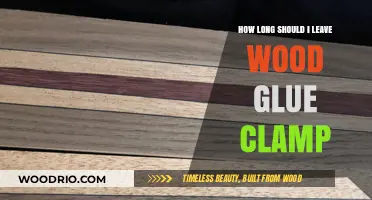

When working with glued wood, clamping time is a critical factor in ensuring a strong and durable bond. The duration for which you should clamp glued wood depends on several variables, including the type of glue used, the wood species, the ambient temperature, and humidity. For instance, common wood glues like PVA (polyvinyl acetate) typically require clamping for at least 30 minutes to an hour, but for maximum strength, leaving the clamp in place for 24 hours is recommended. Epoxy glues, on the other hand, may cure faster but still benefit from extended clamping to ensure proper adhesion. Always refer to the glue manufacturer’s instructions for specific recommendations, as improper clamping time can result in weak joints or glue failure. Understanding these factors ensures your wood project achieves the desired strength and longevity.

| Characteristics | Values |

|---|---|

| Clamp Time for Wood Glue | 30 minutes to 1 hour (for most wood glues) |

| Cure Time for Wood Glue | 24 hours (full strength typically achieved after this period) |

| Clamp Pressure | 100-150 psi (pounds per square inch) for optimal bonding |

| Glue Type | PVA (Polyvinyl Acetate), Epoxy, or Polyurethane (clamp times vary) |

| Wood Type | Hardwoods and softwoods (clamp times may vary slightly) |

| Temperature | 50°F to 90°F (10°C to 32°C) for optimal glue curing |

| Humidity | Moderate humidity (avoid extreme conditions) |

| Joint Type | Edge, miter, or butt joints (clamp times may vary based on joint type) |

| Glue Application | Thin, even coat on both surfaces |

| Excess Glue Removal | Wipe off excess glue immediately to prevent squeezing |

| Re-clamping | Not necessary if initial clamping is done correctly |

| Accelerated Curing | Use warm, dry conditions or specialized glues for faster curing |

| Testing Bond Strength | Wait at least 24 hours before testing the bond |

| Storage of Glued Wood | Store in a dry, stable environment after clamping |

| Safety Precautions | Wear gloves and work in a well-ventilated area |

Explore related products

What You'll Learn

- Clamp Time for Softwoods: Softwoods like pine require less clamping time compared to hardwoods due to faster glue bonding

- Hardwoods Clamping Duration: Dense hardwoods like oak need longer clamping to ensure strong, durable glue joints

- Glue Type Impact: PVA glues need 30 minutes to 24 hours, while epoxy may require up to 72 hours

- Joint Complexity Effect: Complex joints like dovetails need extended clamping to prevent gaps and ensure alignment

- Environmental Factors: Humidity and temperature affect drying time; warmer, drier conditions speed up glue curing

Clamp Time for Softwoods: Softwoods like pine require less clamping time compared to hardwoods due to faster glue bonding

Softwoods, such as pine, spruce, and cedar, exhibit distinct gluing characteristics that allow for shorter clamping times compared to their hardwood counterparts. This is primarily due to their cellular structure, which facilitates faster moisture absorption and glue curing. For instance, pine, a common softwood, typically requires only 30 minutes to 1 hour of clamping time when using standard wood glues like PVA (polyvinyl acetate). This rapid bonding is a result of the wood’s lower density and more open grain, which allows adhesives to penetrate and cure more quickly.

When working with softwoods, it’s essential to balance speed with precision. While the reduced clamping time is advantageous for efficiency, it also demands careful planning. Ensure joints are properly aligned before clamping, as softwoods can be more forgiving during the initial setup but less so once the glue begins to set. For larger projects or load-bearing joints, consider extending the clamping time to 1.5–2 hours to ensure maximum bond strength, even though the glue may appear cured sooner.

A comparative analysis highlights the contrast between softwoods and hardwoods. Hardwoods like oak or maple, with their denser fibers, often require 2–4 hours of clamping time, or even overnight for optimal results. Softwoods, however, allow woodworkers to complete projects more swiftly without compromising bond integrity. This makes softwoods ideal for tasks where quick turnaround is prioritized, such as framing, lightweight furniture, or decorative elements.

Practical tips for clamping softwoods include using moderate pressure—enough to close gaps but not so much as to squeeze out excess glue, which can weaken the joint. Additionally, consider environmental factors: warmer temperatures (around 70°F or 21°C) accelerate curing, while cooler conditions may require slightly longer clamping times. Always follow the glue manufacturer’s recommendations, but remember that softwoods’ inherent properties often allow for flexibility in timing.

In conclusion, softwoods’ faster glue bonding translates to shorter clamping times, making them a time-efficient choice for woodworking projects. By understanding their unique characteristics and applying precise techniques, craftsmen can leverage this advantage to streamline workflows without sacrificing quality. Whether you’re a hobbyist or professional, mastering the clamping time for softwoods opens up opportunities for quicker, more productive builds.

Maximizing Flavor: Understanding the Lifespan of Smoker Wood Chips

You may want to see also

Explore related products

Hardwoods Clamping Duration: Dense hardwoods like oak need longer clamping to ensure strong, durable glue joints

Dense hardwoods like oak, maple, and walnut demand more patience when gluing due to their lower porosity and slower moisture absorption. Unlike softwoods, which allow glue to penetrate more readily, hardwoods require extended clamping times to ensure the adhesive fully bonds to the wood fibers. This is particularly critical for joints under structural stress, such as table legs or cabinet frames, where a weak bond can lead to failure over time.

For PVA (polyvinyl acetate) glues, a common choice for woodworking, clamping times for hardwoods should be at least 30 minutes per inch of wood thickness. For example, a 1.5-inch oak board should be clamped for a minimum of 45 minutes. However, this is a baseline—extending the clamping time to 2–3 hours per inch is advisable for maximum strength, especially in humid environments where curing can be slower. Epoxy resins, while faster-curing, still benefit from longer clamping due to hardwoods’ density, typically requiring 1–2 hours per inch.

Temperature plays a significant role in curing time. Ideal conditions for gluing hardwoods are between 65°F and 80°F (18°C–27°C). Colder temperatures slow curing, necessitating even longer clamping times, while excessive heat can cause the glue to set too quickly, potentially weakening the bond. Always check the manufacturer’s guidelines for specific temperature recommendations.

Practical tips include using cauls to distribute clamping pressure evenly, as hardwoods can dent or warp under uneven force. Additionally, pre-fitting joints and applying a thin, even layer of glue ensures optimal adhesion. For critical joints, consider leaving clamps in place for 24 hours, even if the glue appears set earlier. This extra precaution ensures the bond reaches its full strength, particularly in dense hardwoods where curing can be uneven.

In summary, dense hardwoods like oak require longer clamping times—often 2–3 hours per inch of thickness—to achieve durable glue joints. Patience, attention to temperature, and proper clamping techniques are essential to avoid weak bonds that could compromise the integrity of your project. Always prioritize strength over speed when working with these demanding materials.

Durability of Wood Gazebos: Lifespan and Maintenance Tips

You may want to see also

Explore related products

Glue Type Impact: PVA glues need 30 minutes to 24 hours, while epoxy may require up to 72 hours

The type of glue you choose for your woodworking project significantly influences how long you need to clamp the pieces together. PVA (polyvinyl acetate) glues, commonly used for wood joinery, typically require clamping for 30 minutes to 24 hours. This range depends on factors like humidity, temperature, and the specific brand of glue. For instance, Titebond III, a popular PVA glue, achieves initial strength within 30 minutes but recommends clamping for at least 2 hours for optimal results. In contrast, epoxy glues, known for their superior strength and water resistance, demand a much longer clamping time—up to 72 hours. This extended period ensures the epoxy fully cures, creating a bond that can withstand heavy loads and harsh conditions.

Understanding these differences is crucial for planning your project timeline. If you’re working on a time-sensitive piece, PVA glue might be the better choice, as it allows you to move forward with assembly relatively quickly. However, if durability and strength are paramount, epoxy is worth the wait, despite the longer clamping requirement. For example, a simple wooden frame might be ready for sanding and finishing within a few hours with PVA, while a heavy-duty outdoor table bonded with epoxy could take several days to fully cure.

When using PVA glue, consider the environmental conditions. Higher temperatures and lower humidity accelerate drying, reducing clamping time. Conversely, cold or damp environments can slow the process, pushing the clamping period closer to the 24-hour mark. Epoxy, on the other hand, is less affected by ambient conditions but requires careful mixing and application to ensure proper curing. Follow the manufacturer’s instructions for the correct ratio of resin to hardener, as an imbalance can compromise the bond.

Practical tips can further optimize your gluing process. For PVA, apply a thin, even coat to both surfaces, ensuring they are clean and free of dust. Use clamps with sufficient pressure to eliminate gaps but avoid over-tightening, which can squeeze out excess glue and weaken the joint. With epoxy, work in a well-ventilated area and wear gloves to avoid skin contact. Apply the mixture generously, as epoxy tends to shrink slightly during curing, and ensure the joint is clamped firmly to maintain alignment.

In summary, the choice between PVA and epoxy glue dictates not only the strength of your bond but also your project’s timeline. PVA offers convenience and speed, making it ideal for indoor projects or quick repairs, while epoxy provides unmatched durability at the cost of extended clamping time. By tailoring your glue selection to the project’s needs and following best practices, you can achieve professional results that stand the test of time.

Durability of Wood Countertops: Lifespan and Maintenance Tips Revealed

You may want to see also

Explore related products

Joint Complexity Effect: Complex joints like dovetails need extended clamping to prevent gaps and ensure alignment

The intricate geometry of dovetail joints, with their interlocking fingers, demands a clamping strategy that goes beyond the standard. While a simple butt joint might require 30 minutes to an hour of clamping, dovetails and other complex joints necessitate a more patient approach. Think of it as a delicate dance: the glue needs sufficient time to cure while the clamping pressure maintains perfect alignment of those intricate angles.

Rushing this process risks gaps, misalignment, and ultimately, a weakened joint.

Imagine trying to hold a house of cards together with a gentle breeze blowing. That's akin to clamping a dovetail joint for a mere 30 minutes. The glue, still in its initial tacky stage, lacks the strength to resist the inherent tension within the joint. Over time, this tension can cause the wood to shift, creating unsightly gaps and compromising the joint's integrity.

Extending clamping time to a minimum of 2 hours, and ideally overnight, allows the glue to fully cure, transforming from a pliable adhesive to a rigid bond capable of withstanding the stresses placed on the joint.

The "Joint Complexity Effect" isn't just about time; it's about pressure distribution. Complex joints require strategic clamping to ensure even pressure across all contact points. This might involve using cauls (flat pieces of wood) to distribute pressure evenly across the joint faces, preventing the wood from being crushed or distorted. Additionally, consider using multiple clamps at different angles to counteract the natural tendency of the joint to spring apart as the glue dries.

Think of it as a carefully orchestrated symphony of pressure, ensuring every element of the joint is held firmly in place until the glue sets.

While extended clamping times are crucial, over-clamping can be just as detrimental. Excessive pressure can squeeze out too much glue, leaving weak spots in the joint. Aim for firm, even pressure, not bone-crushing force. Remember, the goal is to hold the joint together securely, not to test the wood's breaking point. With patience, careful clamping techniques, and an understanding of the "Joint Complexity Effect," you can ensure your dovetail joints are not only beautiful but also strong and durable.

Seasoning Locust Wood: Understanding the Timeframe for Optimal Results

You may want to see also

Explore related products

$32.99

Environmental Factors: Humidity and temperature affect drying time; warmer, drier conditions speed up glue curing

Glue curing is a delicate dance with the environment, and humidity and temperature are the lead partners. High humidity slows the process, as moisture in the air competes with the glue for wood absorption. Imagine a crowded room where everyone’s trying to grab the same snack—chaos ensues, and progress stalls. In contrast, low humidity allows the glue to bond more efficiently, as it can penetrate the wood fibers without interference. For optimal results, aim for a humidity level below 50%. If you’re working in a damp basement, consider using a dehumidifier to create a more glue-friendly atmosphere.

Temperature acts as the accelerator in this chemical reaction. Warmer conditions increase molecular activity, causing the glue to cure faster. Think of it as turning up the heat on a simmering pot—the ingredients combine more quickly. Most wood glues perform best between 60°F and 80°F (15°C to 27°C). Below 50°F (10°C), curing time can double or even triple, while temperatures above 90°F (32°C) may cause the glue to set too rapidly, compromising bond strength. If you’re working in a garage during winter, use a space heater to maintain a suitable temperature. Conversely, in a sweltering summer workshop, ensure proper ventilation to prevent overheating.

Practical tip: Monitor your workspace conditions with a hygrometer and thermometer. These tools are inexpensive and invaluable for precision. For instance, if you’re clamping a critical joint and the temperature drops unexpectedly, you’ll know to extend clamping time or adjust the environment. Similarly, in humid conditions, pre-dry your wood in a warm, dry area for 24 hours before gluing to minimize moisture interference.

Comparing environments, a dry, warm indoor workshop offers the most control, while outdoor gluing is a gamble. If you must work outside, choose a sunny day with low humidity and shield your project from wind, which can unevenly cool the glue. For example, a wooden frame glued on a 75°F (24°C) day with 40% humidity will likely cure within 30 minutes to an hour, whereas the same project in 50°F (10°C) and 70% humidity might require 2–3 hours.

In conclusion, mastering environmental factors is key to achieving strong, durable wood bonds. Treat humidity and temperature as variables to manage, not obstacles to ignore. By controlling these elements, you’ll ensure your glued wood not only holds but thrives under stress. Remember, the environment isn’t just a backdrop—it’s an active participant in the gluing process.

Custom Wood Prints Shipping Time: Smallwood Delivery Details Explained

You may want to see also

Frequently asked questions

Clamping time depends on the glue type, but most wood glues require clamping for at least 30 minutes to 1 hour for initial curing. For maximum strength, leave the clamps on for 24 hours.

It’s not recommended to remove clamps prematurely, as the glue may not have fully bonded, leading to weak joints. Wait at least the minimum clamping time specified by the glue manufacturer.

Epoxy typically requires clamping for 8–24 hours, depending on the product. Follow the manufacturer’s instructions for the best results.

Yes, temperature impacts curing time. Warmer temperatures speed up curing, while colder temperatures slow it down. Adjust clamping time accordingly, but avoid extreme temperatures.

Clamping is only needed until the glue sets enough to hold the joint firmly. After initial curing (30 minutes to 1 hour), the clamps can be removed, but the wood should remain undisturbed until fully cured (24 hours).

![Right Angle Clamp, Housolution [4 PACK] Single Handle 90° Aluminum Alloy Corner Clamp, Clamps for Woodworking Adjustable Swing Jaw, Woodworking Tools Photo Frame Vise Holder, Gifts for Men Dad](https://m.media-amazon.com/images/I/71xNSiBOZ+L._AC_UL320_.jpg)