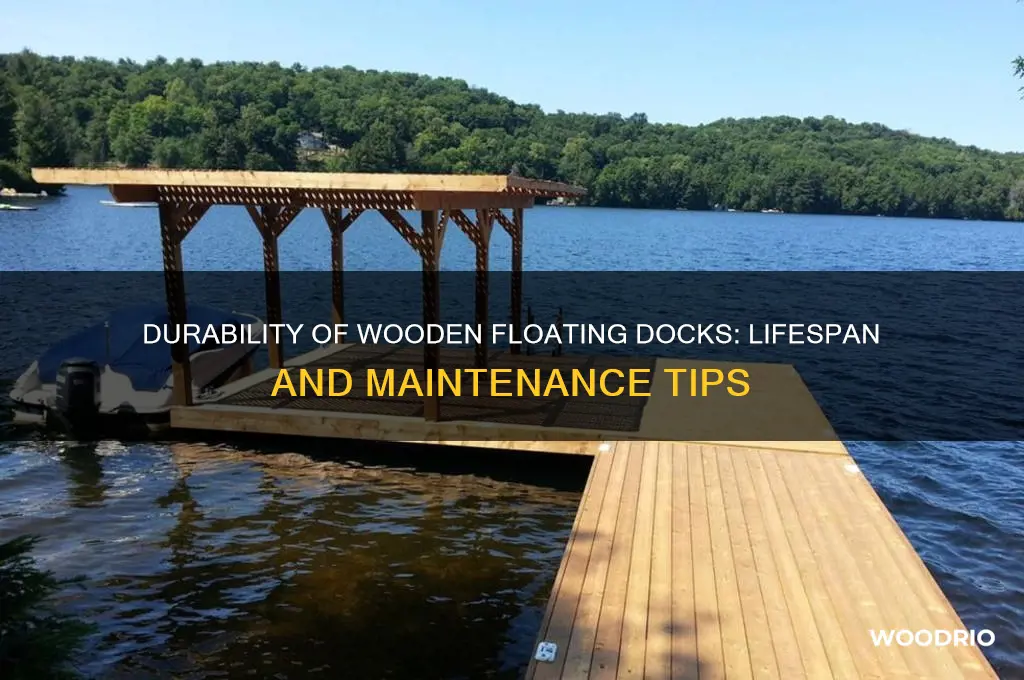

When considering the lifespan of a wooden floating dock, several factors come into play, including the quality of materials, construction techniques, environmental conditions, and maintenance practices. Typically, a well-built wooden floating dock can last anywhere from 15 to 25 years, though some may endure longer with proper care. Exposure to harsh elements like saltwater, UV radiation, and fluctuating water levels can accelerate wear and tear, while regular maintenance, such as sealing, staining, and inspecting for rot or damage, can significantly extend its longevity. Choosing pressure-treated or naturally rot-resistant wood, like cedar or cypress, also plays a crucial role in determining how long the dock will remain functional and safe. Ultimately, investing in high-quality materials and proactive upkeep is key to maximizing the lifespan of a wooden floating dock.

| Characteristics | Values |

|---|---|

| Average Lifespan | 10–15 years (with proper maintenance) |

| Primary Factors Affecting Durability | Wood type, environmental conditions, maintenance frequency |

| Wood Type | Cedar or treated pine (lasts longer than untreated wood) |

| Environmental Conditions | Exposure to sunlight, water salinity, temperature fluctuations |

| Maintenance Requirements | Annual staining, sealing, and inspection for rot or damage |

| Common Issues | Rot, warping, insect damage, hardware corrosion |

| Extended Lifespan with Care | Up to 20+ years with regular maintenance and protective measures |

| Comparative Lifespan (Other Materials) | Aluminum or plastic docks: 20–30+ years |

| Cost Impact | Higher maintenance costs for wood compared to low-maintenance materials |

| Sustainability | Biodegradable but requires frequent replacement compared to alternatives |

Explore related products

$45.99 $52.99

What You'll Learn

Material Quality Impact

The lifespan of a wooden floating dock hinges significantly on the quality of materials used. Opting for premium-grade, pressure-treated lumber, such as southern yellow pine or cedar, can extend durability by up to 20–30 years compared to untreated or lower-grade alternatives. These woods naturally resist rot, decay, and insect damage, making them ideal for aquatic environments. Conversely, using untreated pine or fir may result in structural failure within 5–10 years due to moisture absorption and fungal growth. The initial investment in high-quality materials pays dividends in longevity, reducing the need for frequent repairs or replacements.

Consider the role of hardware in material quality impact. Stainless steel bolts, screws, and brackets are essential for preventing corrosion, which can weaken connections and compromise safety. Galvanized hardware offers a more budget-friendly option but may require replacement after 10–15 years due to rusting. Inferior metals, like standard carbon steel, will fail within 2–3 years in saltwater environments, leading to costly repairs. Pairing high-quality wood with corrosion-resistant hardware ensures the dock remains structurally sound for decades, even in harsh conditions.

Another critical factor is the type of sealant or protective coating applied. A premium marine-grade sealant, reapplied every 2–3 years, can double the lifespan of wooden components by repelling water and UV damage. Epoxy coatings provide an even more durable barrier but require professional application. Neglecting this step or using low-quality sealants leaves the wood vulnerable to cracking, warping, and splintering within 5 years. Regular maintenance, including sanding and resealing, is a small effort that yields substantial returns in dock longevity.

Finally, the choice of flotation devices directly influences material performance. High-density polyethylene (HDPE) floats are superior to styrofoam or foam-filled drums, which degrade within 5–7 years. HDPE floats resist cracking, UV damage, and chemical breakdown, maintaining buoyancy for 20+ years. Pairing these with a robust anchoring system minimizes stress on wooden components, further extending the dock’s life. Investing in quality flotation ensures the dock remains stable and functional, even under heavy use or extreme weather conditions.

In summary, material quality is not just a factor but the cornerstone of a wooden floating dock’s lifespan. From wood selection to hardware, sealants, and flotation devices, each choice compounds the dock’s durability. While premium materials demand a higher upfront cost, they deliver unparalleled longevity, safety, and cost-effectiveness over time. Prioritize quality at every stage to build a dock that withstands the test of time and elements.

How Long Does Wood Stay Wet? Factors Affecting Drying Time

You may want to see also

Explore related products

Maintenance Frequency Tips

A wooden floating dock's lifespan hinges on consistent, proactive maintenance. Neglect this, and you're looking at a mere 5-10 years before rot, warping, or structural failure sets in. Prioritize a bi-annual inspection schedule, ideally in spring and fall, to catch issues early. During these inspections, scrutinize for cracks, splinters, loose hardware, and signs of marine borer activity. Address minor damage immediately—a small repair today prevents a costly replacement tomorrow.

Think of your dock's maintenance like a prescription: regular doses of care keep it healthy. Apply a high-quality, marine-grade sealant every 1-2 years, depending on exposure to sun and water. This acts as a protective barrier against moisture infiltration, the primary culprit behind wood decay. For added protection, consider a UV-resistant stain, which not only enhances aesthetics but also shields against sun damage. Remember, consistency is key—skipping a year can undo previous efforts.

Comparing maintenance approaches reveals a clear winner: prevention over reaction. Reactive maintenance, where you fix problems as they arise, often leads to higher costs and shorter dock life. In contrast, a preventive strategy—regular cleaning, sealing, and hardware tightening—extends longevity to 15-20 years or more. For instance, removing debris and algae buildup monthly prevents slipping hazards and wood degradation, while tightening bolts biannually ensures structural integrity.

Descriptive imagery can drive home the importance of frequency. Imagine a dock left unchecked: splintered boards, sagging supports, and a slimy, algae-covered surface. Now contrast that with a well-maintained dock: smooth, sealed wood, secure railings, and a clean, inviting appearance. The difference lies in the rhythm of care—weekly debris removal, quarterly cleaning, and annual sealing. This disciplined approach not only preserves functionality but also enhances safety and curb appeal.

Finally, tailor your maintenance frequency to environmental factors. Docks in saltwater or high-traffic areas demand more attention than those in calm, freshwater settings. For saltwater environments, increase inspections to quarterly and apply sealant annually. In regions with harsh winters, remove the dock or reinforce it to withstand ice pressure. By adapting your maintenance schedule to these variables, you maximize durability and minimize unexpected failures.

Termite Lifespan in Wood: Understanding Their Survival and Damage Potential

You may want to see also

Explore related products

Environmental Factors Role

Wooden floating docks, while picturesque and functional, are at the mercy of their surroundings. Environmental factors play a pivotal role in determining their lifespan, often dictating whether they endure for decades or deteriorate prematurely. Understanding these influences is crucial for anyone investing in such structures.

The Sun's Relentless Assault: Ultraviolet (UV) radiation from sunlight is a silent but potent enemy. Over time, UV rays break down the lignin in wood, causing it to become brittle and prone to cracking. This process, known as photodegradation, is particularly accelerated in tropical climates with intense sunlight. To mitigate this, consider using UV-resistant stains or sealants, reapplied annually or biennially depending on exposure. Additionally, incorporating shade structures or awnings can significantly reduce direct sunlight exposure, prolonging the dock's life.

Water's Dual Nature: Water, the very element a floating dock is designed for, presents a dual threat. While freshwater environments are generally less corrosive, saltwater is a formidable adversary. The high salt content accelerates corrosion of metal fasteners and can lead to wood rot due to increased moisture absorption. Regular inspections and prompt replacement of corroded hardware are essential. For saltwater environments, consider using stainless steel or galvanized fasteners, and opt for naturally rot-resistant wood species like cedar or cypress.

The Hidden Danger Below: What lies beneath the water's surface is just as critical as what's above. Aquatic organisms, particularly marine borers like shipworms and gribbles, can wreak havoc on wooden structures. These creatures bore into the wood, creating tunnels that weaken its structural integrity. To combat this, consider treating the wood with borate-based preservatives, which are effective against marine borers and environmentally friendly. Alternatively, installing sacrificial anodes can divert the borers' attention away from the dock.

Weathering the Storms: Extreme weather events, such as hurricanes, storms, and even heavy snowfall, can inflict significant damage. High winds can dislodge or destroy docks, while the weight of snow or ice can cause structural failure. When designing a wooden floating dock, factor in local weather patterns and build to exceed minimum safety standards. This may include using heavier-duty materials, adding extra bracing, or implementing a modular design that allows for easy disassembly during severe weather.

The Microbial Menace: Microorganisms, including bacteria and fungi, thrive in damp environments, making wooden docks susceptible to rot and decay. This is particularly problematic in areas with high humidity or where water frequently pools on the dock's surface. To prevent microbial growth, ensure proper drainage by incorporating slight slopes and regularly clearing debris. Applying fungicides and algaecides can also help, but be mindful of their environmental impact and choose eco-friendly options.

By proactively addressing these environmental factors, you can significantly extend the lifespan of a wooden floating dock. While the initial investment in protective measures may seem substantial, it pales in comparison to the cost of premature replacement. A well-maintained dock, designed with its environment in mind, can provide decades of enjoyment and functionality.

Wood Rot Timeline: Factors Affecting Decay and Prevention Tips

You may want to see also

Explore related products

Construction Techniques Effect

The lifespan of a wooden floating dock hinges significantly on the construction techniques employed. Properly executed methods can extend its durability from a mere decade to several generations. For instance, using pressure-treated lumber, which is infused with preservatives under high pressure, can resist rot and insect damage for 20 to 40 years, depending on the treatment level (e.g., UC4A for freshwater or UC4B for saltwater environments). Conversely, untreated wood may deteriorate within 5 to 10 years, even in ideal conditions. This stark contrast underscores the critical role of technique in determining longevity.

Consider the joinery and fastening systems, which are often overlooked but pivotal. Traditional methods like toe-nailing or using galvanized screws can fail prematurely due to wood movement and corrosion. Modern techniques, such as stainless steel hardware and composite brackets, offer superior resistance to rust and structural stress. For example, a dock built with stainless steel bolts and composite corner brackets can maintain its integrity for 30+ years, whereas one with galvanized fasteners may show signs of failure after 15 years. The choice of connection method directly correlates to the dock’s ability to withstand environmental stresses.

Another technique that dramatically impacts durability is the application of protective coatings. While staining or sealing wood is common, the frequency and type of application matter. A high-quality marine-grade sealant applied annually can add 5 to 10 years to a dock’s life by repelling water and UV damage. Conversely, a single coat of low-grade sealant may offer negligible protection after just one season. For maximum efficacy, apply the first coat within 30 days of installation and reapply every 12 months, focusing on high-wear areas like walkways and edges.

Lastly, the design and assembly process itself plays a silent yet crucial role. Docks built with modular, pre-fabricated sections often outlast those constructed on-site due to precision engineering and reduced exposure to moisture during assembly. For example, a dock assembled in a controlled environment and then floated into place can avoid the warping and splitting that occurs when wood is cut and joined in humid or wet conditions. This approach not only ensures tighter joints but also minimizes the risk of early structural failure, potentially doubling the dock’s lifespan.

In summary, construction techniques are not just details—they are determinants of a wooden floating dock’s endurance. From material treatment and fastening systems to protective coatings and assembly methods, each choice compounds to either fortify or undermine the structure. By prioritizing proven techniques and adhering to best practices, builders can craft docks that defy the typical 10-year benchmark, instead standing resilient for decades.

When to Treat Your Wood Privacy Fence for Longevity

You may want to see also

Explore related products

Expected Lifespan Range

The lifespan of a wooden floating dock hinges on material quality, environmental exposure, and maintenance practices. High-grade treated lumber, such as southern yellow pine or cedar infused with preservatives like CCA or ACQ, can endure 20–30 years in freshwater environments. In saltwater, where corrosion and marine borers accelerate decay, even treated wood typically lasts 10–15 years without proactive care. For instance, docks in protected coves with minimal wave action outlast those in open waters, where constant movement stresses joints and fasteners.

To maximize longevity, prioritize regular inspections and maintenance. Annually seal wood surfaces with marine-grade stains or sealants to repel moisture, and replace compromised boards or hardware immediately. Installing sacrificial anodes can mitigate metal corrosion, while adding UV-resistant coatings prevents sun-induced cracking. For docks in harsh conditions, consider composite decking, which, though pricier, offers a 25–40 year lifespan with minimal upkeep.

Comparatively, untreated wood docks rarely exceed 5–7 years, even in ideal conditions. Pressure-treated wood, while more durable, requires re-treatment every 3–5 years to maintain efficacy. For budget-conscious owners, a mid-range solution is using hardwoods like ipe or cumaru, which naturally resist rot and insects but still demand periodic oiling to prevent drying.

Ultimately, the expected lifespan range for wooden floating docks is 10–30 years, with variability dictated by material choice, environmental factors, and maintenance diligence. Freshwater docks at the upper end of this spectrum benefit from less aggressive conditions, while saltwater docks require vigilant care to approach even the lower threshold. By investing in quality materials and consistent upkeep, owners can significantly extend their dock’s functional life.

Air Drying Wood: Understanding the Timeframe for Optimal Results

You may want to see also

Frequently asked questions

A well-maintained wooden floating dock can last between 15 to 25 years, depending on the quality of materials, construction, and environmental conditions.

Factors include exposure to water, sunlight, temperature fluctuations, marine organisms, maintenance frequency, and the type of wood used.

Yes, regular maintenance such as sealing, staining, inspecting for damage, and replacing worn components can significantly extend its lifespan.

Yes, pressure-treated wood is more resistant to rot, decay, and insect damage, making it a better choice for prolonging the dock's lifespan compared to untreated wood.

![Boat Dock Cleats [] - Rustproof Nylon Boat Cleats Tie Down Use for Piers & Docks & Kayaks & Sailboats & Marine Hole Centers Kayak Rope Tie Nautical Decor](https://m.media-amazon.com/images/I/51BpYV11HbL._AC_UL320_.jpg)

![Boat Dock Cleats [] - Rustproof Nylon Boat Cleats Tie Down Use for Piers & Docks & Kayaks & Sailboats & Marine [, Hole Centers] Kayak Rope Tie Nautical Decor](https://m.media-amazon.com/images/I/518llAdTb+L._AC_UL320_.jpg)