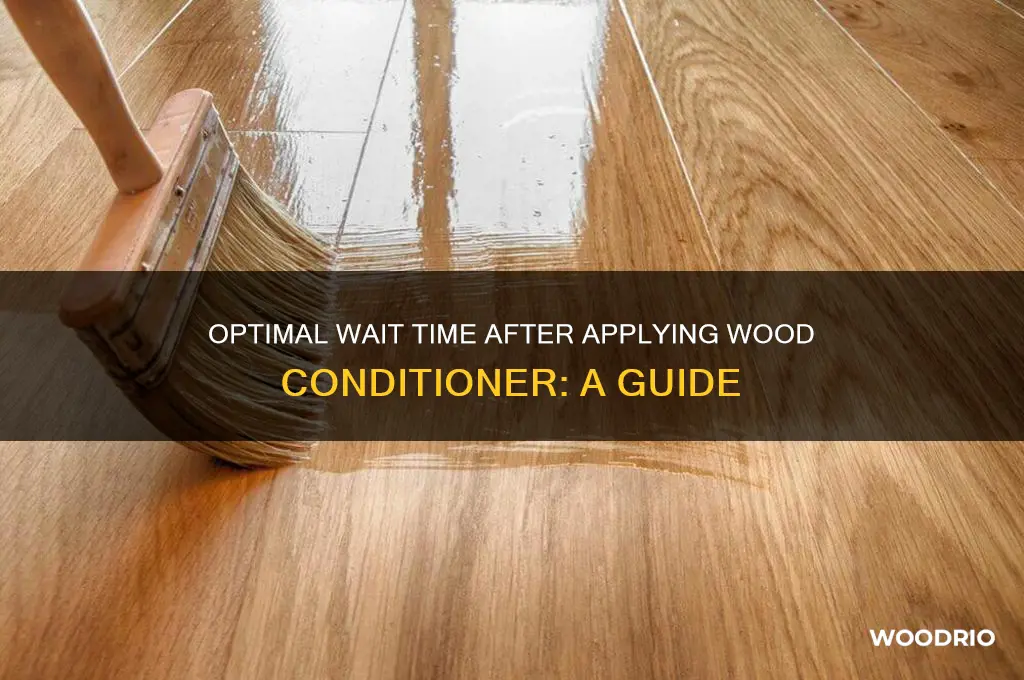

When applying wood conditioner to prepare your wood surface for staining, it’s crucial to understand the waiting time required for optimal results. Wood conditioner, also known as a pre-stain conditioner, helps to ensure even stain absorption and prevent blotching, especially on softwoods like pine. After applying the conditioner, the typical waiting time ranges from 15 minutes to 2 hours, depending on the product and wood type. It’s essential to follow the manufacturer’s instructions, as some conditioners may require a shorter or longer drying period. Waiting too little can lead to uneven staining, while waiting too long may cause the conditioner to dry excessively, reducing its effectiveness. Proper timing ensures the wood is adequately prepared for staining, resulting in a smooth, professional finish.

| Characteristics | Values |

|---|---|

| Recommended Wait Time | 15–30 minutes (varies by product; follow manufacturer’s instructions) |

| Purpose of Waiting | Allows wood conditioner to penetrate and raise the grain |

| Wood Type Influence | Softer woods (pine, cedar) may require less time; harder woods (oak, maple) may need longer |

| Humidity Impact | Higher humidity may extend drying time |

| Temperature Impact | Warmer temperatures accelerate drying; cooler temperatures slow it down |

| Signs of Readiness | Wood surface feels dry to the touch, no tackiness |

| Overwaiting Consequences | Minimal; excess conditioner may be wiped off before applying finish |

| Undertreating Consequences | Poor finish adhesion, uneven stain absorption |

| Product-Specific Variations | Always check product label for exact wait times |

| Multiple Coats | If applying a second coat, wait the same duration between applications |

| Sanding After Conditioning | Lightly sand raised grain after waiting period before finishing |

Explore related products

What You'll Learn

- Recommended Drying Time: 15-30 minutes for optimal absorption before applying stain or finish

- Environmental Factors: Humidity and temperature affect drying; adjust wait time accordingly

- Wood Type Considerations: Dense woods may require longer drying than softer varieties

- Multiple Coats: Wait 2-4 hours between coats for even conditioning

- Testing Readiness: Wipe a small area; if conditioner absorbs, wait longer

Recommended Drying Time: 15-30 minutes for optimal absorption before applying stain or finish

Wood conditioner is a preparatory treatment that enhances the absorption and evenness of stains, but its effectiveness hinges on proper drying time. Waiting 15 to 30 minutes after application allows the conditioner to penetrate the wood fibers fully, creating a more uniform surface for staining. This window is critical because applying stain too soon can dilute the conditioner, while waiting too long risks the wood drying unevenly. Think of this period as the "sweet spot" for optimal results, balancing absorption and readiness for the next step.

From a practical standpoint, timing matters more than you might think. If you’re working on a large project, apply the conditioner in sections to maintain control over drying times. Use a timer to avoid guesswork, especially in humid or dry conditions that can alter drying rates. For softwoods like pine, lean toward the shorter end of the spectrum (15 minutes), as they absorb conditioner quickly. Hardwoods like oak or maple may benefit from the full 30 minutes to ensure deeper penetration. Always test a small, inconspicuous area first to confirm the wood’s response.

The science behind this recommendation lies in the conditioner’s role as a moisture and pigment barrier. By raising the wood’s grain slightly and sealing it partially, the conditioner prevents blotching and uneven stain absorption. However, this effect is only achieved if the conditioner has time to bond with the wood’s cellular structure. Applying stain prematurely can disrupt this process, leading to patchy or streaky results. Patience here isn’t just a virtue—it’s a necessity for professional-grade finishes.

For those new to woodworking, this step might seem minor, but it’s a game-changer for achieving consistent color and texture. Imagine staining a table only to find the legs darker than the top due to rushed conditioning. Such mistakes are easily avoided by respecting the 15-30 minute rule. Pro tip: Use a damp cloth to wipe away any excess conditioner after the drying period, ensuring a clean surface for staining. This simple act can elevate your project from amateur to expert-level quality.

In the end, the 15-30 minute drying time isn’t arbitrary—it’s a deliberate interval designed to maximize the conditioner’s benefits. Whether you’re refinishing furniture or crafting a new piece, adhering to this guideline ensures the wood is primed for stain or finish. Skip it, and you risk undermining hours of work. Embrace it, and you’ll unlock the full potential of your materials, creating finishes that are as durable as they are beautiful.

Soaking Balsa Wood in Olive Oil: Optimal Time for Best Results

You may want to see also

Explore related products

Environmental Factors: Humidity and temperature affect drying; adjust wait time accordingly

Wood conditioner, a crucial step in preparing wood for staining, requires a waiting period before applying the finish. But this isn't a one-size-fits-all scenario. Environmental factors, particularly humidity and temperature, play a significant role in determining the optimal wait time.

Imagine a hot, dry summer day versus a cool, damp autumn morning. The wood in your project will react differently to the conditioner in these contrasting conditions.

Understanding the Impact:

High humidity slows down the drying process. Moisture in the air competes with the solvent in the conditioner, hindering its absorption into the wood fibers. This can lead to a sticky surface and uneven stain absorption. Conversely, low humidity accelerates drying, potentially causing the conditioner to dry too quickly, leaving behind a patchy or uneven finish.

Temperature acts as a catalyst. Warmer temperatures speed up evaporation, shortening the waiting time. Colder temperatures slow down the process, requiring a longer wait.

Practical Adjustments:

As a general rule, aim for a waiting time of 15-30 minutes after applying wood conditioner. However, this is a starting point, not a rigid rule.

- High Humidity: In humid conditions, extend the waiting time by 10-15 minutes. This allows the conditioner more time to penetrate the wood despite the moisture in the air.

- Low Humidity: In dry conditions, you can slightly reduce the waiting time, but be cautious. Monitor the wood closely to ensure it doesn't dry too quickly, leading to an uneven finish.

- Warm Temperatures: In warmer environments, stick to the shorter end of the 15-30 minute range.

- Cool Temperatures: In cooler environments, err on the side of a longer waiting time, closer to 30 minutes or even slightly longer if necessary.

Observing the Wood:

The best indicator of readiness is the wood itself. The surface should feel dry to the touch, but not completely matte. A slight tackiness is acceptable, but it shouldn't feel wet or sticky. If in doubt, wait a few more minutes and re-evaluate.

Controlling the Environment:

While you can't always control the weather, you can create a more favorable environment for drying.

- Humidity Control: If possible, work in a well-ventilated area with moderate humidity. Consider using a dehumidifier in excessively humid conditions.

- Temperature Regulation: Aim for a comfortable room temperature, ideally between 65°F and 75°F (18°C and 24°C). Avoid extreme temperatures, as they can negatively impact drying time and finish quality.

By understanding the interplay between humidity, temperature, and wood conditioner drying, you can adjust your waiting time accordingly, ensuring a beautiful and long-lasting finish for your woodworking projects. Remember, patience and observation are key to achieving professional results.

Phantom Wood Growth Timeline: Understanding Its Development and Duration

You may want to see also

Explore related products

Wood Type Considerations: Dense woods may require longer drying than softer varieties

Dense woods like oak, maple, or teak absorb wood conditioner more slowly due to their tightly packed grain structure. This slower absorption means the conditioner takes longer to penetrate the wood fibers, necessitating an extended drying time before applying stain or finish. Softer woods like pine or cedar, with their looser grain, absorb conditioner more quickly, allowing for a shorter wait time. Understanding this difference is crucial for achieving an even, professional finish.

For dense woods, plan to wait at least 4 to 6 hours after applying wood conditioner before proceeding with staining or finishing. In humid conditions or cooler temperatures, this drying time may extend to 8 hours or more. Softer woods typically require only 1 to 2 hours, but always test a small area to ensure the conditioner has fully dried. Rushing this step can lead to blotchy stains or uneven finishes, as the wood may not have adequately prepared its surface for the next step.

Consider the wood’s moisture content as well, especially if you’re working with reclaimed or outdoor-stored lumber. Dense woods retain moisture longer, which can interfere with conditioner absorption. Use a moisture meter to ensure the wood is below 12% moisture content before applying conditioner. For softer woods, this step is less critical but still recommended for consistency. Proper moisture levels ensure the conditioner works effectively, regardless of wood type.

Practical tips include applying conditioner thinly and evenly, using a brush or cloth to work it into the grain. For dense woods, lightly sanding the surface before application can help open the grain, improving absorption. After waiting the recommended time, wipe off excess conditioner with a clean cloth to prevent buildup. Always follow the manufacturer’s guidelines for the specific conditioner you’re using, as drying times can vary by product.

In summary, dense woods demand patience, often requiring double or triple the drying time of softer varieties. This extra wait ensures the conditioner fully prepares the wood for staining or finishing, preventing common issues like blotching or uneven color. By tailoring your approach to the wood type, you’ll achieve a smoother, more professional result that highlights the wood’s natural beauty.

How Long Does Mopany Wood Float? Unveiling Its Buoyancy Secrets

You may want to see also

Explore related products

Multiple Coats: Wait 2-4 hours between coats for even conditioning

Applying multiple coats of wood conditioner is a meticulous process that demands patience for optimal results. The waiting period between coats, typically 2-4 hours, is not arbitrary; it’s rooted in the chemistry of wood absorption. During this time, the conditioner penetrates the wood fibers, raising the grain slightly and preparing the surface for stain. Rushing this step risks oversaturation, which can lead to blotchy or uneven staining. Conversely, waiting too long may cause the conditioner to dry completely, negating its ability to bond with subsequent coats or stain. This 2-4 hour window strikes the balance, ensuring each coat contributes to a uniform foundation.

Consider the environmental factors that influence drying time. Humidity, temperature, and airflow play significant roles in how quickly the conditioner sets. In high-humidity environments, drying may take closer to 4 hours, while in dry, well-ventilated spaces, 2 hours might suffice. To test readiness, lightly touch the wood surface; if it feels tacky, it’s not ready for the next coat. Practical tip: Use a fan to accelerate drying in humid conditions, but avoid direct heat sources, which can cause uneven drying and compromise adhesion.

The number of coats applied depends on the wood’s porosity and the desired finish. Softwoods like pine, known for their uneven grain, often require two coats of conditioner to ensure even absorption. Hardwoods like oak or maple may only need one coat, as their denser structure absorbs conditioner more uniformly. Always follow the manufacturer’s guidelines for the specific conditioner used, as some products may recommend slightly different intervals or application techniques. Consistency is key; apply each coat with the grain using a clean cloth or brush, ensuring full coverage without pooling.

A common mistake is assuming that more coats equate to better results. Over-conditioning can create a barrier that repels stain, leading to a washed-out or uneven finish. Stick to the recommended 2-4 hour wait time between coats, and limit application to no more than two coats for most projects. If in doubt, test the process on a scrap piece of the same wood type to observe how it absorbs conditioner and stain. This trial run provides valuable insight into the wood’s behavior and helps refine your technique before tackling the final piece.

In conclusion, the 2-4 hour wait between coats of wood conditioner is a critical step in achieving a professional-grade finish. It allows the wood to absorb the conditioner evenly, setting the stage for consistent staining. By accounting for environmental factors, choosing the right number of coats, and avoiding common pitfalls, you can ensure that your wood conditioning process enhances rather than hinders the final result. Patience and attention to detail in this phase pay dividends in the beauty and durability of the finished piece.

COVID-19 Survival Time on Varnished Wood Surfaces: What to Know

You may want to see also

Explore related products

Testing Readiness: Wipe a small area; if conditioner absorbs, wait longer

A simple yet effective method to determine if your wood is ready for staining after applying conditioner is to perform a small absorption test. This technique is particularly useful for those who want to ensure the wood conditioner has fully penetrated the wood fibers, creating an even base for the stain. Here's how you can do it: take a clean, dry cloth and gently wipe a small, inconspicuous area of the wood surface. If the cloth picks up any conditioner residue, it's a clear indication that the wood needs more time to absorb the product.

The waiting game after applying wood conditioner can be a crucial factor in achieving a professional finish. Wood conditioners, typically oil-based or water-based, are designed to prepare the wood by sealing it, ensuring the stain absorbs evenly. However, the absorption rate can vary depending on the wood species, its density, and the environmental conditions. For instance, softer woods like pine may require less waiting time compared to harder woods such as oak or maple. As a general rule, it's recommended to wait at least 15-30 minutes after applying the conditioner, but this is where the absorption test becomes invaluable.

The Absorption Test: A Practical Approach

Instructively, here's a step-by-step guide to mastering this technique:

- Application: Apply the wood conditioner generously, following the manufacturer's instructions. Ensure the product is spread evenly across the wood surface.

- Initial Waiting Period: Allow the recommended minimum waiting time (usually 15-30 minutes) for the conditioner to start its work.

- Test for Absorption: Using a clean cloth, gently wipe a small area. If the cloth remains clean, the conditioner has likely been absorbed. If it picks up residue, the wood needs more time.

- Extended Waiting: If residue is present, wait in 15-minute intervals, retesting each time until the cloth comes away clean.

This method is particularly useful for DIY enthusiasts and professionals alike, ensuring that the wood is ready for staining, thereby preventing uneven color absorption and potential blotching.

Why This Matters

From a comparative perspective, consider the alternative: applying stain too soon can result in a blotchy, uneven finish, especially on softer woods. The stain may pool in areas where the conditioner hasn't fully penetrated, leading to dark patches. By testing for absorption, you're ensuring the wood is ready, creating a uniform surface for the stain to adhere to. This simple test can be the difference between a amateurish and a professional-looking finish.

In practice, this technique is a time-saver, preventing the need for potential re-sanding or touch-ups due to uneven staining. It's a small step that can significantly impact the overall quality of your woodworking project, ensuring a smooth, consistent finish that showcases the natural beauty of the wood. Remember, patience is key, and this simple test is a valuable tool in your woodworking arsenal.

Understanding the Lifespan of Wood Boring Beetles: A Comprehensive Guide

You may want to see also

Frequently asked questions

Typically, you should wait 15–30 minutes after applying wood conditioner before staining, but always follow the manufacturer’s instructions for the specific product.

No, it’s best to wait at least 15 minutes to allow the wood conditioner to penetrate the wood fibers and prepare the surface for staining.

The wood conditioner is ready when it appears dry to the touch, and the wood surface no longer feels wet or tacky.

Waiting too long (more than 2–4 hours) can cause the wood conditioner to dry completely, reducing its effectiveness in preparing the wood for stain absorption.

Lightly sanding with fine-grit sandpaper (220 grit) after the conditioner dries is recommended to remove any raised grain and ensure a smooth surface for staining.