When fastening sheet metal to wood, selecting the appropriate screw length is crucial for ensuring a secure and durable connection. The ideal screw length depends on several factors, including the thickness of the sheet metal, the density and type of wood, and the structural requirements of the project. Generally, the screw should penetrate the wood by at least 1 inch (25 mm) to achieve sufficient holding power, but it must also be long enough to pass through the sheet metal without being excessively long, which could weaken the wood or cause unnecessary material waste. For most applications, screws ranging from 1 to 1.5 inches (25 to 38 mm) are commonly used, but precise measurements and testing are recommended to ensure optimal performance and longevity.

| Characteristics | Values |

|---|---|

| Screw Length | Typically 1/2" to 1-1/2" (12mm to 38mm) |

| Gauge | #6 to #14 (common sizes: #8, #10, #12) |

| Head Type | Hex, Phillips, Flat, or Combination |

| Drive Type | Phillips, Square, or Torx |

| Material | Stainless Steel, Galvanized Steel, or Zinc-Plated Steel |

| Thread Type | Self-Tapping or Self-Drilling |

| Point Type | Sharp or Drill Point |

| Recommended Wood Thickness | At least 1/2" (12mm) for proper hold |

| Sheet Metal Thickness | Up to 0.0625" (1.59mm) for self-tapping screws |

| Pilot Hole | Required for hardwoods or thicker metals |

| Spacing | 6" to 12" (150mm to 300mm) between screws |

| Edge Distance | Minimum 1/2" (12mm) from edge to prevent splitting |

| Load Capacity | Varies by screw size and material (check manufacturer specs) |

| Corrosion Resistance | Higher in stainless steel and galvanized screws |

| Common Applications | Roofing, HVAC, Electrical Boxes, and General Construction |

| Code Compliance | Ensure screws meet local building codes (e.g., ASTM standards) |

Explore related products

What You'll Learn

Screw length calculation methods

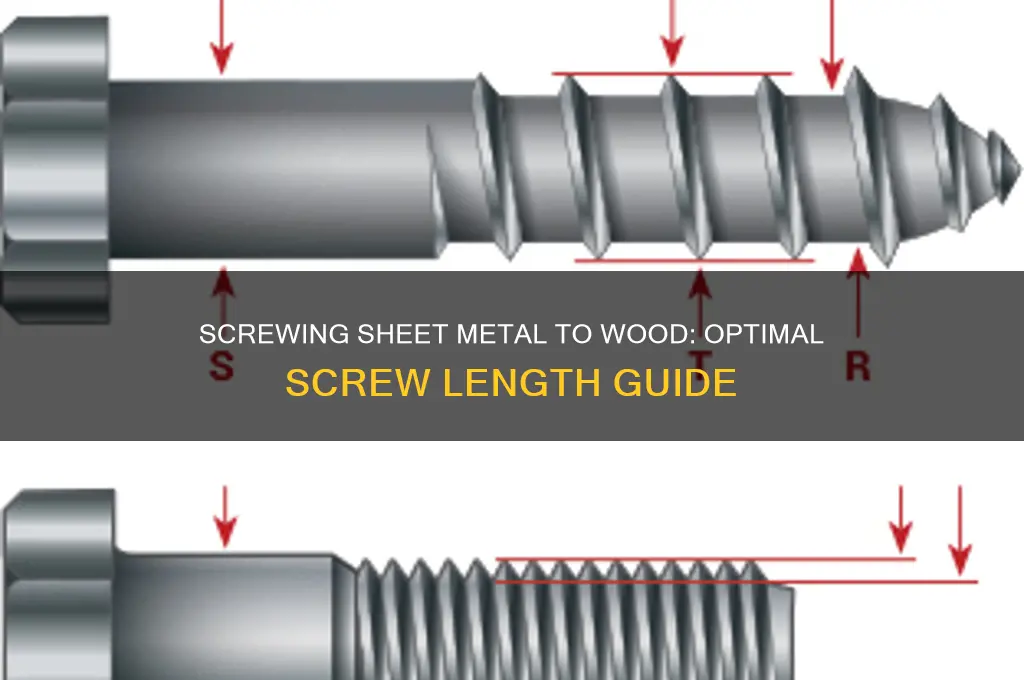

Determining the correct screw length for fastening sheet metal to wood is crucial for ensuring a secure and durable connection. One widely accepted method involves the 2/3rds rule, which dictates that the screw should penetrate the wood by at least two-thirds of its length. For example, if the wood thickness is 1.5 inches, the screw should be at least 2 inches long, with 1 inch embedded in the wood. This rule balances holding power with practicality, as longer screws can split the wood or become difficult to drive.

Another approach is the material thickness method, which considers the combined thickness of the sheet metal and wood. Measure the sheet metal gauge and add it to the wood thickness. For instance, if the sheet metal is 0.032 inches (22 gauge) and the wood is 1 inch thick, the screw should be at least 1.032 inches plus an additional 0.5 inches to ensure proper engagement. This method is particularly useful when working with thinner sheet metal or softer woods, where precision is critical.

For those seeking a more empirical approach, the pilot hole technique can be employed. Drill a pilot hole through the sheet metal and partially into the wood, then insert the screw to gauge its fit. If the screw threads engage the wood without binding, the length is adequate. This trial-and-error method is time-consuming but ensures accuracy, especially in applications where structural integrity is paramount.

Lastly, manufacturer guidelines often provide specific recommendations based on screw type and material compatibility. For instance, self-tapping screws for sheet metal may require less penetration into wood compared to standard wood screws. Always consult product specifications or technical data sheets for optimal lengths, as these resources account for factors like load-bearing capacity and environmental conditions. By combining these calculation methods, you can confidently select the right screw length for any sheet metal-to-wood project.

Standard Full-Size Wooden Bed Slats Length Explained: A Quick Guide

You may want to see also

Explore related products

Sheet metal gauge impact on screw choice

The thickness of sheet metal, measured in gauge, directly influences the screw length and type required for a secure wood-to-metal connection. Thinner gauges (higher numbers, like 24 or 26) demand shorter screws to avoid puncturing through the metal, while thicker gauges (lower numbers, like 12 or 14) can accommodate longer screws for deeper wood penetration. This relationship is critical to prevent material damage and ensure structural integrity.

For instance, when fastening 22-gauge sheet metal to a wooden frame, a #8 screw with a length of ½ inch is often sufficient. This length allows the screw to bite into the wood without risking protrusion through the metal. In contrast, 16-gauge metal, being nearly twice as thick, may require a ¾-inch screw to achieve the same secure hold. Ignoring gauge thickness can lead to screws either pulling through the metal or failing to engage the wood adequately.

Selecting the appropriate screw length also involves considering the wood thickness. A general rule is to have at least ½ inch of screw thread embedded in the wood for a strong hold. For example, if the wood is 1 inch thick and the sheet metal is 20-gauge (0.036 inches thick), a 1-inch screw would provide ½ inch of thread engagement in the wood while accounting for the metal’s thickness. This calculation ensures both materials are securely fastened without compromising either.

Beyond length, the screw’s material and design play a role in gauge compatibility. Self-tapping screws with sharp threads are ideal for thinner gauges (22–26) to minimize metal distortion during installation. For thicker gauges (12–16), coarse-threaded screws offer better grip and durability. Additionally, using a pilot hole in the metal can prevent cracking or warping, especially with thicker gauges that resist self-tapping screws.

In summary, sheet metal gauge is a decisive factor in screw selection for wood-to-metal applications. Matching screw length to both metal thickness and wood depth ensures a secure, long-lasting connection. Practical tips include measuring both materials, using self-tapping screws for thinner gauges, and pre-drilling pilot holes for thicker gauges. By accounting for gauge impact, you avoid common pitfalls like material damage or weak fastening, resulting in a more robust assembly.

Growing Basal Wood: Understanding the Timeframe for Optimal Growth

You may want to see also

Explore related products

Wood density and screw holding power

Wood density plays a pivotal role in determining how effectively a screw will hold when fastening sheet metal to wood. Denser woods, like oak or maple, provide more material for the screw threads to grip, resulting in superior holding power. Softer woods, such as pine or cedar, offer less resistance, which can lead to stripped threads or loosening over time. When selecting screw length, consider the wood’s density: a longer screw may be necessary in softer woods to achieve the same hold strength as a shorter screw in harder woods. For instance, a 1.5-inch screw might suffice in oak, while a 2-inch screw could be required in pine for comparable stability.

To maximize screw holding power, match the screw gauge and thread design to the wood density. Coarse-threaded screws are ideal for softer woods, as they create larger bite points and reduce the risk of splitting. For denser woods, finer threads provide a tighter grip without excessive force during installation. Pre-drilling pilot holes is essential in harder woods to prevent cracking, while softer woods may only require a pilot hole for screw alignment. A practical tip: use a screw length that penetrates at least 1 inch into the wood substrate, ensuring the screw engages enough material to bear the load.

Analyzing the relationship between wood density and screw holding power reveals a trade-off between material strength and fastener design. In high-density woods, shorter screws can achieve robust holds due to the wood’s inherent rigidity. Conversely, low-density woods demand longer screws to compensate for the material’s weaker structure. For example, when fastening sheet metal to a 2x4 stud, a 1.25-inch screw in Douglas fir (medium density) provides adequate hold, whereas a 1.75-inch screw might be needed in balsa wood (low density). This highlights the importance of tailoring screw length to the specific wood type.

A comparative approach underscores the variability in screw performance across wood densities. In a test scenario, a #8 wood screw driven into oak held 250 lbs of shear force, while the same screw in cedar held only 150 lbs. This 40% difference in holding power demonstrates why denser woods are preferred for structural applications. However, softer woods can still be used effectively with longer screws or additional fasteners. For sheet metal to wood connections, consider using a screw that penetrates at least 75% of the wood thickness in softwoods and 50% in hardwoods to balance strength and material conservation.

Instructively, achieving optimal screw holding power in wood requires a systematic approach. First, identify the wood species and its density using a wood density chart (e.g., oak: 45 lbs/ft³, pine: 25 lbs/ft³). Next, select a screw length that ensures at least 1 inch of engagement in the wood substrate. For sheet metal applications, use self-tapping screws to secure the metal without pre-drilling. Finally, test the connection with a torque wrench to ensure it meets the load requirements. By accounting for wood density, you can avoid common pitfalls like screw pull-out or wood splitting, ensuring a durable and reliable fastening solution.

Wood to Stone: Understanding the Petrification Process and Timeline

You may want to see also

Explore related products

Pilot hole size recommendations

Drilling pilot holes is crucial when fastening sheet metal to wood to prevent splitting and ensure a secure hold. The size of the pilot hole depends on the screw diameter and the type of wood. As a general rule, the pilot hole should be slightly smaller than the screw’s root diameter (the thickest part of the screw thread). For example, a #8 screw (0.164 inches in diameter) typically requires a 1/8-inch pilot hole in hardwood and a 7/64-inch hole in softwood. This ensures the threads grip the wood without causing undue stress.

In analytical terms, the relationship between screw size and pilot hole diameter is rooted in material science and mechanics. Hardwoods like oak or maple are denser and less prone to splitting, allowing for smaller pilot holes that maximize thread engagement. Softwoods like pine, however, are more forgiving but require larger pilot holes to prevent the wood from compressing excessively. Ignoring these distinctions can lead to stripped threads, weakened joints, or even cracked wood. Always reference screw manufacturer guidelines for precise recommendations, as variations in screw design (e.g., self-tapping vs. standard) may alter requirements.

Persuasively, investing time in proper pilot hole sizing pays dividends in the longevity and strength of your project. A common mistake is assuming "one size fits all," which often results in stripped screws or damaged wood. For instance, using a 1/8-inch bit for a #6 screw (0.138 inches) in hardwood will likely cause the wood to split, while a 3/32-inch hole is ideal. Similarly, sheet metal screws often require pre-drilling in both the metal and wood to align materials and reduce torque. Skipping this step may compromise the joint’s integrity, especially in load-bearing applications.

Comparatively, pilot hole techniques for sheet metal-to-wood assemblies differ from wood-to-wood fastening. When joining sheet metal to wood, the pilot hole in the wood must accommodate the screw’s threading, while the metal typically requires a clearance hole (slightly larger than the screw’s shank) to allow for fastener passage without resistance. For example, a #10 screw (0.190 inches) would need a 7/32-inch clearance hole in the metal and a 5/32-inch pilot hole in softwood. This dual-hole approach ensures alignment and minimizes the risk of warping or misalignment during installation.

Descriptively, envision the process as a tailored fit rather than a forced connection. The pilot hole acts as a guide, allowing the screw to advance smoothly while the threads bite into the wood fibers. In softer woods, a slightly larger hole prevents compression and splitting, while in hardwoods, a snugger fit maximizes holding power. For sheet metal applications, the wood’s pilot hole should be deep enough to engage the threads fully, typically 2/3 the length of the screw. Always test your setup on scrap material to confirm alignment and fit before committing to the final assembly.

Pressure Treated Wood Lifespan in Soil: Durability and Longevity Explained

You may want to see also

Explore related products

Corrosion resistance screw material options

Selecting the right screw material is crucial when fastening sheet metal to wood, especially in environments prone to moisture or chemical exposure. Corrosion can compromise the integrity of the joint, leading to structural failure over time. Stainless steel screws are a popular choice due to their inherent resistance to rust and oxidation. Grade 304 stainless steel is suitable for indoor applications, while Grade 316 offers superior protection in outdoor or marine environments due to its higher molybdenum content, which enhances resistance to chloride corrosion. For budget-conscious projects, zinc-plated or galvanized screws provide a cost-effective alternative, though their protective coating can wear off over time, limiting long-term durability.

For extreme conditions, consider screws made from exotic materials like titanium or bronze. Titanium screws are lightweight, exceptionally corrosion-resistant, and ideal for high-humidity or saltwater environments, though their high cost restricts them to specialized applications. Bronze screws, on the other hand, offer excellent resistance to saltwater corrosion and are commonly used in marine construction. However, they are softer than steel and may not be suitable for high-stress joints. When choosing a material, assess the specific environmental conditions and the expected lifespan of the project to ensure the screw’s corrosion resistance aligns with the demands of the application.

Coatings and surface treatments can significantly enhance a screw’s corrosion resistance, even if the base material is less durable. For instance, ceramic coatings provide a hard, non-porous barrier that protects against moisture and chemicals, making them ideal for outdoor or industrial settings. Another option is polymer coatings, which offer flexibility and resistance to abrasion, though they may degrade under UV exposure. Electroplating with metals like cadmium or zinc can also improve corrosion resistance, but these methods are less environmentally friendly and may require additional sealing to prevent degradation. Always consider the trade-offs between cost, durability, and environmental impact when selecting a coated screw.

In applications where aesthetics are as important as functionality, aluminum screws with an anodized finish provide a corrosion-resistant solution with a sleek appearance. Anodizing creates a protective oxide layer on the aluminum surface, which resists corrosion and allows for dyeing in various colors. However, aluminum screws are not as strong as steel and may not be suitable for load-bearing joints. For hidden fasteners or applications where the screw head is exposed to the elements, consider using screws with a combination of material and coating, such as stainless steel with a black oxide finish, which offers both corrosion resistance and a low-profile appearance.

Finally, proper installation techniques can maximize the corrosion resistance of any screw material. Pre-drilling pilot holes reduces the risk of wood splitting and ensures a tight fit, minimizing gaps where moisture can penetrate. Using sealants or thread lockers around the screw threads can create an additional barrier against water and chemicals. Regular inspection and maintenance, such as reapplying coatings or replacing screws that show signs of corrosion, will extend the life of the joint. By combining the right material, coating, and installation practices, you can ensure a secure and long-lasting connection between sheet metal and wood, even in challenging environments.

Eliminating Wood Glue Odor: How Long Does the Smell Linger?

You may want to see also

Frequently asked questions

A screw length of 1 to 1.5 inches is commonly used for securing sheet metal to wood, depending on the thickness of the materials.

The screw should be long enough to penetrate the wood by at least 1 inch after passing through the sheet metal. Measure the thickness of the sheet metal and add 1 inch to determine the minimum screw length.

Yes, self-tapping screws are ideal for sheet metal to wood as they eliminate the need for pre-drilling and provide a secure hold in both materials.

A hex head or pan head screw is recommended for sheet metal to wood applications, as they provide a secure grip and are easy to install with a screwdriver or drill.

Pre-drilling is not always necessary, especially with self-tapping screws. However, pre-drilling can prevent the wood from splitting, especially in hardwoods or near the edges of the wood.