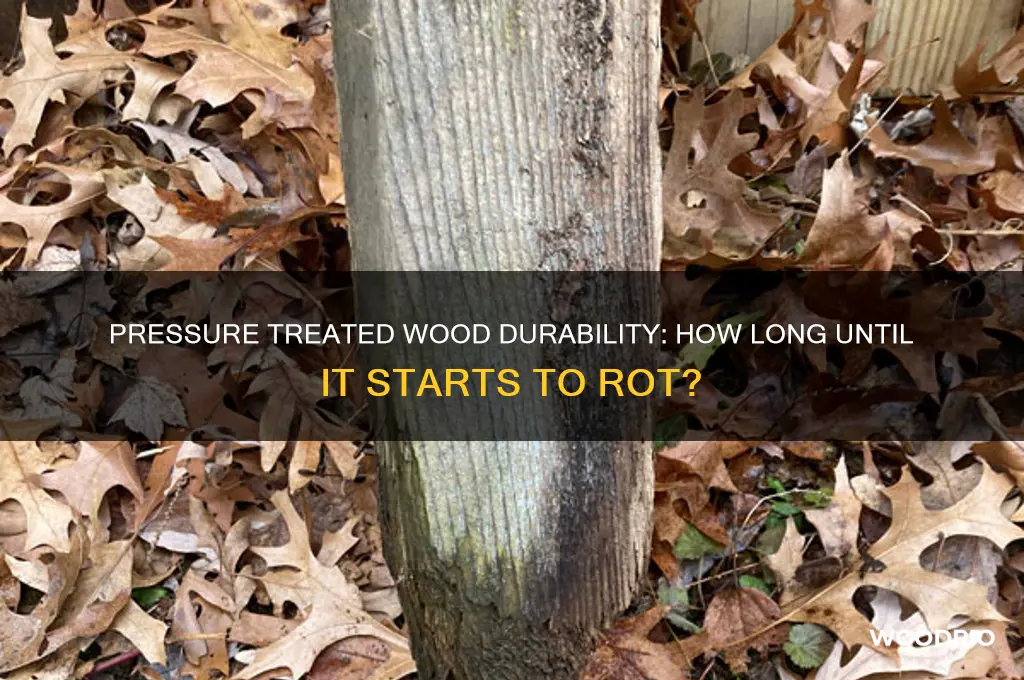

Pressure-treated wood is widely used in outdoor construction due to its enhanced durability and resistance to decay, insects, and moisture. However, despite its treated nature, it is not entirely immune to rot, and its lifespan can vary significantly based on factors such as the type of treatment, environmental conditions, and maintenance. Understanding how long pressure-treated wood takes to rot is essential for planning and ensuring the longevity of structures like decks, fences, and retaining walls. While properly treated and maintained wood can last 20 to 40 years or more, exposure to constant moisture, soil contact, or harsh weather can accelerate deterioration, potentially leading to rot in as little as 5 to 15 years.

| Characteristics | Values |

|---|---|

| Average Lifespan | 20-40 years (varies based on environmental conditions) |

| Ground Contact | 5-10 years (rots faster due to moisture and soil exposure) |

| Above Ground | 20-40+ years (longer lifespan with proper maintenance) |

| Moisture Exposure | High moisture accelerates rot; can reduce lifespan by 50% or more |

| Insect Resistance | Resistant to termites and other wood-boring insects |

| Chemical Treatment | Treated with preservatives like ACQ, CA-B, or CCA (older formulations) |

| UV Exposure | Prolonged sun exposure can degrade wood surface but not internal rot |

| Maintenance Required | Regular sealing or staining can extend lifespan by 5-10 years |

| Environmental Factors | Humidity, temperature, and soil type significantly impact rot rate |

| Biodegradability | Non-biodegradable due to chemical treatment |

| Common Failure Points | Ends and cuts are more susceptible to rot if not sealed |

| Comparative Lifespan (Untreated Wood) | Untreated wood rots in 5-10 years in similar conditions |

Explore related products

What You'll Learn

Climate impact on decay rate

Pressure-treated wood, designed to resist decay, faces a formidable adversary in climate. Moisture, temperature, and sunlight—key climate factors—dictate how quickly even treated wood succumbs to rot. In humid regions, wood remains damp longer, accelerating fungal growth and insect activity. For instance, wood in the Pacific Northwest’s rainy climate may degrade in 5–10 years, while drier areas like Arizona can extend its lifespan to 40+ years. Understanding these regional variations is crucial for predicting durability.

Analyzing the role of temperature reveals a dual-edged sword. Warm climates foster microbial activity, hastening decay, but extreme heat can also dry wood, slowing rot in arid zones. Conversely, cold climates reduce biological activity but increase freeze-thaw cycles, which crack wood and expose it to moisture. For example, pressure-treated wood in Florida’s hot, humid conditions may last 15–20 years, while in Minnesota’s cold, wet springs, it could degrade in 10–15 years. Balancing these factors is key to estimating longevity.

To mitigate climate-induced decay, strategic placement and maintenance are essential. In wet climates, elevate wood structures to improve air circulation and apply water-repellent sealants annually. In sunny regions, use UV-resistant coatings to prevent surface degradation. For cold areas, ensure proper drainage to minimize water pooling. For instance, a deck in Seattle should be sealed every year and inspected for cracks, while one in Phoenix needs UV protection and occasional cleaning. Tailoring care to local conditions maximizes treated wood’s lifespan.

Comparing climates highlights the need for region-specific solutions. Coastal areas face salt corrosion, requiring marine-grade treatments, while inland regions may prioritize insect resistance. A pergola in Miami would benefit from stainless steel fasteners and bi-annual inspections, whereas one in Denver needs snow load considerations and crack repairs. By adapting to climate challenges, homeowners can preserve treated wood’s integrity and delay rot effectively.

Understanding the Lifespan of Wood Boring Beetles: A Comprehensive Guide

You may want to see also

Explore related products

Chemical treatment effectiveness

Pressure-treated wood's longevity hinges on the chemicals used and their application methods. Modern treatments, such as Alkaline Copper Quaternary (ACQ) and Copper Azole (CA-B), are designed to resist rot, decay, and insect damage. These chemicals are forced deep into the wood under high pressure, creating a barrier that significantly extends the material's lifespan. For instance, ACQ-treated wood can last up to 40 years in ground contact, while CA-B-treated wood may endure even longer, depending on environmental conditions. The effectiveness of these treatments lies in their ability to bind with the wood’s cellular structure, making it inhospitable to fungi and termites.

However, not all chemical treatments are created equal. Older methods, like Chromated Copper Arsenate (CCA), were phased out in residential applications due to health concerns but remain in use for industrial purposes. CCA-treated wood can last 50 years or more, but its arsenic content poses risks if burned or handled without proper precautions. In contrast, newer treatments like ACQ and CA-B are considered safer for residential use but require precise application to ensure effectiveness. The retention level, measured in pounds of chemical per cubic foot of wood (e.g., 0.40 lb/ft³ for above-ground use, 0.60 lb/ft³ for ground contact), directly impacts durability. Higher retention levels provide better protection but may increase costs.

To maximize the effectiveness of chemically treated wood, proper installation and maintenance are critical. Avoid cutting or drilling the wood without applying a compatible preservative to exposed areas, as this can create entry points for moisture and pests. Additionally, ensure the wood is not in constant contact with water or soil, as even treated wood can degrade under prolonged exposure to harsh conditions. For example, using gravel or concrete pads as a base for treated posts can reduce ground moisture absorption, further extending their lifespan.

Comparatively, the effectiveness of chemical treatments also depends on the wood species. Softwoods like pine and fir are commonly treated due to their affordability and absorbency, but hardwoods like oak or cedar naturally resist decay without treatment. However, when treated, softwoods outperform untreated hardwoods in durability. For optimal results, choose the right treatment for the intended use: above-ground, ground contact, or freshwater exposure. Manufacturers often label treated wood with a tag indicating its intended application, retention level, and chemical type—always follow these guidelines for best results.

In practice, the effectiveness of chemical treatments can be seen in real-world applications. For instance, a deck built with ACQ-treated wood and proper drainage can outlast one made from untreated lumber by decades. Similarly, fence posts treated with CA-B and installed with gravel backfill can remain structurally sound for 30+ years. While no treatment guarantees indefinite protection, following manufacturer recommendations and best practices ensures treated wood performs as intended. By understanding the nuances of chemical treatments, homeowners and builders can make informed decisions to maximize the lifespan of their wooden structures.

Seasoning Beech Wood: Understanding the Timeframe for Optimal Results

You may want to see also

Explore related products

Moisture exposure levels

Pressure-treated wood is designed to resist decay, but its longevity hinges critically on moisture exposure levels. Wood in constant contact with water, such as fence posts buried in soil or deck supports in damp environments, faces the highest risk. Even pressure-treated wood can begin to show signs of rot within 5 to 10 years under these conditions due to prolonged saturation. Conversely, wood exposed to occasional moisture, like a deck surface that dries quickly after rain, can last 20 years or more. The key factor is the wood’s ability to dry out between exposures, preventing fungal growth and insect infestation.

Analyzing moisture exposure levels requires understanding the wood’s environment. For instance, wood in direct soil contact absorbs moisture continuously, accelerating rot. To mitigate this, elevate wood structures using gravel bases or concrete footings, reducing ground moisture absorption by up to 70%. Similarly, in humid climates, ensure proper ventilation around wooden structures to minimize condensation buildup. For coastal areas, where salt spray increases moisture retention, consider using higher-grade pressure-treated wood with a retention level of 0.60 pounds per cubic foot (PCF) of preservative chemicals, compared to the standard 0.40 PCF for drier regions.

Practical steps can significantly extend the life of pressure-treated wood by managing moisture exposure. Apply a waterproof sealant annually to create a barrier against water infiltration, particularly on horizontal surfaces like decks and walkways. For vertical structures, such as fences, ensure proper drainage by grading the soil away from the wood. In areas prone to standing water, install drainage systems to redirect water flow. Regular inspections for cracks or splinters are essential, as these allow moisture to penetrate the wood’s core, bypassing the protective treatment.

Comparing moisture exposure scenarios highlights the importance of proactive measures. A deck in a rainy climate with poor drainage may show rot within 15 years, while an identical deck with proper sealing and drainage can last 30 years or more. Similarly, a fence post in well-drained soil with a gravel base can outlast one in clay soil by a decade. These examples underscore the need to tailor moisture management strategies to the specific environment, ensuring the wood’s protective treatment remains effective.

In conclusion, moisture exposure levels dictate the lifespan of pressure-treated wood more than any other factor. By understanding the wood’s environment, implementing practical moisture management techniques, and using appropriate materials for specific conditions, you can maximize its durability. Whether through elevation, sealing, or drainage improvements, controlling moisture exposure is the key to preventing rot and ensuring long-term performance.

Untended Wood Lifespan: Factors Affecting Durability and Decay Over Time

You may want to see also

Explore related products

Soil contact effects

Pressure-treated wood is designed to resist decay, but its longevity is significantly influenced by soil contact. When buried or in constant contact with soil, the wood is exposed to moisture, microorganisms, and varying pH levels, all of which accelerate degradation. While above-ground treated wood can last 20–40 years, ground-contact treated wood typically lasts 10–20 years, depending on environmental conditions. This disparity underscores the critical role soil plays in the material’s lifespan.

To mitigate soil contact effects, consider the wood’s preservative treatment level. Ground-contact pressure-treated wood contains higher concentrations of preservatives, such as alkaline copper quaternary (ACQ) or copper azole, compared to above-ground varieties. For instance, ACQ-treated wood for ground contact has a retention level of 0.40 pounds per cubic foot (PCF) or higher, whereas above-ground wood is treated at 0.25 PCF. Always verify the treatment level before installation, as using the wrong type can void warranties and shorten lifespan.

Another practical strategy is to create a barrier between the wood and soil. Gravel, concrete pads, or plastic liners can reduce direct contact and improve drainage, minimizing moisture retention. For posts or structures partially buried, consider using a sacrificial layer of untreated wood at the soil line, which can be replaced more easily than the entire structure. This method is particularly useful for fence posts or deck supports, where soil contact is unavoidable.

Despite these measures, soil type and moisture content remain uncontrollable variables. Clay soils, for example, retain more water than sandy soils, increasing the risk of rot. In humid climates or areas with poor drainage, even ground-contact treated wood may fail prematurely. Regular inspections and proactive maintenance, such as reapplying water-repellent sealants, can extend the wood’s life but cannot entirely counteract the effects of prolonged soil exposure.

Ultimately, understanding soil contact effects is essential for realistic expectations and informed decision-making. While pressure-treated wood is a durable choice, it is not immune to the challenges posed by soil. By selecting the appropriate treatment level, implementing protective barriers, and monitoring environmental conditions, you can maximize its lifespan and ensure long-term performance in ground-contact applications.

Wet Wood Warping Timeline: Factors Affecting Drying and Distortion

You may want to see also

Explore related products

Wood type durability

Pressure-treated wood is a popular choice for outdoor projects due to its enhanced resistance to rot, decay, and insect damage. However, not all wood types are created equal when it comes to durability. The lifespan of pressure-treated wood depends heavily on the species of wood used as the base material. For instance, southern yellow pine, a common choice for pressure treatment, can last 20 to 40 years in ground contact applications, while denser hardwoods like cedar or redwood, though not typically pressure-treated, naturally resist decay for 15 to 30 years without treatment. Understanding the inherent durability of different wood types is crucial for selecting the right material for your project.

When evaluating wood type durability, consider the natural properties of the species. Softwoods like pine and fir are more susceptible to decay but are ideal candidates for pressure treatment because their porous structure allows preservatives to penetrate deeply. Hardwoods, on the other hand, have tighter grain structures that naturally resist moisture and pests but are less receptive to chemical treatments. For example, Douglas fir, when pressure-treated, can outperform untreated cedar in certain conditions due to the added preservatives. Always check the retention level of the treatment chemicals, measured in pounds per cubic foot (pcf), as higher retention levels (e.g., 0.40 pcf for ground contact) provide greater protection.

To maximize the durability of pressure-treated wood, pair the right wood type with the appropriate treatment level. For projects like fence posts or deck supports that will be in direct soil contact, opt for wood treated to UC4A standards, which is designed for severe decay hazard zones. For above-ground applications, such as decking or railings, UC3B-treated wood suffices. Additionally, consider the climate and environmental factors. In humid or wet regions, even pressure-treated wood may require periodic sealing or staining to prolong its life. Regular inspections for cracks, splinters, or signs of insect activity can help catch issues early and extend the wood’s lifespan.

Comparing wood types reveals that while pressure-treated southern yellow pine is cost-effective and widely available, it may not match the aesthetic appeal or natural durability of cedar or redwood. For projects where appearance matters, such as garden furniture or decorative structures, investing in naturally durable wood or higher-grade pressure-treated options can yield better long-term results. However, for utilitarian applications like retaining walls or structural supports, pressure-treated pine offers a balance of durability and affordability. Always weigh the initial cost against the expected lifespan to determine the best value for your specific needs.

Finally, proper installation and maintenance are key to unlocking the full potential of any wood type. Ensure that pressure-treated wood is cut with tools coated in rust-inhibiting oil to prevent staining, and seal all cut ends with a preservative to maintain protection. Avoid placing wood in areas with poor drainage, as standing water accelerates decay. By combining the right wood type, treatment level, and care practices, you can significantly extend the life of your outdoor wood projects, ensuring they remain functional and attractive for decades.

Wood Deck Wet Sanding: Optimal Timing for Smooth, Refinished Surfaces

You may want to see also

Frequently asked questions

Pressure treated wood can last 20 to 40 years or more before rotting, depending on factors like moisture exposure, soil contact, and maintenance.

Yes, pressure treated wood rots faster in wet or humid environments, as prolonged moisture exposure accelerates decay despite its treatment.

Yes, even pressure treated wood can rot when buried in soil due to constant moisture and microbial activity, though it lasts longer than untreated wood.

Yes, newer treatments like ACQ (Alkaline Copper Quaternary) or CA-B (Copper Azole) last longer than older treatments like CCA (Chromated Copper Arsenate).

To extend its lifespan, seal the wood with a water-repellent sealant, ensure proper drainage, and avoid direct soil contact. Regular maintenance also helps.