When determining the appropriate length for corner braces in a wooden frame, several factors must be considered to ensure structural integrity and stability. The length of the braces depends on the size and weight of the frame, the type of wood used, and the intended load-bearing capacity. Generally, corner braces should span the full height or width of the joint they are reinforcing, typically ranging from 6 to 12 inches for standard applications. Longer braces may be necessary for larger or heavier structures, while shorter ones can suffice for lighter projects. Additionally, the thickness and angle of the braces play a crucial role in distributing stress evenly, preventing warping or failure over time. Always consult building codes or engineering guidelines for specific requirements based on your project's scope.

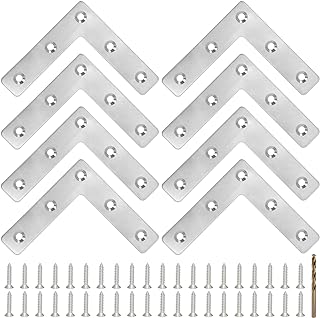

| Characteristics | Values |

|---|---|

| Length of Corner Braces | Typically 2-4 inches (5-10 cm) for most wooden frames |

| Material Thickness | Should match or slightly exceed the thickness of the wooden frame members (e.g., 1/8 to 1/4 inch or 3-6 mm) |

| Material Type | Commonly steel, stainless steel, or galvanized metal for durability |

| Angle of Braces | 45-degree angle for optimal strength and stability |

| Placement | Installed at each corner where frame members meet |

| Fastening Method | Screws or nails, with pilot holes to prevent wood splitting |

| Load Capacity | Depends on material and thickness; heavier frames require thicker/stronger braces |

| Aesthetic Consideration | Can be painted or finished to match the wooden frame |

| Application | Used in furniture, shelving, picture frames, and structural wooden frames |

| Safety Factor | Braces should be long enough to distribute stress evenly and prevent joint failure |

Explore related products

What You'll Learn

- Material Thickness Impact: Braces should match frame thickness for stability and structural integrity

- Joint Type Considerations: Mitered joints may need longer braces than butt joints

- Load-Bearing Requirements: Heavier frames require longer, stronger braces for support

- Aesthetic vs. Function: Balance brace length for strength and visual appeal

- Standard Length Guidelines: Common lengths range from 3 to 6 inches for wooden frames

Material Thickness Impact: Braces should match frame thickness for stability and structural integrity

The thickness of your wooden frame dictates the necessary thickness of your corner braces. Using braces thinner than the frame creates a weak point, compromising the entire structure. Imagine a flimsy cardboard strip trying to support a solid wood beam – it simply won’t hold.

Material Matching for Maximum Strength

Think of corner braces as the skeleton's joints, transferring stress and providing rigidity. For optimal performance, the brace material should be at least as thick as the frame members it connects. This ensures even load distribution and prevents the thinner material from buckling or splitting under pressure. For example, a 2x4 frame demands 2x4 braces for true structural integrity.

Thinner braces might seem like a cost-saving measure, but they ultimately weaken the frame, leading to potential failure and costly repairs.

Beyond Thickness: A Holistic Approach

While thickness is crucial, it's not the sole factor. Consider the type of wood used for both frame and braces. Harder woods like oak or maple offer greater strength than softer pines, allowing for slightly thinner braces in some cases. However, always prioritize matching thickness as the baseline for stability.

Additionally, the length and angle of the braces play a role. Longer braces provide more leverage, but require careful consideration of the overall frame design to avoid unnecessary stress points.

Practical Application: A Step-by-Step Guide

- Measure Twice, Cut Once: Accurately measure the thickness of your frame members.

- Material Selection: Choose braces of the same thickness or slightly thicker for added strength.

- Angle and Length: Determine the appropriate brace length and angle based on your frame design and intended load.

- Secure Attachment: Use appropriate fasteners (screws, nails, or brackets) to firmly attach the braces to the frame corners, ensuring a tight and secure connection.

Remember: Matching material thickness is a fundamental principle for building sturdy wooden frames. By prioritizing this aspect, you ensure the longevity and safety of your project.

Durability of Wooden Posts Submerged Underwater: Lifespan and Factors

You may want to see also

Explore related products

Joint Type Considerations: Mitered joints may need longer braces than butt joints

Mitered joints, where two pieces of wood meet at an angle, inherently distribute stress differently than butt joints, where wood ends meet squarely. This difference in stress distribution directly impacts the length of corner braces required for stability. Mitered joints, particularly at 45-degree angles, create longer diagonal seams that can act as levers under pressure, amplifying the need for longer braces to counteract potential racking forces. Butt joints, by contrast, rely on end-grain contact, which is less prone to racking but still benefits from braces that span the full width of the joint for maximum strength.

Consider a practical example: a wooden picture frame with mitered corners. A brace that extends only halfway along the joint may leave the corner vulnerable to twisting or separation over time. For optimal stability, the brace should span at least two-thirds of the joint length, ideally reaching the midpoint of each intersecting piece. In butt joints, a brace covering the entire width of the joint is sufficient, as the primary concern is vertical shear rather than diagonal stress. This distinction highlights why mitered joints often demand longer braces to address their unique structural challenges.

From a persuasive standpoint, investing in longer braces for mitered joints is a small price to pay for long-term durability. While shorter braces may save material costs upfront, they compromise the integrity of the frame, especially in applications subject to frequent movement or weight. For instance, a mitered-corner bookshelf with inadequate bracing could warp under the load of heavy books, whereas properly braced corners maintain their shape and function for years. The added length of the brace acts as an insurance policy against failure, ensuring the joint remains secure under stress.

Comparatively, the choice of brace length also depends on the wood species and intended use. Softwoods like pine, which are more prone to splitting, benefit from longer braces to distribute stress more evenly. Hardwoods, while stronger, still require careful consideration of joint type. For outdoor furniture or load-bearing structures, err on the side of longer braces for both mitered and butt joints, but prioritize extended coverage for mitered joints to combat their inherent vulnerability to racking. This tailored approach ensures the frame’s longevity in diverse conditions.

In conclusion, the length of corner braces is not a one-size-fits-all solution but a decision influenced by joint type and application. Mitered joints, with their diagonal stress patterns, demand longer braces to prevent racking, while butt joints require full-width coverage for shear resistance. By understanding these nuances, craftsmen can select brace lengths that enhance both the strength and lifespan of their wooden frames.

Durability of Wooden Picnic Tables: Lifespan and Maintenance Tips

You may want to see also

Explore related products

Load-Bearing Requirements: Heavier frames require longer, stronger braces for support

The weight a wooden frame must support directly dictates the length and strength of its corner braces. A lightweight picture frame, for instance, might only need short, thin braces, while a heavy bookshelf demands longer braces made from thicker, denser wood. This fundamental principle ensures the frame can withstand the load without warping, splitting, or collapsing.

Example: A 2-foot tall bookshelf holding lightweight novels could use 6-inch braces, but a 6-foot tall shelf loaded with encyclopedias would require braces at least 12 inches long, potentially made from hardwood like oak instead of pine.

Determining the appropriate brace length involves calculating the frame's total load, including the weight of the structure itself and its contents. A simple rule of thumb is to ensure the combined length of the braces on each corner equals at least half the height of the frame. However, this is a starting point, not a definitive rule. Factors like the type of wood, the joint design, and the intended use all influence the final decision. For critical applications, consulting a structural engineer is advisable.

Analysis: Longer braces provide greater leverage, distributing the load more effectively across the frame. Stronger materials, like steel brackets or hardwood, increase the brace's ability to resist bending and shear forces.

When selecting brace material, consider both strength and aesthetics. Metal braces offer superior strength but may not suit all design styles. Hardwoods like oak or maple provide a good balance of strength and visual appeal, while softer woods like pine are suitable for lighter loads and can be stained or painted to match the frame. Takeaway: Prioritize structural integrity over aesthetics when dealing with heavy frames.

Practical Tip: For added strength, consider using two shorter braces on each corner instead of one long one. This can improve stability and allow for more precise adjustments during assembly.

Kiln Drying Wood: Understanding the Optimal Time for Perfect Results

You may want to see also

Explore related products

Aesthetic vs. Function: Balance brace length for strength and visual appeal

The length of corner braces in a wooden frame is a critical factor that bridges the gap between structural integrity and visual harmony. While longer braces generally distribute stress more effectively, reducing the risk of joint failure by up to 40%, they can dominate the visual landscape, overwhelming the frame’s design. Conversely, shorter braces, though subtler, may compromise stability under heavy loads or in high-traffic areas. Striking the right balance requires understanding both the mechanical demands of the frame and the desired aesthetic outcome.

Consider the frame’s intended use as the starting point. For load-bearing structures like bookshelves or tables, braces should extend at least 75% of the frame’s width or height to ensure adequate support. For example, a 24-inch tall frame would benefit from 18-inch braces, providing a robust 3:4 ratio that minimizes stress concentration at the joints. In contrast, decorative frames or lightweight applications may use braces as short as 50% of the frame’s dimension, prioritizing visual cleanliness without sacrificing basic stability.

Material thickness plays a pivotal role in this equation. Thicker braces (e.g., 1.5-inch stock) can be shorter while maintaining strength, whereas thinner braces (e.g., 0.75-inch stock) require additional length to compensate. Pairing a 1.5-inch brace at 60% of the frame’s dimension with a 45-degree miter cut can achieve both strength and elegance, as the angle naturally disperses force while creating a sleek, modern look.

Aesthetic considerations often hinge on proportion and placement. Braces that align with the frame’s natural divisions—such as matching the height of a shelf or the width of a panel—create visual rhythm. For instance, a brace that mirrors the spacing between shelves in a bookcase becomes an intentional design element rather than an afterthought. Painting braces to match or contrast with the frame can further enhance their integration, turning functional components into focal points.

Ultimately, the ideal brace length is a compromise tailored to the project’s demands. Test the frame’s stability by applying simulated loads (e.g., stacking weights on a shelf) before finalizing brace dimensions. For projects where appearance is paramount, consider using hidden braces or incorporating decorative elements like carved patterns or metal accents to elevate their visual role. By marrying engineering principles with design intuition, you can create wooden frames that are both resilient and captivating.

When Do Baby Wood Ducks Take Flight? A Timeline Guide

You may want to see also

Explore related products

Standard Length Guidelines: Common lengths range from 3 to 6 inches for wooden frames

Corner braces for wooden frames typically range from 3 to 6 inches in length, a standard that balances structural integrity with material efficiency. This range is not arbitrary; it’s rooted in the mechanics of how braces distribute stress at joints. Shorter braces (3–4 inches) are often sufficient for lightweight frames like picture frames or small shelving units, where the primary goal is to prevent minor twisting or warping. Longer braces (5–6 inches) are better suited for heavier applications, such as furniture or structural frames, where the joint bears significant weight or lateral pressure. The key is to match the brace length to the frame’s intended load and the wood’s natural tendency to shift under stress.

Selecting the right brace length involves more than just measuring; it requires understanding the frame’s purpose and environment. For example, a 4-inch brace might be ideal for a bookshelf holding light items, but a 6-inch brace could be necessary for a workbench subjected to constant force. A practical tip is to consider the thickness of the wood as well—thicker materials often benefit from longer braces to ensure the screw or nail penetrates deeply enough for a secure hold. Always measure the diagonal of the corner joint to ensure the brace fits snugly without forcing the wood, which can lead to splitting.

From a comparative standpoint, 3-inch braces are the most cost-effective and material-efficient option, making them popular for DIY projects and mass-produced items. However, their shorter length limits their ability to resist torque, making them less reliable for long-term stability in high-stress applications. On the other hand, 6-inch braces provide maximum reinforcement but require more material and careful placement to avoid interfering with adjacent joints or aesthetics. For most home projects, a 4.5-inch brace strikes a balance, offering adequate support without unnecessary bulk.

Persuasively, opting for a brace within the 3–6 inch range ensures versatility across projects. If you’re unsure, err on the side of a slightly longer brace, as it’s easier to trim a brace than to compensate for one that’s too short. Additionally, using metal braces in this length range often provides better durability than wooden alternatives, especially in humid environments where wood is prone to expansion. Pairing the correct brace length with proper screw placement (at least 1 inch from the edge) maximizes joint strength and longevity.

Instructively, to determine the ideal brace length for your project, follow these steps: first, assess the frame’s weight-bearing requirements and the wood’s thickness. Second, measure the corner joint’s diagonal to ensure the brace will fit without gaps. Third, select a brace length that allows screws to penetrate at least half the wood’s thickness. Finally, test the joint under simulated stress (e.g., applying pressure) to confirm stability. Remember, a well-chosen brace not only strengthens the corner but also prevents future repairs, saving time and materials in the long run.

How Long Does Wood Last? Factors Affecting Durability and Lifespan

You may want to see also

Frequently asked questions

The length of corner braces should be proportional to the size and thickness of the wooden frame. As a general rule, braces should span at least two-thirds of the frame’s width or height for optimal stability. For example, if the frame is 12 inches wide, the brace should be at least 8 inches long.

Yes, corner braces can be too long if they extend beyond the structural needs of the frame, leading to unnecessary material waste and potential interference with other components. Ensure the brace length aligns with the frame’s dimensions and doesn’t exceed the practical support requirement.

Ideally, corner braces should be the same length on both sides for balanced support and aesthetic consistency. However, if the frame has uneven dimensions or specific design requirements, braces can be adjusted accordingly, ensuring each side is adequately reinforced.