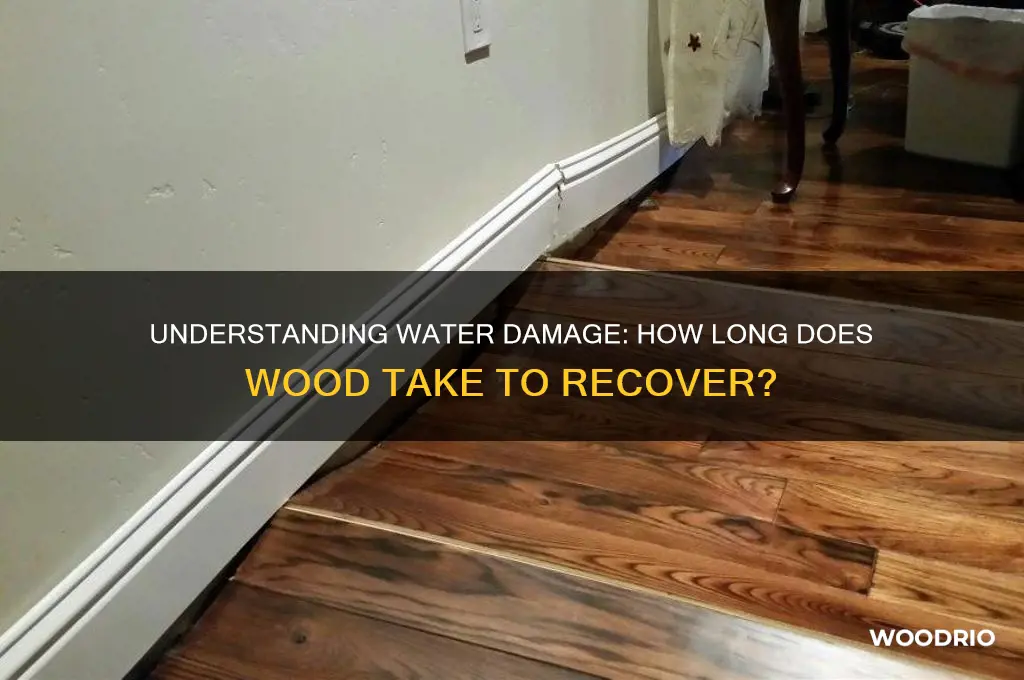

Water damage in wood can vary significantly depending on the duration and extent of exposure to moisture. Immediate effects, such as swelling, discoloration, and warping, may appear within hours of water contact, especially in softwoods. Prolonged exposure, typically beyond 48 hours, increases the risk of mold growth, structural weakening, and irreversible damage. Hardwoods generally resist damage longer than softwoods but are not immune to long-term effects. Understanding the timeline of water damage is crucial for timely intervention, as prompt drying and treatment can often mitigate or reverse the harm, preserving the wood's integrity and appearance.

| Characteristics | Values |

|---|---|

| Time for Initial Water Absorption | Within minutes to hours, depending on wood type and water exposure. |

| Visible Warping/Swelling | 24-48 hours after water exposure. |

| Mold Growth | 24-48 hours in humid conditions; visible within 1-2 weeks. |

| Structural Weakening | 3-7 days for significant weakening; varies by wood density. |

| Discoloration | 1-3 days for noticeable stains; depends on wood type and water source. |

| Rotting (Dry Rot/Wet Rot) | 7-14 days for initial signs; full degradation takes weeks to months. |

| Odor Development | 2-3 days for musty smells; persists until wood dries or is treated. |

| Cracking/Splitting | 3-7 days as wood dries unevenly; worsens over weeks. |

| Permanent Damage Risk | After 48 hours, restoration becomes difficult; replacement may be needed. |

| Drying Time (Without Treatment) | 1-2 weeks for surface drying; internal moisture takes 2-4 weeks. |

Explore related products

What You'll Learn

Initial Signs of Water Damage

Water damage in wood doesn’t announce itself with a grand entrance; it begins subtly, often escaping notice until the problem escalates. The first sign is usually a change in texture. Wood exposed to moisture will feel cooler to the touch and may appear slightly swollen or warped. Run your hand over suspect areas—if the surface feels uneven or the edges of planks seem raised, water has likely begun its insidious work. This initial swelling occurs within hours to days of exposure, depending on the wood type and moisture level. Hardwoods like oak resist swelling longer than softwoods like pine, but neither is immune to the effects of prolonged dampness.

Another early indicator is discoloration. Wood absorbs water like a sponge, and the result is often a darkening or blotchy appearance. Look for patches that seem out of place—a floorboard with a sudden grayish hue or a cabinet corner with a faint brown stain. These changes typically manifest within 24 to 48 hours of water contact, though they may take longer in less porous woods. If the water source is contaminated, such as from a flood or sewage backup, the discoloration can be more pronounced and may carry a musty odor. Addressing these signs promptly can prevent deeper structural damage.

A less obvious but equally critical sign is the sound wood makes underfoot or when tapped. Dry wood produces a solid, dull thud, but waterlogged wood sounds hollow or muted. Test this by lightly knocking on suspect areas with a mallet or even your knuckles. If the sound seems off, moisture has likely compromised the wood’s integrity. This acoustic change often becomes noticeable within 3 to 5 days of exposure, depending on the wood’s density and the amount of water present. Ignoring this warning can lead to costly repairs, as weakened wood is prone to cracking or splitting under pressure.

Finally, pay attention to the environment around the wood. Peeling paint or wallpaper, bubbling finishes, or the sudden appearance of mold are indirect but telling signs of water damage. Mold, in particular, thrives in damp conditions and can colonize wood within 24 to 48 hours of sustained moisture. If you spot fuzzy patches or a greenish-black growth, the wood beneath is almost certainly compromised. These secondary signs often indicate that water has been present long enough to penetrate deeply, making immediate intervention critical to salvage the material.

Catching these initial signs early can mean the difference between a simple cleanup and a full-scale restoration. Regularly inspect wood surfaces, especially in moisture-prone areas like kitchens, bathrooms, and basements. Use a moisture meter to quantify dampness if visual cues aren’t clear. Acting within the first 24 to 72 hours of exposure gives you the best chance to mitigate damage, whether through drying techniques, sealant application, or professional intervention. Remember, wood is resilient but not invincible—early detection is its best defense.

Maximizing Traeger Wood Pellet Lifespan: Storage Tips and Burn Time

You may want to see also

Explore related products

Drying Time for Wet Wood

The drying time for wet wood is a critical factor in preventing permanent damage, warping, or mold growth. Factors like wood type, moisture content, humidity, temperature, and airflow significantly influence this timeline. Hardwoods like oak or maple generally dry more slowly than softwoods like pine due to their denser structure. For instance, a 1-inch thick pine board might take 1-2 weeks to dry under optimal conditions, while a similarly sized oak board could require 3-4 weeks or more.

To expedite drying, control the environment. Maintain a temperature of 70-80°F (21-27°C) and humidity below 50%. Use fans or dehumidifiers to improve airflow, ensuring air circulates around all surfaces of the wood. Avoid direct heat sources like heaters or hairdryers, as these can cause uneven drying and cracking. For larger pieces, elevate the wood off the ground using blocks or a drying rack to prevent moisture absorption from below.

A practical tip is to monitor the wood’s moisture content using a moisture meter. Aim for a moisture level below 12-15% for indoor use, as this minimizes the risk of shrinkage or mold. If the wood is part of a structure, such as flooring or furniture, assess adjacent materials for hidden moisture pockets. For example, subflooring beneath wet hardwood planks may retain moisture longer, requiring additional drying time or professional intervention.

Comparatively, kiln-drying offers a faster, more controlled method but is typically reserved for commercial applications. This process can reduce drying time to days instead of weeks, though it’s less feasible for DIY scenarios. For home projects, patience is key. Rushing the drying process often leads to irreversible damage, making it essential to balance speed with thoroughness.

In conclusion, drying wet wood is a delicate balance of time, environment, and technique. By understanding the variables at play and employing practical strategies, you can salvage water-damaged wood effectively. Always prioritize gradual, even drying over quick fixes to preserve the wood’s integrity and longevity.

Maximizing Garden Benefits: Wood Chips Lifespan and Decomposition Explained

You may want to see also

Explore related products

$13.05 $14.77

$15.99

Factors Affecting Wood Recovery

The duration for wood to recover from water damage isn't a fixed timeline—it's a complex interplay of factors that dictate whether the wood can be salvaged or if replacement is necessary. Understanding these factors is crucial for anyone dealing with water-damaged wood, whether it's a homeowner, contractor, or restoration specialist.

Moisture Content and Exposure Time: The longer wood remains saturated, the more severe the damage. Wood with a moisture content exceeding 20% for over 72 hours is at high risk for warping, cracking, and mold growth. For example, hardwood floors exposed to a burst pipe for 48 hours may show signs of cupping but could still be salvageable with prompt drying techniques.

Wood Species and Density: Different wood species react differently to water. Softwoods like pine absorb moisture quickly and are more prone to swelling and distortion, while denser hardwoods like oak or teak may resist initial damage but can still crack under prolonged exposure. A comparative analysis shows that pine flooring might need replacement after 24–48 hours of water exposure, whereas oak could withstand up to 72 hours with proper intervention.

Temperature and Humidity: Environmental conditions significantly impact recovery time. High humidity slows evaporation, prolonging drying time, while elevated temperatures can accelerate mold growth. For instance, drying water-damaged wood in a warm, humid basement (70°F and 60% humidity) could take 2–3 weeks, whereas a controlled environment with dehumidifiers and fans might reduce this to 3–5 days.

Drying Techniques and Tools: Proper drying methods are critical. Air movement from fans, dehumidifiers to reduce moisture, and in severe cases, professional kiln drying can expedite recovery. A step-by-step approach includes: 1) Remove standing water immediately. 2) Use industrial fans to circulate air. 3) Maintain a dehumidifier at 50% relative humidity. 4) Monitor moisture levels with a wood moisture meter, aiming for 12–15% moisture content for structural wood.

Preventive Measures and Maintenance: Post-recovery, sealing wood with waterproof finishes and ensuring proper ventilation can prevent future damage. For example, applying a polyurethane sealant to wooden surfaces in moisture-prone areas like bathrooms or kitchens can add a protective barrier. Regular inspections for leaks or condensation buildup are also essential to catch issues early.

By addressing these factors systematically, the recovery timeline for water-damaged wood can be minimized, potentially saving time and costs while preserving the integrity of wooden structures.

Into the Woods Runtime: How Long is the Play?

You may want to see also

Explore related products

Preventing Permanent Wood Damage

Water damage in wood is a race against time, with the clock starting the moment moisture makes contact. The first 24 to 48 hours are critical; within this window, wood can absorb up to 10% of its weight in water, leading to swelling, warping, and discoloration. After 48 hours, mold growth becomes a significant risk, as spores can colonize damp wood in as little as 24 to 48 hours under ideal conditions. Beyond a week, structural integrity is compromised, with cellulose breakdown accelerating in the presence of prolonged moisture. Understanding this timeline underscores the urgency of preventive measures.

To prevent permanent wood damage, act swiftly at the first sign of water exposure. Begin by removing standing water using towels, mops, or wet-dry vacuums. For larger areas, industrial-grade dehumidifiers can reduce ambient moisture, slowing absorption. Fans or air movers should be positioned to circulate air, but avoid direct heat sources like hair dryers, which can cause uneven drying and cracking. If the wood is part of flooring or furniture, elevate it off wet surfaces using blocks or foil to minimize contact. These immediate steps can buy crucial hours, reducing the likelihood of irreversible harm.

A comparative analysis of preventive treatments reveals that sealants and finishes are not created equal. Polyurethane coatings, for instance, provide a robust barrier against moisture but require reapplication every 2–3 years, especially in high-humidity environments. Penetrating oil sealers, such as linseed or tung oil, offer deeper protection by bonding with wood fibers but may need more frequent application (annually) for optimal performance. For outdoor wood, consider marine-grade varnishes, which resist UV degradation and moisture penetration for up to 5 years. Choosing the right product depends on the wood’s exposure level and maintenance tolerance.

Descriptive examples illustrate the importance of proactive maintenance. In coastal regions, untreated wooden decks often show signs of rot within 1–2 years due to salt spray and rain. Conversely, decks treated with a combination of pressure washing, sanding, and resealing every 18 months can last over a decade. Similarly, indoor hardwood floors in kitchens or bathrooms benefit from waterproof rugs, immediate spill cleanup, and periodic refinishing every 5–7 years. These practices create a protective routine that extends wood lifespan by mitigating cumulative moisture damage.

Persuasively, investing in preventive measures is far more cost-effective than repairing or replacing water-damaged wood. For example, sealing a wooden countertop costs approximately $50–$100 in materials, whereas replacing a warped or moldy surface can run $500–$1,500, depending on size and wood type. Regular inspections, especially after leaks or storms, can identify vulnerabilities early. Keep humidity levels below 50% using hygrometers and dehumidifiers, and ensure proper ventilation in wood-heavy areas like basements or attics. By treating prevention as an ongoing commitment, you safeguard both the aesthetic and structural value of wood.

Exploring Muir Woods: Ideal Time for a Serene Nature Experience

You may want to see also

Explore related products

$32.69

Repairing Water-Damaged Wood

Water damage in wood can manifest in various ways, from minor warping to severe rot, and the timeline for deterioration depends on factors like moisture level, wood type, and environmental conditions. Softwoods like pine may show signs of damage within days, while denser hardwoods like oak can take weeks or months. Recognizing the early stages—such as discoloration, swelling, or a musty odor—is crucial for timely intervention. Ignoring these signs can lead to structural instability, mold growth, or irreversible decay, making prompt action essential.

One effective technique for restoring water-damaged wood is the use of epoxy resins. These two-part compounds penetrate deep into the wood, stabilizing cracks and strengthening weakened areas. Mix the epoxy according to the manufacturer’s instructions, apply it generously to the damaged zone, and allow it to cure fully—typically 24 to 48 hours. Sand the area smooth once cured, then refinish to match the surrounding wood. Epoxy is particularly useful for preserving the original piece, especially in antique or sentimental items.

Preventive measures are just as critical as repair techniques. After addressing the damage, apply a waterproof sealant or wood preservative to protect against future moisture intrusion. Ensure proper ventilation in areas prone to humidity, such as basements or bathrooms, and promptly fix leaks or water infiltration. Regular inspections, especially after heavy rain or flooding, can catch issues early. For outdoor wood structures, consider using naturally rot-resistant species like cedar or treating with borate solutions for added durability.

While DIY methods can handle minor to moderate damage, severe cases may require professional intervention. Structural beams, load-bearing elements, or extensive rot often demand specialized equipment and expertise. Professionals may employ techniques like tenting and dehumidification for large-scale drying or use advanced treatments like pressure injection of fungicides. Knowing when to call in experts can save time, money, and ensure the safety of the structure. With the right approach, water-damaged wood can be restored to its former strength and beauty, prolonging its lifespan and functionality.

Wood Frog Lifespan: Understanding Their Survival in the Wild

You may want to see also

Frequently asked questions

Water damage in wood can become noticeable within 24 to 48 hours, depending on the type of wood and the amount of moisture exposure. Initial signs include swelling, discoloration, or a damp smell.

Wood typically begins to warp or distort within 48 to 72 hours of prolonged water exposure. The severity depends on the wood’s density and the extent of moisture absorption.

Yes, wood can often recover if dried within 24 to 48 hours. Quick action to remove moisture and proper drying techniques can prevent permanent damage like warping or mold growth.

Mold can begin to grow on water-damaged wood within 24 to 72 hours in ideal conditions (warmth and humidity). Prompt drying and cleaning are essential to prevent mold infestation.

Complete rotting of water-damaged wood can take several weeks to months, depending on factors like humidity, temperature, and the presence of fungi. Structural integrity is compromised long before complete rot occurs.