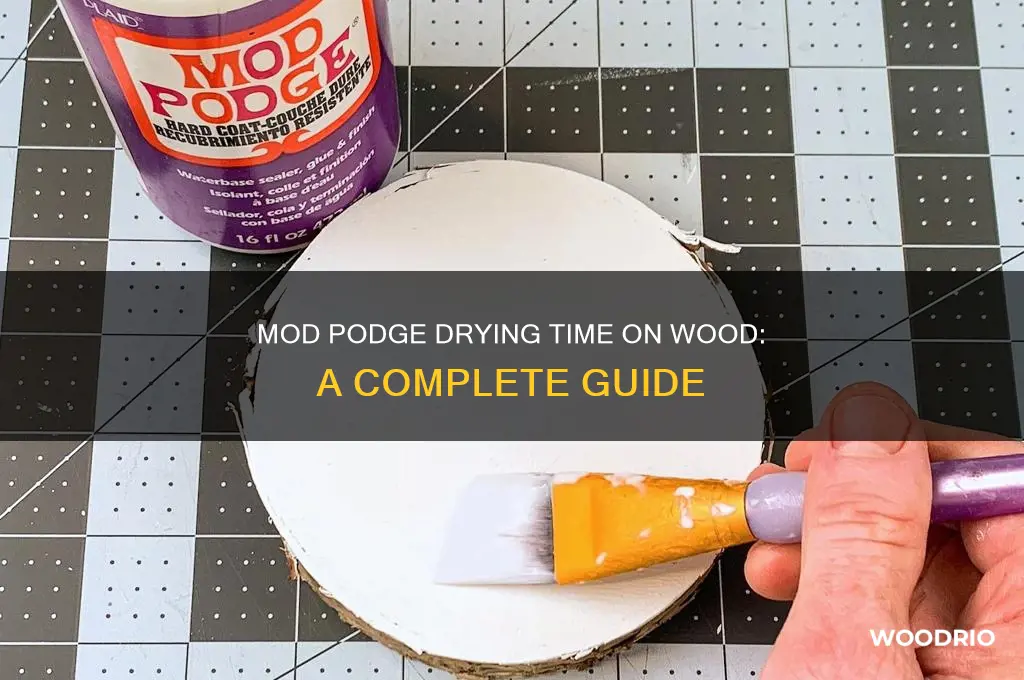

Mod Podge is a popular decoupage medium and sealant used for various crafting projects, including those involving wood. When applying Mod Podge to wood, understanding the drying time is crucial for achieving a smooth, durable finish. Typically, Mod Podge takes about 15 to 20 minutes to dry to the touch, but it can take up to 24 hours to fully cure, depending on factors such as humidity, temperature, and the thickness of the application. Proper ventilation and thin, even coats can help expedite the drying process, ensuring your wood project is ready for use or further embellishment.

| Characteristics | Values |

|---|---|

| Drying Time (Light Coat) | 15-20 minutes |

| Drying Time (Thick Coat) | 1-2 hours |

| Cure Time (Full Hardness) | 28 days |

| Factors Affecting Drying Time | Humidity, temperature, thickness of application, type of Mod Podge |

| Recommended Conditions | Room temperature (70-75°F or 21-24°C), low humidity |

| Accelerating Drying | Use a fan, heat gun (with caution), or apply thinner coats |

| Types of Mod Podge | Matte, Gloss, Satin, Outdoor (each may vary slightly in drying time) |

| Re-coating Time | 15-20 minutes after initial dryness |

| Surface Preparation | Clean, dry, and smooth wood surface for optimal drying |

| Finish Characteristics | Dries clear, non-yellowing, and water-resistant after full cure |

Explore related products

What You'll Learn

- Factors Affecting Drying Time: Humidity, temperature, and coat thickness impact Mod Podge drying time on wood

- Average Drying Times: Mod Podge typically dries to touch in 15-20 minutes, fully in 24 hours

- Accelerating Drying Process: Use a fan, low heat, or thin coats to speed up drying on wood

- Curing Time for Durability: Allow 2-4 weeks for Mod Podge to fully cure and harden on wood

- Testing Dryness: Lightly touch the surface; if non-sticky, it’s dry; if tacky, wait longer

Factors Affecting Drying Time: Humidity, temperature, and coat thickness impact Mod Podge drying time on wood

Mod Podge drying time on wood isn’t a fixed number—it’s a variable influenced by environmental conditions and application techniques. Humidity, temperature, and coat thickness play pivotal roles in how quickly (or slowly) your project sets. Understanding these factors allows you to plan effectively, whether you’re sealing a small wooden trinket or decoupaging a large surface.

Humidity acts as a silent saboteur in the drying process. High moisture levels in the air slow evaporation, prolonging drying time. In humid climates or during rainy seasons, a thin coat of Mod Podge might take up to 24 hours to dry to the touch, compared to 15–20 minutes under ideal conditions. To mitigate this, work in a well-ventilated area or use a dehumidifier. If humidity is unavoidable, plan for extended drying periods and avoid stacking or handling pieces prematurely.

Temperature accelerates drying, but only within a specific range. Mod Podge performs best in environments between 70°F and 75°F (21°C–24°C). Below 60°F (15°C), drying slows significantly, and the adhesive may remain tacky. Above 85°F (29°C), the product can dry too quickly, leading to uneven finishes or air bubbles. For optimal results, avoid extreme temperatures and direct sunlight, which can warp wood or cause Mod Podge to dry before it’s evenly spread.

Coat thickness is a double-edged sword. A thin, even layer dries faster—typically within 15–20 minutes—and adheres smoothly. However, thicker coats, while tempting for added protection, can take hours or even overnight to dry completely. For multi-coat projects, allow each layer to dry fully before applying the next. Sand lightly between coats with 220-grit sandpaper to ensure proper adhesion and a professional finish.

In practice, these factors often interact. For instance, a thick coat applied in a warm, humid room could take 48 hours to cure fully. Conversely, a thin layer in a cool, dry space might set in under an hour. By controlling humidity, temperature, and application thickness, you can predict and manage drying time effectively. Always test a small area first to gauge conditions and adjust your approach accordingly.

Bondo Wood Filler Durability: Longevity and Performance Explained

You may want to see also

Explore related products

Average Drying Times: Mod Podge typically dries to touch in 15-20 minutes, fully in 24 hours

Mod Podge, a versatile decoupage medium, offers a quick initial drying time, typically setting to the touch within 15 to 20 minutes. This rapid surface drying is ideal for crafters who need to handle their projects soon after application. However, it’s crucial to understand that this is only the first stage of the drying process. The full curing time, where the adhesive reaches maximum strength and durability, takes significantly longer—up to 24 hours. This distinction is essential for ensuring the longevity of your wood projects, as premature handling or exposure to moisture can compromise the finish.

The 15- to 20-minute touch-dry window is a practical feature for multi-step projects. For instance, if you’re layering Mod Podge or adding embellishments, this quick drying time allows you to proceed without smudging or damaging the initial coat. However, patience is key during the full 24-hour curing period. Avoid placing heavy objects on the surface or exposing it to moisture, as the adhesive is still vulnerable. Crafters often use this time to plan additional decorative elements or prepare the project for its final use.

Environmental factors play a significant role in drying times. Humidity, temperature, and airflow can either accelerate or delay the process. In humid conditions, Mod Podge may take longer to dry fully, while a warm, well-ventilated space can expedite curing. For optimal results, apply thin, even coats and allow each layer to dry completely before adding another. This method not only ensures even drying but also minimizes the risk of bubbling or wrinkling, common issues when Mod Podge is applied too thickly.

For wood projects, the type of wood and its porosity can also influence drying times. Softwoods, like pine, absorb Mod Podge more readily, potentially shortening drying times, while denser hardwoods may require slightly longer. Always test a small area first to gauge how the wood interacts with the medium. Additionally, sanding the wood surface lightly before application can improve adhesion and reduce drying time by creating a more receptive surface for the Mod Podge.

In summary, while Mod Podge’s 15- to 20-minute touch-dry time is convenient for quick project progression, the full 24-hour curing period is non-negotiable for durability. By understanding and respecting these timelines, crafters can ensure their wood projects remain intact and visually appealing. Practical tips, such as controlling the environment and preparing the wood surface, further enhance the drying process, making Mod Podge an efficient and reliable choice for decoupage and sealing.

How Long Will a 40lb Bag of Wood Pellets Last?

You may want to see also

Explore related products

Accelerating Drying Process: Use a fan, low heat, or thin coats to speed up drying on wood

Drying times for Mod Podge on wood can vary significantly, influenced by factors like humidity, temperature, and application thickness. While standard drying can take 15–20 minutes between coats and up to 24 hours for full curing, certain techniques can expedite this process. By manipulating environmental conditions and application methods, you can achieve a faster, more efficient finish without compromising quality.

Strategic Airflow: The Role of a Fan

Using a fan is one of the simplest yet most effective ways to accelerate drying. Position a desk fan or oscillating fan 2–3 feet away from the project, ensuring the airflow is gentle and consistent. Direct the fan at a slight angle to avoid dust settling on the wet surface. This method reduces drying time between coats to 10–15 minutes, as the moving air evaporates moisture more rapidly. Avoid high-speed settings, as they can create bubbles or uneven drying. For best results, use a fan in a well-ventilated area to maintain a steady airflow without introducing debris.

Low Heat Application: A Delicate Balance

Applying low heat can significantly shorten drying times, but it requires caution. Use a hairdryer on its coolest setting, holding it 12–18 inches away from the surface. Move the dryer continuously to prevent overheating, which can cause bubbling or cracking. Alternatively, place the project near a heater or in a warm, dry room (70–75°F), ensuring it’s not exposed to direct heat. This method can reduce drying time to 5–10 minutes between coats, but monitor closely to avoid damage. Never use high heat or place wood in an oven, as extreme temperatures can warp or scorch the material.

Thin Coats: Precision Over Quantity

The thickness of Mod Podge application directly impacts drying time. Instead of applying one heavy coat, use multiple thin layers with a foam brush or sponge. Each thin coat dries in 5–10 minutes, allowing you to build up coverage without prolonging the process. Ensure each layer is fully dry before applying the next to prevent tackiness or peeling. This technique not only speeds up drying but also results in a smoother, more professional finish. For intricate projects, consider diluting Mod Podge slightly with water (1:10 ratio) to create an even thinner consistency, further reducing drying time.

Combining Methods for Optimal Results

For maximum efficiency, combine these techniques. Apply thin coats, then use a fan to enhance airflow while maintaining low heat in the room. This multi-pronged approach can reduce total drying time by up to 50%, allowing you to complete projects in a fraction of the usual time. However, always prioritize the integrity of the finish over speed. Test these methods on a small area first to ensure compatibility with your specific wood type and Mod Podge formula. With careful execution, you can achieve a quick, durable result that meets your creative needs.

Durability of Eucalyptus Wood Furniture: Longevity and Care Tips

You may want to see also

Explore related products

Curing Time for Durability: Allow 2-4 weeks for Mod Podge to fully cure and harden on wood

Mod Podge, a versatile decoupage medium, is a crafter's go-to for sealing and protecting wood projects. While it may feel dry to the touch within hours, achieving maximum durability requires patience. The key to long-lasting results lies in understanding the difference between drying and curing.

Drying, the initial stage, is the evaporation of the water content in Mod Podge, leaving a tack-free surface. This typically takes 15-30 minutes, depending on humidity and application thickness. However, this doesn't mean your project is ready for heavy use.

Curing, the crucial second stage, is a chemical process where the Mod Podge hardens and reaches its full strength. This process takes significantly longer, requiring 2-4 weeks for complete curing on wood surfaces. During this time, the Mod Podge molecules cross-link and bond with the wood fibers, creating a robust and protective layer.

Rushing this curing process can compromise the durability of your project. Avoid exposing your Mod Podge-treated wood to excessive moisture, heat, or rough handling during this period. Think of it as letting a freshly poured concrete foundation set – patience is key to ensuring strength and longevity.

For optimal results, consider these practical tips:

- Thin Coats: Apply Mod Podge in thin, even coats, allowing each layer to dry completely before adding the next. This promotes faster curing and reduces the risk of cracking.

- Ventilation: Ensure good airflow in your workspace to aid the drying and curing process.

- Temperature: Room temperature (around 70°F/21°C) is ideal for curing. Avoid extreme temperatures, as they can affect the curing process.

- Testing: Before subjecting your project to heavy use, test the cured Mod Podge by gently scratching a small, inconspicuous area. If it resists scratching, it's fully cured.

Remember, allowing Mod Podge to fully cure on wood is an investment in the longevity of your craft. By understanding the curing process and following these guidelines, you'll ensure your creations remain beautiful and durable for years to come.

Galvanized Ties Near Wood: Lifespan and Durability Explained

You may want to see also

Explore related products

Testing Dryness: Lightly touch the surface; if non-sticky, it’s dry; if tacky, wait longer

A simple yet effective method to determine if your Mod Podge application on wood is dry is the touch test. This technique is particularly useful for crafters who need to ensure their project is ready for the next step without relying on time estimates, which can vary widely depending on environmental conditions. By gently touching the surface, you can gather immediate feedback on the drying process.

The touch test is straightforward: use the back of your hand or a fingertip to lightly graze the Mod Podged area. If the surface feels smooth and non-sticky, it’s a clear indication that the Mod Podge has dried completely. This method is especially handy for matte finishes, where visual cues might be less apparent. However, if the surface feels tacky or your finger leaves a slight impression, it’s a sign that the Mod Podge needs more time to cure. Avoid pressing too hard, as this can disrupt the finish, especially if it’s not fully set.

Environmental factors play a significant role in drying times, making the touch test a more reliable indicator than a timer. Humidity, temperature, and airflow can all influence how quickly Mod Podge dries. For instance, in a warm, dry room with good ventilation, Mod Podge may dry to the touch within 15–20 minutes, while in a damp, cool environment, it could take several hours. The touch test eliminates guesswork, allowing you to proceed with confidence regardless of external conditions.

One practical tip is to test an inconspicuous area first, especially if you’re working on a large or intricate piece. This ensures you don’t accidentally mar the visible surface while checking for dryness. Additionally, if you’re applying multiple coats, the touch test is essential between layers. Each coat typically requires 15–20 minutes to dry, but this can vary, so always test before adding another layer. Patience is key—rushing the process can lead to smudges or uneven finishes.

In summary, the touch test is a quick, reliable way to assess whether Mod Podge on wood is dry. Its simplicity and accuracy make it an invaluable tool for crafters of all skill levels. By incorporating this method into your workflow, you can ensure each step of your project is executed flawlessly, resulting in a professional-looking finish. Remember, a non-sticky surface means you’re ready to move forward, while tackiness signals the need for more drying time.

Stardew Valley Wood Fence Lifespan: Durability and Maintenance Tips

You may want to see also

Frequently asked questions

Mod Podge usually takes about 15-20 minutes to dry to the touch on wood, but it can take up to 24 hours to fully cure, depending on humidity and thickness of application.

Yes, you can speed up drying by using a hairdryer on a low setting or placing the project in a warm, well-ventilated area. However, avoid excessive heat, as it may cause bubbling or uneven drying.

Apply 2-3 thin coats of Mod Podge to wood, allowing each coat to dry for 15-20 minutes before adding the next. This ensures even coverage and proper adhesion.