Curing wood before burning it in a fireplace is essential for efficiency, safety, and heat output. Freshly cut wood, known as green wood, contains a high moisture content, typically around 40-60%, which makes it difficult to burn efficiently and can lead to excessive smoke, creosote buildup, and reduced heat output. Properly cured wood, with a moisture content of 20% or less, burns hotter, cleaner, and more efficiently. The curing time for wood depends on factors such as the type of wood, the environment, and the initial moisture content, but generally, it takes 6 months to 2 years for wood to cure adequately. Hardwoods like oak and maple typically take longer to cure than softer woods like pine. To ensure the wood is ready for burning, it should be stored in a dry, well-ventilated area, protected from rain and snow, and allowed to air-dry naturally. Using a moisture meter can help determine when the wood is sufficiently cured, ensuring a safe and enjoyable fireplace experience.

| Characteristics | Values |

|---|---|

| Ideal Curing Time | 6 months to 2 years |

| Minimum Curing Time | 6 months |

| Moisture Content After Curing | Below 20% (ideally 15-20%) |

| Wood Type (Hardwoods) | Longer curing time (up to 2 years) |

| Wood Type (Softwoods) | Shorter curing time (6-12 months) |

| Splitting and Stacking | Essential for proper air circulation and drying |

| Covered Storage | Required to protect from rain and snow |

| Elevated Storage | Recommended to prevent ground moisture absorption |

| Seasoning Indicators | Checks (cracks) in wood, lighter weight, and dull appearance |

| Burning Efficiency | Properly cured wood burns hotter, cleaner, and with less smoke |

| Environmental Impact | Reduced creosote buildup and lower emissions |

Explore related products

What You'll Learn

- Ideal Curing Time: 6-12 months for hardwood, 6 months for softwood to ensure proper drying

- Moisture Content: Aim for 20% or less moisture content for efficient, safe burning

- Stacking Methods: Split and stack wood in a dry, ventilated area for faster curing

- Seasoning Indicators: Check for cracks, lighter weight, and a hollow sound when tapped

- Risks of Burning Wet Wood: Creosote buildup, reduced heat output, and increased chimney fire risk

Ideal Curing Time: 6-12 months for hardwood, 6 months for softwood to ensure proper drying

Freshly cut wood contains a high moisture content, typically between 30% and 50%. Burning wood with this level of moisture is inefficient and problematic. It produces less heat, more smoke, and creosote buildup in your chimney, increasing the risk of chimney fires.

The curing process allows wood to air dry, reducing moisture content to below 20%, the ideal range for clean, efficient burning. Hardwoods like oak, maple, and hickory are denser and take longer to cure, requiring 6-12 months of proper seasoning. Softer woods like pine and spruce dry faster due to their looser cell structure, needing only 6 months of curing.

Imagine stacking freshly cut logs directly into your fireplace. The fire would struggle to ignite, producing a smoky, sooty mess. Properly cured wood, on the other hand, ignites easily, burns hotter, and leaves minimal ash. This not only enhances your fireplace experience but also protects your chimney and reduces environmental impact.

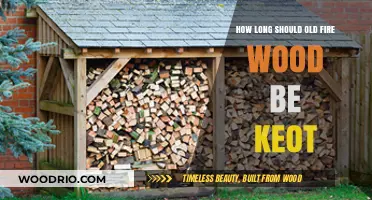

To ensure optimal curing, stack wood in a dry, well-ventilated area, preferably under a roof or tarp to protect it from rain and snow. Leave space between logs for air circulation, and elevate the stack off the ground to prevent rot. Regularly check the wood's moisture content using a moisture meter; aim for readings below 20% before burning.

Durable Wood Blinds: Lifespan, Maintenance, and Longevity Tips

You may want to see also

Explore related products

Moisture Content: Aim for 20% or less moisture content for efficient, safe burning

Freshly cut wood, often called green wood, can contain up to 50% moisture content. Burning wood with such high moisture is inefficient and potentially hazardous. As wood dries, it becomes denser, allowing for more complete combustion, which translates to more heat output and less smoke. The sweet spot for moisture content in firewood is 20% or less. At this level, the wood burns hotter, cleaner, and with minimal creosote buildup in your chimney, reducing the risk of chimney fires.

Aiming for 20% moisture content isn't just about efficiency; it's about safety. Wet wood produces more smoke, which contains harmful pollutants like carbon monoxide and particulate matter. These pollutants not only contribute to air pollution but can also pose health risks, especially for individuals with respiratory conditions. By ensuring your firewood is properly seasoned (dried) to 20% moisture or less, you're not only getting the most out of your firewood but also protecting your health and the environment.

Determining the moisture content of your firewood is surprisingly straightforward. You can purchase a moisture meter specifically designed for firewood, which provides an accurate reading. These meters are readily available at hardware stores and online retailers. Alternatively, you can perform a simple "knock test." Seasoned wood with low moisture content will produce a sharp, clear sound when two pieces are struck together, while green wood will sound dull and thudding. While not as precise as a moisture meter, the knock test can give you a good indication of your firewood's readiness.

Remember, achieving 20% moisture content takes time. The curing process, also known as seasoning, typically takes 6 to 12 months, depending on the wood species and environmental conditions. Harder woods like oak and maple take longer to season than softer woods like pine. Proper stacking and storage are crucial during this period. Stack your firewood in a sunny, well-ventilated area, off the ground, and covered to protect it from rain and snow.

Optimal Drying Time for Wood Before Sealing: A Comprehensive Guide

You may want to see also

Explore related products

Stacking Methods: Split and stack wood in a dry, ventilated area for faster curing

Proper stacking is pivotal for accelerating the curing of firewood, a process that reduces moisture content to below 20% for efficient burning. Split wood exposes more surface area to air, while strategic stacking maximizes ventilation, allowing moisture to escape rather than stagnate. A well-stacked pile can halve curing time, turning a year-long wait into a six-month process.

Steps for Optimal Stacking:

- Split Wood to Uniform Thickness: Aim for 3–6 inch diameter pieces, as thinner splits dry faster. Use a sharp axe or hydraulic splitter for clean cuts, minimizing jagged edges that trap moisture.

- Choose a Dry, Elevated Location: Stack wood on a raised platform (e.g., pallets or railroad ties) to prevent ground moisture absorption. Position the pile in a sunny, south-facing area with good airflow.

- Stack in a Crisscross Pattern: Build a loose, airy structure by alternating layers in a perpendicular arrangement. This "log cabin" style promotes airflow through the pile, drying all sides of the wood evenly.

- Cover the Top, Not the Sides: Use a tarp or waterproof cover to shield the stack from rain and snow, but leave sides exposed to wind and sun. Ensure the cover slopes downward to prevent water pooling.

Cautions to Avoid:

Avoid stacking wood directly against walls or fences, as this restricts airflow and traps humidity. Overcrowding the pile can also slow drying, so maintain a maximum height of 4 feet for stability and ventilation. Never use plastic sheeting to enclose the stack, as it traps moisture and fosters mold or rot.

Comparative Advantage:

Improperly stacked wood can take 18–24 months to cure, while a well-ventilated pile achieves readiness in 6–12 months. For example, oak, a dense hardwood, benefits significantly from proper stacking, drying from 50% to 20% moisture in one season instead of two.

Practical Tip:

Test moisture levels with a wood moisture meter ($20–$50) before burning. Readings above 20% indicate incomplete curing, leading to inefficient combustion and creosote buildup. For faster results, split and stack wood in early spring, allowing it to dry through summer and fall for winter use.

By mastering these stacking methods, you transform raw logs into fireplace-ready fuel, ensuring warmer fires and fewer chimney hazards. The effort invested in proper stacking pays dividends in both efficiency and safety.

Wood Duck Egg Incubation: Duration and Nesting Habits Explained

You may want to see also

Explore related products

Seasoning Indicators: Check for cracks, lighter weight, and a hollow sound when tapped

Wood that’s ready for the fireplace doesn’t just look dry—it feels, sounds, and behaves differently. One of the most reliable ways to determine if your wood is properly seasoned is by checking for specific indicators: cracks, lighter weight, and a hollow sound when tapped. These signs reveal the wood’s moisture content, which should ideally be below 20% for efficient burning. Unseasoned wood, often heavier and denser, retains moisture that leads to inefficient combustion, creosote buildup, and increased smoke. By mastering these seasoning indicators, you can ensure your firewood burns hotter, cleaner, and safer.

Cracks are the wood’s silent confession of proper seasoning. As moisture escapes, the wood shrinks, causing the ends to split. These cracks, often radial and extending a few inches inward, are a visual cue that the drying process is complete. Freshly cut wood, in contrast, appears smooth and intact. To test, inspect the ends of the logs—fine cracks indicate readiness, while a lack of splitting suggests the wood needs more time. Avoid wood with deep, longitudinal cracks, as this may indicate excessive drying or structural weakness.

Weight is another critical indicator. Properly seasoned wood feels noticeably lighter than freshly cut logs of the same size. This is because water, which constitutes up to 50% of a living tree’s weight, has evaporated. A practical tip: compare a seasoned log to a freshly cut one. If the seasoned log feels significantly lighter, it’s likely ready. For precision, weigh a sample piece—seasoned hardwoods like oak or maple should weigh about 30-40% less than their green counterparts.

The hollow sound test is a simple yet effective method. Strike two pieces of wood together or tap a log with a mallet. Seasoned wood produces a sharp, resonant sound, akin to knocking on a door. Green wood, however, sounds dull and thudding, betraying its moisture-laden interior. This auditory cue is particularly useful when visual or weight checks are inconclusive. Practice this test on known seasoned and unseasoned wood to train your ear for the difference.

Mastering these indicators—cracks, lighter weight, and a hollow sound—transforms guesswork into certainty. Properly seasoned wood not only burns better but also protects your chimney from creosote buildup, reducing fire hazards. Aim to stack and store wood for at least 6–12 months in a dry, well-ventilated area to achieve these seasoning benchmarks. By prioritizing these checks, you’ll ensure every fireplace session is efficient, safe, and enjoyable.

How Long Can Bacteria Survive on Wood Surfaces?

You may want to see also

Explore related products

Risks of Burning Wet Wood: Creosote buildup, reduced heat output, and increased chimney fire risk

Burning wet wood in your fireplace might seem like a quick solution when you're low on dry logs, but it’s a decision that comes with significant risks. The primary danger lies in creosote buildup, a tar-like substance that forms when unburned wood gases condense in your chimney. Wet wood burns inefficiently, producing more smoke and gases than heat, which accelerates creosote accumulation. Over time, this sticky residue hardens into a highly flammable layer, increasing the risk of a chimney fire. A single spark can ignite this buildup, leading to a blaze that can spread to your roof or home.

Beyond the threat of fire, burning wet wood drastically reduces heat output. Water requires energy to evaporate, and when wood is damp, a substantial portion of the heat generated is wasted on drying the wood rather than warming your space. This inefficiency means you’ll burn more wood to achieve the same level of comfort, costing you time, money, and resources. For optimal heat production, firewood should have a moisture content of 20% or less, a level achieved through proper seasoning, which typically takes 6 to 12 months depending on the wood type and climate.

The risks don’t stop at creosote and inefficiency—burning wet wood also elevates the likelihood of a chimney fire. When creosote ignites, temperatures inside the chimney can soar to 2,000°F or higher, hot enough to crack masonry, warp metal, or even set nearby combustibles ablaze. Regular chimney inspections and cleanings are essential, but prevention starts with using properly seasoned wood. A simple moisture meter, available for under $20, can help you verify that your firewood is ready to burn safely.

To mitigate these risks, prioritize seasoning your wood correctly. Stack logs in a sunny, well-ventilated area, ensuring they’re raised off the ground and covered to protect from rain while allowing airflow. Softwoods like pine dry faster, typically within 6 months, while denser hardwoods like oak may require a full year. If you’re in a pinch and need to burn wood that’s not fully seasoned, mix it with drier pieces to improve combustion and reduce smoke. However, this should be a temporary measure, not a long-term practice.

In summary, the risks of burning wet wood—creosote buildup, reduced heat output, and increased chimney fire risk—far outweigh any convenience. By investing time in proper wood seasoning and using tools like moisture meters, you can ensure safer, more efficient fires that protect both your home and your wallet. Remember, a little patience in curing wood goes a long way in preventing costly and dangerous consequences.

Aluminum Clad Wood Windows Lifespan: Durability and Longevity Explained

You may want to see also

Frequently asked questions

Wood should ideally cure for 6 to 12 months before burning in a fireplace to ensure it is properly seasoned and has a moisture content below 20%.

Burning freshly cut wood (green wood) is not recommended as it contains high moisture levels, which can lead to poor combustion, creosote buildup, and reduced heat output.

Properly cured wood will have cracks at the ends, a dull grayish color, and a hollow sound when knocked together. A moisture meter can also confirm it has less than 20% moisture content.

Yes, denser hardwoods like oak or maple may take closer to 12 months to cure, while softer woods like pine or fir may be ready in 6 months. Always ensure the wood is fully seasoned before burning.