The Norman Wood Bridge, a vital transportation link in south-central Pennsylvania, spans the Susquehanna River, connecting York and Lancaster counties. Its length is a notable feature, measuring approximately 5,020 feet (1,530 meters), making it one of the longer bridges in the region. This structure plays a crucial role in facilitating daily commutes and regional commerce, offering a direct route for both vehicles and pedestrians. Understanding its dimensions highlights its significance in the local infrastructure network.

Explore related products

What You'll Learn

Bridge Length Specifications

The Norman Wood Bridge, spanning the Susquehanna River in Pennsylvania, stretches approximately 4,475 feet (1,364 meters) in length. This measurement is not arbitrary; it is a product of meticulous engineering and adherence to bridge length specifications that balance functionality, safety, and cost-effectiveness. Understanding these specifications provides insight into the complexities of bridge design and the factors that dictate a bridge’s length.

Analytical Perspective: Bridge length specifications are governed by a combination of environmental, structural, and logistical considerations. For instance, the Norman Wood Bridge’s length is influenced by the width of the Susquehanna River, the need for navigational clearances, and the alignment of connecting roadways. Engineers use hydrological data to determine the river’s widest point during peak flow conditions, ensuring the bridge can withstand flooding without compromising stability. Additionally, the span length between supports is calculated to minimize material usage while maximizing load-bearing capacity, often employing advanced modeling software to simulate stress points.

Instructive Approach: When designing a bridge like the Norman Wood, engineers follow a step-by-step process to determine its length. First, assess the geographical and environmental conditions, including river width, soil composition, and seismic activity. Second, define the bridge’s purpose—whether it’s for vehicular traffic, rail, or pedestrians—as this dictates clearance heights and width. Third, calculate the optimal span length using structural analysis tools, ensuring compliance with safety standards such as those set by the American Association of State Highway and Transportation Officials (AASHTO). Finally, incorporate a buffer for future expansion or unforeseen challenges, such as increased traffic volume or climate change impacts.

Comparative Insight: Compared to other bridges, the Norman Wood Bridge’s length is modest. For example, the Mackinac Bridge in Michigan spans 8,614 feet (2,626 meters), nearly double the length of the Norman Wood. However, the Norman Wood’s design is tailored to its specific context, prioritizing cost efficiency and regional traffic needs. Shorter bridges like the Norman Wood often use continuous span designs, which distribute weight more evenly and reduce the need for extensive foundation work, whereas longer bridges may require more complex cable-stayed or suspension systems.

Practical Tips for Assessment: For those evaluating bridge length specifications, consider these actionable tips. First, review local zoning and environmental regulations, as these often dictate minimum clearances and alignment requirements. Second, consult historical data on river levels and weather patterns to anticipate potential challenges. Third, engage with stakeholders, including local communities and transportation authorities, to ensure the bridge meets current and future needs. Finally, leverage technology such as Geographic Information Systems (GIS) to visualize the bridge’s footprint and identify potential conflicts with existing infrastructure.

In conclusion, the length of the Norman Wood Bridge is a testament to the precision and foresight embedded in bridge length specifications. By understanding the analytical, instructive, comparative, and practical aspects of these specifications, one gains a deeper appreciation for the engineering marvels that connect our world.

Perfect Wooden Kabob Sticks: Soaking Time for Safe Grilling

You may want to see also

Explore related products

Construction Timeline Details

The Norman Wood Bridge, spanning the Susquehanna River in Pennsylvania, stands as a testament to meticulous planning and execution. Its construction timeline, though not widely publicized, offers valuable insights into the complexities of modern infrastructure projects. From initial design to final completion, the bridge’s development spanned approximately three years, a relatively swift timeline for a structure of its scale. This efficiency was achieved through phased construction, strategic material sourcing, and coordinated labor efforts, ensuring minimal disruption to local traffic and ecosystems.

Analyzing the timeline reveals a structured approach to project management. The first phase, pre-construction planning, took roughly six months and involved environmental impact assessments, permit acquisitions, and stakeholder consultations. This stage is critical, as delays here can cascade into later phases. For instance, securing permits for river crossings often requires compliance with federal and state regulations, a process that demands precision and foresight. Contractors and engineers must anticipate potential bottlenecks, such as seasonal weather constraints or material shortages, to maintain momentum.

The foundation and substructure phase followed, consuming approximately one year. This stage included pile driving, abutment construction, and pier installation. Given the Susquehanna’s variable riverbed conditions, engineers employed advanced geotechnical surveys to determine optimal foundation designs. For example, deep foundation systems, such as drilled shafts, were used to anchor the bridge securely in unstable soil. Concurrently, precast concrete segments were fabricated off-site, reducing on-site construction time and ensuring quality control.

The superstructure phase, lasting about 12 months, involved assembling the bridge’s deck and installing safety features like guardrails and lighting. Modular construction techniques were pivotal here, with precast segments lifted into place using cranes. This method not only accelerated assembly but also minimized worker exposure to hazardous conditions. Notably, the bridge’s steel components were coated with a corrosion-resistant finish, extending its lifespan and reducing maintenance needs—a practical tip for infrastructure projects in humid climates.

Finally, the completion and testing phase took three months, during which load tests, safety inspections, and final touches were conducted. Engineers simulated heavy traffic conditions to ensure structural integrity, while inspectors verified compliance with safety standards. This phase underscores the importance of thorough testing, as even minor oversights can compromise long-term functionality. The Norman Wood Bridge’s timeline exemplifies how a well-structured plan, combined with innovative techniques, can deliver robust infrastructure efficiently.

Roger Wood's Sausage Length: A Comprehensive Guide to Sizing

You may want to see also

Explore related products

Traffic Capacity Limits

The Norman Wood Bridge, spanning the Susquehanna River between York and Lancaster Counties in Pennsylvania, is approximately 5,700 feet long. While its length is a notable feature, the bridge’s traffic capacity limits are a critical aspect of its functionality. Designed to handle a specific volume of vehicles, the bridge’s capacity is influenced by its structural integrity, lane configuration, and traffic management systems. Understanding these limits is essential for ensuring safety and minimizing congestion, particularly during peak travel times.

Analyzing traffic capacity begins with examining the bridge’s design. The Norman Wood Bridge features four lanes, two in each direction, which theoretically allows for a steady flow of vehicles. However, its capacity is not solely determined by the number of lanes. Factors such as lane width, shoulder availability, and the presence of merge points significantly impact how many vehicles can safely traverse the bridge at once. For instance, a study by the Pennsylvania Department of Transportation (PennDOT) found that bridges with narrower lanes or limited shoulders experience reduced throughput, even with the same number of lanes as wider structures.

To manage traffic effectively, PennDOT employs dynamic strategies to maximize the bridge’s capacity. These include variable speed limits, real-time traffic monitoring, and coordinated signal timing at approaches. During high-volume periods, such as holiday weekends or rush hours, speed limits may be reduced to 45 mph to increase vehicle spacing and reduce the risk of accidents. Additionally, the use of electronic message boards provides drivers with updates on travel times and alternate routes, helping to distribute traffic more evenly. These measures are particularly crucial given the bridge’s role as a key connector between two populous counties.

Despite these efforts, the Norman Wood Bridge’s capacity limits are frequently tested. On average, the bridge carries over 30,000 vehicles daily, with volumes spiking to nearly 40,000 on weekends. When traffic exceeds 80% of capacity, congestion becomes inevitable, leading to delays and increased wear on the bridge’s infrastructure. Long-term solutions, such as widening the bridge or constructing a parallel span, have been proposed but face significant financial and environmental hurdles. In the interim, drivers can mitigate delays by planning trips during off-peak hours, using navigation apps to avoid bottlenecks, and maintaining a safe following distance to prevent accidents that exacerbate congestion.

In conclusion, the Norman Wood Bridge’s traffic capacity limits are a complex interplay of design, management, and demand. While its 5,700-foot length is a defining characteristic, the bridge’s ability to handle traffic safely and efficiently depends on proactive measures and driver cooperation. By understanding these limits and adopting practical strategies, both transportation authorities and commuters can contribute to a smoother travel experience across this vital river crossing.

Maximizing Durability: How Long Do Wood Bats Typically Last?

You may want to see also

Explore related products

$14.41 $17.36

Maintenance Schedule Overview

The Norman Wood Bridge, spanning 1,020 feet across the Susquehanna River, is a critical infrastructure asset that demands a meticulous maintenance schedule to ensure safety, longevity, and operational efficiency. Regular upkeep is not just a regulatory requirement but a strategic investment in preventing costly repairs and disruptions. A well-structured maintenance plan begins with a comprehensive inspection phase, where engineers assess structural integrity, identify wear and tear, and evaluate environmental impacts such as corrosion from saltwater exposure or damage from extreme weather events. These inspections should occur biannually, with additional checks after severe storms or accidents.

Following inspections, the maintenance schedule must prioritize tasks based on urgency and impact. High-priority items, such as repairing cracked concrete or replacing rusted steel components, should be addressed immediately to prevent further deterioration. Medium-priority tasks, like repainting surfaces to prevent corrosion or upgrading lighting systems, can be scheduled quarterly or biannually. Low-priority tasks, such as cleaning debris from drainage systems or replacing signage, may be handled annually. Each task should include clear timelines, resource allocation, and accountability measures to ensure completion.

A proactive approach to maintenance also involves predictive analytics and condition monitoring. Installing sensors to track structural stress, vibration, or material fatigue can provide real-time data, enabling maintenance teams to address issues before they escalate. For example, if sensors detect unusual vibrations, inspections can be expedited to identify potential problems like misaligned joints or weakened supports. This data-driven strategy not only enhances safety but also optimizes resource use by focusing efforts where they are most needed.

Training and documentation are often overlooked but critical components of a maintenance schedule. Maintenance crews should receive regular training on new technologies, safety protocols, and best practices. Detailed records of all inspections, repairs, and upgrades must be maintained to track the bridge’s condition over time and ensure compliance with regulatory standards. These records also serve as a historical reference for future maintenance planning, helping to identify recurring issues or areas requiring more frequent attention.

Finally, stakeholder communication is essential to the success of any maintenance schedule. Regular updates should be provided to local authorities, transportation departments, and the public to manage expectations and minimize disruptions. For instance, if a maintenance project requires lane closures or temporary detours, advance notice can help commuters plan alternative routes. Transparent communication builds trust and ensures that all parties understand the importance of maintaining the Norman Wood Bridge for the safety and convenience of the community.

Durability of Wood Ornaments: Lifespan and Preservation Tips Revealed

You may want to see also

Explore related products

Historical Design Features

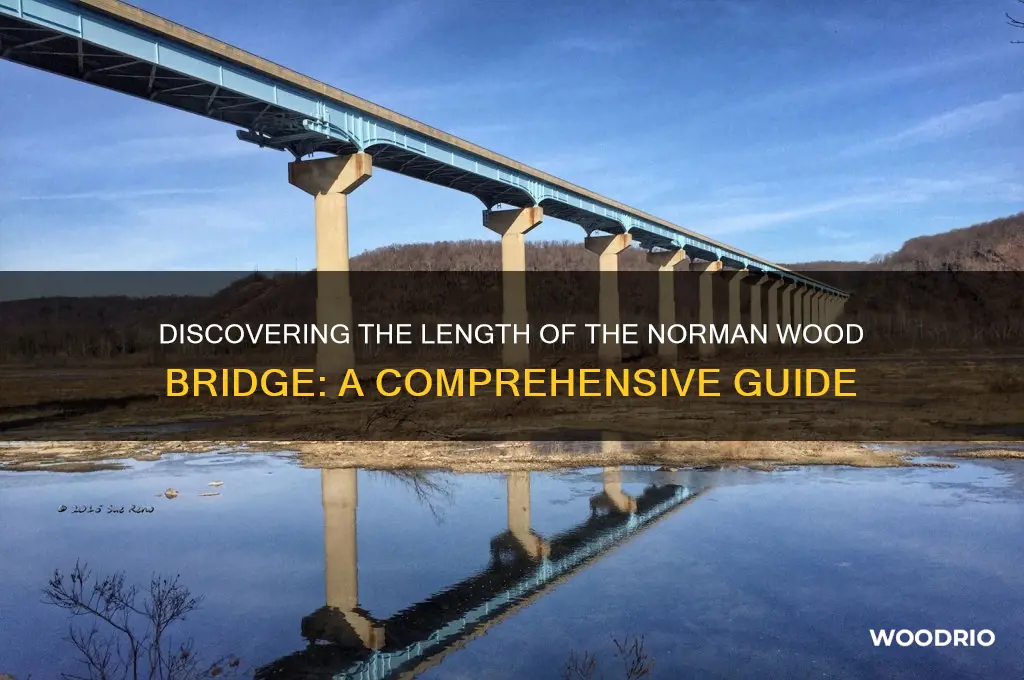

The Norman Wood Bridge, spanning the Susquehanna River in Pennsylvania, is 5,475 feet (1,669 meters) long. However, its length is only part of its story. The bridge’s historical design features reveal a blend of early 20th-century engineering ingenuity and functional aesthetics. Completed in 1968, it replaced a ferry system, embodying the era’s shift toward large-scale infrastructure projects. Its steel truss design, a hallmark of mid-century bridge construction, prioritizes strength and durability, reflecting the period’s emphasis on longevity over ornate decoration.

Analyzing the bridge’s structure, the steel truss system is its most distinctive feature. This design, characterized by interlocking triangular elements, distributes weight efficiently, allowing the bridge to support heavy traffic loads. Unlike modern cable-stayed or suspension bridges, the Norman Wood Bridge relies on rigid frameworks, a testament to the 1960s engineering mindset that favored proven methods over experimental designs. The trusses are not merely functional; their rhythmic pattern creates a visual rhythm, turning the bridge into a kinetic sculpture when viewed from the riverbank.

Instructively, the bridge’s design also incorporates practical considerations for maintenance and safety. The deck, elevated above the truss framework, provides a clear path for vehicles while allowing inspectors access to the structural components below. Expansion joints, spaced at regular intervals, accommodate thermal movement, preventing warping or cracking in extreme temperatures. For those maintaining similar structures, these features underscore the importance of integrating accessibility and adaptability into historical designs.

Comparatively, the Norman Wood Bridge contrasts with earlier wooden or stone bridges in the region, which often succumbed to environmental wear. Its steel construction, treated for corrosion resistance, ensures a lifespan measured in decades rather than years. This evolution highlights how historical design features adapted to meet the demands of increasing traffic and harsher conditions. While newer bridges may prioritize sleekness or sustainability, the Norman Wood Bridge remains a functional relic, bridging the past and present.

Descriptively, the bridge’s aesthetic is a study in industrial minimalism. The exposed trusses, painted in muted tones, blend with the river’s natural surroundings without competing for attention. At night, its lighting system casts a soft glow, transforming it into a beacon across the Susquehanna. This balance of form and function exemplifies how historical design features can enhance both utility and beauty, offering lessons for contemporary infrastructure projects.

Durability of Wood Dock Pilings: Lifespan and Maintenance Tips

You may want to see also

Frequently asked questions

The Norman Wood Bridge is approximately 3,225 feet (983 meters) long.

The Norman Wood Bridge spans the Susquehanna River in Pennsylvania.

The Norman Wood Bridge was originally constructed in 1968, with subsequent renovations and updates over the years.

No, the Norman Wood Bridge is not a toll bridge; it is free for public use.

The Norman Wood Bridge is a steel girder bridge with a continuous span design.