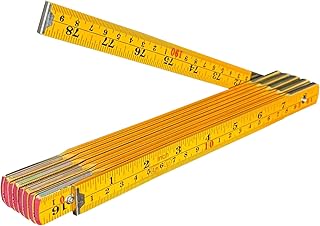

The wood unfolding tape measuring stick, often referred to as a carpenter's folding rule or a zigzag rule, is a traditional measuring tool that has been used for centuries in woodworking and construction. Typically made from a series of hinged wooden or metal sections, it unfolds to provide a straight, rigid measuring edge. The length of such a tool can vary widely depending on its design and intended use, with common sizes ranging from 1 to 20 feet. Shorter versions, around 6 to 8 feet, are popular for general carpentry tasks, while longer ones are favored for larger-scale projects like framing or layout work. Understanding the length and functionality of a wood unfolding tape measuring stick is essential for selecting the right tool for precise measurements in various applications.

Explore related products

$6.97

What You'll Learn

- Understanding the Length: Standard lengths of wood unfolding tape measuring sticks vary by model and purpose

- Material Impact: Wood type affects flexibility, durability, and overall length of the measuring stick

- Portability vs. Length: Longer sticks are less portable; shorter ones may limit measurement range

- Measurement Accuracy: Wood expansion/contraction can influence precision; consider environmental factors

- Common Sizes: Typical lengths range from 1 to 100 feet, depending on application

Understanding the Length: Standard lengths of wood unfolding tape measuring sticks vary by model and purpose

Wood unfolding tape measuring sticks, often referred to as carpenter’s folding rules, come in a range of standard lengths tailored to specific tasks and user needs. The most common lengths are 6 feet (72 inches or 2 meters) and 8 feet (96 inches or 2.4 meters), which are ideal for general carpentry, construction, and DIY projects. These lengths strike a balance between portability and functionality, allowing users to measure large spans without the bulk of a rigid tape measure. For more specialized applications, shorter lengths like 4 feet (48 inches or 1.2 meters) are available, often used in precision work or confined spaces. Understanding these standard lengths ensures you select the right tool for your project, avoiding unnecessary strain or inaccuracy.

The length of a wood unfolding tape measuring stick is not arbitrary but designed to align with the scale and scope of typical tasks. For instance, a 6-foot rule is perfect for measuring door frames, window openings, or furniture dimensions, while an 8-foot rule extends its utility to larger structures like walls or flooring. Longer lengths, such as 10 feet (120 inches or 3 meters), are less common but exist for industrial or professional applications where extended reach is essential. When choosing a length, consider the size of the objects you’ll measure most frequently and the convenience of carrying the tool on your belt or in your toolbox.

One practical tip for maximizing the utility of these measuring sticks is to pair them with complementary tools. For example, a 6-foot wood rule can be used alongside a retractable tape measure for tasks requiring both precision and flexibility. Additionally, some models feature metric and imperial markings, allowing for seamless transitions between measurement systems. Always inspect the stick’s graduations for clarity and durability, as worn markings can lead to errors. Proper care, such as storing the rule in a dry place and avoiding excessive bending, will prolong its lifespan and maintain accuracy.

Comparatively, wood unfolding tape measuring sticks offer advantages over metal or plastic alternatives, particularly in terms of durability and readability. The wooden body is lightweight yet sturdy, resistant to warping when handled with care. The tape itself, often made of steel or fiberglass, is embedded with clear, easy-to-read markings that stand the test of time. While metal rules may be more rigid, wood rules provide a tactile, traditional feel that many craftsmen prefer. However, they require mindful use to avoid damage from moisture or rough handling, making them best suited for indoor or controlled environments.

In conclusion, the standard lengths of wood unfolding tape measuring sticks are a testament to their versatility and adaptability across various trades. By selecting the appropriate length for your needs—whether 4, 6, 8, or 10 feet—you can streamline your workflow and enhance precision. Pairing the right tool with proper care ensures longevity and reliability, making these measuring sticks an indispensable asset in any toolkit. Whether you’re a professional carpenter or a weekend warrior, understanding these lengths empowers you to measure with confidence and efficiency.

Perfect Soaking Time for Wood Wicks: A Beginner's Guide

You may want to see also

Explore related products

Material Impact: Wood type affects flexibility, durability, and overall length of the measuring stick

Wood type is a critical factor in determining the flexibility, durability, and overall length of an unfolding tape measuring stick. For instance, balsa wood, known for its lightweight and softness, offers excellent flexibility but lacks durability, making it unsuitable for heavy-duty measuring tasks. In contrast, oak, a dense and robust hardwood, provides exceptional durability but is less flexible, which can limit its ability to unfold smoothly or conform to curved surfaces. Understanding these material properties allows users to select the right wood type for their specific needs, balancing flexibility and strength.

When crafting or purchasing a wooden measuring stick, consider the intended use. For outdoor applications, teak or cedar are ideal choices due to their natural resistance to moisture and decay. These woods can withstand harsh weather conditions, ensuring the measuring stick remains functional and accurate over time. However, their higher density may result in a slightly shorter overall length compared to softer woods, as thicker walls are needed for structural integrity. For indoor or occasional use, pine offers a cost-effective solution with moderate flexibility and durability, though it may require more frequent maintenance.

Flexibility in a wooden measuring stick is not just about the wood type but also its grain orientation. Woods with straight, uniform grains, like maple, tend to bend more predictably, making them suitable for sticks that need to unfold or curve slightly. Conversely, woods with irregular grains, such as walnut, may have natural weak points that reduce flexibility and increase the risk of breakage. To maximize flexibility without compromising strength, look for woods with fine, even grains and consider the direction of the grain in relation to the stick’s design.

Durability is another key consideration, especially for professionals who rely on their measuring sticks daily. Hardwoods like hickory or ash are excellent choices for their high impact resistance and ability to withstand repeated use. However, their rigidity can make them less forgiving in cold temperatures, where wood tends to become more brittle. To enhance durability, apply a protective finish such as linseed oil or polyurethane, which can seal the wood against moisture and minor abrasions. Regular inspection for cracks or splinters is also essential to ensure longevity.

Finally, the overall length of a wooden measuring stick is influenced by both the wood type and its thickness. Softer woods can be crafted into longer, thinner sticks without sacrificing flexibility, but they may lack the precision needed for detailed measurements. Harder woods, while more durable, often require greater thickness to prevent breakage, which can limit their maximum length. For optimal performance, choose a wood type that aligns with your desired length and application, and consider reinforcing joints or hinges with metal components to extend the stick’s lifespan. By carefully selecting the material, you can create a measuring stick that meets both your functional and dimensional requirements.

Wood Green to Heathrow: Travel Time and Best Routes Explained

You may want to see also

Explore related products

Portability vs. Length: Longer sticks are less portable; shorter ones may limit measurement range

Wooden unfolding tape measuring sticks, often used in forestry, construction, and outdoor activities, present a unique trade-off between portability and length. A typical stick ranges from 5 to 20 feet, with 10-foot and 16-foot options being the most common. Longer sticks, such as the 20-foot variety, offer extended reach for measuring tall trees or spanning large distances but come at the cost of bulkiness. For instance, a 20-foot stick folded in half still measures 10 feet, making it cumbersome to carry in a backpack or vehicle. Shorter sticks, like the 5-foot version, are lightweight and easy to transport but may require additional measurements or tools to cover longer distances, potentially introducing errors.

Consider the intended use when choosing a length. For foresters measuring tree heights, a 16-foot stick strikes a balance, allowing for most tree diameter measurements without excessive weight. Hobbyists or hikers might prefer a 5-foot stick for its convenience, accepting the limitation of piecing together measurements for longer spans. In construction, where precision is critical, a 10-foot stick often suffices for framing or layout tasks, while longer sticks are reserved for specialized applications like roof measurements. Always pair the stick with a measuring tape for accuracy, especially when dealing with non-linear distances.

Portability isn’t just about length—material and design matter too. Lightweight woods like cedar or pine reduce overall weight, while aluminum or fiberglass alternatives offer durability without added bulk. Folding mechanisms vary; some sticks use hinged joints, while others employ telescoping designs. Hinged sticks are simpler but less compact, whereas telescoping models collapse into a smaller footprint, ideal for tight storage spaces. For maximum portability, look for sticks with carrying cases or straps, which protect the tool and free up hands during transport.

To optimize the length-portability balance, adopt practical strategies. For longer sticks, attach a carabiner to the end for easy attachment to belts or bags. When using shorter sticks, mark common measurement intervals (e.g., 6 feet for standing reach) to streamline repetitive tasks. Always practice unfolding and folding the stick before use to avoid delays in the field. For extended measurements, pair a shorter stick with a laser distance measurer to cover gaps efficiently. Regularly inspect the stick for wear, as warping or splitting can compromise accuracy, especially in longer models.

Ultimately, the choice between portability and length depends on the task at hand. Longer sticks excel in scenarios requiring extended reach but demand careful handling and storage. Shorter sticks prioritize convenience, making them ideal for quick, on-the-go measurements. By understanding these trade-offs and leveraging complementary tools, users can maximize efficiency without sacrificing precision. Whether in the forest, on a job site, or during a hike, the right wooden unfolding tape measuring stick ensures the job gets done with minimal hassle.

Seasoning Wood for Furniture: Understanding the Ideal Drying Time

You may want to see also

Explore related products

Measurement Accuracy: Wood expansion/contraction can influence precision; consider environmental factors

Wood, a natural material, is inherently susceptible to environmental changes, particularly fluctuations in temperature and humidity. These factors cause wood to expand or contract, a phenomenon that can significantly impact the accuracy of measurements taken with a wooden unfolding tape measuring stick. For instance, a wooden measuring stick exposed to high humidity may absorb moisture, leading to swelling and an increase in length. Conversely, in dry conditions, the wood may shrink, resulting in a shorter measurement. This variability underscores the importance of understanding and accounting for wood’s dynamic nature when precision is critical.

To mitigate the effects of wood expansion and contraction, it’s essential to control the environment in which measurements are taken. Ideally, wooden measuring tools should be stored and used in conditions with stable temperature and humidity levels. For example, maintaining a relative humidity of 40–60% and a temperature of 68–72°F (20–22°C) can minimize dimensional changes in wood. If such control is not feasible, consider calibrating the measuring stick regularly against a more stable reference, such as a metal or composite ruler, to ensure accuracy.

Another practical approach is to select wood species with lower coefficients of thermal expansion and moisture absorption. Hardwoods like maple or oak tend to be more dimensionally stable than softwoods like pine. Additionally, treating the wood with sealants or finishes can reduce its susceptibility to moisture, though this may not entirely eliminate expansion or contraction. For applications requiring high precision, pairing a wooden measuring stick with a digital caliper or laser measurer can provide a cross-check, ensuring reliability despite wood’s natural variability.

In scenarios where environmental control is impossible, such as outdoor construction or fieldwork, it’s crucial to document the conditions under which measurements are taken. Note the temperature, humidity, and time of day, as these factors can later be used to adjust measurements if discrepancies arise. For example, if a wooden tape measure was used in 90°F (32°C) weather with 80% humidity, expect the wood to be slightly longer than in cooler, drier conditions. Adjustments can then be made based on known expansion rates for the specific wood species.

Ultimately, while wooden unfolding tape measuring sticks offer a classic and lightweight solution for measurement, their accuracy is inherently tied to environmental stability. By understanding wood’s behavior, controlling storage and usage conditions, and employing complementary tools or adjustments, users can maximize precision. For critical applications, however, consider transitioning to materials like fiberglass or metal, which are less affected by environmental factors and provide consistent measurements regardless of external conditions.

Wood Filler Drying Time: How Long Does It Take to Harden?

You may want to see also

Explore related products

Common Sizes: Typical lengths range from 1 to 100 feet, depending on application

Wooden unfolding tape measuring sticks, often referred to as carpenter’s or surveyor’s tapes, come in a surprisingly wide array of lengths tailored to specific tasks. At the shorter end, 1 to 10-foot versions are ideal for precision work like framing windows, aligning cabinets, or marking cuts in woodworking. These compact tools offer rigidity and accuracy in tight spaces where flexibility isn’t needed. On the opposite spectrum, 100-foot tapes are the go-to for large-scale projects such as land surveying, laying out foundations, or measuring property boundaries. Between these extremes, 25- and 50-foot lengths are the most common, balancing portability with versatility for tasks like room measurements, landscaping, or construction layout.

Choosing the right length isn’t just about convenience—it’s about efficiency. A tape that’s too short forces you to remeasure or use awkward extensions, while one that’s too long becomes cumbersome and prone to tangling. For instance, a 25-foot tape is perfect for most indoor renovations, while a 50-foot version handles outdoor projects without excessive bulk. Pro tip: If you’re unsure, opt for a mid-range length like 30 or 50 feet, as these cover 90% of typical applications without sacrificing usability.

Material and design also play a role in how these tapes perform at different lengths. Longer tapes often feature reinforced blades and sturdy cases to handle the added stress of extended use, while shorter ones prioritize compactness and ease of handling. For example, a 100-foot wooden tape might include a winding crank to manage the bulk, whereas a 5-foot version could be lightweight and pocket-sized. Always consider the trade-offs: longer tapes offer more reach but require careful handling to avoid kinks or breaks.

One often-overlooked factor is the application’s precision requirements. Shorter tapes, especially those under 10 feet, are typically marked with finer graduations (e.g., 1/16-inch increments) for detailed work. Longer tapes may sacrifice this precision for durability, with markings spaced at 1/8-inch or even 1/4-inch intervals. If your project demands accuracy, prioritize length and graduations accordingly—a 25-foot tape with 1/16-inch markings strikes a balance for most tradespeople.

Finally, consider the environment where the tape will be used. For outdoor or rough conditions, opt for longer, more durable tapes with corrosion-resistant coatings. Indoor or delicate work may call for shorter, smoother-operating models. Practical tip: Keep multiple lengths on hand to adapt to various scenarios. A 6-foot tape for cabinetry, a 25-foot tape for general construction, and a 100-foot tape for outdoor projects ensure you’re always prepared without overcomplicating your toolkit.

Understanding 3 Wood Shaft Length: A Comprehensive Guide for Golfers

You may want to see also

Frequently asked questions

A standard wood unfolding tape measuring stick typically ranges from 6 to 12 feet in length, with 6 feet being the most common size.

No, a wood unfolding tape measuring stick is fixed in length and cannot be extended beyond its designed size.

It is primarily used for measuring and marking straight lines, especially in carpentry, construction, and DIY projects where a rigid, straight edge is needed.

Yes, longer versions up to 20 feet are available, though they are less common and typically used for specialized applications requiring extended reach.