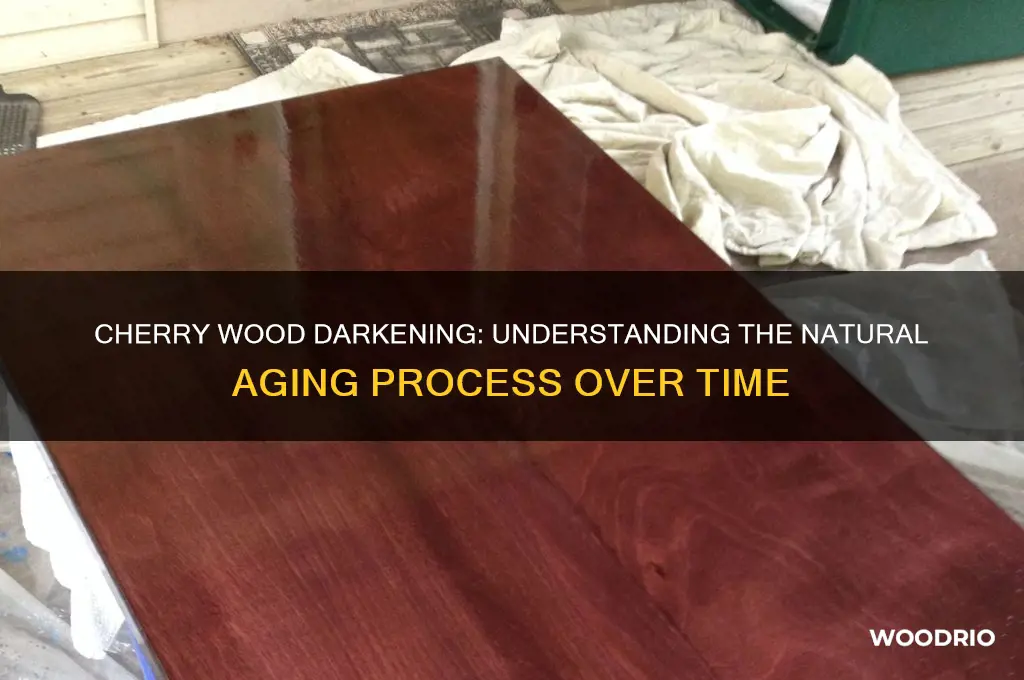

Cherry wood is renowned for its beautiful, warm tones that naturally deepen and darken over time, a process influenced by exposure to light, particularly ultraviolet (UV) rays. When freshly milled, cherry wood typically exhibits a light pinkish-brown hue, but as it ages, it gradually transforms into a rich, reddish-brown color. This darkening process can take several months to a few years, depending on factors such as the intensity of light exposure, humidity levels, and the wood’s initial grain pattern. For those seeking to accelerate this transformation, controlled exposure to sunlight or UV lamps can expedite the process, while others may prefer to let the wood age naturally for a more gradual and organic patina. Understanding this timeline is essential for woodworkers, furniture makers, and homeowners who wish to appreciate or manipulate the evolving beauty of cherry wood.

| Characteristics | Values |

|---|---|

| Initial Color | Light pinkish-brown |

| Final Color | Rich, reddish-brown |

| Time to Noticeable Darkening | 2-4 weeks (under exposure to light) |

| Time for Full Darkening | 6 months to 2 years (varies with exposure and environment) |

| Factors Affecting Darkening | UV light exposure, oxygen, humidity, temperature |

| Optimal Conditions for Darkening | Direct sunlight or UV light exposure |

| Darkening Process | Oxidation and photochemical reaction |

| Stability After Darkening | Color stabilizes after 2-3 years |

| Maintenance for Even Darkening | Rotate wood items periodically to ensure uniform exposure |

| Accelerating Darkening | Use tung oil or other finishes that enhance UV penetration |

| Preventing Uneven Darkening | Avoid prolonged exposure to direct sunlight in one area |

| Reversibility | Not reversible; darkening is a permanent process |

| Common Uses for Cherry Wood | Furniture, cabinetry, flooring, and decorative items |

| Environmental Impact | Natural process; no additional chemicals required |

| Comparison to Other Woods | Faster darkening than oak, slower than walnut |

Explore related products

What You'll Learn

Natural Aging Process

Cherry wood's transformation over time is a captivating natural phenomenon, marked by its gradual shift from a light, reddish-brown hue to a rich, deep brown. This process, known as the natural aging process, is influenced by various factors, including exposure to light, oxygen, and moisture. As cherry wood interacts with these elements, its cellular structure undergoes subtle changes, leading to the breakdown of certain compounds and the formation of new ones. One key player in this process is the oxidation of tannins, which contributes to the wood's darkening and deepening of color.

The rate at which cherry wood darkens can vary significantly, depending on the specific conditions it's exposed to. In general, cherry wood can take anywhere from 6 months to 2 years to notice a significant change in color, with the most dramatic transformations occurring within the first 1-2 years. However, it's not uncommon for the wood to continue darkening and evolving over several decades. To accelerate this process, some woodworkers and enthusiasts employ techniques such as exposing the wood to direct sunlight or using oxidizing agents like hydrogen peroxide. It's essential to note that these methods can be unpredictable and may alter the wood's natural patina, so caution and experimentation are advised.

A comparative analysis of different environments reveals that cherry wood darkens more rapidly in spaces with higher humidity levels and increased exposure to natural light. For instance, a cherry wood table placed near a window in a humid climate may darken noticeably within 6-12 months, whereas the same table in a dry, windowless room could take 2-3 years to exhibit similar changes. This highlights the importance of considering the intended environment when working with cherry wood, as it can significantly impact the wood's appearance and aging trajectory. By understanding these variables, craftsmen and homeowners can make informed decisions about placement and care to achieve their desired aesthetic.

To harness the natural aging process effectively, consider the following practical tips: when selecting cherry wood for a project, choose pieces with a consistent grain pattern and color, as this will ensure a more uniform darkening over time. Additionally, avoid using harsh chemicals or sealants that may inhibit the wood's natural oxidation process. Instead, opt for breathable finishes like tung oil or wax, which allow the wood to darken gradually while providing protection against moisture and wear. By embracing the natural aging process and working in harmony with the wood's inherent properties, you can create stunning, timeless pieces that develop character and depth as they age. As the wood matures, its unique beauty will unfold, making each piece a one-of-a-kind testament to the passage of time and the artistry of nature.

Phil Robertson's Wilderness Life: Years Spent in the Woods

You may want to see also

Explore related products

Accelerating Darkening Methods

Cherry wood's natural darkening process can take years, but for those seeking a quicker transformation, several methods can accelerate this aging effect. One of the most effective techniques is heat application. Exposing cherry wood to controlled heat sources, such as a heat gun or an oven, can expedite the oxidation process responsible for the wood's color change. For instance, setting an oven to 150-200°F (65-95°C) and placing the wood inside for 2-4 hours can yield noticeable darkening. However, caution is essential to avoid scorching or warping the wood. Always monitor the process and maintain a consistent temperature to achieve an even patina.

Another innovative approach involves chemical treatments, particularly the use of ammonia fumes. This method, known as ammonia fuming, reacts with the wood's tannins to produce a rich, dark hue. To execute this, place the cherry wood in an enclosed space, such as a plastic tent, and introduce ammonia (household ammonia works well) in small quantities. The reaction time varies, typically ranging from 12 to 48 hours, depending on the desired depth of color. Safety is paramount here; ensure proper ventilation and wear protective gear, as ammonia fumes are toxic. This method is ideal for small projects or intricate pieces where uniform darkening is crucial.

For those preferring a more hands-on, natural approach, sunlight exposure remains a tried-and-true method. Cherry wood darkens when exposed to ultraviolet (UV) light, and direct sunlight can significantly speed up this process. Place the wood in a sunny area, rotating it periodically to ensure even exposure. While this method is slower compared to heat or chemical treatments, it requires minimal effort and is entirely non-toxic. Combining sunlight exposure with a light sanding every few weeks can enhance the wood's ability to absorb UV rays, accelerating the darkening effect.

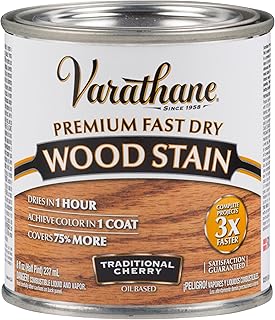

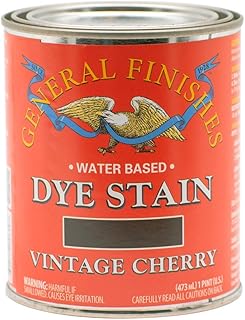

Lastly, finishing products can be strategically employed to both protect the wood and enhance its darkening. Certain oils, such as tung oil or linseed oil, can deepen the wood's color while providing a protective barrier. For a more pronounced effect, consider using a tinted wood finish or a glaze specifically designed to enrich cherry wood tones. When applying these products, follow the manufacturer’s instructions carefully, as overuse can lead to an unnatural appearance. This method is particularly useful for furniture or decorative pieces where both aesthetics and durability are priorities.

Each of these methods offers a unique pathway to accelerate cherry wood's darkening, catering to different project needs and preferences. Whether through heat, chemicals, sunlight, or finishes, the key lies in patience, precision, and an understanding of the wood's natural properties. By experimenting with these techniques, craftsmen and enthusiasts alike can achieve the desired aged look in a fraction of the time nature would otherwise require.

Durability of Wood Docks: Lifespan, Maintenance, and Longevity Factors

You may want to see also

Explore related products

Environmental Factors Impact

Cherry wood's transformation from its initial light reddish-brown hue to a richer, darker tone is a process influenced by various environmental factors. Among these, light exposure stands as a primary catalyst. Ultraviolet (UV) rays from sunlight accelerate the oxidation of the wood’s surface, causing it to darken more rapidly. For instance, cherry wood furniture placed near a sunny window can show noticeable color changes within months, while pieces in dimly lit rooms may take years to achieve the same depth. To control this, consider using UV-filtering window films or rotating furniture periodically to ensure even exposure.

Humidity and temperature also play critical roles in the darkening process. Cherry wood is hygroscopic, meaning it absorbs and releases moisture in response to its environment. High humidity levels can cause the wood to swell and darken unevenly, while low humidity may lead to drying and cracking, which can affect its ability to darken uniformly. Ideal conditions for controlled darkening include a relative humidity of 40-50% and a temperature range of 68-72°F. Using a dehumidifier or humidifier can help maintain these levels, especially in extreme climates.

Air quality is another often-overlooked factor. Pollutants such as cigarette smoke, cooking fumes, and even household chemicals can react with the wood’s surface, altering its color prematurely or unevenly. For example, smoke can cause cherry wood to develop a yellowish tint before it darkens naturally. To mitigate this, ensure proper ventilation in spaces where cherry wood is present and avoid exposing it to harsh chemicals. Regular dusting with a microfiber cloth can also prevent particulate buildup that might interfere with the darkening process.

Finally, the wood’s geographic origin and the environment in which it was initially seasoned can influence its darkening trajectory. Cherry wood from regions with higher tannin content, such as the northeastern United States, tends to darken more dramatically than wood from other areas. Additionally, kiln-dried wood may darken differently than air-dried wood due to variations in moisture retention. When selecting cherry wood, inquire about its source and drying method to better predict its color evolution. By understanding and managing these environmental factors, you can guide the natural darkening of cherry wood to achieve the desired aesthetic outcome.

Joe Smith's Mysterious Journey: How Long Was He in the Woods?

You may want to see also

Explore related products

Finish Types Influence

Cherry wood's natural darkening process is a captivating phenomenon, but the finish you choose can significantly alter its timeline and final appearance. Oil-based finishes, such as tung oil or linseed oil, penetrate the wood deeply, enhancing its natural color and allowing it to darken more uniformly over time. These finishes typically take 3 to 5 years to show noticeable darkening, depending on exposure to light and humidity. For a faster, more controlled darkening effect, consider using a tinted oil finish, which can expedite the process by 1 to 2 years while adding a subtle hue.

In contrast, water-based finishes create a barrier on the wood’s surface, slowing down the darkening process. Polyurethane, a popular water-based option, can delay noticeable color changes by up to 7 years, especially in low-light environments. If you prefer a lighter, more consistent tone for longer, this finish is ideal. However, for those seeking a quicker transformation, avoid water-based finishes altogether, as they prioritize protection over color evolution.

Lacquer finishes strike a balance between oil and water-based options. They dry quickly and provide a durable surface while allowing cherry wood to darken at a moderate pace—typically within 4 to 6 years. This finish is particularly effective for furniture or cabinetry that requires both protection and aesthetic enhancement. To accelerate darkening under lacquer, ensure the piece is exposed to natural light, as UV rays are a primary catalyst for the process.

Wax finishes, such as beeswax or carnauba wax, offer minimal protection but allow cherry wood to darken rapidly, often within 2 to 3 years. These finishes are best suited for indoor pieces with low wear and tear, like decorative shelves or wall panels. For optimal results, reapply wax annually to maintain the wood’s luster while fostering its natural color progression.

Ultimately, the finish you select dictates not only the speed of darkening but also the character of the final result. Oil finishes deepen the wood’s warmth, water-based finishes preserve its initial tone, lacquer balances durability and aesthetics, and wax accelerates the transformation. Choose based on your desired timeline and the intended use of the piece, ensuring the finish complements both the wood’s natural beauty and your practical needs.

Maximizing Grill Efficiency: Wood Pellet Lifespan and Usage Tips

You may want to see also

Explore related products

Timeframe Expectations

Cherry wood's transformation from its initial light, reddish-brown hue to a rich, deep brown is a process that captivates woodworkers and homeowners alike. This natural darkening, known as patina development, is influenced by several factors, primarily exposure to light and oxygen. Understanding the timeframe for this process is essential for setting realistic expectations and planning projects effectively.

The Gradual Darkening Process

Cherry wood begins its color shift almost immediately upon exposure to ultraviolet (UV) light, typically from sunlight. In the first few weeks, the wood may appear slightly warmer, with subtle hints of deepening red tones. Over the first 6 months, the change becomes more noticeable, especially in areas with consistent light exposure. By the end of the first year, cherry wood often achieves a medium brown shade, though this can vary based on the wood’s initial color and grain pattern. For a full, deep patina, expect a timeframe of 5 to 10 years, depending on environmental conditions.

Accelerating or Slowing the Process

If you’re eager to expedite the darkening, strategic placement of cherry wood furniture or fixtures near windows with ample sunlight can hasten the process. However, direct sunlight can also cause uneven fading, so consider rotating pieces periodically. Conversely, if you prefer to slow the darkening, use UV-blocking window films or keep the wood in low-light areas. Applying a finish, such as polyurethane or oil, can also preserve the wood’s original color longer, though it may slightly alter the natural patina.

Environmental Factors at Play

Humidity and temperature play secondary roles in cherry wood’s darkening. High humidity can cause the wood to darken more rapidly due to increased oxidation, while dry environments may slow the process. Temperature fluctuations, particularly extreme heat, can accelerate aging but may also lead to cracking or warping. For optimal results, maintain a stable indoor environment with moderate humidity (around 40-50%) and avoid placing cherry wood near heat sources like radiators or fireplaces.

Practical Tips for Managing Expectations

When working with cherry wood, embrace its evolving nature rather than fighting it. If uniformity is a priority, select pieces from the same wood batch and expose them to similar lighting conditions. For custom projects, consider using wood samples to simulate aging under your specific environmental conditions. Finally, document the wood’s progress with periodic photographs to track changes and adjust your care routine as needed. Patience is key—cherry wood’s darkening is a natural, gradual process that rewards those who allow it to unfold organically.

Do Daddy Long Legs Burrow in Wood? Unveiling the Truth

You may want to see also

Frequently asked questions

Cherry wood begins to darken almost immediately upon exposure to light, with noticeable changes occurring within the first few weeks to months.

The speed of darkening depends on exposure to light (especially UV rays), humidity, temperature, and the finish applied to the wood.

No, cherry wood reaches its darkest shade after several years, typically within 5 to 10 years, depending on environmental conditions.

Yes, using UV-blocking finishes or keeping the wood away from direct sunlight can slow darkening, while increased light exposure will accelerate it.