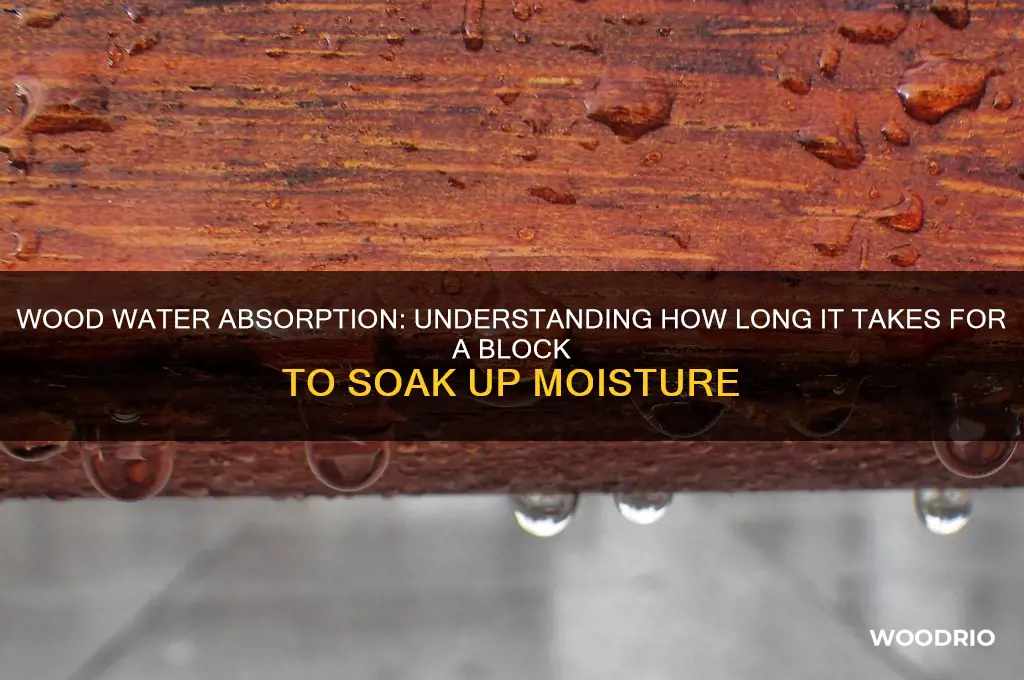

The rate at which a block of wood absorbs water depends on several factors, including the type of wood, its density, porosity, and the environmental conditions such as temperature and humidity. Hardwoods like oak or maple generally absorb water more slowly due to their tighter grain structure, while softwoods like pine absorb water more quickly because of their larger pores. Additionally, the surface area exposed to water, the presence of finishes or treatments, and the duration of immersion play crucial roles. Understanding these variables is essential for predicting how long it will take for a block of wood to absorb water, whether for practical applications like woodworking or scientific experiments.

| Characteristics | Values |

|---|---|

| Time to Absorb Water | Varies significantly based on wood type, density, and environmental conditions. Generally, softwoods absorb water faster than hardwoods. |

| Wood Type | Softwoods (e.g., pine, cedar) absorb water faster than hardwoods (e.g., oak, maple). |

| Density | Lower density woods absorb water more quickly due to larger pores. |

| Grain Direction | End grain absorbs water faster than side grain due to exposed pores. |

| Temperature | Warmer water accelerates absorption; colder water slows it down. |

| Humidity | Higher humidity increases absorption rate. |

| Surface Area | Larger surface area exposed to water results in faster absorption. |

| Initial Moisture Content | Dry wood absorbs water faster than wood already containing moisture. |

| Pressure Treatment | Pressure-treated wood absorbs water more slowly due to chemical treatments. |

| Coating/Sealant | Wood with coatings or sealants absorbs water more slowly or not at all. |

| Submersion vs. Exposure | Full submersion leads to faster absorption than partial exposure. |

| Water Type | Fresh water is absorbed faster than saltwater or chemical solutions. |

| Time to Saturation | Can range from hours (softwoods) to days or weeks (hardwoods), depending on conditions. |

| Swelling Effect | Wood expands as it absorbs water, with softwoods swelling more than hardwoods. |

| Long-Term Absorption | Wood can continue to absorb moisture over weeks or months if exposed to a humid environment. |

Explore related products

$15.99

What You'll Learn

Factors Affecting Absorption Rate

The rate at which a block of wood absorbs water is not uniform; it varies based on several key factors. Understanding these factors can help predict absorption times and optimize processes like wood treatment or preservation. For instance, a block of pine might absorb water at a different rate compared to oak due to inherent material properties. This variability underscores the importance of considering specific conditions when estimating absorption times.

Material Density and Porosity:

Denser woods, such as teak or mahogany, typically absorb water more slowly than less dense varieties like balsa or pine. Porosity plays a critical role here—woods with larger, more open cell structures allow water to penetrate faster. For example, a block of pine with a density of 400 kg/m³ might fully saturate in 24 hours, while a denser hardwood like oak could take up to 48 hours under the same conditions. To accelerate absorption in denser woods, consider pre-soaking the wood in a warm water bath (around 40°C) to open the pores before full immersion.

Surface Area and Thickness:

The ratio of surface area to volume directly impacts absorption speed. A thin, flat block of wood will absorb water faster than a thick, cube-shaped block of the same material because water has more entry points relative to its mass. For practical applications, such as treating wooden posts, sawing grooves or holes into the surface can increase exposure and reduce absorption time by up to 30%. However, avoid excessive thinning, as it may compromise structural integrity.

Water Temperature and Pressure:

Warmer water accelerates absorption by reducing water viscosity and increasing wood cell activity. For instance, water at 60°C can halve absorption time compared to room temperature water (20°C). Applying pressure, such as through vacuum-pressure treatment, forces water into the wood more rapidly, reducing saturation time from days to hours. This method is commonly used in industrial wood preservation but requires specialized equipment to avoid damaging the wood fibers.

Moisture Content and Pre-Treatment:

Wood that is already partially saturated absorbs additional water more slowly than dry wood. Pre-drying wood in a kiln to a moisture content below 12% can significantly speed up absorption during treatment. Conversely, applying a water-repellent sealant or oil pre-treatment will slow or prevent absorption altogether. For DIY projects, lightly sanding the wood surface before immersion can remove barriers and enhance water uptake.

Environmental Conditions:

Humidity and air circulation affect evaporation rates, which in turn influence how quickly water is drawn into the wood. In high-humidity environments (above 70%), absorption may slow due to reduced evaporation from the wood’s surface. Ensuring good airflow around the wood can mitigate this effect. For outdoor treatments, avoid rainy or excessively humid days to maintain consistent absorption conditions.

By manipulating these factors—material properties, physical dimensions, water conditions, pre-treatments, and environment—one can control and predict the absorption rate of a block of wood with greater precision. This knowledge is invaluable for applications ranging from woodworking to construction, ensuring optimal results in water-related treatments.

Wood's Durability in Water: Factors Affecting Longevity and Preservation

You may want to see also

Explore related products

Wood Type and Density Impact

The rate at which a block of wood absorbs water is not a one-size-fits-all scenario. Wood type and density play pivotal roles in this process, dictating how quickly or slowly moisture permeates the material. For instance, softwoods like pine, with their larger cells and lower density, tend to absorb water more rapidly than hardwoods such as oak or maple. This fundamental difference underscores the importance of selecting the right wood for applications where moisture resistance is critical, such as outdoor furniture or marine construction.

Consider the density of wood as a gatekeeper for water absorption. Denser woods, characterized by tighter cell structures, inherently resist water penetration better than less dense varieties. A block of balsa wood, one of the least dense woods available, will saturate much faster than a block of teak, a dense hardwood known for its natural oils and moisture resistance. To illustrate, a 1-inch thick block of pine might absorb noticeable amounts of water within hours, while a similarly sized block of mahogany could take days to show significant moisture uptake. This highlights the need to match wood density to the environmental demands of its intended use.

For those looking to mitigate water absorption in wood projects, understanding these properties is key. Applying a sealant or waterproof finish can significantly reduce moisture uptake, but the choice of wood remains a primary factor. In practical terms, if you’re building a wooden planter box, opt for cedar or redwood, both naturally resistant to moisture due to their density and resin content. Conversely, avoid using lightweight woods like spruce or fir in humid environments without proper treatment, as they will warp and degrade quickly.

A comparative analysis reveals that wood density isn’t the sole determinant of water absorption; the presence of natural oils and resins also plays a role. Woods like walnut and cherry, while denser than pine, contain oils that repel water, further slowing absorption. This dual defense mechanism makes them ideal for kitchenware or decorative items exposed to occasional moisture. However, no wood is entirely impervious to water, and prolonged exposure will eventually lead to absorption, regardless of type or density.

In conclusion, the interplay between wood type and density offers a nuanced approach to managing water absorption. By selecting woods with appropriate density and natural protective properties, and applying additional treatments when necessary, you can significantly extend the lifespan of wooden objects in moist environments. Whether crafting a cutting board or constructing a dock, this knowledge ensures your project stands the test of time against the elements.

Carpenter Ants: Understanding Their Wood Destruction Timeline and Prevention

You may want to see also

Explore related products

Water Temperature Influence

The rate at which a block of wood absorbs water is significantly influenced by water temperature, a factor often overlooked in casual discussions. Warmer water molecules possess higher kinetic energy, enabling them to penetrate the wood’s cellular structure more rapidly than colder water. For instance, at 60°C (140°F), a softwood block may absorb up to 50% of its dry weight in water within 2 hours, whereas at 10°C (50°F), the same process could take over 24 hours. This disparity underscores the critical role temperature plays in accelerating or decelerating moisture uptake.

To harness this phenomenon effectively, consider the following practical steps. When treating wood for outdoor projects, such as decking or fencing, pre-soak the material in warm water (40–50°C or 104–122°F) for 3–4 hours before applying preservatives. This opens the wood’s pores, allowing deeper penetration of treatments. Conversely, for projects requiring minimal warping, like furniture making, use cold water (10–20°C or 50–68°F) to slow absorption and maintain dimensional stability during the initial stages of moisture uptake.

A comparative analysis reveals that hardwoods, with their denser structure, exhibit less temperature sensitivity than softwoods. For example, oak absorbs water at a relatively consistent rate across temperatures, while pine shows a pronounced acceleration in warm water. This highlights the need to tailor temperature strategies based on wood type. For softwoods, moderate heating of water can expedite drying processes, but for hardwoods, temperature adjustments yield marginal benefits, making mechanical methods like air circulation more efficient.

Despite its advantages, using high-temperature water carries risks. Prolonged exposure to temperatures above 70°C (158°F) can degrade lignin, the natural adhesive in wood, leading to structural weakness. Additionally, rapid absorption in warm water may cause uneven swelling, particularly in end grains. To mitigate this, limit warm water treatments to 2–3 hours and follow with a gradual cooling phase. For delicate projects, maintain water temperatures below 30°C (86°F) to ensure controlled, uniform absorption without compromising integrity.

In conclusion, water temperature is a powerful lever in managing wood’s moisture absorption, offering both opportunities and challenges. By understanding its effects and applying targeted techniques, craftsmen and hobbyists can optimize outcomes, whether speeding up treatments or preserving wood quality. Always balance temperature adjustments with the specific demands of the wood type and project goals for the best results.

How Long Does Flavored Wood Last? A Comprehensive Guide

You may want to see also

Explore related products

Surface Area Exposure

The rate at which a block of wood absorbs water is directly influenced by its surface area exposure. Imagine a wooden cube submerged in water: the more faces exposed, the faster it saturates. This principle isn’t just theoretical—it’s measurable. For instance, a 10cm³ pine block fully submerged (all six faces exposed) can absorb up to 50% of its dry weight in water within 24 hours, while a similar block with only one face exposed might take 48–72 hours to reach the same saturation level. This disparity underscores the critical role of surface area in water absorption dynamics.

To maximize or control absorption, consider the practical steps of altering surface area exposure. For woodworking projects requiring even moisture distribution, saw the block into thinner planks or drill holes to increase exposed surfaces. Conversely, if you’re sealing wood to prevent water uptake, minimize exposed areas by applying waterproof coatings to all sides. A cautionary note: increasing surface area exposure accelerates not just water absorption but also the risk of warping or cracking, especially in hardwoods like oak or maple. Always balance exposure with the wood’s structural integrity.

From a comparative standpoint, softwoods like pine or cedar absorb water more rapidly than dense hardwoods due to their looser cellular structure, but surface area exposure remains the dominant factor across all wood types. For example, a cedar block with 50% of its surface exposed will still outpace a similarly exposed oak block by 20–30% in absorption rate over 24 hours. This highlights that while wood density matters, manipulating surface area exposure offers a more immediate and controllable variable for managing water uptake.

Finally, understanding surface area exposure has real-world applications beyond experiments. In construction, untreated wooden beams with greater exposed surfaces (e.g., those in contact with damp soil) degrade 2–3 times faster than those with limited exposure. To mitigate this, builders often use pressure-treated wood or apply sealants to reduce effective surface area. For hobbyists, this knowledge can inform techniques like pre-soaking wood for carving by submerging only the necessary faces, saving time without compromising material quality. Master this principle, and you’ll wield precise control over wood’s interaction with water.

Cedar Wood Moth Balls Lifespan: How Long Do They Last?

You may want to see also

Explore related products

Time for Full Saturation

The time it takes for a block of wood to fully saturate with water depends heavily on its density, porosity, and the environmental conditions. Hardwoods like oak or maple, with tighter grain structures, absorb water more slowly than softwoods like pine or cedar, which have larger, more open pores. For instance, a 2x4 pine block submerged in water at room temperature might reach full saturation in 24 to 48 hours, while an oak block of the same size could take several days to a week. This disparity underscores the importance of understanding wood type when estimating saturation time.

To expedite saturation, consider submerging the wood in water and applying gentle heat, such as placing the container on a warming plate set to 100–120°F (40–50°C). Heat reduces water viscosity, allowing it to penetrate wood fibers more efficiently. However, avoid exceeding 140°F (60°C), as this can cause the wood to warp or crack. Alternatively, periodically flipping the wood block ensures even absorption, particularly for thicker pieces. For projects requiring precise moisture content, use a moisture meter to monitor progress, aiming for a reading of 20–25% for most woodworking applications.

Comparatively, pressure-treating methods, often used in outdoor construction, force water and preservatives into wood under high pressure, reducing saturation time to mere hours. This industrial approach, while effective, is impractical for DIY projects due to specialized equipment requirements. Instead, hobbyists can simulate this by vacuum-sealing the wood in a bag with water, removing air pockets that hinder absorption. This method can cut saturation time by up to 50%, making it a viable option for time-sensitive tasks like crafting or restoration.

Finally, environmental factors like humidity and temperature play a critical role. In arid climates, wood may absorb water more rapidly due to the moisture gradient between the wood and its surroundings. Conversely, high humidity slows absorption as the wood reaches equilibrium moisture content sooner. For consistent results, control the environment by saturating wood in a sealed container at a stable temperature of 70–75°F (21–24°C). This minimizes variables, ensuring predictable saturation times and uniform moisture distribution throughout the block.

Understanding Wood Checking: Duration, Causes, and Prevention Tips

You may want to see also

Frequently asked questions

The time it takes for a block of wood to absorb water depends on factors like the type of wood, its density, and the water's temperature. Softwoods like pine may absorb water within hours, while hardwoods like oak can take days or even weeks.

Yes, the size of the wood block plays a significant role. Smaller blocks or thinner pieces will absorb water faster than larger, thicker blocks due to less material for the water to penetrate.

Absolutely. Wood that is already saturated or has a high moisture content will absorb additional water much more slowly compared to dry wood, which can absorb water more rapidly.

![Ziruma Non-Toxic Wood Wax - Natural Wood Conditioner for Butcher Blocks, Wooden Utensils & Bowls – No Mineral Oil, No Petroleum - Pure Beeswax, Lemon & Flaxseed Oil [7 oz]](https://m.media-amazon.com/images/I/61jR838SaKL._AC_UL320_.jpg)