When discussing the standard size of a wood piece, it's important to note that dimensions can vary widely depending on the type of wood, its intended use, and regional standards. However, in the context of lumber, common sizes in North America typically include 2x4s, which are actually 1.5 inches by 3.5 inches in cross-section and come in lengths ranging from 8 to 20 feet. Plywood, another standard wood product, is often available in 4x8 foot sheets with thicknesses ranging from 1/8 inch to 1 inch. Understanding these standard sizes is crucial for planning construction projects, ensuring compatibility with tools and hardware, and optimizing material usage.

Explore related products

$25.64 $26.99

What You'll Learn

- Common Lumber Dimensions: Standard sizes for boards, planks, and beams in construction and woodworking

- Softwood vs. Hardwood Sizes: Differences in dimensions between softwood and hardwood pieces

- Metric vs. Imperial Measurements: Comparison of wood sizes in metric and imperial systems

- Standard Lengths: Typical lengths of wood pieces for various applications

- Thickness and Width Variations: Common thickness and width options for standard wood pieces

Common Lumber Dimensions: Standard sizes for boards, planks, and beams in construction and woodworking

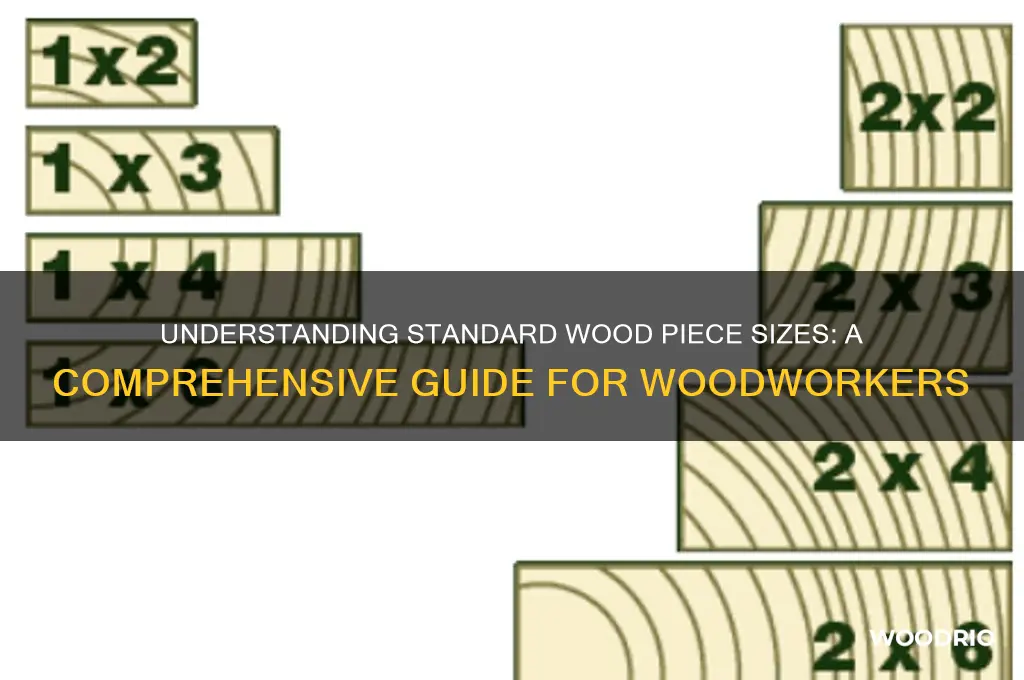

Lumber dimensions are standardized to streamline construction and woodworking projects, ensuring compatibility and efficiency. In North America, the most common sizes for boards and planks are based on nominal versus actual measurements due to shrinkage during drying and planning. For instance, a "2x4" board starts as a 2-inch by 4-inch rough piece but is milled down to 1.5 inches by 3.5 inches in its finished form. This discrepancy is critical for precise planning, as using nominal dimensions in calculations can lead to material shortages or misfits.

Beams, often used in structural applications, follow a different sizing convention. Standard beam sizes, such as 4x6, 6x8, or 8x10, are typically sold in their actual dimensions, which simplifies load-bearing calculations. For example, an 8x10 beam is precisely 8 inches by 10 inches, providing clear data for engineers and builders. However, lengths vary widely—beams are commonly available in 8-foot to 24-foot increments, with custom lengths possible for specialized projects. Understanding these variations ensures structural integrity and cost-effectiveness.

In woodworking, thickness is a defining factor for boards and planks. Standard thicknesses include ½ inch, ¾ inch, and 1 inch, with ¾ inch being the most versatile for furniture and cabinetry. Widths range from 4 inches to 12 inches, though wider planks are available for specific applications like tabletops. Lengths typically span 6 feet to 16 feet, with 8-foot and 12-foot boards being the most common. Selecting the right dimensions minimizes waste and aligns with project requirements, whether crafting a bookshelf or framing a wall.

For those working internationally, metric lumber dimensions differ significantly. European and Australian standards use measurements like 22mm, 28mm, or 45mm for thickness, with widths and lengths in meters or centimeters. Adapting to these systems requires careful conversion and an understanding of regional building codes. For instance, a 22mm board is roughly equivalent to a 7/8-inch board in the U.S., but structural applications may demand precise matches rather than approximations.

Practical tips for working with standard lumber sizes include always measuring actual dimensions before cutting, accounting for material loss due to saw kerf, and planning projects around readily available lengths to reduce costs. For example, designing a bookshelf to use full 8-foot boards eliminates the need for splicing. Additionally, leveraging standard sizes simplifies sourcing materials, as most suppliers stock these dimensions. Mastery of these standards transforms lumber from raw material into a predictable, efficient building block for any project.

The Enduring Legacy of Wooden Bats in Baseball History

You may want to see also

Explore related products

Softwood vs. Hardwood Sizes: Differences in dimensions between softwood and hardwood pieces

Softwood and hardwood pieces often differ in standard dimensions due to their distinct structural properties and typical applications. Softwoods, like pine and spruce, are generally harvested from coniferous trees and are more readily available in longer, thicker pieces. For instance, a standard 2x4 softwood stud is commonly sold in lengths of 8, 10, or 12 feet, making it ideal for framing in construction. In contrast, hardwoods, such as oak or maple, are denser and harder to work with, leading to shorter and more precise sizing. A typical hardwood board might measure 1x6 or 1x8 and come in lengths of 4 to 8 feet, catering to finer woodworking projects like furniture or cabinetry.

The dimensional differences stem from how these woods are processed and their intended uses. Softwoods are often rough-cut and air-dried, allowing for larger, more forgiving sizes that can be trimmed on-site. Hardwoods, however, are frequently kiln-dried and milled to exact specifications, resulting in smaller, more uniform pieces. For example, a softwood plank might have slight variations in thickness or width, while a hardwood board is often planed to a precise ¾ inch thickness. This precision in hardwood sizing is essential for joinery and intricate designs, where even a millimeter can affect the final product.

When selecting wood for a project, understanding these size differences can save time and reduce waste. Softwoods are better suited for structural applications where longer lengths and larger cross-sections are needed, such as in building frames or subflooring. Hardwoods, with their shorter, more refined dimensions, excel in projects requiring detail and durability, like tabletops or decorative moldings. For instance, a 10-foot softwood plank might be ideal for a wall stud, while a 6-foot hardwood board is perfect for a drawer front.

Practical tips for working with these woods include planning cuts carefully to maximize material use, especially with hardwoods, which are often more expensive. For softwoods, consider purchasing slightly longer pieces to account for potential defects or uneven edges. Always measure twice and cut once, particularly with hardwoods, where mistakes can be costly. Additionally, store hardwoods in a controlled environment to prevent warping, as their density makes them more susceptible to moisture changes. By recognizing the inherent size differences between softwood and hardwood, craftsmen can make informed decisions that enhance both efficiency and the quality of their work.

Durability of Faux Wood Blinds: Lifespan and Maintenance Tips

You may want to see also

Explore related products

Metric vs. Imperial Measurements: Comparison of wood sizes in metric and imperial systems

Woodworkers and DIY enthusiasts often encounter a fundamental divide in measurement systems: metric versus imperial. A standard 2x4 lumber piece, nominally called so in the imperial system, actually measures approximately 1.5 inches by 3.5 inches due to drying and planing. In metric terms, this translates to 38mm x 89mm, a size that feels less intuitive to those accustomed to inches. This discrepancy highlights the first challenge in comparing systems: nominal sizes rarely reflect actual dimensions, requiring constant mental conversions or reliance on reference charts.

Consider the precision required for joinery or framing. Metric measurements, based on multiples of ten, simplify calculations—halving or doubling dimensions is straightforward. For instance, a 50mm width can be easily adjusted to 25mm or 100mm. Imperial measurements, however, rely on fractions (e.g., 3/4 inch or 7/8 inch), which complicate quick estimations. Yet, imperial units often align better with traditional tooling, as many saw blades and routers are calibrated in inches. This creates a practical dilemma: metric logic versus imperial tool compatibility.

Regional standards further complicate the choice. In Europe and much of the world, metric sizes dominate, with wood commonly sold in lengths like 2.4 meters or 3 meters. In the U.S. and Canada, imperial lengths such as 8 feet or 10 feet prevail. This geographic split means a project designed in one system may require custom milling or wasteful adjustments when executed in another. For international collaborations or sourcing materials abroad, understanding both systems is not just convenient—it’s essential.

To bridge the gap, adopt a dual-measurement approach. Label cut lists with both systems (e.g., "100mm (4 inches)") to avoid errors. Invest in tools with dual scales, such as tape measures or digital calipers, to streamline workflows. When purchasing wood, verify actual dimensions rather than relying on nominal sizes, especially when mixing systems. For example, a metric 22mm board is closer to a 7/8-inch imperial board than a full inch, ensuring tighter fits in hybrid projects.

Ultimately, the metric-imperial divide in woodworking isn’t about superiority but context. Metric offers simplicity and global alignment, while imperial retains legacy tool and project compatibility. Mastery of both systems empowers craftsmen to adapt to any scenario, whether restoring a vintage piece measured in inches or building a modern design in millimeters. The key lies in flexibility, not allegiance to one system over the other.

Woods Hole to Nantucket Ferry Ride: Duration and Travel Tips

You may want to see also

Explore related products

Standard Lengths: Typical lengths of wood pieces for various applications

Wood comes in various standard lengths, tailored to specific applications, ensuring efficiency and minimizing waste. For construction, dimensional lumber is commonly available in 8, 10, 12, 14, 16, and 20-foot lengths. These sizes align with typical wall heights and structural requirements, allowing builders to choose the most suitable length for framing, flooring, or roofing. For instance, 8-foot pieces are ideal for interior walls, while 16-foot lengths are often used for longer spans or exterior walls. Understanding these standard lengths helps in planning projects and reducing the need for excessive cutting or joining.

In furniture making, wood pieces are often shorter, reflecting the scale of the final product. Common lengths include 4, 6, and 8 feet, which are versatile for crafting tables, chairs, and cabinets. For example, a 6-foot piece of hardwood can be used to create a tabletop, while 4-foot lengths are perfect for chair legs or shelving. Custom furniture may require non-standard lengths, but starting with these typical sizes simplifies the design and assembly process. Always measure twice and cut once to ensure precision in your work.

For woodworking hobbies or small projects, wood is frequently sold in 2, 4, or 6-foot lengths. These shorter pieces are practical for crafting items like picture frames, birdhouses, or decorative shelves. Craft stores often carry pre-cut wood in these sizes, making it convenient for beginners or those with limited workspace. When selecting wood for small projects, consider the grain direction and thickness to ensure stability and aesthetics in the finished piece.

In landscaping and outdoor applications, standard wood lengths are often longer to accommodate fencing, decking, and structural supports. Common sizes include 6, 8, 10, and 12 feet, with 8-foot lengths being the most popular for fence panels and garden borders. For decking, 12-foot boards are frequently used to minimize seams and create a cleaner appearance. Pressure-treated wood in these lengths is widely available, offering durability against weather and pests. Always check local building codes when using wood for outdoor structures to ensure compliance with safety standards.

Finally, specialty applications like boatbuilding or musical instrument crafting require unique wood lengths. For boats, planks are often custom-cut to fit specific curves and dimensions, though standard lengths like 12 or 16 feet may serve as a starting point. In luthiery, wood for guitars or violins is typically shorter, ranging from 1 to 4 feet, with precise thicknesses and grain patterns. These niche applications highlight the importance of understanding standard lengths as a foundation, even when customization is necessary. Always source high-quality wood for such projects to ensure longevity and performance.

Resanding Wet Wood: Optimal Timing for Smooth, Flawless Results

You may want to see also

Explore related products

Thickness and Width Variations: Common thickness and width options for standard wood pieces

Standard wood dimensions are far from one-size-fits-all. Thickness and width variations are dictated by intended use, structural requirements, and aesthetic preferences. Common thicknesses for lumber range from ½ inch to 1½ inches, with ¾ inch being a ubiquitous choice for shelving, furniture, and cabinetry. Wider boards, typically 4 to 12 inches, are standard for structural applications like framing, while narrower widths (2 to 3 inches) are favored for trim, molding, and decorative elements. Understanding these variations is crucial for selecting the right wood for your project.

Consider the load-bearing capacity when choosing thickness. A 1½-inch thick board can support significantly more weight than a ½-inch one, making it ideal for heavy-duty applications like workbenches or flooring. Conversely, thinner boards are lightweight and cost-effective, suitable for projects like picture frames or lightweight shelving. Width plays a role in stability and visual appeal. Wider boards provide a more substantial look but are prone to warping if not properly supported. Narrower widths offer versatility and are easier to manipulate, especially in intricate designs.

For furniture making, ¾-inch thick plywood or solid wood is a standard choice, balancing strength and workability. Cabinet doors often use ½-inch material for a sleek profile, while drawer bottoms might be as thin as ¼ inch to reduce weight. In contrast, structural beams for decking or framing typically measure 2x4 (1½ inches thick by 3½ inches wide) or 2x6 (1½ inches thick by 5½ inches wide), providing the necessary strength for load-bearing tasks.

When selecting wood, consider the grain direction as well. Thicker boards with a straight grain are less likely to warp, while thinner pieces may require additional support or laminating to maintain stability. For outdoor projects, opt for thicker, wider boards to withstand weather exposure. Always account for material loss due to planing or sanding when planning your dimensions. By carefully evaluating thickness and width, you can ensure your wood pieces are both functional and aesthetically pleasing.

Seasoning Split Cherry Wood: Timeframe for Optimal Results Explained

You may want to see also

Frequently asked questions

The standard length for a piece of lumber is typically 8 feet, though lengths of 10 feet and 12 feet are also common.

Standard widths for dimensional lumber include 2 inches, 4 inches, 6 inches, and 8 inches, though actual dimensions are slightly smaller due to drying and planing.

Standard plywood thicknesses range from 1/8 inch to 1 inch, with common sizes being 1/4 inch, 1/2 inch, and 3/4 inch.

Yes, common sizes for furniture boards include 1x4, 1x6, 1x8, and 1x12, with actual dimensions slightly smaller than the nominal size.

Standard wooden dowel sizes range from 1/4 inch to 2 inches in diameter and are typically available in lengths of 24 inches, 36 inches, and 48 inches.