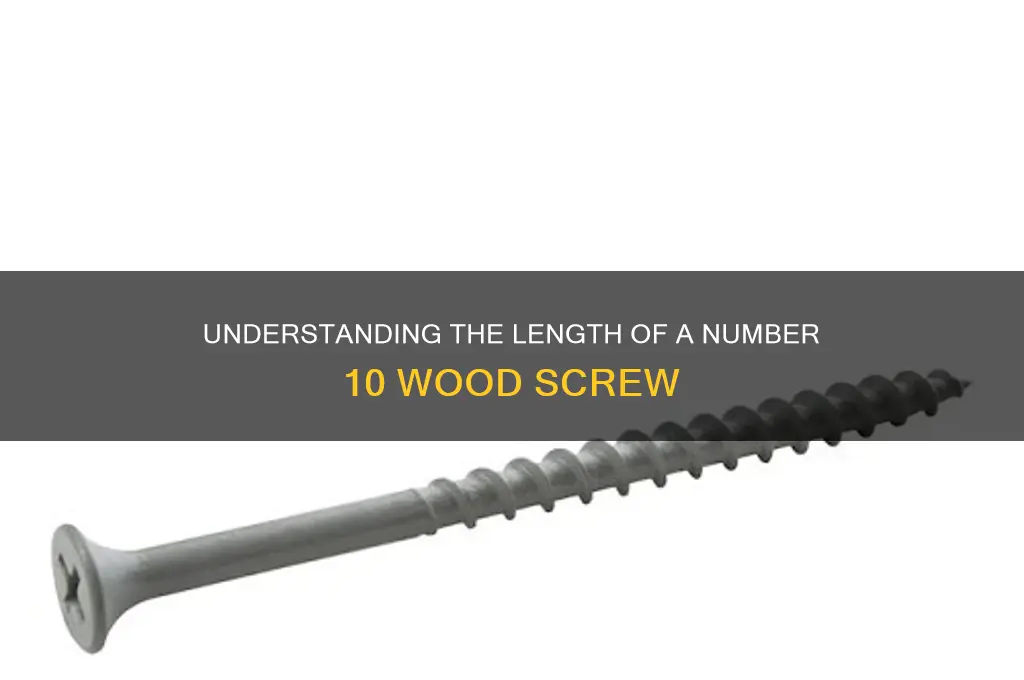

The length of a number 10 wood screw is a common question in construction and DIY projects, as it directly impacts the screw's holding power and suitability for specific materials. A number 10 wood screw typically refers to its gauge, which measures the screw's diameter, but the length can vary widely depending on the application. Standard lengths for a number 10 wood screw range from 1/2 inch to 4 inches, with the most common sizes being 1 inch, 1.5 inches, and 2 inches. The appropriate length depends on factors such as the thickness of the wood being joined, the need for additional support, and the overall structural requirements of the project. Understanding these variations ensures the correct screw is selected for optimal performance and durability.

Explore related products

What You'll Learn

- Standard Lengths: Common sizes range from 1 to 4 inches, depending on application needs

- Diameter Measurement: Shaft diameter is #10, approximately 0.190 inches or 3/16 inch

- Thread Type: Coarse or fine threads affect grip and material compatibility

- Material Considerations: Steel, stainless steel, or brass impact durability and corrosion resistance

- Head Styles: Flat, round, or oval heads determine screw visibility and finish

Standard Lengths: Common sizes range from 1 to 4 inches, depending on application needs

A number 10 wood screw is a versatile fastener, but its length is not one-size-fits-all. Standard lengths for this gauge typically fall between 1 and 4 inches, a range that accommodates a variety of woodworking and construction tasks. This spectrum allows for precise selection based on the thickness of the materials being joined and the structural requirements of the project. For instance, a 1-inch screw might be ideal for attaching thin trim or molding, while a 4-inch screw could be necessary for securing heavy structural elements like beams or posts.

When selecting a screw length, consider the combined thickness of the materials being fastened and the depth required to achieve adequate thread engagement. A general rule of thumb is to ensure the screw penetrates at least half its length into the base material. For example, a 2.5-inch screw should engage at least 1.25 inches into the wood to provide sufficient holding power. This principle ensures the screw performs its intended function without compromising the integrity of the joint.

The application itself often dictates the appropriate length. In cabinetry, shorter screws (1 to 1.5 inches) are commonly used to avoid protruding through the material or damaging internal components. Conversely, outdoor decking or framing projects may require longer screws (3 to 4 inches) to withstand environmental stresses and provide robust connections. Always match the screw length to the specific demands of the task to avoid failures such as pull-out or material splitting.

Practical tips can further refine your selection. For softwoods, a slightly longer screw may be necessary to achieve proper thread engagement compared to hardwoods, which provide more resistance. Additionally, pre-drilling pilot holes is often recommended, especially for longer screws or harder materials, to prevent wood splitting and ensure a clean, secure fit. By understanding the interplay between screw length, material thickness, and application requirements, you can make informed choices that enhance both the durability and aesthetics of your project.

Wood Storks' Ancient Origins: Unveiling Their Remarkable Evolutionary Journey

You may want to see also

Explore related products

$18.04 $18.99

Diameter Measurement: Shaft diameter is #10, approximately 0.190 inches or 3/16 inch

The shaft diameter of a #10 wood screw, approximately 0.190 inches or 3/16 inch, is a critical specification for ensuring proper fit and structural integrity in woodworking projects. This measurement refers to the thickness of the screw’s threaded shaft, excluding the head. Understanding this dimension is essential because it directly impacts the screw’s holding power and compatibility with pre-drilled holes. For instance, a #10 screw’s diameter is larger than that of a #8 screw (0.164 inches) but smaller than a #12 screw (0.216 inches), making it a versatile middle-ground option for medium-duty applications.

When selecting a #10 wood screw, consider the material you’re fastening. Softer woods like pine may not require pre-drilling, but harder woods such as oak or maple often do to prevent splitting. The 0.190-inch diameter ensures sufficient thread engagement without excessive force, reducing the risk of damage to the workpiece. For optimal results, use a drill bit slightly smaller than the shaft diameter—a #7 or 5/32-inch bit works well—to create a snug fit that maximizes holding strength.

Comparatively, the #10 diameter strikes a balance between strength and practicality. While larger screws offer greater load-bearing capacity, they may be overkill for lighter tasks and can cause unnecessary material stress. Conversely, smaller screws might not provide adequate grip. The #10’s 3/16-inch diameter is particularly useful in applications like cabinetmaking, furniture assembly, or securing trim, where durability and precision are key.

To illustrate, imagine attaching a bookshelf bracket to a wooden frame. A #10 screw with its 0.190-inch diameter provides enough bite to support the weight of books without compromising the wood’s integrity. Pairing this screw with a pilot hole ensures smooth installation and reduces the likelihood of the wood cracking under pressure. Always test in a scrap piece of the same material to confirm compatibility before committing to your project.

In summary, the #10 wood screw’s shaft diameter of approximately 0.190 inches or 3/16 inch is a versatile and reliable choice for woodworking. By understanding this measurement and its implications, you can make informed decisions that enhance both the functionality and longevity of your projects. Whether you’re a hobbyist or a professional, mastering this detail ensures your work stands the test of time.

Cedar Wood Cladding Durability: Lifespan, Maintenance, and Longevity Explained

You may want to see also

Explore related products

Thread Type: Coarse or fine threads affect grip and material compatibility

The thread type of a screw—whether coarse or fine—plays a pivotal role in determining its grip strength and compatibility with different materials. Coarse threads, characterized by fewer threads per inch, provide a stronger initial grip and are ideal for softer woods like pine or cedar. Fine threads, with more threads per inch, offer superior holding power in harder materials such as oak or maple, but require more torque to drive in. Understanding this distinction ensures the screw performs optimally in its intended application.

For instance, a number 10 wood screw with coarse threads (typically 16 threads per inch) is better suited for fastening two pieces of softwood together, where the threads can bite into the material without splitting it. In contrast, fine threads (around 24 threads per inch) are recommended for hardwoods or materials like MDF, where the increased thread count provides a tighter hold without compromising the material’s integrity. Always match the thread type to the material density for maximum efficiency.

When selecting between coarse and fine threads, consider the load-bearing requirements of your project. Coarse threads excel in applications where quick assembly and disassembly are needed, such as framing or temporary structures. Fine threads, however, are preferable for projects requiring precision and long-term stability, like cabinetry or furniture making. The choice directly impacts the screw’s ability to withstand shear and tensile forces over time.

Practical tip: Test the screw in a scrap piece of the material you’re using to ensure compatibility. If the screw drives in smoothly without splitting the wood and holds firmly under pressure, you’ve chosen the correct thread type. If the wood splits or the screw feels loose, switch to the alternative thread pattern. This simple step can prevent costly mistakes and ensure a professional finish.

In summary, the thread type of a number 10 wood screw is not a one-size-fits-all decision. Coarse threads offer robust grip in soft materials, while fine threads provide precision and strength in harder substrates. By aligning the thread type with the material and project demands, you can achieve both structural integrity and longevity in your woodworking endeavors.

How Long Do Essential Oils Scent Wood Surfaces?

You may want to see also

Explore related products

Material Considerations: Steel, stainless steel, or brass impact durability and corrosion resistance

The material of a number 10 wood screw significantly influences its performance, particularly in terms of durability and corrosion resistance. Steel, stainless steel, and brass are the most common options, each with distinct properties that cater to different environmental conditions and applications. Understanding these differences ensures the screw’s longevity and reliability in its intended use.

Analytical Perspective:

Steel screws are the most cost-effective and widely used option, offering high tensile strength ideal for structural applications. However, they are prone to rust in humid or outdoor environments unless coated with zinc or another protective layer. Stainless steel screws, on the other hand, provide superior corrosion resistance due to their chromium content, making them suitable for marine or high-moisture settings. Brass screws, while less strong than steel, excel in aesthetic applications and resist corrosion well in moderate conditions, though they are softer and more prone to stripping.

Instructive Approach:

When selecting a material, consider the environment first. For indoor, dry projects where strength is paramount, opt for hardened steel screws. If the project will be exposed to moisture or saltwater, stainless steel is the best choice to prevent rust and maintain structural integrity. Brass screws are ideal for decorative purposes or low-stress applications where their unique finish adds visual appeal. Always inspect coatings on steel screws for completeness, as even small defects can lead to premature corrosion.

Comparative Analysis:

While steel screws offer the highest strength-to-cost ratio, their susceptibility to corrosion limits their use in harsh conditions. Stainless steel screws, though more expensive, provide unmatched durability in corrosive environments, making them a long-term investment. Brass screws, despite their lower strength, are valued for their corrosion resistance and malleability, which reduces the risk of wood splitting during installation. Each material’s advantages and limitations dictate its suitability for specific tasks.

Practical Tips:

For outdoor furniture or decking, stainless steel screws are recommended to withstand weather exposure. In coastal areas, use marine-grade stainless steel to combat saltwater corrosion. For interior cabinetry or trim work, brass screws offer a polished look without compromising on moderate corrosion resistance. Always pre-drill pilot holes when using brass screws to prevent thread damage due to their softer nature. Regularly inspect steel screws in outdoor applications and replace them if signs of rust appear, even with protective coatings.

By carefully matching the material of a number 10 wood screw to the demands of its environment, you can ensure optimal performance and extend the life of your project.

Preserving Tomatoes with Wood Ash: Duration and Best Practices

You may want to see also

Explore related products

$16.99 $17.99

Head Styles: Flat, round, or oval heads determine screw visibility and finish

Flat, round, and oval heads are more than just aesthetic choices for screws—they directly impact how visible and integrated the fastener appears in your project. Flat heads, also known as countersunk heads, are designed to sit flush with or below the surface of the wood. This style is ideal for applications where a smooth, unobtrusive finish is desired, such as in fine woodworking or furniture making. When using a flat-head screw, pre-drill a countersink hole to ensure the head sits perfectly level, avoiding any surface protrusion.

Round heads, in contrast, stand proud of the surface, creating a visible and often decorative element. This style is commonly used in applications where the screw needs to be easily accessible for removal or adjustment, such as in cabinetry or outdoor furniture. While round heads may not offer the same seamless finish as flat heads, they can add a rustic or industrial aesthetic to a project. For best results, pair round-head screws with materials that benefit from a more pronounced fastener appearance.

Oval heads strike a balance between flat and round styles, offering a slightly raised but smooth profile. This head style is often used in applications where a flat head might be too flush but a round head too prominent. Oval heads are particularly useful in projects where both aesthetics and functionality are important, such as in trim work or decorative paneling. When selecting oval-head screws, consider the surrounding material and lighting conditions, as their subtle elevation can catch light in ways that enhance or detract from the overall finish.

Choosing the right head style depends on the project’s requirements and desired outcome. For hidden fastening, flat heads are unmatched. For accessibility and a bold look, round heads excel. For a middle ground that combines subtlety with presence, oval heads are the way to go. Always consider the wood type and grain direction when driving screws, as these factors influence how the head sits and performs over time. By matching the head style to the project’s needs, you ensure both structural integrity and visual appeal.

Quick Heat-Up Times: Wood Pellet Grills' Warm-Up Duration Explained

You may want to see also

Frequently asked questions

A number 10 wood screw typically refers to the gauge or diameter of the screw, not its length. The length of a number 10 wood screw can vary, commonly ranging from 1 inch to 4 inches, depending on the specific application.

"Number 10" refers to the gauge or diameter of the wood screw. In the U.S. standard system, a #10 screw has a diameter of approximately 0.190 inches (3/16 inch). The length is separate from the gauge and is specified independently.

To choose the correct length for a number 10 wood screw, ensure the screw is long enough to penetrate the material being fastened by at least half its length, but not so long that it protrudes through the other side. For example, for a 1-inch thick board, a 1.5-inch to 2-inch screw would be appropriate.