitation patterns further dictate wood’s lifespan, particularly in regions with heavy rainfall or snow. Prolonged exposure to water can lead to rot and insect infestation, even in treated wood. In the Pacific Northwest, for example, untreated Douglas fir may deteriorate within 15 years due to consistent rain, whereas pressure-treated lumber can extend this to 20–30 years. To combat this, ensure proper drainage around wooden structures and elevate them above ground level. Additionally, incorporate breathable waterproof membranes to allow moisture to escape while preventing water ingress.

Air quality and pollution levels are often overlooked but can significantly impact wood durability, especially in urban environments. Acid rain, common in industrial areas, can corrode wood fibers, reducing lifespan by up to 30%. Coastal regions face salt spray, which accelerates corrosion in both wood and metal fasteners. In such areas, use corrosion-resistant hardware and apply marine-grade finishes to wooden surfaces. Regular cleaning to remove salt deposits can also prolong wood’s life. For urban or coastal projects, prioritize hardwoods like ipe or composite materials designed to withstand harsh environmental conditions.

Finally, altitude and its associated climatic conditions can uniquely affect wood durability. At higher elevations, wood is exposed to lower atmospheric pressure, increased UV radiation, and wider temperature swings, all of which accelerate degradation. In mountainous regions like the Alps, untreated spruce may last only 10–15 years, compared to 25–30 years at sea level. To counteract these effects, select wood species with high density and natural resilience, such as larch or oak, and apply multi-layered protective coatings. Periodic maintenance, including reapplication of finishes every 2–3 years, is essential to ensure longevity in such challenging environments.

Unveiling the Mystery: Yellow Jackets' Duration in the Woods

You may want to see also

Explore related products

Wood Type Lifespan Comparison

The lifespan of wood varies dramatically depending on species, treatment, and environmental exposure. Hardwoods like teak and oak can endure for centuries, often seen in historic buildings and furniture, while softer woods such as pine or cedar typically last 10–40 years without preservation. Pressure-treated lumber, infused with preservatives, extends lifespan to 40 years or more, making it ideal for outdoor structures like decks. Untreated wood in direct contact with soil, however, may decay within 5–10 years due to moisture and pests. Understanding these differences is crucial for selecting the right wood for specific applications.

Consider the role of climate in wood longevity. In arid regions, untreated wood can last longer due to reduced moisture, while humid or wet environments accelerate rot and insect damage. For instance, cedar, naturally resistant to decay, thrives in moist climates but still benefits from sealing to maximize its 20–30-year lifespan. Conversely, tropical hardwoods like ipe or mahogany, with natural oils that repel insects and moisture, can last 40–75 years outdoors without treatment. Applying a protective finish or sealant can add 5–10 years to any wood type, making maintenance a key factor in lifespan extension.

When comparing wood types for structural use, density and grain pattern matter. Dense, tight-grained woods like maple or walnut resist wear and tear, making them suitable for high-traffic areas like flooring, where they can last 50–100 years. Lighter, open-grained woods like fir or spruce, while less durable, are cost-effective for framing and can last 30–50 years if protected from moisture. Engineered wood products, such as plywood or laminated veneer lumber (LVL), offer consistent strength and resistance to warping, often outperforming solid wood in stability but with a lifespan capped at 30–50 years depending on use.

For outdoor projects, the choice of wood type directly impacts maintenance needs and replacement frequency. Redwood, with its natural tannins, resists decay and insects, lasting 20–30 years untreated and up to 50 years when sealed. Pressure-treated pine, a budget-friendly option, requires periodic staining to maintain its 40-year lifespan. Exotic hardwoods like cumaru or tigerwood, though expensive, offer unparalleled durability, often lasting 75+ years with minimal upkeep. For those prioritizing sustainability, reclaimed wood, if properly restored, can match or exceed the lifespan of new wood while reducing environmental impact.

Finally, consider the economic and environmental trade-offs in wood selection. While hardwoods offer longer lifespans, their higher cost and slower regrowth rates make them less accessible for large-scale projects. Softwoods, though shorter-lived, are renewable and affordable, making them suitable for temporary or low-impact uses. Composite materials, blending wood fibers with plastic, offer a 25–50-year lifespan with minimal maintenance but come with environmental concerns related to plastic production. By balancing durability, cost, and sustainability, you can choose a wood type that meets both functional and ethical requirements for your project.

Glitter Glue Drying Time on Wood: A Quick Guide

You may want to see also

Explore related products

Maintenance Extending Wood Life

Wood's longevity is a testament to nature's resilience, but even the hardest varieties succumb to time without proper care. Exposure to moisture, sunlight, and pests accelerates deterioration, making maintenance the linchpin of preservation. For instance, untreated pine might last a decade outdoors, while pressure-treated lumber can endure for 40 years or more with regular upkeep. The key lies in understanding that wood is not immutable; it requires proactive measures to thwart the elements and biological threats.

Consider the role of sealants and finishes, which act as the first line of defense against moisture infiltration. Water-based sealers, such as Thompson’s WaterSeal, penetrate wood fibers to block water absorption, while oil-based options like linseed oil enhance grain appearance and flexibility. Reapplication every 2–3 years is critical, especially in humid climates or high-traffic areas. For maximum efficacy, clean surfaces thoroughly before application, ensuring no dirt or old finish remains. Neglecting this step can lead to peeling or uneven absorption, undermining the protective barrier.

Beyond surface treatments, structural maintenance is equally vital. Inspect wooden structures annually for cracks, splinters, or signs of insect damage. Termites, carpenter ants, and wood-boring beetles can compromise integrity swiftly. Treat infestations promptly with borate-based solutions, which act as both a pesticide and fungicide. For preventive measures, store firewood at least 20 feet from structures and ensure proper drainage to avoid standing water near wooden foundations. These practices disrupt pest habitats and reduce decay-inducing moisture.

Environmental factors also dictate maintenance frequency. In regions with harsh winters, snow and ice can warp or crack wood, necessitating springtime repairs. Use a plastic shovel instead of metal to clear surfaces, minimizing abrasion. Conversely, intense UV exposure in arid climates fades and dries wood, requiring annual refinishing with UV-resistant stains. Even indoor wood benefits from humidity control; maintain levels between 30–50% to prevent warping or splitting.

Ultimately, extending wood’s life is a commitment to routine vigilance and timely intervention. By combining protective treatments, structural inspections, and environmental adaptations, one can preserve wood’s beauty and functionality for decades. The effort yields not just longevity but also sustainability, reducing the need for frequent replacements and conserving natural resources. In this way, maintenance becomes an act of stewardship, honoring wood’s enduring value.

Sealing Dried Wood: Optimal Timing for Durable and Long-Lasting Results

You may want to see also

Explore related products

Indoor vs. Outdoor Longevity

Wood's lifespan is dramatically different when exposed to the elements versus sheltered indoors. Outdoor wood faces a relentless assault: UV radiation breaks down fibers, moisture swells and contracts causing warping, and insects see it as a buffet. Even rot-resistant species like cedar or teak will eventually succumb without proper care. A well-maintained cedar deck might last 15-20 years, while untreated pine could deteriorate in half that time.

Contrast this with indoor wood, which enjoys a controlled environment. Temperature and humidity fluctuations are minimal, sunlight exposure is limited, and pests are far less likely to invade. A hardwood floor made of oak or maple, for instance, can easily last a century with proper refinishing every decade or so. Even softer woods like pine can endure for generations indoors if protected from heavy wear and moisture.

To maximize outdoor wood longevity, prioritize preventative measures. Sealants and stains act as a barrier against moisture and UV damage, but they require reapplication every 1-3 years depending on exposure. Consider using pressure-treated lumber for structural elements, as the chemical treatment deters rot and insects. For furniture, choose dense, naturally rot-resistant woods like ipe or cypress, and store cushions indoors during inclement weather.

Indoor wood care is simpler but still essential. Regular dusting prevents grit from scratching surfaces, while prompt spill cleanup avoids water damage. Avoid placing furniture near heat sources or in direct sunlight to prevent warping and fading. For high-traffic areas, area rugs and felt pads under furniture legs minimize wear. Refinishing every 10-15 years breathes new life into floors and furniture, removing scratches and restoring the wood's natural beauty.

Ultimately, the key to extending wood's lifespan lies in understanding its environment. Outdoor wood demands proactive protection against nature's forces, while indoor wood thrives with minimal, consistent care. By tailoring your approach to the setting, you can ensure that wood remains a durable and beautiful material for decades, if not centuries.

Spider Wood Waterlogging: Understanding the Timeframe for Aquarium Use

You may want to see also

Explore related products

Pest and Decay Resistance

Wood's longevity is significantly influenced by its natural resistance to pests and decay, a trait that varies widely among species. For instance, cedar and redwood are renowned for their inherent ability to repel insects and resist fungal growth, thanks to natural oils and extractives that act as biological deterrents. These woods can last 20–30 years or more in outdoor applications without treatment, making them ideal for decking, fencing, and siding. In contrast, species like pine and spruce are more susceptible to decay and insect damage, often requiring chemical treatments to extend their lifespan beyond 5–10 years in exposed environments.

To enhance pest and decay resistance in less durable woods, pressure-treating with preservatives like chromated copper arsenate (CCA) or alkaline copper quaternary (ACQ) is a common practice. These treatments involve forcing preservative chemicals deep into the wood’s cellular structure, providing a barrier against termites, beetles, and fungi. For example, ACQ-treated lumber can last 40 years or more in ground-contact applications, while untreated pine in the same conditions might degrade within 5 years. When applying treated wood, ensure proper installation by using stainless steel or hot-dipped galvanized fasteners to avoid corrosion, which can compromise the wood’s integrity.

For those seeking eco-friendly alternatives, thermal modification offers a chemical-free method to improve wood’s resistance to pests and decay. This process involves heating wood to high temperatures in a controlled environment, altering its cellular structure to make it less hospitable to insects and fungi. Thermally modified wood, such as heat-treated ash or pine, can last 25–30 years in outdoor settings. However, this treatment reduces the wood’s moisture absorption capacity, making it more brittle and less suitable for structural applications. Always pre-drill holes when fastening thermally modified wood to prevent splitting.

In humid or tropical climates, where decay and pest activity are heightened, selecting naturally resistant species like ipe or teak can be a strategic choice. These hardwoods contain high levels of natural oils and tannins that deter insects and resist rot, allowing them to endure for 40–75 years with minimal maintenance. For added protection, apply a UV-resistant sealant every 2–3 years to prevent surface checking and maintain the wood’s structural integrity. Conversely, in drier climates, softer woods treated with borate preservatives can be cost-effective, as borates are highly effective against termites and fungi but may leach out in wet conditions.

Finally, proactive maintenance is key to maximizing wood’s pest and decay resistance. Regularly inspect wood structures for signs of infestation, such as sawdust piles or mushroom-like fungal growths, and address issues promptly. Keep wood surfaces clean and well-ventilated to discourage moisture accumulation, which accelerates decay. For existing damage, spot-treat affected areas with wood hardeners or fungicides, following manufacturer guidelines for application rates (typically 1–2 coats for fungicides). By combining species selection, treatment, and maintenance, wood’s lifespan can be significantly extended, ensuring durability and performance in diverse environments.

Wood Oil Drying Time: Factors Affecting Cure and Finish Duration

You may want to see also

Frequently asked questions

The lifespan of wood type depends on factors like wood species, environmental conditions, and maintenance. Hardwoods like oak or teak can last 50+ years, while softer woods like pine may last 10–20 years with proper care.

Yes, wood type used indoors can last significantly longer (decades) due to controlled conditions, while outdoor wood type is exposed to weather, moisture, and pests, reducing its lifespan to 5–15 years without treatment.

Absolutely. Sealants, stains, and regular maintenance can protect wood type from moisture, UV damage, and rot, potentially doubling or tripling its lifespan, especially for outdoor applications.