Air drying wood is a natural process that allows moisture to evaporate from the wood over time, making it suitable for various applications such as furniture making, construction, and woodworking. The duration of air drying depends on several factors, including the wood species, initial moisture content, thickness of the wood, humidity, temperature, and airflow. Hardwoods like oak or maple typically take longer to dry than softwoods like pine. On average, wood can take anywhere from 6 months to 2 years to air dry, with thicker pieces requiring more time. Proper stacking and spacing of wood during the drying process are essential to ensure even drying and prevent warping or cracking. Understanding these factors helps in planning and achieving the desired moisture level for optimal wood usage.

| Characteristics | Values |

|---|---|

| Average Air Drying Time | 1-3 years (varies by wood species and thickness) |

| Factors Affecting Drying Time | Wood species, thickness, moisture content, humidity, temperature, airflow |

| Softwood Drying Time | 6-12 months (e.g., Pine, Spruce) |

| Hardwood Drying Time | 1-3 years (e.g., Oak, Maple, Mahogany) |

| Thickness Impact | 1-inch thick wood dries in ~1 year; 2-inch thick takes ~2 years |

| Initial Moisture Content | Freshly cut wood: 30-200% moisture content |

| Target Moisture Content | 6-12% for indoor use; 12-15% for outdoor use |

| Optimal Conditions | 60-70°F (15-21°C), 50-70% humidity, good airflow |

| Stacking Method | Stickers placed between layers to allow airflow |

| Shrinkage | 4-10% depending on wood species and grain orientation |

| Cracking/Checking Risk | Higher in hardwoods and thicker pieces without proper stacking |

| Kiln Drying Alternative | 2-6 weeks (faster but more expensive) |

| Seasonal Impact | Slower drying in winter; faster in summer with controlled conditions |

| Monitoring Method | Moisture meter to track progress |

| Environmental Impact | Air drying is eco-friendly; kiln drying uses more energy |

Explore related products

$26.99 $29.99

$26.99 $30.54

What You'll Learn

- Factors Affecting Drying Time: Wood type, humidity, temperature, airflow, thickness, and initial moisture content

- Softwood vs. Hardwood: Softwoods dry faster (6-12 months), hardwoods take longer (1-2+ years)

- Stacking Techniques: Proper stacking ensures airflow, reduces warping, and speeds up drying

- Moisture Content Goals: Aim for 12-15% moisture content for indoor use, 18-20% for outdoor

- Accelerating Drying: Use kilns, solar drying, or fans to shorten air-drying time significantly

Factors Affecting Drying Time: Wood type, humidity, temperature, airflow, thickness, and initial moisture content

Wood species play a pivotal role in determining drying time, with denser hardwoods like oak and maple taking significantly longer to air dry than softer woods like pine or cedar. For instance, oak can require 1-2 years per inch of thickness, while pine might dry in half that time. This disparity stems from the cellular structure of the wood: hardwoods have more complex cell walls and smaller vessels, slowing moisture escape. When selecting wood for a project, consider not just aesthetics but also the practical implications of drying time, especially if you’re working on a tight timeline.

Humidity and temperature form a dynamic duo in the drying process, with their interplay dictating how efficiently moisture evaporates from wood. Ideal drying conditions involve a relative humidity below 65% and temperatures between 60°F and 90°F (15°C and 32°C). In high-humidity environments, moisture in the wood has nowhere to go, prolonging drying time. Conversely, low humidity paired with moderate heat accelerates evaporation. For outdoor drying, stack wood under a shed or cover to shield it from rain while allowing airflow. Indoor drying benefits from dehumidifiers or fans to maintain optimal conditions.

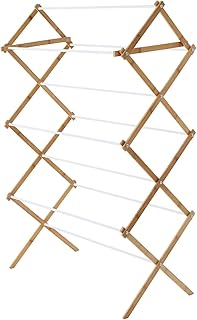

Airflow is the unsung hero of air drying, as stagnant air around the wood creates a barrier that traps moisture. Proper stacking techniques, such as using stickers (spacers) between boards and elevating the pile off the ground, ensure air circulates freely. For thicker pieces, consider a solar kiln or a well-ventilated shed with vents on opposite sides to create a natural draft. Even small adjustments, like positioning the stack perpendicular to prevailing winds, can shave weeks off drying time. Without adequate airflow, even the driest climate won’t prevent internal moisture buildup.

Thickness and initial moisture content are directly proportional to drying time—the thicker the wood and the wetter it starts, the longer it takes. A 4/4 board (1 inch thick) might air dry in 6-12 months, while an 8/4 board (2 inches thick) could take 2-4 years. To expedite the process, rough-saw wood to its final thickness before drying, reducing the material’s moisture-holding capacity. For green wood with 80-100% moisture content, expect a lengthy drying period; kiln-drying or using a moisture meter to monitor progress can help manage expectations and prevent cracks or warping.

Each factor—wood type, humidity, temperature, airflow, thickness, and initial moisture content—interacts to create a unique drying timeline. For example, a thick oak board in a humid, poorly ventilated area could take years to dry, while a thin pine board in a dry, well-ventilated space might be ready in months. By understanding these variables, you can tailor your approach to suit your project’s needs. Whether you’re a hobbyist or professional, mastering these factors ensures wood dries efficiently, retaining its strength and beauty for years to come.

Exploring Muir Woods: Ideal Time to Experience Its Majestic Beauty

You may want to see also

Explore related products

Softwood vs. Hardwood: Softwoods dry faster (6-12 months), hardwoods take longer (1-2+ years)

The drying time of wood is a critical factor in its usability and quality, and the type of wood plays a significant role in this process. Softwoods, such as pine and spruce, typically air dry much faster than hardwoods, with a timeframe of 6 to 12 months. This is due to their cellular structure, which allows moisture to escape more readily. For instance, a stack of freshly cut pine boards, if properly stacked with stickers to allow airflow, can be ready for use in furniture or construction within a year. This makes softwoods a popular choice for projects that require quick turnaround times.

In contrast, hardwoods like oak, maple, and mahogany demand patience, often requiring 1 to 2 years or more to air dry thoroughly. Their denser, more complex cell structure retains moisture longer, necessitating a slower drying process to prevent cracking or warping. Imagine a craftsman waiting for a batch of walnut planks to dry—this extended period is essential to ensure the wood’s stability and durability. For those working with hardwoods, planning ahead is crucial, as the drying phase can significantly impact project timelines.

To illustrate the practical implications, consider a scenario where a builder needs to choose between softwood and hardwood for a flooring project. If time is of the essence, softwood might be the better option, as it can be dried and installed within a year. However, if longevity and aesthetic appeal are priorities, hardwood’s longer drying time is a worthwhile investment, despite the wait. This decision-making process highlights the importance of understanding wood types and their drying characteristics.

For those looking to expedite the drying process, a few strategies can be employed. Softwoods benefit from being stacked in a well-ventilated area, protected from direct sunlight and rain. Hardwoods, on the other hand, may require additional measures, such as using a moisture meter to monitor progress and ensuring the wood is sealed on the ends to minimize end-grain drying, which can lead to splits. Regardless of the type, proper stacking and storage are key to achieving optimal results.

In conclusion, the choice between softwood and hardwood should be guided by both the project’s requirements and the time available. While softwoods offer the advantage of quicker drying, hardwoods provide superior strength and beauty, albeit with a longer wait. By understanding these differences and planning accordingly, woodworkers and builders can ensure their materials are ready when needed, contributing to the success of their projects.

Cedar Wood Durability: How Long It Lasts Outdoors and Why

You may want to see also

Explore related products

Stacking Techniques: Proper stacking ensures airflow, reduces warping, and speeds up drying

Air-drying wood is a delicate balance of patience and precision, where stacking techniques play a pivotal role in determining the outcome. Improper stacking can lead to uneven drying, warping, or even mold growth, significantly extending the drying time. For instance, hardwoods like oak or maple can take anywhere from 6 months to 2 years to air dry, depending on thickness and environmental conditions. Softwoods, such as pine, dry faster, often within 3 to 6 months. However, these timelines are heavily influenced by how the wood is stacked. A well-executed stack promotes consistent airflow, reduces moisture pockets, and minimizes stress on the wood fibers, ensuring a more uniform and efficient drying process.

To achieve optimal results, start by preparing a flat, elevated surface for stacking. Use stickers—narrow, uniform pieces of wood—placed perpendicular to the boards to create gaps that allow air circulation. Stickers should be spaced approximately 12 to 16 inches apart for most lumber, though wider spacing may be necessary for thicker pieces. Stack the wood in a crisscross pattern, alternating the direction of each layer to prevent warping. For example, if the first layer runs north-south, the next should run east-west. This method distributes weight evenly and reduces the risk of cupping or twisting. Additionally, ensure the stack is no more than 4 to 6 feet high to maintain structural integrity and airflow.

While stacking, consider the environmental factors that affect drying. Wood should be stored in a covered but well-ventilated area, protected from direct rain but exposed to natural airflow. Humidity levels below 65% are ideal, as higher moisture in the air slows the drying process. In regions with high humidity, using a dehumidifier or strategically placing the stack near a fan can accelerate drying. Conversely, in arid climates, occasional misting of the air around the stack (not the wood itself) can prevent the wood from drying too quickly, which can cause cracking.

One common mistake is neglecting to monitor the stack over time. As wood dries, it shrinks, and gaps between boards may widen. Periodically check the stack and adjust stickers as needed to maintain consistent spacing. For larger batches, consider rotating the position of boards within the stack every few months to ensure even exposure to air. This proactive approach not only speeds up drying but also improves the overall quality of the wood.

In conclusion, proper stacking is a critical yet often overlooked aspect of air-drying wood. By employing techniques such as using stickers, alternating board directions, and monitoring environmental conditions, woodworkers can significantly reduce drying times and improve the final product. While the process requires attention to detail, the payoff is well worth the effort—high-quality, warp-free wood ready for any project. Whether you’re drying a few boards or an entire lumber pile, mastering stacking techniques is essential for success.

How Quickly Does Mold Grow on Wood Surfaces?

You may want to see also

Explore related products

Moisture Content Goals: Aim for 12-15% moisture content for indoor use, 18-20% for outdoor

Air-drying wood is a delicate balance between patience and precision, especially when targeting specific moisture content levels. For indoor applications, the ideal moisture content ranges from 12% to 15%. This range ensures the wood is stable enough to resist warping, cracking, or shrinking once installed in climate-controlled environments. Achieving this level typically requires 6 to 12 months of air drying, depending on factors like wood species, thickness, and local humidity. For instance, softwoods like pine dry faster than hardwoods like oak, which retain moisture longer due to their denser structure.

Outdoor projects demand a different approach. Aim for a moisture content of 18% to 20% to allow the wood to acclimate to fluctuating weather conditions without excessive degradation. This slightly higher moisture level acts as a buffer against rapid changes in humidity and temperature, reducing the risk of splitting or twisting. Expect outdoor drying to take 3 to 6 months, though this can vary based on regional climate. In arid regions, wood may dry faster, while humid areas slow the process significantly.

To monitor progress, invest in a reliable moisture meter, which provides accurate readings and helps prevent overdrying. Stack wood with stickers (spacers) between layers to promote airflow, and store it in a well-ventilated area protected from direct rain or sunlight. For indoor wood, consider sealing the ends with wax or paint to minimize moisture loss from the most porous parts of the board.

Comparing indoor and outdoor goals highlights the importance of tailoring drying practices to end use. While indoor wood requires a lower moisture content for stability, outdoor wood benefits from retaining enough moisture to withstand environmental stress. Ignoring these distinctions can lead to costly mistakes, such as indoor wood warping due to excess moisture or outdoor wood cracking from overdrying.

In practice, achieving these moisture content goals isn’t just about time—it’s about strategy. Regularly rotate and restack wood piles to ensure even drying, and plan projects well in advance to account for drying time. For example, if you’re building an outdoor deck, start drying the wood during the off-season to ensure it’s ready when construction begins. By understanding and respecting these moisture content targets, you’ll produce wood that performs reliably, whether it’s framing a bookshelf or weathering the elements outside.

Understanding Standard 2x4 Lumber Dimensions: Lengths and Uses Explained

You may want to see also

Explore related products

Accelerating Drying: Use kilns, solar drying, or fans to shorten air-drying time significantly

Air-drying wood is a patient process, often taking months or even years for thicker pieces to reach optimal moisture levels. But what if you need that lumber sooner? Kilns, solar drying, and fans offer three distinct methods to accelerate drying, each with its own advantages and considerations.

Let's delve into these techniques, exploring their mechanisms, suitability, and potential drawbacks.

Kiln Drying: Precision and Control

Imagine a controlled environment where temperature, humidity, and airflow are meticulously regulated. This is the essence of kiln drying. Wood is stacked within a chamber, and heat is applied gradually, drawing moisture out through a combination of evaporation and diffusion. Kiln drying is the fastest method, reducing drying times from years to weeks or even days, depending on wood species and thickness. Dehumidification kilns, which remove moisture from the air within the chamber, are particularly efficient, minimizing the risk of warping and cracking. However, kilns require significant investment and energy consumption, making them more suitable for commercial operations or those with high-volume needs.

For optimal results, kiln schedules, which dictate temperature and humidity levels over time, are tailored to specific wood species. These schedules ensure even drying and prevent defects.

Solar Drying: Harnessing Nature's Power

For a more sustainable and cost-effective approach, solar drying utilizes the sun's energy to accelerate the process. Wood is stacked in a greenhouse-like structure, allowing sunlight to heat the air and promote evaporation. While slower than kiln drying, solar drying can significantly reduce air-drying times, especially in regions with abundant sunshine. Proper ventilation is crucial to prevent moisture buildup and mold growth. Orienting the solar dryer to maximize sunlight exposure and using reflective materials to enhance heat absorption can further improve efficiency. This method is particularly appealing for environmentally conscious woodworkers and those with access to ample sunlight.

Fans: A Simple Yet Effective Boost

For a low-cost and readily available solution, fans can be employed to increase airflow around the wood, facilitating moisture evaporation. While not as rapid as kiln or solar drying, fans can noticeably shorten air-drying times, especially for thinner pieces. Strategically placing fans to create a cross-breeze and ensuring adequate spacing between wood stacks for optimal air circulation are key to success. This method is best suited for small-scale projects and hobbyists seeking a simple way to expedite drying.

Choosing the Right Method:

The optimal drying method depends on factors like wood species, desired drying time, budget, and available resources. Kilns offer unparalleled speed and control but come with a higher cost. Solar drying provides a sustainable and cost-effective alternative, albeit with slower drying times. Fans offer a simple and affordable solution for smaller projects. By understanding the strengths and limitations of each method, woodworkers can make informed decisions to accelerate the drying process and bring their projects to life sooner.

Wood Wicks vs. Cotton: Which Burns Longer and Why?

You may want to see also

Frequently asked questions

The time it takes for wood to air dry varies depending on factors like wood species, thickness, humidity, and temperature, but it generally ranges from 6 months to 2 years.

Yes, denser hardwoods like oak or maple take longer to air dry (1-2 years) compared to softer woods like pine, which may dry in 6-12 months.

Absolutely. Warmer, drier climates speed up drying, while cold, humid conditions slow it down. Proper stacking and sheltering wood can mitigate weather effects.

Wood is fully air-dried when its moisture content is around 12-15%. You can test this using a moisture meter or by checking for cracks, warping, or a lighter weight.