The length of a plank of wood can vary significantly depending on its intended use, the type of wood, and regional standards. Commonly, planks are available in standard lengths such as 8, 10, 12, or 16 feet, though custom lengths can be cut to meet specific project requirements. In construction and woodworking, longer planks are often preferred for structural integrity and aesthetic continuity, while shorter lengths may be more practical for smaller projects or detailed work. Understanding the standard and customizable lengths of wood planks is essential for planning and executing projects efficiently, ensuring minimal waste and optimal material usage.

Explore related products

What You'll Learn

- Standard plank lengths: Common sizes for planks in construction and woodworking

- Custom plank sizing: How to measure and cut planks to specific lengths

- Plank length variations: Differences in length based on wood type and purpose

- Plank length in projects: Determining ideal plank length for furniture or structures

- Measuring plank length: Tools and techniques for accurately measuring wood planks

Standard plank lengths: Common sizes for planks in construction and woodworking

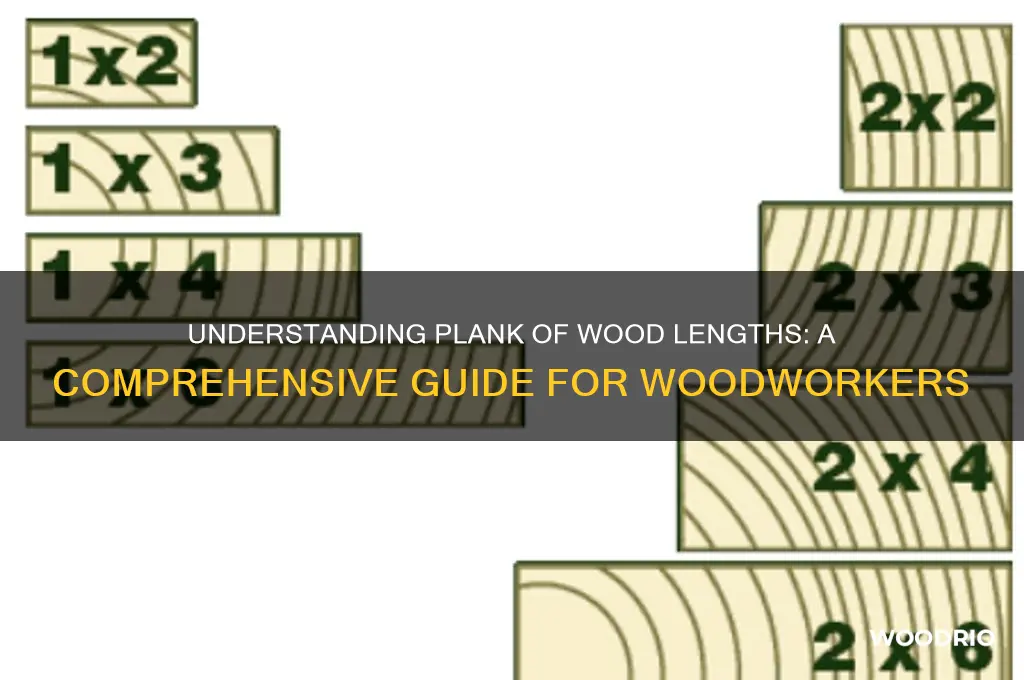

Plank lengths in construction and woodworking are not arbitrary; they are standardized to ensure efficiency, compatibility, and ease of use. Common plank lengths typically range from 8 to 20 feet, with 8, 10, 12, and 16 feet being the most prevalent. These lengths are chosen because they align with the dimensions of building materials, transportation constraints, and structural requirements. For instance, an 8-foot plank is ideal for shelving or framing, while a 16-footer is often used for flooring or roofing, where longer spans are needed. Understanding these standard lengths is essential for minimizing waste and maximizing material utility in any project.

In woodworking, the choice of plank length often depends on the project’s scale and design. Shorter planks, such as those measuring 4 to 6 feet, are commonly used for furniture making, where precision and manageability are key. Longer planks, ranging from 12 to 20 feet, are more suitable for structural applications like decking or wall framing. It’s important to note that while these lengths are standard, custom lengths can be ordered for specialized projects. However, opting for standard sizes is generally more cost-effective due to their widespread availability and reduced cutting requirements.

Transportation and storage are critical factors influencing plank lengths. Most lumberyards and hardware stores stock planks in lengths that fit standard truck beds or storage racks, typically up to 16 feet. Longer planks, such as 20-footers, are less common and may require special ordering or delivery arrangements. For DIY enthusiasts, it’s practical to plan projects around readily available lengths to avoid additional costs and logistical challenges. Always measure your workspace and transportation method before purchasing to ensure the planks can be safely handled and stored.

Comparing standard plank lengths across different applications highlights their versatility. In construction, 8- and 10-foot planks are staples for stud walls and subflooring, while 12- and 16-foot planks are preferred for decking and roofing. In woodworking, shorter planks dominate for crafting tables, chairs, and cabinets, where intricate joinery and finishing are involved. This comparison underscores the importance of matching plank length to the specific demands of the project, ensuring both structural integrity and aesthetic appeal.

Finally, a practical tip for working with standard plank lengths is to plan cuts strategically to minimize waste. For example, when building a 12-foot-long structure, use two 8-foot planks with a splice joint rather than cutting a single 16-footer, which may leave unusable remnants. Additionally, always account for material shrinkage or expansion due to environmental conditions, especially in outdoor projects. By aligning your project design with standard plank lengths and employing smart cutting techniques, you can achieve professional results while optimizing material usage.

Understanding the Time It Takes for Wood to Decompose Naturally

You may want to see also

Explore related products

$44

Custom plank sizing: How to measure and cut planks to specific lengths

Planks of wood come in standard lengths, typically 8, 10, or 12 feet, but custom sizing is often necessary for precise projects. Whether you’re building furniture, framing a wall, or crafting a DIY project, knowing how to measure and cut planks to specific lengths is essential. Start by identifying the exact dimensions required for your project, accounting for any overlaps, joints, or decorative elements. Use a tape measure and mark the cut lines clearly with a pencil or carpenter’s square to ensure accuracy.

Measuring for custom plank sizing involves more than just length. Consider the width and thickness of the plank, as these dimensions can affect structural integrity and aesthetics. For example, a 2x4 plank is actually 1.5 inches by 3.5 inches due to milling, so factor in these discrepancies when planning. If your project requires multiple planks of the same length, measure the first one meticulously and use it as a template for consistency. Always measure twice to avoid costly mistakes.

Cutting planks to specific lengths demands the right tools and techniques. A circular saw or miter saw is ideal for straight cuts, while a jigsaw or hand saw can handle curves or intricate shapes. Secure the plank firmly with clamps or a vice to prevent movement during cutting. For clean, splinter-free edges, use a fine-toothed blade and cut along the marked line with steady pressure. If precision is critical, consider using a stop block or guide rail to ensure the cut is perfectly aligned.

Safety is paramount when custom-sizing planks. Always wear safety goggles, ear protection, and a dust mask to guard against flying debris and sawdust. Keep your hands clear of the blade and unplug power tools when adjusting settings or changing blades. For beginners, practice on scrap wood to familiarize yourself with the tools and techniques before working on your project. Remember, a well-executed cut not only enhances the final product but also saves time and materials.

Finally, finishing touches can elevate your custom-sized planks. Sand the cut edges with 120-grit sandpaper to smooth rough surfaces, then progress to finer grits for a polished look. If the planks will be exposed to moisture or wear, apply a sealant or stain to protect the wood. Label or organize your cut pieces to avoid confusion during assembly, especially for complex projects. With careful measurement, precise cutting, and attention to detail, custom plank sizing becomes a straightforward task that transforms raw materials into tailored components for your vision.

Engineered Wood Durability: Longevity, Maintenance, and Lifespan Explained

You may want to see also

Explore related products

$29.99

Plank length variations: Differences in length based on wood type and purpose

The length of a plank of wood is not a one-size-fits-all measurement. From the dense, heavy hardwoods used in construction to the lighter, more flexible softwoods favored for crafting, the type of wood significantly influences its standard length. For instance, oak planks, prized for their durability, often come in lengths ranging from 8 to 16 feet, ideal for flooring and furniture. In contrast, pine planks, commonly used for DIY projects, are typically available in shorter lengths, such as 6 to 12 feet, due to their lighter weight and ease of handling.

Consider the purpose of the plank, as it dictates not only the wood type but also the optimal length. Structural applications, like framing or decking, often require longer planks—up to 20 feet—to minimize joints and ensure stability. For example, pressure-treated lumber for outdoor decks is frequently sold in 12- to 20-foot lengths to accommodate large spans. Conversely, decorative or functional items like shelving or picture frames may use planks as short as 2 to 4 feet, tailored to specific design needs.

When selecting plank length, balance practicality with aesthetics. Longer planks reduce seams in flooring or siding, creating a cleaner look, but they can be cumbersome to transport and install. Shorter planks, while easier to manage, may result in more visible joints. For example, a 10-foot cedar plank is perfect for a garden bench, offering both strength and manageability, whereas a 16-foot Douglas fir plank is better suited for a load-bearing beam in a home renovation.

To maximize efficiency, plan projects with standard plank lengths in mind. Most lumberyards stock wood in even increments (e.g., 2, 4, 6, 8, 10, 12, 16, 20 feet), so designing around these sizes reduces waste. For custom lengths, consider ordering pre-cut planks or cutting standard lengths yourself, but factor in an extra 10% for mistakes or irregularities. For instance, a 12-foot plank can be divided into two 6-foot sections for a bookshelf, with minimal material leftover.

Ultimately, understanding plank length variations based on wood type and purpose empowers smarter material choices. Hardwoods like maple or walnut excel in longer lengths for high-impact applications, while softwoods like spruce or cedar are versatile across shorter to medium lengths. By aligning plank length with both the wood’s natural properties and the project’s demands, you ensure durability, efficiency, and visual appeal in every woodworking endeavor.

Oven Drying Wood: Optimal Time for Perfectly Seasoned Wood Pieces

You may want to see also

Explore related products

Plank length in projects: Determining ideal plank length for furniture or structures

Plank length is a critical factor in woodworking projects, influencing both aesthetics and structural integrity. For furniture, standard plank lengths often range from 6 to 12 feet, but the ideal length depends on the piece’s design and intended use. A dining table, for instance, might require planks up to 8 feet to minimize joints, while a bookshelf could use shorter 4-foot planks for stability and ease of assembly. Understanding these project-specific needs ensures the final product is both functional and visually cohesive.

When determining plank length for structures like decks or framing, consider load-bearing requirements and material efficiency. Longer planks (12–16 feet) reduce the number of joints, enhancing strength and reducing waste. However, longer lengths can be cumbersome to handle and may require additional support during installation. For example, a deck spanning 20 feet might use 16-foot planks to minimize seams, but a smaller garden bridge could utilize 8-foot planks for simplicity. Always balance structural demands with practicality.

To optimize plank length for your project, start by sketching a detailed plan with dimensions. Measure the longest continuous spans and add 10–15% for cutting allowances. For furniture, prioritize symmetry and proportion—a headboard, for example, should align plank lengths with the bed’s width for visual harmony. For structures, consult building codes or engineering guidelines to ensure safety. Tools like a miter saw or circular saw can help achieve precise cuts, but always double-check measurements before cutting.

Comparing pre-cut planks to custom lengths highlights the trade-offs between convenience and customization. Pre-cut planks (8, 10, or 12 feet) are readily available and cost-effective but may require additional joints or trimming. Custom lengths, while more expensive, offer seamless integration and reduced waste. For a high-end dining table, investing in custom 10-foot planks might be justified, whereas a DIY garden bench could efficiently use standard 8-foot boards. Weigh these factors based on project scope and budget.

Finally, consider the wood species and its natural characteristics when selecting plank length. Hardwoods like oak or maple are denser and can support longer spans without warping, making them ideal for 12-foot applications. Softer woods like pine may require shorter lengths (6–8 feet) to maintain stability, especially in humid environments. Always account for wood movement due to moisture changes—incorporate expansion gaps in flooring or outdoor structures. By aligning plank length with material properties, you ensure longevity and performance in your project.

How Long Does Wood Finish Smell Last? A Complete Guide

You may want to see also

Explore related products

$26.99 $28.99

Measuring plank length: Tools and techniques for accurately measuring wood planks

A standard plank of wood can vary widely in length, typically ranging from 6 to 20 feet, depending on its intended use. Whether you're a professional carpenter or a DIY enthusiast, accurately measuring wood planks is crucial for ensuring structural integrity and material efficiency. The right tools and techniques not only save time but also minimize waste and errors. Here’s how to approach this task with precision.

Tools for the Job: The most common tool for measuring wood planks is a tape measure, ideally one that extends to at least 25 feet for longer planks. For finer accuracy, especially in woodworking, a steel rule or a digital caliper can be invaluable. Laser distance measurers are another modern option, offering quick and precise measurements up to 100 feet or more. Each tool has its strengths: tape measures are versatile, calipers excel in small-scale measurements, and lasers provide speed and convenience for longer distances.

Techniques for Accuracy: When measuring, ensure the plank lies flat on a stable surface to avoid distortions. For longer planks, use a straightedge or another plank as a guide to extend your measurement if your tape measure falls short. Always measure from the same reference point—typically one end—to maintain consistency. If using a laser measurer, ensure the device is calibrated and the surface is reflective enough for an accurate reading. For irregular shapes, break the plank into smaller, measurable segments and sum the lengths.

Common Pitfalls to Avoid: One of the most frequent mistakes is misreading the tape measure or misaligning it with the plank’s edge. Always double-check your measurements and ensure the tape is straight and taut. Another error is neglecting to account for the plank’s thickness when measuring diagonally or along a curved edge. For such cases, use the Pythagorean theorem or a combination square to ensure accuracy. Lastly, avoid measuring warped or uneven planks without first flattening or straightening them, as this can lead to significant discrepancies.

Practical Tips for Efficiency: Mark your measurements directly on the plank using a pencil or carpenter’s chalk to avoid confusion when cutting. If working with multiple planks of the same length, create a template or jig to streamline the process. For large projects, document your measurements in a notebook or digital app to keep track of progress. Finally, always measure twice and cut once—a timeless adage that remains the cornerstone of accurate woodworking. By combining the right tools with thoughtful techniques, you can ensure your wood planks are measured with precision every time.

Seasoning Firewood: Understanding the Time It Takes for Optimal Results

You may want to see also

Frequently asked questions

A standard plank of wood typically ranges from 8 to 16 feet in length, though lengths can vary depending on the type of wood and its intended use.

Yes, planks of wood can be custom cut to specific lengths based on project requirements, often done at lumberyards or by carpenters.

For flooring, planks are commonly available in lengths ranging from 1 to 7 feet, with 2 to 4 feet being the most standard lengths.

Yes, longer planks, such as those used for beams or structural purposes, can be found in lengths up to 24 feet or more, depending on the supplier and wood type.