When using a pocket jig for joining 1-1/2 inch thick wood, selecting the correct screw length is crucial for achieving a strong and durable connection. The ideal screw length depends on the jig's specifications and the type of joint being created, but generally, for 1-1/2 inch wood, a 2-1/2 inch screw is recommended. This length ensures that the screw penetrates at least 1 inch into the adjoining board, providing sufficient thread engagement for a secure hold. Using screws that are too short can result in weak joints, while overly long screws may protrude through the material or cause splitting. Always consult the pocket jig's manual or manufacturer guidelines to confirm the appropriate screw length for your specific application.

| Characteristics | Values |

|---|---|

| Wood Thickness | 1-1/2 inches (38 mm) |

| Recommended Screw Length | 2-1/2 inches (63.5 mm) |

| Screw Type | Coarse thread, self-tapping screws |

| Screw Head Type | Flat or round head (depending on jig and preference) |

| Pilot Hole Depth | Approximately 1/4 inch (6 mm) less than screw length |

| Pocket Hole Angle | Typically 15 degrees (varies by jig model) |

| Screw Material | Zinc-plated or stainless steel for durability |

| Common Screw Sizes | #8 or #10 gauge |

| Application | Joining two pieces of 1-1/2 inch thick wood at a 90-degree angle |

| Jig Compatibility | Works with most pocket hole jigs (e.g., Kreg Jig, Porter Cable, etc.) |

Explore related products

What You'll Learn

Screw length calculation for 1-1/2 wood using pocket jig

Determining the correct screw length for a pocket jig joint in 1-1/2" wood requires precision to ensure a strong, durable connection. The screw must be long enough to penetrate the adjoining board by at least 1" while avoiding blowout on the opposite side. A common rule of thumb is to use a screw that is 2/3 the combined thickness of the two boards being joined. For 1-1/2" wood, this translates to a screw length of approximately 2-1/2" to 2-3/4", depending on the specific jig and screw type. This calculation ensures the screw engages sufficiently into the second board without compromising the joint’s integrity.

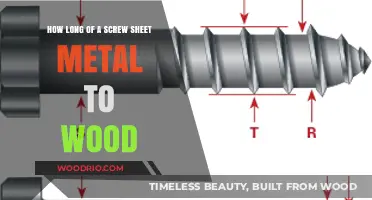

Analyzing the mechanics of pocket hole joints reveals why screw length is critical. The pocket jig creates an angled hole, typically at 15 degrees, which allows the screw to pull the boards together tightly. If the screw is too short, it won’t achieve the necessary bite into the second board, resulting in a weak joint. Conversely, a screw that’s too long risks splitting the wood or protruding through the opposite side. For 1-1/2" material, a #8 or #10 gauge screw with a coarse thread is ideal, as it provides better grip and reduces the risk of stripping the wood.

To calculate the exact screw length, follow these steps:

- Measure the thickness of both boards being joined.

- Add their thicknesses together (e.g., 1-1/2" + 1-1/2" = 3").

- Multiply the combined thickness by 2/3 (e.g., 3" × 2/3 = 2").

- Round up to the nearest standard screw length, typically available in increments of 1/4". For this example, a 2-1/2" screw would be appropriate.

A practical tip is to test the screw length on scrap wood before committing to your project. Insert the screw into the pocket hole and ensure it penetrates the second board by at least 1" without protruding. If using hardwoods, which are denser, consider slightly shorter screws to prevent splitting. For softer woods like pine, the full calculated length is usually safe.

In conclusion, screw length calculation for 1-1/2" wood using a pocket jig is a balance of precision and practicality. By following the 2/3 rule and testing on scrap material, you can achieve joints that are both strong and reliable. Remember, the goal is to maximize screw engagement without causing damage, ensuring your project stands the test of time.

Wood Glue Drying Time: Factors Affecting Cure Speed and Strength

You may want to see also

Explore related products

Pocket hole depth and screw size compatibility

Achieving the correct pocket hole depth is crucial for ensuring screw size compatibility and joint strength when working with 1-1/2" thick wood. The depth of the pocket hole directly influences how much of the screw engages with the adjacent board, affecting both the mechanical hold and the overall stability of the joint. For 1-1/2" material, a pocket hole depth of approximately 1" is typically recommended. This depth allows for sufficient screw thread engagement without compromising the integrity of the wood. Using a pocket hole jig with adjustable depth settings can help achieve this precision, ensuring the screw seats properly and the joint remains secure.

Selecting the appropriate screw length is equally important and depends on the combined thickness of the two boards being joined. For 1-1/2" wood, a common screw length is 2-1/2". This length ensures that the screw passes through the first board and embeds at least 3/4" into the second board, providing a strong hold. However, if the joint involves a thinner secondary piece, such as 3/4" plywood, a shorter screw, like 2", may be more suitable to avoid breakout on the opposite side. Always measure the combined thickness of the materials and choose a screw that is at least 1/2" to 3/4" shorter than this total to prevent protrusion.

A practical tip for ensuring compatibility is to test the screw length and pocket hole depth on scrap wood before committing to the final project. This trial run allows you to verify that the screw seats correctly and that the joint is tight. If the screw bottoming out or the joint feels loose, adjust the pocket hole depth or screw length accordingly. For example, if the screw doesn’t reach the second board, increase the pocket hole depth slightly or switch to a longer screw. Conversely, if the screw protrudes, reduce the depth or use a shorter screw.

Another consideration is the screw type and thread design, as these factors influence how effectively the screw grips the wood. Coarse-threaded screws are ideal for softwoods, while fine-threaded screws work better with hardwoods. For 1-1/2" wood, a #8 or #10 gauge screw is typically appropriate, depending on the wood density and joint requirements. Using the correct driver bit is also essential to prevent stripping the screw head during installation. By carefully matching pocket hole depth, screw length, and type, you can create durable and professional-looking joints in your woodworking projects.

How Long Does Flavored Wood Last? A Comprehensive Guide

You may want to see also

Explore related products

$20.99

Best screw types for pocket hole joinery

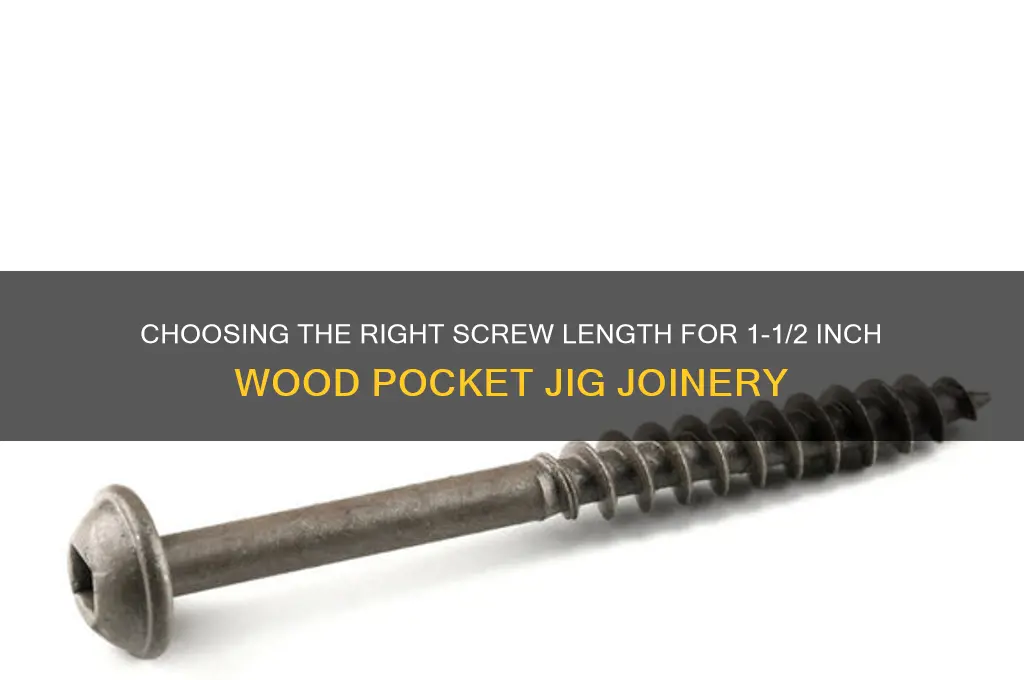

Selecting the right screw for pocket hole joinery in 1-1/2" wood is critical to ensuring a strong, durable connection. The screw length must account for the thickness of both boards and the depth of the pocket hole, typically leaving 3/4" to 1" of thread engagement in the second board. For 1-1/2" material, a 2-1/2" screw is the standard choice, as it provides sufficient bite into the adjoining piece without compromising the joint’s integrity. Always pre-drill pilot holes in hardwoods to prevent splitting, even with self-tapping screws.

Among screw types, coarse-thread screws are ideal for pocket hole joinery in softwoods like pine or cedar. Their aggressive threads create a tighter hold, reducing the risk of stripping during installation. For hardwoods such as oak or maple, fine-thread screws are preferable, as they minimize the risk of wood fibers tearing. Square-drive screws are recommended over Phillips or flathead styles, as they resist cam-out and provide better torque control, especially when driving screws at an angle.

Coated screws significantly impact performance and longevity. Zinc-plated screws offer basic corrosion resistance and are cost-effective for indoor projects. For exterior applications or humid environments, opt for ceramic-coated or stainless steel screws to prevent rust. Ceramic coatings, in particular, reduce friction during installation and enhance the screw’s grip, making them a premium choice for high-stress joints.

While screw length and type are paramount, the screw head design also plays a role in pocket hole joinery. Flat-head screws create a flush finish, ideal for surfaces that will be visible or sanded smooth. For hidden joints or structural applications, round-head screws provide ample strength without the need for precision countersinking. Always test screws in scrap wood to ensure they seat properly and align with the pocket hole’s angle.

Finally, consider the screw’s material composition. Standard carbon steel screws are economical but prone to corrosion. For outdoor furniture or projects exposed to moisture, invest in stainless steel or hardened steel screws. These materials offer superior strength and rust resistance, ensuring the joint remains secure over time. Pairing the right screw with a high-quality pocket hole jig will yield professional results, whether you’re building cabinets, frames, or outdoor structures.

Sola Wood Flowers Shipping Time: What to Expect for Delivery

You may want to see also

Explore related products

Avoiding screw blowout in 1-1/2 thick wood

Screw blowout in 1-1/2" thick wood is a common frustration when using pocket hole jigs, often resulting from screws that are too long or improperly driven. The key to prevention lies in selecting the right screw length and technique. For 1-1/2" material, a 1-1/4" pocket hole screw is typically ideal, as it allows sufficient thread engagement without breaking through the opposite side. Longer screws, such as 1-1/2" or 2", increase the risk of blowout by exerting excessive force on the wood fibers during driving. Always reference the jig manufacturer’s guidelines, but this 1-1/4" rule is a reliable starting point for most hardwoods and softwoods.

The anatomy of a pocket hole screw plays a critical role in blowout prevention. Coarse-threaded screws are preferred for softer woods like pine, as they provide better grip without splitting. For harder woods like oak or maple, fine-threaded screws reduce the stress on the wood fibers. Additionally, screws with a flat head design distribute force more evenly, minimizing the risk of surface damage. Self-tapping screws are also advantageous, as they eliminate the need for pre-drilling, which can weaken the joint and increase blowout potential.

Technique matters as much as screw selection. Driving the screw too quickly or with excessive force can cause blowout, even with the correct length. Start by positioning the drill at a slow speed and gradually increase pressure as the screw advances. If using a power drill, consider using a clutch setting to limit torque and prevent over-tightening. Hand-tightening the first few threads before engaging the drill can also reduce the risk of splitting, especially in brittle woods.

A lesser-known but effective strategy is to reinforce the joint area before driving the screw. Applying a thin layer of wood glue to the pocket hole and joint surfaces increases the wood’s density, providing additional resistance to blowout. For high-stress applications, such as tabletop joints, consider using a hardwood dowel or epoxy in conjunction with the pocket hole screw. This dual reinforcement ensures a stronger, more durable connection while minimizing the risk of failure.

Finally, test your setup on scrap wood before committing to the final project. Variability in wood grain, moisture content, and density can affect screw performance, even with the correct length and technique. By experimenting with different screw lengths, thread types, and driving speeds, you can identify the optimal combination for your specific material. This proactive approach not only prevents blowout but also ensures a professional-quality joint that stands the test of time.

Wood Duck Egg Incubation: Understanding Their Nesting Duration

You may want to see also

Explore related products

Screw length charts for pocket hole jigs

Selecting the correct screw length for a pocket hole jig in 1-1/2" thick wood is a critical step in ensuring joint strength and longevity. Screw length charts serve as indispensable tools for woodworkers, eliminating guesswork and minimizing errors. These charts typically correlate wood thickness with screw length, accounting for factors like pilot hole depth and the need for sufficient thread engagement in the adjoining piece. For 1-1/2" material, a common recommendation is a 2-1/2" screw, which allows 1" of thread to engage the adjacent board, ensuring a robust connection. However, this is a general guideline, and variations exist based on jig design, wood density, and joint type.

Analyzing screw length charts reveals a consistent principle: the screw must penetrate the adjoining board by at least 1" to achieve optimal holding power. For 1-1/2" wood, this means the screw length is the sum of the wood thickness and the required engagement depth. For example, a 2-1/2" screw provides 1" of thread in the adjoining board, while a 2-3/4" screw offers additional margin for denser hardwoods or heavier loads. Charts often include adjustments for edge joints versus face joints, as edge joints typically require less screw length due to the orientation of the joint.

A persuasive argument for using screw length charts is their role in preventing common mistakes, such as screws protruding through the adjoining board or failing to achieve adequate thread engagement. For instance, using a 2" screw in 1-1/2" wood might seem sufficient, but it leaves only 1/2" of thread in the adjoining piece, compromising joint integrity. Charts also account for the drill bit depth used in the pocket hole jig, ensuring the screw seats properly without stripping the wood. This precision is particularly vital in projects where structural stability is paramount, such as cabinetry or furniture.

Comparing screw length charts across different jig brands highlights both similarities and nuances. Kreg, a leading manufacturer, provides detailed charts tailored to their jig models, often recommending screws like the 2-1/2" coarse thread for 1-1/2" wood. Other brands may suggest slightly different lengths based on their drill bit angles or screw head designs. For example, a jig with a steeper drill angle might require a longer screw to achieve the same engagement depth. Woodworkers should always consult the chart specific to their jig to ensure compatibility and accuracy.

In practice, using a screw length chart involves three key steps: first, measure the thickness of both boards in the joint; second, identify the appropriate screw length from the chart; and third, verify the screw’s compatibility with the jig’s drill bit depth. A practical tip is to test the joint on scrap wood before committing to the final piece, ensuring the screw seats correctly and the joint is tight. For 1-1/2" wood, keeping a supply of 2-1/2" and 2-3/4" screws on hand allows flexibility for different joint scenarios. Ultimately, screw length charts are not just reference tools—they are essential guides for achieving professional-quality results in woodworking.

Drying Wood Post-Leak: Understanding the Timeframe for Effective Restoration

You may want to see also

Frequently asked questions

For 1-1/2 inch thick wood, use 1-1/4 inch screws with a pocket jig to ensure proper joint strength and penetration into the mating piece.

While longer screws can be used, 1-1/4 inch screws are ideal for 1-1/2 inch wood. Longer screws may protrude through the mating piece, causing damage or safety hazards.

No, 1-inch screws are too short for 1-1/2 inch wood. They won’t provide enough penetration into the mating piece, resulting in a weak joint.

Most pocket jigs create a pilot hole as part of the process, so additional pre-drilling is usually unnecessary. Follow the jig’s instructions for best results.