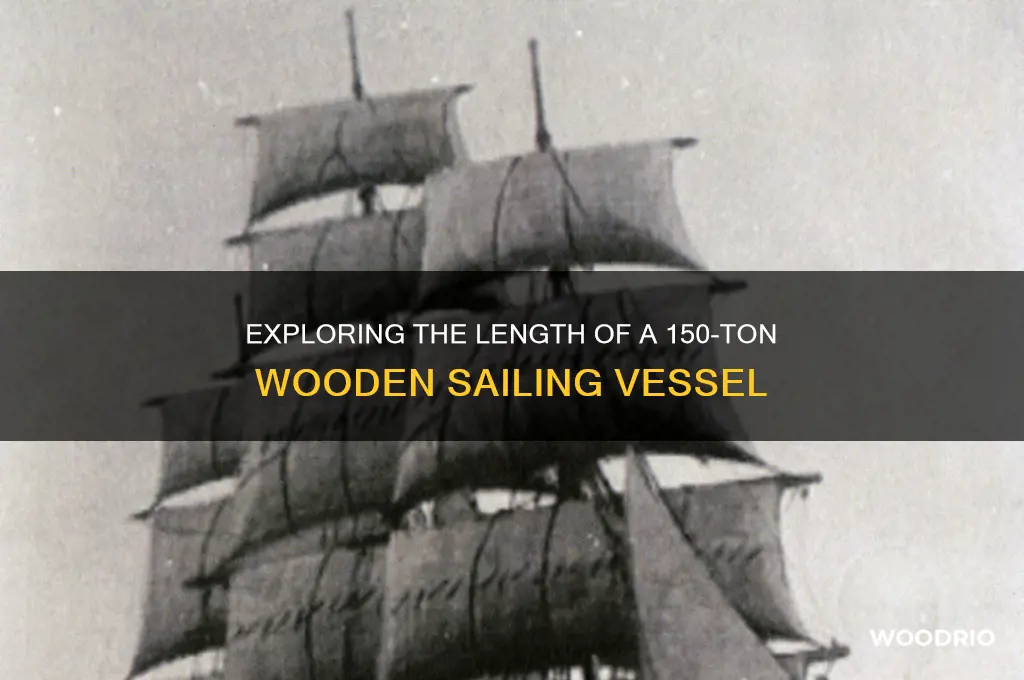

The length of a 150-ton wooden sailing vessel can vary significantly depending on its design, purpose, and historical era. Typically, such vessels from the 18th and 19th centuries, like merchant brigs or schooners, might range between 80 to 120 feet in length overall. For instance, a 150-ton brigantine could measure around 100 feet, while a more streamlined vessel might be slightly longer to optimize cargo capacity and sailing efficiency. Factors such as beam (width), draft (depth), and hull shape also influence size, as builders often balanced tonnage with maneuverability and stability. Modern replicas or custom-built wooden ships of this tonnage might adhere to similar dimensions, though advancements in design could allow for variations. Ultimately, the exact length would depend on the vessel's specific role, whether for trade, exploration, or leisure, and the craftsmanship of its construction.

Explore related products

What You'll Learn

Historical vessel size standards

The length of a 150-ton wooden sailing vessel varied significantly depending on its historical period, purpose, and design. In the 18th and 19th centuries, tonnage was often calculated using the Builder’s Old Measurement (BOM) system, which related cargo capacity to a vessel’s length, beam, and depth. For a 150-ton ship, this typically translated to a length of 70 to 90 feet, though merchant vessels might be shorter and bulkier, while naval ships could be longer and sleeker. For instance, a 150-ton brigantine from the early 19th century might measure around 80 feet in length, optimized for speed and maneuverability in trade routes.

Analyzing historical records reveals that vessel size standards were not uniform. Coastal trading vessels, designed for shallow waters and frequent docking, were often shorter and wider, while deep-sea ships prioritized length for stability and cargo capacity. A 150-ton coastal schooner might be as short as 65 feet, whereas a transatlantic trader could exceed 90 feet. These variations highlight the interplay between function, geography, and shipbuilding technology of the era.

To estimate the length of a 150-ton wooden vessel, consider its intended use. Fishing boats and coastal traders prioritized compactness, while warships and cargo vessels emphasized length for efficiency. For practical application, consult historical shipbuilding manuals or naval architecture texts from the period in question. For example, the *Treatise on Shipbuilding* by William Sutherland (1820) provides formulas linking tonnage to dimensions, offering a starting point for accurate reconstructions.

Comparatively, modern tonnage measurements (e.g., gross tonnage) focus on internal volume rather than cargo capacity, rendering historical estimates less intuitive. However, understanding the BOM system—where 1 ton equaled 100 cubic feet of cargo space—allows for more precise calculations. A 150-ton vessel under this system would have 15,000 cubic feet of cargo space, which, when paired with typical beam and depth ratios, narrows the estimated length to the 70–90 foot range.

In conclusion, determining the length of a 150-ton wooden sailing vessel requires contextualizing its historical period, purpose, and design principles. By studying specific examples and applying period-appropriate measurement systems, enthusiasts and historians can reconstruct these vessels with greater accuracy. Practical tips include referencing contemporary shipbuilding treatises and considering the vessel’s role—whether coastal trading, deep-sea exploration, or naval warfare—to refine length estimates.

Optimal Kiln Drying Time for Wood: A Comprehensive Guide

You may want to see also

Explore related products

$16.99

Wood type impact on length

The choice of wood significantly influences the length of a 150-ton wooden sailing vessel, as different woods offer varying strengths, weights, and durability. For instance, oak, a dense and robust hardwood, allows for shorter hulls due to its ability to withstand high structural stresses. In contrast, lighter woods like pine or cedar require longer hulls to distribute the same weight effectively, as they cannot support as much stress per unit length. This relationship between wood type and vessel length is critical in achieving both stability and efficiency at sea.

Consider the practical implications of wood selection. A 150-ton vessel built with oak might measure around 80–100 feet in length, while the same tonnage in pine could extend to 120–140 feet. This disparity arises because pine’s lower density necessitates a larger volume to achieve the same buoyancy and structural integrity. Builders must balance these factors, as longer vessels are more complex to maneuver and maintain, while shorter ones may compromise on cargo or passenger space.

From a persuasive standpoint, opting for denser woods like teak or mahogany can justify a higher initial investment. These woods not only reduce vessel length but also offer superior resistance to rot, saltwater damage, and insect infestation. Over time, the reduced maintenance costs and extended lifespan of the vessel can offset the higher material expenses. For long-term projects, prioritizing wood quality over immediate cost savings is a strategic decision.

Comparatively, modern composites and treated softwoods present alternatives to traditional hardwoods. While these materials can mimic the strength of denser woods, they often lack the natural resilience and aesthetic appeal of hardwoods. For purists or historical recreations, sticking to traditional woods like oak or cedar remains essential, even if it means accepting a longer vessel design. The choice ultimately hinges on the intended use, budget, and desired longevity of the sailing vessel.

Instructively, when planning a 150-ton wooden vessel, start by defining the wood type based on your priorities. If minimizing length is critical, select hardwoods like oak or teak. If cost is a primary concern, consider pine or fir, but account for the additional length and maintenance requirements. Always consult naval architects or experienced shipwrights to ensure the chosen wood aligns with the vessel’s intended purpose and environmental conditions. This proactive approach ensures both structural integrity and operational efficiency.

Ground Contact Wood Durability: Lifespan and Preservation Tips Explained

You may want to see also

Explore related products

Design vs. cargo capacity

The length of a 150-ton wooden sailing vessel is inherently tied to its design and cargo capacity, with historical examples like the 19th-century Baltic trader averaging 80–100 feet in length. These vessels prioritized beam (width) and depth to maximize cargo space while maintaining stability, often sacrificing speed for efficiency. A wider beam allowed for more hold volume, but increased length was necessary to balance sail area and reduce drag, illustrating the delicate trade-off between design and functionality.

Consider the design constraints: a vessel’s length-to-beam ratio directly impacts its cargo capacity and seaworthiness. For instance, a 150-ton ship with a 4:1 length-to-beam ratio (e.g., 100 feet long, 25 feet wide) could carry bulkier cargo but would require a deeper draft, limiting access to shallow ports. Conversely, a 5:1 ratio (e.g., 125 feet long, 25 feet wide) improves speed and maneuverability but reduces cargo space. Designers must weigh these factors, often using historical blueprints or modern naval architecture software to optimize hull shape and displacement.

Persuasively, prioritizing cargo capacity over sleek design can yield higher profitability for short-haul trade routes. A 150-ton vessel with a boxier hull and shorter length (e.g., 75 feet) could carry up to 120 tons of cargo, leaving 30 tons for ballast and provisions. However, this sacrifices open-water performance, making it unsuitable for long voyages. For shipbuilders, the decision hinges on intended use: a cargo-focused design maximizes revenue per trip, while a streamlined design suits luxury or expedition purposes.

Comparatively, modern replicas of 150-ton wooden vessels often prioritize aesthetics and passenger comfort over cargo capacity, reflecting their role in tourism or education. These ships may stretch to 120 feet to accommodate cabins, galleys, and decks while carrying minimal cargo. In contrast, historically accurate reconstructions adhere to original dimensions, balancing cargo space with sail efficiency. For enthusiasts, understanding this distinction helps in selecting the right vessel for restoration or commissioning.

Practically, when designing or restoring a 150-ton wooden sailing vessel, start by defining its primary purpose. For cargo-centric use, allocate 70–80% of hull volume to storage, ensuring a draft no deeper than 12 feet for versatility. Use lightweight yet durable woods like oak for the frame and pine for planking to reduce deadweight. For dual-purpose vessels, incorporate modular interiors to switch between cargo and passenger configurations. Always consult maritime regulations for safety and tonnage compliance, as overloading can compromise structural integrity.

Rubber Cement Drying Time on Wood: Quick Guide for Crafters

You may want to see also

Explore related products

$15.39 $16.99

Modern vs. traditional dimensions

The length of a 150-ton wooden sailing vessel varies significantly between modern and traditional designs, reflecting shifts in purpose, materials, and technology. Traditional vessels, often built for cargo or exploration, prioritized beam (width) and depth for stability and storage, resulting in shorter lengths relative to tonnage. For instance, a 19th-century brigantine might measure 80–100 feet, with a beam of 20–25 feet, to accommodate bulk cargo while maintaining seaworthiness. In contrast, modern wooden sailing vessels, designed for leisure or racing, emphasize length-to-beam ratios for speed and efficiency. A contemporary 150-ton wooden yacht could stretch to 120–150 feet, with a narrower beam of 15–20 feet, optimized for hydrodynamics and reduced drag.

Analyzing these dimensions reveals trade-offs between functionality and performance. Traditional designs sacrificed speed for cargo capacity, with shorter hulls and fuller forms that provided buoyancy under heavy loads. Modern vessels, however, leverage advanced naval architecture and lightweight woods (e.g., teak or cedar) to achieve longer waterlines, reducing wave resistance and increasing speed. For example, a modern 150-foot wooden sloop might displace the same tonnage as a 100-foot traditional schooner but sail 30–40% faster under comparable conditions. This evolution underscores how technological advancements have redefined the relationship between size, weight, and efficiency in wooden shipbuilding.

Instructively, builders and designers must consider the intended use when determining dimensions. For a traditional replica or cargo vessel, prioritize a shorter length with greater beam to ensure stability and storage. Use historical blueprints or consult maritime archives for accurate proportions. For modern applications, such as luxury cruising or racing, invest in computational fluid dynamics (CFD) modeling to optimize hull shape and length. Incorporate features like bulb keels or twin rudders to enhance performance without compromising structural integrity. Always balance aesthetics with practicality, as overly elongated designs can introduce challenges in maneuverability and maintenance.

Persuasively, the choice between modern and traditional dimensions is not merely technical but philosophical. Traditional designs evoke a sense of heritage and craftsmanship, appealing to purists and historians. Modern dimensions, however, cater to contemporary demands for speed, comfort, and innovation. For instance, a 150-ton wooden vessel built to traditional specifications might become a floating museum or educational tool, while its modern counterpart could dominate regattas or offer opulent charter experiences. Ultimately, the decision hinges on whether one values nostalgia or progress, each approach offering distinct rewards and challenges.

Comparatively, the materials and construction techniques further differentiate modern and traditional vessels. Traditional wooden ships relied on heavy timbers, often oak or pine, joined with trunnels and caulked seams, contributing to their shorter, sturdier profiles. Modern wooden vessels, however, utilize epoxy resins, laminated woods, and composite reinforcements to achieve longer, sleeker forms without sacrificing strength. For example, a 150-ton modern wooden catamaran might feature a balsa or foam core sandwiched between thin wood layers, reducing weight while maintaining rigidity. This innovation allows for greater length and complexity in design, bridging the gap between tradition and modernity in wooden shipbuilding.

Understanding Wood's Durability: How It Withstands Stress Over Time

You may want to see also

Explore related products

Comparative analysis with steel ships

Wooden sailing vessels, particularly those in the 150-ton range, historically averaged between 80 to 120 feet in length, depending on design and purpose. These dimensions reflect the balance between cargo capacity, maneuverability, and the structural limitations of wood. When comparing wooden ships to their steel counterparts, several key factors emerge, including material strength, durability, and maintenance requirements. Steel ships, introduced in the mid-19th century, revolutionized maritime construction by offering greater structural integrity and longevity, but at the cost of increased weight and complexity.

From an analytical perspective, the length of a 150-ton wooden vessel is constrained by the natural properties of wood. Wood, while flexible and lightweight, is prone to rot, warping, and damage from marine borers. Steel, on the other hand, can support larger and longer structures without the same risk of degradation. For instance, a 150-ton steel vessel might measure 100 to 150 feet in length, benefiting from steel’s higher tensile strength and resistance to environmental factors. This comparison highlights how material choice directly influences vessel size and lifespan.

Instructively, builders of wooden ships must prioritize regular maintenance to counteract wood’s vulnerabilities. This includes caulking seams, applying protective coatings, and replacing damaged planks—tasks that are less frequent and less labor-intensive on steel ships. For those restoring or maintaining a 150-ton wooden vessel, allocate at least 20% of your annual budget to preservation efforts, focusing on areas like the hull and deck. Steel ships, while requiring less frequent maintenance, demand specialized skills for tasks like welding and corrosion prevention.

Persuasively, wooden vessels retain a unique appeal despite their maintenance demands. Their aesthetic and historical value often outweigh the practical advantages of steel. For enthusiasts or operators, investing in a wooden ship is as much about preserving maritime heritage as it is about functionality. However, for commercial or long-term use, steel ships offer undeniable benefits in terms of durability and scalability. A 150-ton wooden vessel might be ideal for short-haul coastal trade or tourism, while a steel counterpart would be better suited for extended voyages or heavy cargo.

Comparatively, the lifespan of a wooden vessel is typically 20 to 30 years with diligent care, whereas a steel ship can last 50 years or more. This disparity underscores the trade-offs between tradition and modernity. For operators, the choice between wood and steel should consider not only the vessel’s intended use but also the resources available for maintenance. A 150-ton wooden sailing vessel, while shorter in length and lifespan than its steel equivalent, offers a timeless connection to maritime history that steel cannot replicate.

How Long Does Mopany Wood Float? Unveiling Its Buoyancy Secrets

You may want to see also

Frequently asked questions

A 150-ton wooden sailing vessel typically ranges between 80 to 120 feet (24 to 37 meters) in length, depending on its design and purpose.

No, tonnage measures cargo capacity or volume, not length. However, larger tonnage often correlates with a longer vessel, though design and hull shape also play significant roles.

Factors include the vessel's purpose (e.g., cargo, passenger, or leisure), hull design, beam (width), and historical period, as older designs may differ from modern ones.

Yes, historical 150-ton vessels like small merchant ships or fishing boats often ranged from 90 to 110 feet (27 to 34 meters), though this varies based on regional construction styles and era.