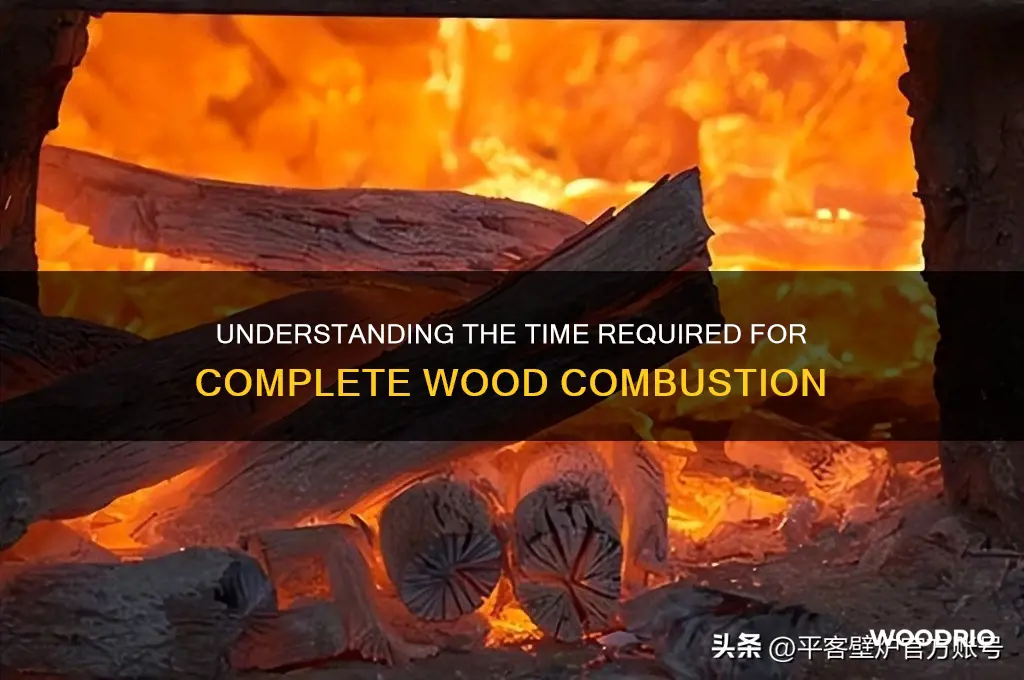

The question of how long it takes for 10 units of wood to combust depends on several factors, including the type of wood, its moisture content, the presence of oxygen, and the temperature at which it is exposed. Generally, wood combustion is a complex process that involves the release of volatile gases, which ignite and sustain the burning process. Dry, well-seasoned hardwoods like oak or maple tend to burn more efficiently and quickly compared to softwoods or damp wood. Under optimal conditions, such as in a well-ventilated fireplace or controlled environment, 10 units of dry wood could combust within minutes to hours, but the exact duration varies widely based on the specific circumstances and conditions present.

| Characteristics | Values |

|---|---|

| Time to Combust 10 Pounds of Wood | Varies based on wood type, moisture content, and combustion conditions |

| Dry Hardwood (e.g., Oak) | Approximately 1-2 hours in a well-ventilated fire |

| Softwood (e.g., Pine) | Approximately 0.5-1 hour due to higher resin and lower density |

| Green (Wet) Wood | Significantly longer (3-6 hours) due to moisture evaporation |

| Optimal Combustion Temperature | 500-1,100°F (260-593°C) for efficient burning |

| Moisture Content Impact | Higher moisture content increases combustion time |

| Oxygen Availability | Adequate airflow reduces combustion time |

| Wood Density | Higher density woods (e.g., hardwoods) burn slower |

| Particle Size | Smaller pieces combust faster than larger logs |

| Combustion Efficiency | Varies; dry, seasoned wood burns more efficiently |

| External Factors | Weather, humidity, and fire containment affect combustion time |

Explore related products

What You'll Learn

- Wood Type Impact: Different wood types burn at varying rates, affecting combustion time significantly

- Moisture Content Effect: Higher moisture in wood prolongs combustion time due to water evaporation

- Oxygen Availability: Adequate oxygen supply is crucial for efficient and faster wood combustion

- Combustion Temperature: Higher temperatures accelerate wood combustion, reducing overall burning time

- Wood Density Role: Denser wood burns slower due to compacted fibers, extending combustion duration

Wood Type Impact: Different wood types burn at varying rates, affecting combustion time significantly

The density and moisture content of wood are critical factors in determining how quickly it combusts. Hardwoods like oak and maple, known for their high density, burn slower and longer compared to softwoods like pine or cedar. This is because dense wood has more fibers per unit volume, requiring more energy to break down and ignite. For instance, a 10-inch log of oak might take 2-3 hours to combust fully, while the same size pine log could burn out in just 1-1.5 hours. Understanding this difference is essential for anyone managing a fire, whether for heating, cooking, or outdoor activities.

To maximize combustion efficiency, consider the moisture content of the wood. Freshly cut or "green" wood contains up to 50% water, which must evaporate before the wood can burn effectively. This process consumes heat, slowing down combustion. Seasoned wood, dried for 6-12 months, has a moisture content of 20% or less, allowing it to ignite faster and burn hotter. For example, a 10-inch log of seasoned oak will combust more rapidly than the same size green oak log, reducing the time to full combustion by as much as 30-40%. Always prioritize seasoned wood for quicker and more efficient burning.

Softwoods, while faster-burning, have their advantages in specific scenarios. Their lower density and resin content make them ideal for kindling or starting fires, as they ignite quickly and produce a hot flame. However, their rapid combustion means they are less suitable for long-lasting fires. If you’re aiming for a 10-hour burn, combine softwoods with hardwoods: use pine or cedar to get the fire going, then add oak or hickory to sustain it. This layered approach ensures a consistent burn rate and extends the overall combustion time.

For those seeking precise control over combustion time, selecting the right wood type is as important as managing the fire itself. Hardwoods like ash or beech burn at a moderate pace, offering a balance between heat output and longevity. A 10-inch log of ash might take 1.5-2 hours to combust fully, making it a reliable choice for steady, long-term fires. Pairing this with proper airflow and firebox size can further optimize burn time. For example, a well-maintained fireplace with adequate ventilation can extend the combustion time of a hardwood log by 10-15%, ensuring a more efficient and prolonged burn.

Finally, consider the environmental and practical implications of wood type selection. While softwoods burn faster, they also produce more creosote, a flammable byproduct that can build up in chimneys and increase fire risk. Hardwoods, though slower-burning, produce less creosote and are safer for prolonged use. For a 10-hour burn, opt for hardwoods like cherry or walnut, which offer a clean, steady flame with minimal residue. Always prioritize safety and sustainability by choosing wood types that align with your combustion goals and maintenance capabilities.

Petrified Wood Formation: Understanding the Timeframe for Fossilization

You may want to see also

Explore related products

Moisture Content Effect: Higher moisture in wood prolongs combustion time due to water evaporation

Wood with higher moisture content takes significantly longer to combust because the energy from the fire must first evaporate the water before the wood can ignite and burn efficiently. This process, known as latent heat absorption, consumes a substantial portion of the heat generated, effectively delaying the combustion process. For instance, wood with a moisture content of 20% requires nearly twice as much energy to reach ignition temperature compared to dry wood at 10% moisture. This principle underscores why seasoned firewood, typically dried to below 20% moisture, is preferred for efficient burning.

To illustrate, consider the practical implications for homeowners or campers. If you attempt to burn freshly cut wood (often 50-100% moisture content), the fire will struggle to sustain itself. The heat produced is diverted to drying the wood rather than maintaining combustion. In contrast, kiln-dried wood, with moisture levels around 10-15%, ignites faster and burns hotter, reducing the time needed to achieve a consistent flame. For optimal results, aim to use wood with a moisture content below 20%, and invest in a moisture meter to verify levels before burning.

From a comparative standpoint, the moisture content effect is akin to trying to light a wet newspaper versus a dry one. The wet newspaper smolders and produces smoke, while the dry one catches fire quickly. Similarly, high-moisture wood not only prolongs combustion but also increases creosote buildup in chimneys, posing a fire hazard. Dry wood, however, burns cleaner and more efficiently, minimizing residue and maximizing heat output. This comparison highlights why moisture management is critical in wood combustion.

For those looking to expedite the drying process, stack firewood in a well-ventilated area, ensuring it is raised off the ground to prevent moisture absorption. Cover the stack with a tarp, leaving the sides open for airflow. In humid climates, consider using a dehumidifier or storing wood indoors for several months before use. If time is a constraint, purchasing kiln-dried wood is a reliable alternative, though it comes at a higher cost. These steps can significantly reduce combustion time and improve overall fire performance.

In conclusion, understanding the moisture content effect is essential for anyone relying on wood as a fuel source. By prioritizing dry wood and implementing proper storage techniques, you can minimize combustion time, enhance fire efficiency, and reduce safety risks. Whether for heating or recreational use, managing moisture content is a key factor in achieving optimal wood-burning results.

Durability of Wooden Conservatories: Lifespan and Maintenance Tips

You may want to see also

Explore related products

Oxygen Availability: Adequate oxygen supply is crucial for efficient and faster wood combustion

Wood combustion is a delicate dance of fuel, heat, and oxygen. Without sufficient oxygen, this process falters, leading to inefficient burning, increased smoke, and a longer time to reach full combustion. Imagine a campfire struggling to ignite due to damp wood and a weak breeze; the lack of oxygen starves the fire, resulting in smoldering embers instead of a roaring blaze. This scenario underscores the critical role of oxygen in wood combustion.

To optimize combustion, ensuring an adequate oxygen supply is paramount. The ideal air-fuel ratio for wood burning typically ranges between 1:10 and 1:20, meaning 1 part oxygen to 10-20 parts fuel. In practical terms, this translates to proper ventilation in wood-burning stoves or fireplaces. For instance, a stove with a 6-inch flue should have an air intake of at least 30 square inches to maintain this balance. Insufficient airflow not only slows combustion but also increases creosote buildup, a leading cause of chimney fires.

Consider the difference between a well-ventilated fireplace and one with blocked vents. In the former, wood burns cleanly, reaching temperatures of 1,100°F (593°C) within minutes, ensuring complete combustion. In the latter, temperatures may barely exceed 600°F (315°C), leading to partial combustion and the release of harmful pollutants like carbon monoxide. This comparison highlights how oxygen availability directly impacts both the speed and efficiency of wood burning.

For those seeking to accelerate wood combustion, practical steps include using dry, seasoned wood with a moisture content below 20%, as wet wood consumes oxygen to evaporate moisture rather than burn. Additionally, arranging logs in a "log cabin" or "teepee" structure promotes airflow through the stack. For outdoor fires, positioning the woodpile in a windy area or using a bellows can increase oxygen supply. In enclosed spaces, installing an external air kit for stoves ensures a direct oxygen source without drawing cold air from the room.

In summary, oxygen is the unsung hero of wood combustion. By understanding its role and implementing simple strategies to enhance its availability, you can significantly reduce the time it takes to combust wood while improving safety and efficiency. Whether you're tending a fireplace or managing a wood stove, prioritizing oxygen supply is key to a faster, cleaner burn.

Understanding Wood Lovers Paralysis Duration: Symptoms, Recovery, and Treatment

You may want to see also

Explore related products

Combustion Temperature: Higher temperatures accelerate wood combustion, reducing overall burning time

Wood combustion is a delicate dance of heat, oxygen, and fuel, where temperature plays the lead role. At 572°F (300°C), wood begins to release volatile gases, the first step in combustion. However, it’s not until temperatures reach 1,112°F (600°C) that these gases ignite and sustain a flame. This threshold highlights why higher temperatures are critical: they expedite the release and ignition of these gases, significantly reducing the time it takes for wood to combust fully. For instance, in a well-insulated wood stove operating at 1,202°F (650°C), a 10-inch log can burn completely in as little as 45 minutes, compared to over 2 hours in an open fire pit where temperatures rarely exceed 800°F (427°C).

To harness this principle, consider the practical steps for optimizing combustion temperature. First, ensure proper airflow to maintain a consistent oxygen supply, as oxygen starvation can lower temperatures and prolong burning time. Second, use dry, seasoned wood with a moisture content below 20%, as moisture absorbs heat, reducing the overall temperature. Third, preheat the combustion chamber before adding wood to create an environment where temperatures are already near the ignition threshold. For example, in a fireplace, crumpling newspaper and kindling to create a small, intense fire can preheat the flue and surrounding air, allowing larger logs to combust more rapidly once added.

A comparative analysis reveals the stark difference in combustion times based on temperature control. In a controlled environment like a modern wood-burning stove, temperatures can be maintained at 1,200°F (649°C) or higher, enabling a 10-inch log to burn completely in under an hour. Conversely, in an open campfire, where temperatures fluctuate and rarely exceed 900°F (482°C), the same log may take 2–3 hours to combust fully. This disparity underscores the importance of temperature management, not just for efficiency but also for reducing emissions, as higher temperatures ensure more complete combustion, leaving less unburned carbon.

For those seeking to minimize combustion time, a persuasive argument lies in the benefits of investing in temperature-optimized systems. Wood stoves with secondary combustion chambers, for instance, reintroduce exhaust gases into a high-temperature environment, ensuring they burn completely. Similarly, rocket mass heaters use a J-shaped combustion chamber to maintain temperatures above 1,800°F (982°C), allowing wood to combust in minutes rather than hours. While these systems require an initial investment, the reduced fuel consumption and faster heating times make them a cost-effective solution for long-term use.

Finally, a descriptive example illustrates the transformative effect of temperature on wood combustion. Imagine a 10-inch oak log placed in a traditional fireplace versus a high-efficiency wood stove. In the fireplace, the log smolders, releasing smoke and creosote as it slowly burns over hours. In the stove, the same log is engulfed in a clean, intense flame, reducing to ash in under an hour. This contrast is not just a matter of aesthetics but a testament to the power of temperature control in accelerating combustion, proving that heat is the linchpin of efficient wood burning.

John Wooden's Legendary Coaching Tenure at UC: A Timeline

You may want to see also

Explore related products

Wood Density Role: Denser wood burns slower due to compacted fibers, extending combustion duration

The density of wood is a critical factor in determining how long it takes to combust. Denser woods, such as oak or hickory, have tightly compacted fibers that restrict oxygen flow, slowing the burning process. This means a log of dense wood can take significantly longer to burn compared to a less dense variety like pine or cedar. For instance, a 10-inch diameter oak log might burn steadily for 6–8 hours, while a similarly sized pine log could be reduced to ash in just 3–4 hours. Understanding this relationship allows you to choose the right wood for your needs, whether you’re aiming for a quick, intense fire or a long-lasting, steady burn.

To maximize combustion duration, consider the practical steps involved in selecting and preparing dense wood. Start by splitting logs into smaller pieces to expose more surface area, which can help initiate combustion despite the wood’s density. However, avoid splitting too finely, as this can reduce burn time. Aim for pieces 4–6 inches in diameter for optimal performance. Additionally, ensure the wood is well-seasoned, as moisture content can further hinder combustion. Denser woods typically require at least 12–18 months of drying time, compared to 6–12 months for less dense varieties. Proper seasoning not only extends burn time but also improves efficiency and reduces creosote buildup.

From a comparative perspective, the role of wood density in combustion duration becomes even more apparent when examining different species. For example, ash wood, with a density of around 45 pounds per cubic foot, burns slower and hotter than balsa wood, which has a density of just 8 pounds per cubic foot. This difference is not just theoretical—it has practical implications for applications like heating or cooking. If you’re using a wood stove, denser woods are ideal for overnight burns, as they maintain a consistent temperature for longer periods. Conversely, less dense woods are better suited for quick fires, such as those used for outdoor cooking or recreational campfires.

Finally, the takeaway is clear: denser wood burns slower due to its compacted fibers, making it a superior choice for extended combustion. However, this advantage comes with trade-offs, such as longer seasoning times and the need for proper preparation. For those seeking to optimize burn duration, investing in dense hardwoods like maple, beech, or walnut is a strategic decision. Pair this with good fire management practices, such as maintaining adequate airflow and using a proper firebox, to ensure you get the most out of your wood. By mastering the relationship between wood density and combustion, you can achieve efficient, long-lasting fires tailored to your specific needs.

Teak Oil Durability: How Long Does It Protect Wood Surfaces?

You may want to see also

Frequently asked questions

The time it takes for 10 pounds of wood to completely combust depends on factors like wood type, moisture content, oxygen supply, and temperature. Typically, it can take 1-3 hours under optimal conditions in a well-ventilated fire.

Yes, the type of wood significantly affects combustion time. Hardwoods like oak burn slower and longer, while softwoods like pine burn faster. Moisture content and density also play a role.

Absolutely. Wet or green wood contains more moisture, which requires additional energy to evaporate before combustion can occur. This can significantly increase the time it takes for 10 pounds of wood to burn completely.

Adequate oxygen supply is crucial for efficient combustion. Limited oxygen can slow down the process or result in incomplete burning. In a well-ventilated environment, 10 pounds of wood will combust faster and more thoroughly.