The duration wood needs to be in a kiln depends on several factors, including the wood species, initial moisture content, desired final moisture content, and the kiln’s efficiency. Softwoods like pine typically dry faster, often requiring 2 to 4 weeks, while hardwoods such as oak or maple may need 4 to 8 weeks or more due to their denser structure. Kiln drying is a controlled process that removes moisture to prevent warping, cracking, and decay, ensuring the wood is suitable for construction, furniture, or other applications. Proper drying time is crucial to achieve the ideal moisture level, usually around 6% to 8% for indoor use, balancing speed with quality to maintain the wood’s integrity.

| Characteristics | Values |

|---|---|

| Kiln Drying Time for Softwoods | 2-4 weeks (varies based on thickness and moisture content) |

| Kiln Drying Time for Hardwoods | 4-8 weeks (varies based on thickness and moisture content) |

| Optimal Moisture Content Goal | 6-8% for indoor use; 12-15% for outdoor use |

| Temperature Range in Kiln | 120°F to 200°F (49°C to 93°C) |

| Relative Humidity in Kiln | Gradually reduced from 90% to 30% |

| Thickness of Wood | Thicker wood requires longer drying time (e.g., 4/4" vs. 8/4") |

| Initial Moisture Content | Higher initial moisture content increases drying time |

| Kiln Type | Conventional kilns: longer time; Dehumidification kilns: shorter time |

| Airflow in Kiln | Consistent airflow is critical for even drying |

| Post-Kiln Conditioning Time | 1-2 weeks to stabilize moisture content after kiln drying |

| Species-Specific Variations | Dense hardwoods (e.g., oak) take longer than softwoods (e.g., pine) |

| Environmental Factors | Humidity and temperature outside the kiln can affect drying time |

Explore related products

What You'll Learn

- Optimal Drying Time: Factors like wood type, thickness, and moisture content determine ideal kiln duration

- Kiln Temperature Settings: Lower temps dry slower but reduce cracking; higher temps speed drying but risk damage

- Moisture Content Goals: Target 6-8% moisture for indoor use; 12-15% for outdoor applications

- Wood Species Variations: Hardwoods take longer (3-6 weeks) than softwoods (1-3 weeks) to dry fully

- Kiln Scheduling: Pre-drying, equalization, and final drying phases ensure uniform moisture removal

Optimal Drying Time: Factors like wood type, thickness, and moisture content determine ideal kiln duration

The drying time of wood in a kiln is not a one-size-fits-all process. A 4/4 hardwood board (1 inch thick) might require 4-6 weeks in a kiln, while a thicker 8/4 board (2 inches) could need 8-12 weeks. These estimates, however, are just starting points. The optimal duration hinges on a delicate interplay of factors unique to each piece of wood.

Wood Type: Different species have inherent variations in density and cellular structure, directly impacting drying speed. Dense hardwoods like oak or maple dry slower than softer woods like pine. For instance, kiln-drying 1-inch thick oak might take twice as long as the same thickness of pine.

Thickness: Thicker wood requires more time for moisture to migrate from the core to the surface. Imagine a sponge – the thicker it is, the longer it takes to dry completely. A 2-inch thick board will need significantly more kiln time than a 1-inch board of the same species.

Moisture Content: The initial moisture content of the wood is crucial. Freshly cut wood, known as green wood, can have moisture contents exceeding 100%. Kiln drying aims to reduce this to a stable level, typically around 6-8% for furniture and 12-15% for construction. Wood with higher initial moisture content will require a longer kiln stay.

Practical Considerations: Kiln operators use moisture meters to monitor progress, aiming for a uniform moisture content throughout the wood. A schedule, often starting at higher temperatures and gradually decreasing, is employed to prevent cracking and warping.

Understanding these factors allows for precise control over the drying process, ensuring the wood reaches its optimal moisture content for its intended use. This precision not only enhances the wood's stability and durability but also minimizes the risk of defects, ultimately leading to a higher-quality end product.

Durability Unveiled: Understanding the Lifespan of Wooden Sheds

You may want to see also

Explore related products

Kiln Temperature Settings: Lower temps dry slower but reduce cracking; higher temps speed drying but risk damage

The delicate dance of kiln drying wood hinges on temperature control. Lower temperatures, typically ranging from 100°F to 140°F (38°C to 60°C), act as a gentle nudge, coaxing moisture from the wood fibers at a leisurely pace. This method, while time-consuming, significantly reduces the risk of cracks, splits, and warping, making it ideal for delicate or high-value wood species like walnut, cherry, or mahogany. Imagine a spa day for your lumber, where patience yields pristine results.

Drying times at these lower temperatures can extend from several weeks to several months, depending on wood thickness and initial moisture content. For instance, a 1-inch thick board might take 4-6 weeks, while a 2-inch slab could require 8-12 weeks. This extended timeframe demands careful monitoring and a commitment to the process, but the reward is wood that retains its structural integrity and aesthetic appeal.

Conversely, higher temperatures, ranging from 160°F to 200°F (71°C to 93°C), accelerate the drying process, slashing timelines to days or weeks. This approach is tempting for commercial operations or projects with tight deadlines. However, the increased heat acts like a double-edged sword, heightening the risk of internal stresses, checks, and honeycombing. Think of it as a sprint versus a marathon – faster results come with a higher chance of injury.

Higher temperatures are best suited for less valuable or more resilient wood species like pine, fir, or spruce, which can withstand the thermal stress. Even then, careful monitoring and gradual temperature increases are crucial to mitigate damage. A sudden spike in heat can be catastrophic, akin to throwing a delicate plant into a scorching desert.

The sweet spot lies in finding the optimal temperature range for each wood species and project requirement. This often involves a staged drying process, starting at lower temperatures to gently remove surface moisture, then gradually increasing heat to accelerate the drying of the wood’s core. This hybrid approach balances speed and safety, minimizing the risk of defects while achieving acceptable drying times.

Ultimately, kiln temperature settings are a delicate balancing act, requiring a deep understanding of wood properties, project demands, and the drying process itself. By carefully considering the trade-offs between speed and quality, woodworkers can harness the power of kilns to transform raw lumber into a stable, beautiful, and functional material.

Straightening Warped Wood: Timeframe and Effective Techniques Explained

You may want to see also

Explore related products

$69.99

Moisture Content Goals: Target 6-8% moisture for indoor use; 12-15% for outdoor applications

Wood's moisture content is a critical factor in its durability, stability, and suitability for specific applications. For indoor use, the target moisture content should be 6-8%, ensuring the wood is dry enough to prevent warping, cracking, or mold growth in controlled environments. This range is particularly important for furniture, flooring, and cabinetry, where dimensional stability is essential. Achieving this level typically requires kiln drying for 2-4 weeks, depending on the wood species and initial moisture content. Softwoods like pine may dry faster than hardwoods like oak, which have denser fibers that retain moisture longer.

For outdoor applications, a higher moisture content of 12-15% is ideal. This range allows the wood to better withstand environmental fluctuations, such as rain and humidity, without excessive swelling or shrinkage. Outdoor structures like decks, fences, and siding benefit from this slightly higher moisture level, as it provides a buffer against the elements. Kiln drying for outdoor wood usually takes 1-3 weeks, with the process adjusted to retain enough moisture for resilience. For example, cedar, a popular outdoor wood, is often dried to this range to enhance its natural resistance to decay and insects.

The drying time in a kiln is not one-size-fits-all; it depends on factors like wood thickness, species, and initial moisture content. Thicker boards require longer drying times, as moisture migrates more slowly through denser material. A 1-inch thick board might reach 6-8% moisture in 2 weeks, while a 2-inch board could take 4-6 weeks. Monitoring moisture levels with a kiln-integrated meter ensures precision, preventing overdrying, which can make wood brittle, or underdrying, which risks future issues.

Practical tips for achieving these moisture goals include pre-drying wood in a well-ventilated area before kiln use to reduce initial moisture content and using a dehumidification system within the kiln to maintain optimal conditions. For outdoor wood, consider a final conditioning phase where the wood is exposed to ambient humidity to stabilize at 12-15%. This two-step approach ensures the wood is ready for its intended use without compromising quality.

In summary, moisture content goals of 6-8% for indoor use and 12-15% for outdoor applications are achievable through precise kiln drying. Tailoring the drying process to the wood’s characteristics and intended use ensures longevity and performance. Whether crafting indoor furniture or building outdoor structures, understanding and controlling moisture content is key to successful woodworking.

2004 Pressure Treated Wood Lifespan: Durability and Maintenance Tips

You may want to see also

Explore related products

Wood Species Variations: Hardwoods take longer (3-6 weeks) than softwoods (1-3 weeks) to dry fully

The drying time of wood in a kiln is not a one-size-fits-all process. A critical factor dictating this duration is the wood species, with hardwoods and softwoods exhibiting distinct behaviors. Hardwoods, known for their denser cellular structure, require a more extended stay in the kiln, typically ranging from 3 to 6 weeks. This prolonged period is essential to ensure the wood's moisture content is adequately reduced, preventing future warping, cracking, or decay. In contrast, softwoods, with their less dense composition, dry more rapidly, often needing only 1 to 3 weeks to reach optimal moisture levels.

Consider the practical implications of this variation. For instance, if you're a furniture maker planning to craft a dining table from oak (a hardwood), you must account for a minimum of 3 weeks of kiln drying time. This forethought is crucial to avoid delays in your project timeline. Conversely, if you're constructing a pine (softwood) bookshelf, the shorter drying period allows for quicker turnaround, enabling you to meet tighter deadlines. Understanding these species-specific drying times empowers woodworkers to make informed decisions, ensuring both the quality and efficiency of their craft.

The science behind these differences lies in the wood's cellular structure. Hardwoods possess smaller, more numerous cells with thicker cell walls, which impede the escape of moisture. Softwoods, on the other hand, have larger, less dense cells with thinner walls, facilitating faster moisture evaporation. Kiln operators must carefully monitor temperature and humidity levels, adjusting them according to the wood species to prevent overheating or under-drying. For hardwoods, a gradual increase in temperature is recommended, starting at 100°F and peaking at 140°F, while softwoods can tolerate a more rapid temperature rise.

A comparative analysis reveals the economic implications of these drying times. The longer kiln duration for hardwoods translates to higher energy costs, which are often reflected in the final price of hardwood products. Softwoods, with their quicker drying process, offer a more cost-effective option for certain applications. However, the choice between hardwood and softwood should not be solely based on drying time or cost. Factors such as durability, aesthetic appeal, and intended use must also be considered to ensure the best material selection for each project.

In practice, woodworkers can optimize the kiln drying process by sorting wood by species and thickness before loading. This segregation allows for more precise control over drying conditions, minimizing the risk of defects. For mixed loads containing both hardwoods and softwoods, a staged drying approach can be employed. Softwoods can be removed after 1-3 weeks, while hardwoods continue to dry for the remaining 3-6 weeks. This method maximizes kiln efficiency and reduces overall processing time. By tailoring the drying process to the unique characteristics of each wood species, craftsmen can achieve superior results, ensuring the longevity and beauty of their wooden creations.

When Does Pressure Treated Wood Stop Shrinking? A Timeline Guide

You may want to see also

Explore related products

$32.62 $35

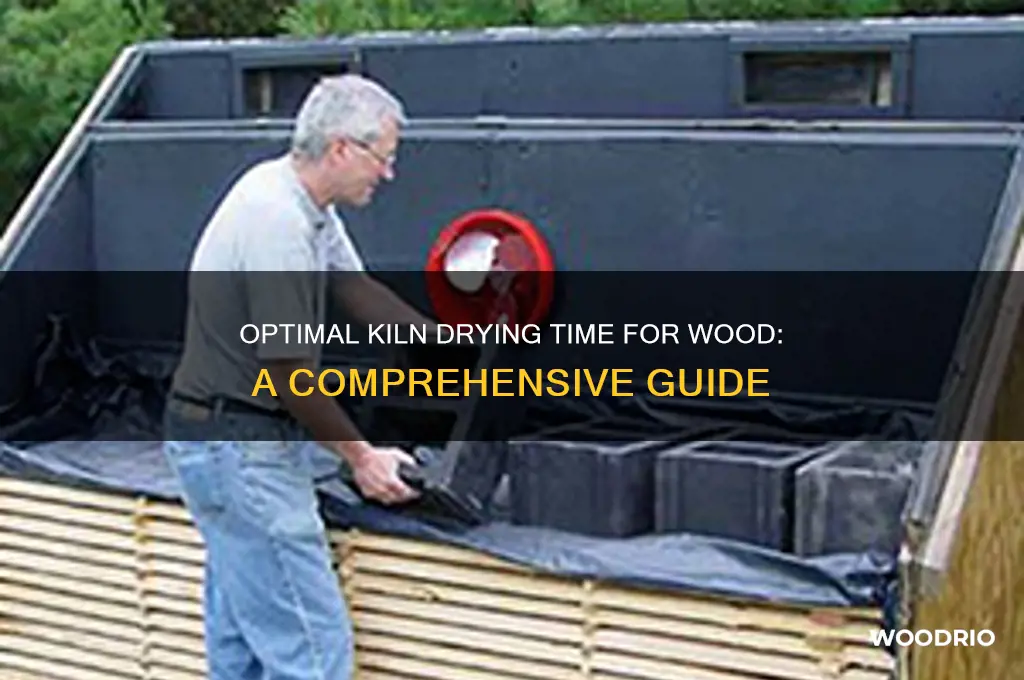

Kiln Scheduling: Pre-drying, equalization, and final drying phases ensure uniform moisture removal

The duration wood spends in a kiln is not a one-size-fits-all answer. It's a carefully orchestrated dance of moisture removal, dictated by the wood species, initial moisture content, and desired final moisture content. Kiln scheduling, the strategic manipulation of temperature and humidity, is the conductor of this dance, ensuring uniform drying and minimizing defects.

Key to this process are three distinct phases: pre-drying, equalization, and final drying.

Pre-drying: Imagine a marathon runner stretching before a race. Pre-drying is the wood's warm-up, gently removing surface moisture at lower temperatures (around 100-120°F) and higher humidity. This initial phase, lasting 2-5 days, prevents surface checking and splitting by allowing the wood to acclimate to the drying environment. Think of it as easing the wood into the drying process, preventing shock and potential damage.

For hardwoods like oak or maple, pre-drying might involve a slightly longer duration (3-5 days) compared to softer woods like pine (2-3 days).

Equalization: This phase is the balancing act. After the initial moisture removal, the wood's interior moisture content is higher than the surface. Equalization, typically lasting 3-7 days, involves slightly higher temperatures (120-140°F) and controlled humidity to allow moisture to migrate from the core to the surface. This ensures uniform drying throughout the wood, preventing warping and internal stresses. Picture it as a team effort, where the wood's cells work together to achieve moisture equilibrium.

Final Drying: Now the race intensifies. The final drying phase employs higher temperatures (140-160°F) and lower humidity to rapidly remove the remaining moisture. This stage, lasting 5-10 days or more, demands careful monitoring to prevent over-drying, which can lead to brittleness and cracking. Think of it as the final sprint, requiring precision and control to reach the finish line – the desired moisture content – without overexertion.

For furniture-grade lumber, a final moisture content of 6-8% is ideal, while structural timber might aim for 12-15%.

Practical Tips:

- Moisture Meter: Invest in a reliable moisture meter to monitor progress throughout the drying process.

- Kiln Charts: Utilize kiln drying schedules specific to your wood species and desired moisture content. These charts provide temperature and humidity guidelines for each phase.

- Airflow: Ensure adequate airflow within the kiln to promote even drying and prevent moisture pockets.

- Patience is Key: Rushing the drying process can lead to disastrous results. Allow each phase sufficient time for optimal results.

Remember, kiln drying is a science and an art. By understanding the principles of pre-drying, equalization, and final drying, and by employing careful monitoring and control, you can transform raw lumber into a stable, high-quality material ready for its intended purpose.

Ickey Woods' NFL Career: Duration and Legacy Explored

You may want to see also

Frequently asked questions

The drying time in a kiln varies depending on wood species, thickness, and moisture content, but it typically ranges from 2 to 14 days.

Yes, thinner wood pieces dry faster and may only require 2 to 4 days in a kiln, while thicker pieces can take up to 2 weeks.

Yes, denser hardwoods like oak or maple take longer to dry (up to 14 days), while softer woods like pine dry more quickly (2 to 6 days).

Yes, over-drying can cause wood to become brittle or cracked. Proper monitoring and moisture content targets (typically 6-8%) are essential.

Higher humidity levels outside the kiln can slow the drying process, potentially extending the time wood needs to remain in the kiln.