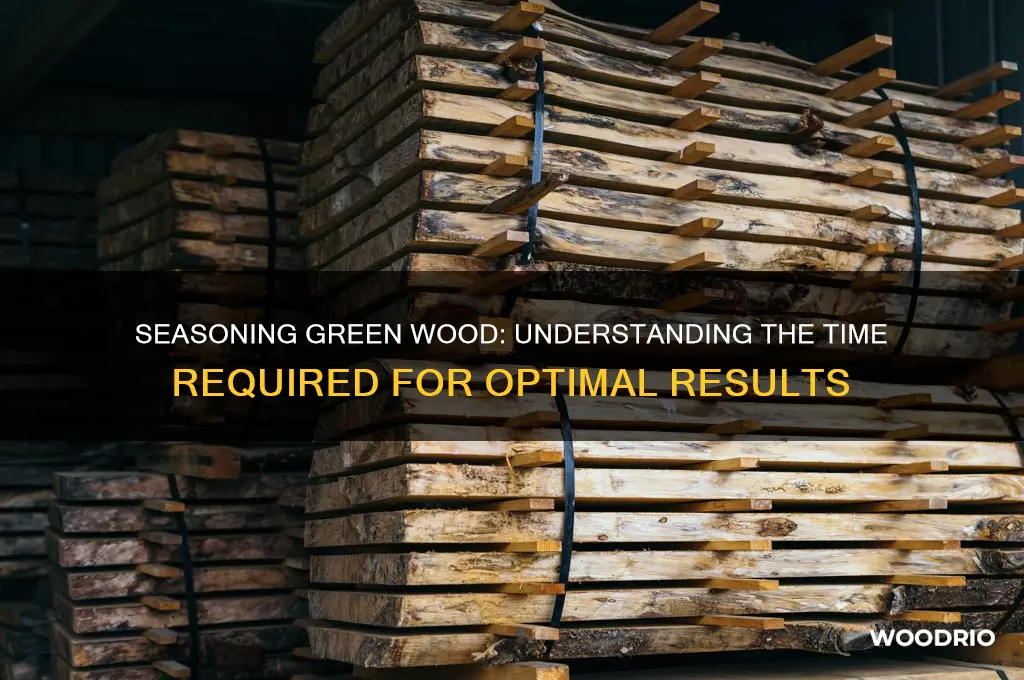

Seasoning green wood is a crucial process for anyone working with wood, whether for firewood, construction, or crafting. Green wood, freshly cut from a living tree, contains a high moisture content, typically ranging from 30% to 200%, depending on the species. To make it suitable for use, the wood must be dried or seasoned to reduce its moisture content to around 12-20%. The time required for green wood to season varies significantly based on factors such as the wood species, initial moisture content, environmental conditions, and the method of seasoning. Softwoods like pine may season in as little as 6 months, while denser hardwoods like oak can take 1 to 2 years or more. Proper seasoning ensures the wood is stable, durable, and less prone to cracking or warping, making it essential to understand the timeline and techniques involved in this process.

| Characteristics | Values |

|---|---|

| Time to Season (General) | 6 months to 2 years, depending on wood type and conditions |

| Factors Affecting Drying Time | Wood species, thickness, moisture content, humidity, temperature, airflow |

| Softwood (e.g., Pine, Spruce) | 6–12 months |

| Hardwood (e.g., Oak, Maple) | 1–2 years |

| Optimal Moisture Content | 12–20% for most woodworking applications |

| Stacking Method | Sticker stacking with 1-inch spacers for airflow |

| Ideal Drying Conditions | Covered, well-ventilated area with 50–70% humidity and moderate temperature |

| Thickness Impact | Thicker wood takes longer to season (e.g., 4-inch logs: 2+ years) |

| Kiln Drying Alternative | 2–4 weeks, but requires specialized equipment |

| Signs of Properly Seasoned Wood | Checks (cracks), lighter weight, dull sound when tapped |

Explore related products

What You'll Learn

- Factors Affecting Drying Time: Moisture content, wood type, climate, and storage conditions impact seasoning duration

- Ideal Seasoning Duration: Typically 6 months to 2 years, depending on wood thickness and species

- Accelerated Drying Methods: Kiln drying, solar drying, or air circulation can shorten seasoning time

- Testing Wood Readiness: Check moisture levels with a meter; aim for 12-20% moisture content

- Signs of Properly Seasoned Wood: Cracked ends, lighter weight, and dull sound when tapped

Factors Affecting Drying Time: Moisture content, wood type, climate, and storage conditions impact seasoning duration

The initial moisture content of green wood is a critical determinant of how long it will take to season. Freshly cut wood can contain up to 100% moisture relative to its dry weight, meaning it holds as much water as its own mass. For example, a log weighing 50 pounds when green might contain 25 pounds of water. Reducing this moisture to 20% or less—the ideal range for most woodworking applications—requires time and the right conditions. Wood with higher initial moisture content will naturally take longer to dry, often extending the seasoning process from months to over a year. To expedite this, some woodworkers use kilns, which can reduce drying time to weeks by controlling temperature and humidity.

Wood type plays a significant role in seasoning duration due to variations in density, grain structure, and natural oils. Softwoods like pine dry faster than hardwoods like oak because they are less dense and have larger, more open cell structures that allow moisture to escape more easily. For instance, pine can season in 6–12 months under optimal conditions, while oak may require 1–2 years. Additionally, woods with high natural resin content, such as cedar, dry more slowly but are more resistant to decay during the process. Understanding these differences helps in selecting the right wood for a project and planning the seasoning timeline accordingly.

Climate is an uncontrollable but influential factor in seasoning green wood. In regions with low humidity and warm temperatures, wood dries faster due to increased evaporation rates. For example, wood seasoned in a dry desert climate may take half the time compared to a humid coastal area. However, extreme heat can cause cracks or warping, so gradual drying is still essential. In colder or wetter climates, wood should be stored in a sheltered area with good airflow to prevent mold or rot. Using a moisture meter to monitor progress is particularly useful in unpredictable climates, ensuring the wood reaches the desired moisture level without damage.

Proper storage conditions can significantly reduce seasoning time and improve wood quality. Stacking wood off the ground on stickers (small supports) allows air to circulate around each piece, promoting even drying. The stack should be covered with a waterproof tarp to protect from rain while leaving the sides open for airflow. For best results, store wood in a shaded area to prevent rapid drying from direct sunlight. In humid environments, consider spacing pieces further apart to enhance air circulation. Regularly inspecting the stack for signs of mold or insect infestation is also crucial, as these issues can compromise the wood’s integrity.

Combining these factors—moisture content, wood type, climate, and storage—provides a clear roadmap for efficient seasoning. For instance, a woodworker in a humid climate might choose less dense wood, start with lower moisture content, and invest in a kiln to control drying conditions. Conversely, someone in a dry climate could opt for denser hardwoods and rely on natural conditions with careful stacking. By tailoring the approach to these variables, the seasoning process becomes more predictable and successful, ensuring the wood is ready for use in optimal condition.

Exploring Muir Woods: Ideal Time to Experience Its Majestic Beauty

You may want to see also

Explore related products

Ideal Seasoning Duration: Typically 6 months to 2 years, depending on wood thickness and species

The time it takes for green wood to season is not a one-size-fits-all scenario. A 2-inch thick oak board, for instance, will take significantly longer to dry than a 1-inch thick pine board. This is because thicker wood has more moisture to release, and denser hardwoods like oak dry more slowly than softer woods like pine. Understanding these variables is crucial for anyone working with wood, whether you're a hobbyist crafting furniture or a professional builder.

Factors at Play:

Wood thickness is the primary determinant of seasoning time. As a rule of thumb, allow one year of drying for every inch of thickness. So, a 4-inch log could take up to four years to fully season. However, this is a general guideline, and species-specific characteristics must also be considered.

Species Matters:

Different wood species have varying densities and moisture contents, which directly impact drying time. Softwoods like cedar or spruce typically season faster than hardwoods like maple or walnut. For example, pine might be ready in 6–12 months, while oak could require 18–24 months or more. Always research the specific wood you’re working with to avoid underestimating drying time.

Practical Tips for Faster Seasoning:

To expedite the process, split logs into smaller pieces or saw boards to the desired thickness before seasoning. Stack wood in a well-ventilated area, ensuring air can circulate on all sides. Cover the stack with a waterproof tarp to protect it from rain while allowing moisture to escape. For thicker pieces, consider using a kiln, which can reduce drying time to weeks instead of months, though this method requires specialized equipment.

Why Patience Pays Off:

Rushing the seasoning process can lead to cracks, warping, or mold growth. Properly seasoned wood has a moisture content of 12–15%, making it stable and ready for use. While 6 months might suffice for thin, softwood pieces, thicker hardwoods demand closer to 2 years. Investing this time ensures the wood’s longevity and performance in your projects.

Untreated Pine Wood Durability: Lifespan and Outdoor Survival Guide

You may want to see also

Explore related products

Accelerated Drying Methods: Kiln drying, solar drying, or air circulation can shorten seasoning time

Green wood, freshly cut and laden with moisture, requires seasoning to achieve stability and usability. Traditionally, this process takes months, even years, relying on natural air drying. However, for those seeking faster results, accelerated drying methods offer a compelling solution. Kiln drying, solar drying, and air circulation techniques significantly shorten seasoning time, each with its own advantages and considerations.

Let's delve into these methods, exploring their mechanisms, suitability, and practical implications.

Kiln Drying: Precision and Control

Kiln drying stands as the industry standard for rapid and controlled wood seasoning. This method involves placing wood in a specially designed chamber where temperature, humidity, and airflow are meticulously regulated. Heat is applied gradually, drawing moisture from the wood while preventing cracking or warping. Kiln drying can reduce seasoning time from months to days or weeks, depending on wood species and desired moisture content. For example, hardwoods like oak might require 2-4 weeks, while softer woods like pine can be kiln-dried in a matter of days.

While highly effective, kiln drying demands specialized equipment and expertise, making it more suitable for commercial operations or individuals with access to such facilities.

Solar Drying: Harnessing Nature's Power

Solar drying offers a more accessible and environmentally friendly alternative. This method utilizes sunlight and natural convection to remove moisture from wood. Wood is stacked in a greenhouse-like structure, allowing sunlight to heat the air and promote evaporation. Proper ventilation is crucial to ensure consistent airflow and prevent mold growth.

Solar drying is particularly effective in regions with abundant sunshine. It's a cost-effective option for small-scale woodworkers and hobbyists, though drying times can be longer and less predictable than kiln drying, typically ranging from several weeks to a few months.

Air Circulation: The Power of Movement

Even without specialized equipment, improving air circulation can significantly accelerate seasoning. Storing wood in a well-ventilated area, off the ground and with spacers between boards, allows air to circulate freely, aiding moisture evaporation. Fans can further enhance airflow, expediting the process.

While not as rapid as kiln or solar drying, this method is simple, cost-effective, and suitable for small quantities of wood. Patience is key, as air drying can still take several months, depending on climate and wood species.

Choosing the Right Method:

The optimal accelerated drying method depends on factors like wood type, desired turnaround time, budget, and available resources. Kiln drying offers speed and precision but requires investment. Solar drying is eco-friendly and accessible but relies on sunlight. Air circulation is simple and affordable but demands patience. By understanding these methods and their nuances, woodworkers can make informed decisions to achieve optimally seasoned wood in a timeframe that suits their needs.

Chicken of the Woods Shelf Life: Freshness and Storage Tips

You may want to see also

Explore related products

Testing Wood Readiness: Check moisture levels with a meter; aim for 12-20% moisture content

Green wood, freshly cut from a living tree, contains a high moisture content that can exceed 50%. This excess moisture makes it unsuitable for most woodworking projects, as it warps, cracks, and decays when drying unevenly. To determine when wood is ready for use, you must measure its moisture content (MC) with a reliable tool. A moisture meter, either pin-type or pinless, is essential for this task. Pin-type meters provide precise readings by penetrating the wood, while pinless meters offer a non-invasive scan, ideal for quick checks or finished surfaces. Aim for a target MC range of 12-20%, which aligns with the ambient humidity of most indoor environments, ensuring stability and durability in your projects.

The process of testing wood readiness is straightforward but requires attention to detail. First, calibrate your moisture meter according to the manufacturer’s instructions to ensure accuracy. Next, take multiple readings across different sections of the wood, including the ends, middle, and edges, as moisture distribution can vary. For thicker pieces, measure at various depths to account for internal moisture. If using a pin-type meter, insert the pins approximately 1 inch into the wood for a consistent reading. Record the highest MC value, as it indicates the wettest area, which dictates the overall readiness of the wood.

Comparing moisture meters reveals their strengths and limitations. Pin-type meters are more accurate for dense or unevenly dried wood but leave small holes, which may be undesirable for fine woodworking. Pinless meters, while faster and non-destructive, can be less precise on rough or irregular surfaces. For hobbyists, a pinless meter often suffices, while professionals may prefer the pin-type for critical projects. Regardless of the tool, consistency in testing methods is key to reliable results.

Persuasively, investing in a quality moisture meter is a small price to pay for the long-term success of your woodworking projects. Wood that appears dry to the touch can still harbor excessive moisture, leading to costly mistakes like warped furniture or cracked carvings. By regularly testing MC and waiting until it falls within the 12-20% range, you ensure the wood’s structural integrity and aesthetic appeal. This simple step transforms green wood from a liability into a stable, workable material, saving time, effort, and resources in the long run.

Finally, a practical tip: store wood in a well-ventilated, covered area during the seasoning process to control moisture loss. Stack pieces with spacers to allow air circulation, and avoid direct sunlight or rain, which can cause uneven drying. Periodically test the MC of a sample piece to monitor progress. Once the entire batch reaches the desired 12-20% range, it’s ready for use. This methodical approach ensures you’re working with wood that’s not just dry, but optimally seasoned for your craft.

Pressed Wood Furniture Lifespan: Durability, Maintenance, and Longevity Tips

You may want to see also

Explore related products

Signs of Properly Seasoned Wood: Cracked ends, lighter weight, and dull sound when tapped

The journey from green wood to seasoned timber is marked by distinct transformations that signal readiness for use. One of the most telling signs is the appearance of cracked ends. These cracks, often referred to as "checks," occur as moisture escapes and the wood fibers contract. While they might seem like flaws, these cracks are a natural part of the drying process and indicate that the wood is shedding excess moisture. However, it’s crucial to distinguish between seasoning cracks and those caused by improper drying, such as deep, longitudinal splits, which can weaken the wood.

Another unmistakable sign of properly seasoned wood is its lighter weight. Green wood is heavy due to its high moisture content, which can be as much as 50% or more. As the wood dries, this moisture evaporates, reducing its weight significantly. A practical tip is to compare the weight of a freshly cut piece to one that has been drying for several months. The difference is often striking and serves as a quick, hands-on test for moisture loss. For precise measurements, a moisture meter can confirm that the wood has reached an optimal moisture content of 12-15%, ideal for most woodworking projects.

The sound of wood when tapped is a subtle yet revealing indicator of its seasoning. Green wood produces a dull, thudding sound due to its high moisture content, which dampens vibrations. In contrast, properly seasoned wood emits a sharper, more resonant sound, akin to a knock on a hollow door. This auditory test is particularly useful for assessing larger pieces or stacks of wood where visual and weight checks are less practical. Tapping the wood with a mallet or even your knuckles can provide immediate feedback on its dryness.

While these signs—cracked ends, lighter weight, and a dull sound—are reliable indicators, they should be considered collectively rather than in isolation. For instance, cracked ends alone do not guarantee the wood is fully seasoned; it could still retain excessive moisture internally. Similarly, weight loss without the accompanying dull sound might suggest uneven drying. Combining these observations with environmental factors, such as the wood’s exposure to air and time, ensures a more accurate assessment. Patience is key, as seasoning times vary widely depending on wood species, thickness, and drying conditions, ranging from six months to two years or more.

Finally, understanding these signs empowers woodworkers and enthusiasts to make informed decisions about their materials. Properly seasoned wood not only works better—it’s easier to cut, shape, and finish—but it also ensures the longevity of the final product. By recognizing cracked ends, lighter weight, and the distinctive sound of dry wood, you can avoid the pitfalls of using green or inadequately seasoned timber, such as warping, splitting, or mold growth. Whether you’re crafting furniture, building a deck, or fueling a fireplace, these signs are your roadmap to quality and durability.

Durability of Wooden Spoons: Lifespan and Care Tips Revealed

You may want to see also

Frequently asked questions

It typically takes 6 to 12 months for green wood to season, depending on factors like wood type, moisture content, and environmental conditions.

Yes, green wood can season faster in dry, sunny climates, but proper stacking and airflow are still essential to prevent cracking or warping.

Yes, denser hardwoods like oak take longer to season (12+ months), while softer woods like pine may season in 6 to 9 months.

Yes, you can speed up seasoning by splitting wood into smaller pieces, storing it in a dry, well-ventilated area, and using a wood shed or kiln for controlled drying.

![Cedar Plank Seasoning - 4.0 oz. [ 113.4 grams ] Jar - KOSHER (Small & Bulk Options available)](https://m.media-amazon.com/images/I/81MyTK0u0sL._AC_UL320_.jpg)