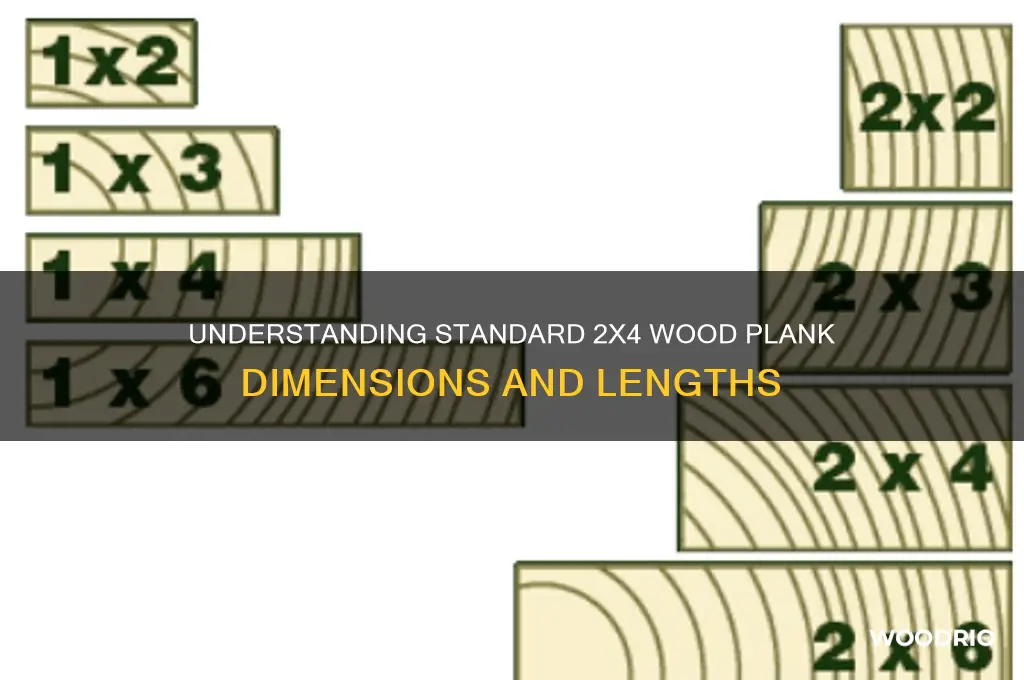

When discussing the dimensions of a 2 x 4 plank of wood, it’s important to note that the actual measurements differ from the nominal size due to standard milling practices. A nominal 2 x 4 plank is typically labeled as such, but its actual dimensions are usually around 1.5 inches by 3.5 inches. This discrepancy arises because the wood is initially cut to the nominal size and then dried and planed, reducing its final thickness and width. Understanding these actual measurements is crucial for accurate planning in construction, woodworking, or any project requiring precise material sizing.

| Characteristics | Values |

|---|---|

| Nominal Dimensions | 2 inches x 4 inches |

| Actual Dimensions | 1.5 inches x 3.5 inches |

| Standard Lengths | 8 feet, 10 feet, 12 feet, 14 feet, 16 feet, 20 feet |

| Material | Typically softwood (e.g., pine, fir, spruce) or hardwood (less common) |

| Weight (per 8-foot length) | Approximately 9-12 pounds (softwood) |

| Common Uses | Framing, furniture, shelving, DIY projects |

| Moisture Content | Typically kiln-dried to 19% or less |

| Grade | Varies (e.g., Select Structural, #2, #3) based on defects and appearance |

| Finish | Usually untreated, but can be pressure-treated for outdoor use |

| Cost (per board) | $3-$8 (softwood), varies by length and grade |

Explore related products

What You'll Learn

- Standard Lengths: 2x4 planks typically come in 8, 10, or 12 feet lengths

- Lumber Sizing: Actual dimensions are 1.5x3.5 inches, not 2x4 inches

- Custom Cuts: Can be cut to shorter lengths for specific projects

- Metric Equivalents: Common lengths in meters: 2.44, 3.05, or 3.66 meters

- Availability: Longer lengths (16+ feet) are available but less common

Standard Lengths: 2x4 planks typically come in 8, 10, or 12 feet lengths

A trip to the lumber aisle reveals a predictable pattern: 2x4 planks, those workhorses of construction, are rarely found in odd lengths. Instead, they adhere to a standard trio: 8, 10, and 12 feet. This uniformity isn't arbitrary. It reflects a practical compromise between maximizing material yield from timber and providing builders with manageable, versatile lengths.

Consider the 8-foot plank. It’s the shortest standard option, ideal for framing interior walls, building small structures like garden beds, or creating shelving units. Its compact size makes it easier to transport and maneuver, especially in tight spaces. However, its limited length restricts its use in larger projects, where joining multiple planks becomes necessary.

Here’s where the 10-foot plank steps in. It offers a middle ground, balancing length with practicality. It’s a popular choice for floor joists, deck railings, and longer spans in framing. While still manageable for most DIYers, it provides more flexibility than the 8-foot option without becoming unwieldy.

The 12-foot plank is the heavyweight champion of standard lengths. Its size makes it ideal for structural elements like ceiling beams, long spans in decks, or the framework of larger sheds. However, its length demands careful handling and transportation. It’s less suited for solo projects and often requires additional manpower or equipment to move and position safely.

Durability of Wood Decking: Lifespan, Maintenance, and Longevity Tips

You may want to see also

Explore related products

Lumber Sizing: Actual dimensions are 1.5x3.5 inches, not 2x4 inches

A trip to the lumber aisle can be a lesson in expectations versus reality. That ubiquitous "2x4" plank, a staple of construction and DIY projects, isn't actually 2 inches by 4 inches. Its true dimensions are closer to 1.5 inches by 3.5 inches. This discrepancy isn't a trick of the trade; it's a result of a long-standing industry practice rooted in the drying and planing process.

Raw lumber, freshly sawn from a log, is thicker and rougher. Drying shrinks the wood, and planing creates a smooth, consistent surface. This process removes a significant amount of material, resulting in the final dimensions we see on store shelves.

Understanding this sizing convention is crucial for accurate planning and material estimation. Imagine building a frame for a bookshelf, meticulously calculating based on 2-inch thickness, only to find your joints don't align because the actual thickness is 1.5 inches. This miscalculation could lead to wasted materials, structural weaknesses, and a whole lot of frustration.

Always factor in the actual dimensions when designing and purchasing lumber. Most hardware stores provide charts or guides detailing the nominal (stated) versus actual dimensions of common lumber sizes.

The "2x4" phenomenon highlights a broader point about industry standards and consumer awareness. While the naming convention might seem misleading at first glance, it's a widely accepted practice within the construction industry. As consumers, it's our responsibility to educate ourselves about these standards to ensure successful projects.

Don't let the numbers fool you. A little knowledge about lumber sizing goes a long way in preventing costly mistakes and ensuring your DIY dreams become reality.

Drying Fresh Wood: Essential Tips for Optimal Curing Time

You may want to see also

Explore related products

$26.99 $28.99

Custom Cuts: Can be cut to shorter lengths for specific projects

A standard 2x4 plank of wood typically comes in lengths of 8, 10, or 12 feet, but these dimensions don’t always align with the needs of a specific project. This is where custom cuts come into play. Whether you’re framing a small structure, building furniture, or crafting a DIY project, the ability to cut a 2x4 to a shorter length is invaluable. Most hardware stores offer cutting services, often free with purchase, allowing you to tailor the wood to your exact measurements. This eliminates waste and ensures a precise fit, saving both time and material.

Analyzing the practicality of custom cuts reveals their significance in project efficiency. For instance, if your project requires a 5-foot piece but you’re limited to 8-foot boards, cutting to size prevents unnecessary bulk and simplifies handling. Additionally, shorter lengths reduce the risk of warping or damage during transport and storage. Custom cuts also enable creativity, as they allow for intricate designs or modular components that pre-cut lengths might not accommodate. This flexibility is particularly useful in projects like shelving units, where varying lengths are often needed.

When opting for custom cuts, precision is key. Measure twice and mark clearly to avoid errors, as even a quarter-inch mistake can derail a project. If cutting at home, use a sharp saw blade and secure the wood firmly to prevent splintering or uneven cuts. For angled or complex cuts, consider using a miter saw or circular saw with a guide. If relying on store cutting services, bring detailed measurements or a sketch to ensure accuracy. Always account for additional length if your project requires overlapping or joining pieces.

Comparatively, pre-cut lengths may seem convenient, but they often lead to compromises in design or functionality. Custom cuts, on the other hand, offer a tailored solution that aligns perfectly with your vision. For example, a custom-cut 2x4 can serve as a precise support beam in a loft bed or a perfectly sized frame for a garden box. This level of customization not only enhances the project’s aesthetics but also its structural integrity. By investing a little extra time in measuring and cutting, you can achieve professional-grade results.

In conclusion, custom cuts transform a standard 2x4 into a versatile material suited for any project. Whether you’re a seasoned carpenter or a weekend DIYer, the ability to shorten a plank to exact specifications opens up endless possibilities. From reducing waste to enabling intricate designs, this simple adjustment can elevate your work. So, the next time you’re faced with a 2x4 that’s too long, remember: a custom cut isn’t just an option—it’s an opportunity.

Installing a Wood Basketball Court: Timeframe and Process Explained

You may want to see also

Explore related products

Metric Equivalents: Common lengths in meters: 2.44, 3.05, or 3.66 meters

A 2x4 plank of wood, a staple in construction and DIY projects, is often discussed in imperial measurements, but understanding its metric equivalents can be equally crucial, especially in regions where the metric system prevails. The lengths 2.44, 3.05, and 3.66 meters are not arbitrary; they directly correspond to the standard 8-foot, 10-foot, and 12-foot lengths commonly available in lumberyards. These metric equivalents simplify planning and purchasing for international projects or collaborations.

Analytical Insight:

The 2.44-meter (8-foot) plank is the most versatile, often used for framing, shelving, or basic structural support. Its length strikes a balance between manageability and utility, making it ideal for both small-scale repairs and larger builds. The 3.05-meter (10-foot) plank, while less common, offers extended reach for projects like long spans or continuous runs, reducing the need for joints. The 3.66-meter (12-foot) plank, the longest standard size, is best reserved for applications requiring minimal seams, such as ceiling joists or long walls, though its size can make transportation and handling more challenging.

Instructive Guidance:

When selecting a plank length, consider the project’s scale and logistical constraints. For example, a 2.44-meter plank fits easily in most vehicles and is suitable for tasks like building a raised garden bed or framing a small door. If your project requires longer, uninterrupted lengths—such as a pergola or a room divider—opt for the 3.66-meter plank, but ensure you have the means to transport and maneuver it safely. Always measure twice and account for cuts to minimize waste.

Comparative Perspective:

While the 2.44-meter plank is the most widely used due to its practicality, the 3.05-meter plank offers a middle ground for projects that demand slightly more length without the bulk of the 3.66-meter option. For instance, a 3.05-meter plank is ideal for constructing a workbench or a long shelf, where a single piece provides both stability and aesthetics. However, the 3.66-meter plank, despite its unwieldiness, is unmatched for applications like floor joists or large-scale framing, where fewer joints translate to greater structural integrity.

Practical Tips:

To maximize efficiency, plan your cuts in advance, especially when working with longer planks. For example, a 3.66-meter plank can be divided into three 1.22-meter sections for shelving or two 1.83-meter pieces for framing. Always wear safety gear when handling long planks, as their weight and length can pose risks during cutting or installation. If transporting longer lengths, secure them properly to avoid damage or accidents. By understanding these metric equivalents and their applications, you can streamline your projects and achieve professional results.

Maximizing Wood Pellet Lifespan in Your Smoker: Tips and Insights

You may want to see also

Explore related products

Availability: Longer lengths (16+ feet) are available but less common

Standard 2x4 lumber, a staple in construction and DIY projects, typically comes in lengths ranging from 8 to 16 feet. These sizes are readily available at most hardware stores and lumberyards, catering to the needs of both professionals and hobbyists. However, for those seeking longer lengths—16 feet and beyond—the search becomes more challenging. While these extended planks do exist, their availability is limited, often requiring special orders or visits to specialized suppliers. This scarcity is partly due to transportation constraints, as longer boards are more difficult to handle and ship, and partly because the demand for such lengths is relatively low compared to their shorter counterparts.

For projects demanding uninterrupted spans or specific aesthetic requirements, longer 2x4 planks can be a game-changer. Imagine framing a large room without the need for excessive joints or creating a sleek, modern bookshelf with minimal seams. To secure these longer lengths, start by contacting local lumberyards or mills that specialize in custom orders. Online platforms and specialty wood suppliers are also valuable resources, though shipping costs can be a consideration. When ordering, specify the exact length needed and inquire about lead times, as these boards may not be readily available off the shelf.

One practical tip for working with longer 2x4s is to plan for transportation and storage. These planks require vehicles with ample space and may need to be secured to prevent damage during transit. At the worksite, ensure you have adequate space to maneuver and store them safely. Additionally, consider the structural implications of using longer lengths. While they reduce the need for joints, they may require additional support to prevent sagging or warping, especially in load-bearing applications.

From a cost perspective, longer 2x4 planks are generally more expensive than their shorter counterparts due to their limited availability and the additional handling required. However, the investment can pay off in terms of time saved and the overall quality of the finished project. For instance, a 20-foot plank might cost 20-30% more than a 16-foot one, but it eliminates the need for splicing, reducing labor and potential weak points in the structure. Weighing these factors against your project’s budget and timeline is crucial.

In conclusion, while longer 2x4 planks (16+ feet) are less common, they are not impossible to find. With proper planning, resourcefulness, and a willingness to invest, these extended lengths can elevate your project’s functionality and aesthetics. Whether you’re a professional builder or a DIY enthusiast, understanding the availability and practicalities of these planks ensures you’re well-equipped to tackle even the most ambitious tasks.

Durability of Manufactured Wood Furniture: Lifespan and Maintenance Tips

You may want to see also

Frequently asked questions

A standard 2 x 4 plank of wood is typically 8 feet long, which is equivalent to 96 inches or 2.44 meters.

While 8 feet is the most common length, 2 x 4 planks can also be found in other lengths, such as 10 feet, 12 feet, or 16 feet, depending on the supplier and intended use.

Despite being called a 2 x 4, the actual dimensions of a 2 x 4 plank are approximately 1.5 inches by 3.5 inches due to drying and planing during the milling process.

Yes, many lumber suppliers offer custom cutting services, allowing you to purchase 2 x 4 planks in specific lengths tailored to your project needs.