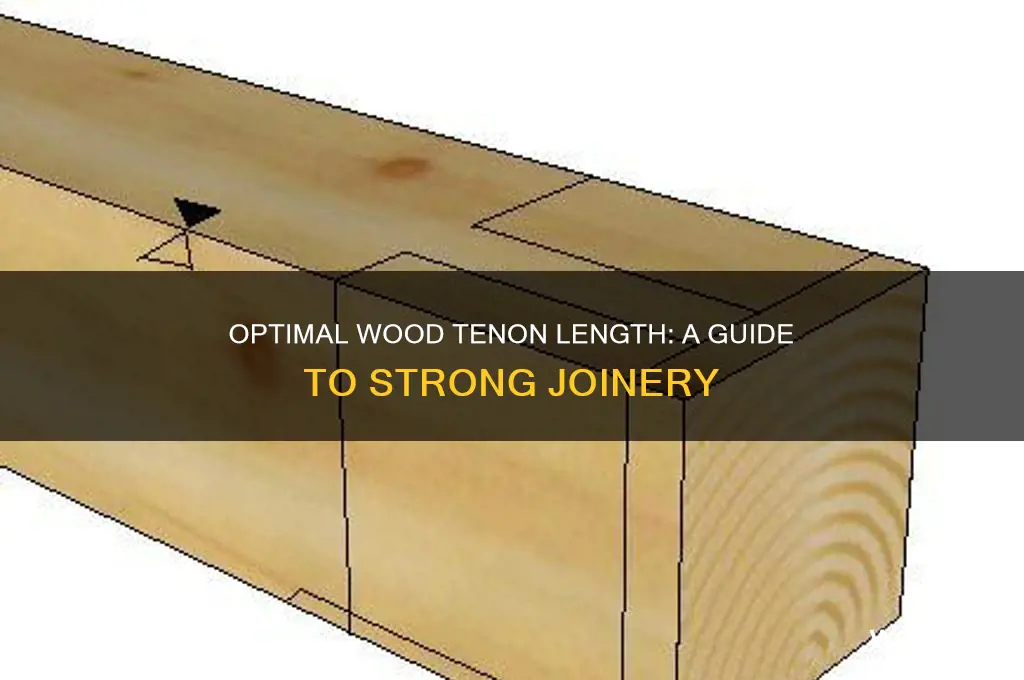

When determining the appropriate length for wood tenons, it is essential to consider factors such as the type of joint, the strength required, and the material properties of the wood. Generally, tenon lengths range from one-third to one-half the thickness of the corresponding mortise piece, ensuring a secure fit without excessive weakening of the wood. For stronger joints, such as those in furniture or structural applications, longer tenons are recommended, while shorter tenons may suffice for lighter-duty projects. Additionally, the grain orientation of the wood plays a crucial role, as tenons aligned with the grain provide greater strength. Always test the joint for fit and stability before finalizing the tenon length to ensure both durability and functionality.

Explore related products

What You'll Learn

- Standard Tenon Lengths: Common guidelines for tenon length based on wood type and joint strength

- Rule of Thumb: General rule: tenon length equals 1-3 times the wood thickness

- Load-Bearing Joints: Longer tenons for structural joints to ensure maximum stability and durability

- Decorative Joints: Shorter tenons for non-structural, aesthetic joints with minimal stress

- Material Considerations: Adjust tenon length based on wood hardness and grain direction

Standard Tenon Lengths: Common guidelines for tenon length based on wood type and joint strength

Tenon length is a critical factor in woodworking, directly influencing joint strength and longevity. While there’s no one-size-fits-all rule, standard guidelines emerge based on wood type and intended joint function. For softwoods like pine or cedar, tenons typically range from 1 to 1.5 times the thickness of the stock, balancing ease of assembly with adequate surface area for glue adhesion. Hardwoods, such as oak or maple, often require longer tenons—1.5 to 2 times the stock thickness—due to their denser grain structure, which demands more mechanical engagement for stability.

Consider the joint’s purpose when determining tenon length. For non-load-bearing joints, such as cabinet frames, shorter tenons (1 to 1.25 times the stock thickness) suffice, as they rely heavily on glue for strength. In contrast, load-bearing joints like table legs or chair rungs necessitate longer tenons (1.5 to 2 times the stock thickness) to distribute stress effectively. For example, a mortise-and-tenon joint in a dining table leg might use a tenon 2 inches long for a 1-inch thick rail, ensuring durability under weight.

Wood movement must also factor into tenon design. Hardwoods expand and contract more than softwoods, so tenons in hardwood joints should leave a slight shoulder gap to accommodate seasonal shifts. For instance, a tenon in a walnut drawer front might be 1.75 times the stock thickness, with a 1/16-inch shoulder gap to prevent binding. Softwoods, with less movement, can use tighter fits without risk of splitting.

Practical tips include testing wood movement by exposing samples to humidity changes and adjusting tenon length accordingly. Always dry-fit joints before gluing to ensure proper alignment and stress distribution. For beginners, start with tenons at 1.5 times the stock thickness and refine based on wood behavior and joint performance. Remember, the goal is not just to join pieces but to create a connection that withstands time and use.

Wood-Fired Hot Tub Heating Time: What to Expect

You may want to see also

Explore related products

$24.92 $28.92

Rule of Thumb: General rule: tenon length equals 1-3 times the wood thickness

A fundamental principle in woodworking is the relationship between tenon length and wood thickness. The rule of thumb that tenon length should equal 1-3 times the thickness of the wood being joined is a widely accepted guideline. This ratio ensures a balance between strength and practicality, allowing the tenon to bear the necessary load without excessive material waste or difficulty in assembly. For instance, if you’re working with ¾-inch thick stock, a tenon length between ¾ and 2¼ inches would fall within this range, providing ample surface area for glue and mechanical bonding while maintaining structural integrity.

Analyzing this rule reveals its adaptability across various woodworking projects. In finer joinery, such as cabinetmaking, a tenon length closer to 1 times the wood thickness is often sufficient, as the emphasis is on precision and aesthetics. Conversely, in heavier applications like timber framing, a tenon length of 2-3 times the wood thickness is more appropriate to handle greater stresses and ensure longevity. This scalability makes the 1-3 times rule a versatile starting point for woodworkers of all skill levels, allowing adjustments based on specific project demands.

From a practical standpoint, adhering to this guideline simplifies the planning and execution of joints. Begin by measuring the thickness of the wood you’re using, then calculate the tenon length accordingly. For example, if your material is 1 inch thick, a tenon between 1 and 3 inches will provide a secure fit. Always consider the grain direction and the type of joint (e.g., mortise and tenon, bridle joint) to ensure the tenon aligns with the wood’s natural strength. Using a marking gauge to define the tenon shoulders and a sharp chisel or router for clean cuts will further enhance the joint’s effectiveness.

While the 1-3 times rule is a reliable benchmark, it’s not without exceptions. Factors such as wood species, moisture content, and intended load can influence the ideal tenon length. Hardwoods like oak or maple may require longer tenons due to their density, while softer woods like pine might perform well with shorter ones. Additionally, joints exposed to outdoor conditions or heavy use may benefit from tenons on the higher end of the range to account for potential material degradation over time. Always test your joints in a scrap piece of wood to ensure they meet the specific requirements of your project.

In conclusion, the rule of thumb that tenon length should equal 1-3 times the wood thickness is a practical and adaptable guideline for woodworkers. By understanding its application across different scenarios and making informed adjustments, you can create joints that are both strong and efficient. Whether you’re crafting delicate furniture or robust structures, this principle serves as a foundational tool in achieving durable and aesthetically pleasing results.

Wood Sealant Drying Time: Factors Affecting Cure and Application Tips

You may want to see also

Explore related products

Load-Bearing Joints: Longer tenons for structural joints to ensure maximum stability and durability

In load-bearing joints, the length of a tenon directly correlates with the joint’s ability to withstand shear forces and distribute stress. A tenon that is too short risks premature failure under heavy loads, as the reduced surface area limits glue bond strength and mechanical interlocking. For structural applications like timber framing or heavy furniture, tenons should typically span 2 to 3 times the thickness of the stock material. For example, in a 2-inch thick hardwood joint, a tenon length of 4 to 6 inches ensures sufficient engagement to resist racking and twisting forces. This proportional approach balances material efficiency with structural integrity, avoiding unnecessary waste while maximizing stability.

Consider the grain orientation when determining tenon length, as it significantly impacts durability. Tenons cut with the grain (longitudinally) are stronger in tension but require greater length to compensate for potential splitting under shear stress. A rule of thumb is to add 10–15% to the calculated length when working with end grain or cross-grain scenarios to mitigate this risk. For instance, a 5-inch tenon in a cross-grain joint might be extended to 5.5 inches to ensure the joint remains intact under dynamic loads. This adjustment is particularly critical in outdoor structures exposed to moisture fluctuations, where wood movement can exacerbate stress concentrations.

The choice of joint type further dictates tenon length requirements. In mortise-and-tenon joints used for load-bearing applications, the tenon should extend at least 2/3 the depth of the mortise to prevent rocking or pivoting under load. For through-tenon joints, where the tenon passes entirely through the receiving piece, the exposed portion should be 1.5 to 2 times the stock thickness to allow for proper pegging or wedging, enhancing both aesthetics and structural security. These guidelines ensure the tenon acts as a rigid connector rather than a weak point in the assembly.

Practical implementation requires careful planning and execution. When cutting longer tenons, use a shoulder-to-shoulder length ratio of 1:3 to maintain a robust shoulder that resists pull-out forces. For example, in a 6-inch tenon, allocate 1.5 inches to the shoulder and 4.5 inches to the body. Additionally, pre-drill pilot holes for fasteners or wedges to prevent splitting, especially in hardwoods. Always test-fit the joint dry before gluing to verify alignment and adjust as needed. By adhering to these principles, longer tenons in load-bearing joints not only ensure maximum stability but also extend the lifespan of the structure, even under extreme conditions.

Perfect Wood Pigeon Hanging Time: Tips for Tender, Flavorful Game Meat

You may want to see also

Explore related products

Decorative Joints: Shorter tenons for non-structural, aesthetic joints with minimal stress

In decorative woodworking, where joints serve as both functional and artistic elements, the length of tenons can be significantly reduced compared to their structural counterparts. For non-structural, aesthetic joints with minimal stress, tenons as short as 1/4 to 1/2 inch are often sufficient. This length ensures the joint remains discreet, allowing the surrounding wood grain and design to take center stage. For example, in a delicate frame or a decorative box, a 3/8-inch tenon provides enough stability without detracting from the visual appeal. The key is to balance visibility and strength, ensuring the joint enhances rather than dominates the piece.

When crafting decorative joints, consider the wood species and its inherent properties. Softer woods like pine or cedar may require slightly longer tenons (up to 5/8 inch) to prevent splitting, while harder woods like maple or walnut can accommodate shorter lengths without compromise. Additionally, the orientation of the grain matters—tenons cut with the grain are less likely to fail, even at shorter lengths. For instance, a 1/4-inch tenon in quarter-sawn oak can be remarkably durable in a low-stress application like a cabinet door panel. Always test the joint’s fit and strength before finalizing the design.

A persuasive argument for shorter tenons in decorative work lies in their ability to preserve material and reduce waste. Longer tenons often require more wood, which can be impractical or costly when working with exotic or expensive species. By opting for a 1/2-inch tenon instead of a 1-inch one, woodworkers can maximize yield while maintaining the joint’s integrity. This approach aligns with sustainable practices, ensuring that every piece of wood contributes meaningfully to the final design. It also allows for more intricate patterns and details, as shorter tenons leave more room for creativity.

Comparatively, structural joints demand tenons that are typically 1.5 to 3 times the thickness of the wood for maximum strength, but decorative joints operate under different constraints. A 1/4-inch tenon in a 3/4-inch thick board might seem insufficient for load-bearing purposes, yet it excels in applications like picture frames or inlay work, where stress is minimal. The takeaway is that shorter tenons are not a compromise but a deliberate choice tailored to the joint’s role. By understanding this distinction, woodworkers can elevate their designs, combining functionality with artistry seamlessly.

Finally, practical tips for implementing shorter tenons in decorative joints include using precision tools like a fine-toothed saw or a router with a small-diameter bit to achieve clean, accurate cuts. Applying a thin layer of glue can enhance the joint’s stability without adding bulk. For added discretion, consider chamfering or rounding the tenon edges to create a subtle, refined appearance. Always dry-fit the joint to ensure proper alignment and adjust as needed. With these techniques, shorter tenons become a powerful tool in the woodworker’s arsenal, enabling joints that are both beautiful and enduring.

Optimal Wooden Dowel Shoulder Dislocation Duration: A Comprehensive Guide

You may want to see also

Explore related products

Material Considerations: Adjust tenon length based on wood hardness and grain direction

Wood hardness directly influences tenon length because softer woods, like pine or cedar, compress more readily under joint stress. A tenon in softwood should be longer—typically 1.5 to 2 times the thickness of the mating piece—to distribute force across a greater surface area. Harder woods, such as oak or maple, require shorter tenons (1 to 1.5 times the thickness) because their density resists deformation, making excessive length unnecessary and potentially wasteful. This adjustment ensures the joint remains stable without overloading the wood’s natural strength.

Grain direction complicates this calculation, as wood splits more easily along the grain than across it. When the tenon runs parallel to the grain, it must be shorter to avoid splitting, particularly in brittle woods like cherry or walnut. Conversely, a tenon cut perpendicular to the grain can be longer, as it leverages the wood’s cross-grain strength. Always orient the grain of the tenon piece to align with the direction of force in the joint, reducing the risk of failure under stress.

For mixed-material joints, such as joining hardwood to softwood, prioritize the weaker material’s requirements. If a hardwood tenon fits into a softwood mortise, size the tenon for the softwood’s needs to prevent the softer material from crushing. Conversely, a softwood tenon in a hardwood mortise should be shorter to avoid excessive play or weakening of the harder material. This approach balances the structural demands of both woods.

Practical testing can refine these guidelines. For critical joints, create test pieces to assess how the wood responds to tenon length variations under load. Apply a force equivalent to the joint’s expected stress and observe for gaps, splitting, or deformation. Adjust the tenon length incrementally until the joint holds firmly without compromising the wood’s integrity. This method ensures precision tailored to the specific materials and joint design.

In summary, tenon length is not one-size-fits-all but a dynamic decision based on wood hardness and grain orientation. Softwoods demand longer tenons for stability, while hardwoods benefit from brevity. Grain alignment dictates vulnerability to splitting, necessitating shorter tenons when parallel to the force direction. By accounting for these material properties, woodworkers can craft joints that are both durable and efficient, maximizing the wood’s natural characteristics without over-engineering.

Cedar Wood Deck Lifespan: Durability, Maintenance, and Longevity Explained

You may want to see also

Frequently asked questions

Wood tenons should generally be 1 to 1.5 times the thickness of the wood being joined to ensure sufficient strength and stability in the joint.

Yes, the length of a wood tenon can vary depending on the joint type. For example, mortise and tenon joints typically require longer tenons compared to simpler joints like stub tenons.

Yes, a wood tenon can be too long if it extends beyond the necessary length for the joint, leading to unnecessary material waste and potential weakening of the wood around the mortise. It should fit snugly without excessive overhang.