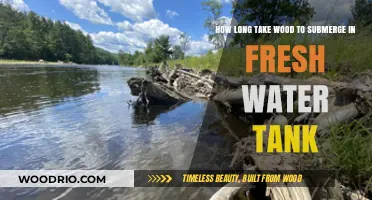

Acclimating wood before installation is a crucial step often overlooked in construction and woodworking projects. Wood is a natural material that expands and contracts with changes in humidity and temperature, and failing to allow it to adjust to its new environment can lead to warping, gaps, or other structural issues. The acclimation period typically ranges from 5 to 14 days, depending on the type of wood, the climate, and the specific conditions of the installation site. During this time, the wood should be stored in the same area where it will be installed, allowing it to reach moisture equilibrium with its surroundings. Proper acclimation ensures the longevity and stability of the wood, preventing costly repairs and maintaining the aesthetic appeal of the finished project.

| Characteristics | Values |

|---|---|

| Acclimation Time | 3-7 days (minimum), up to 2 weeks for thicker or exotic wood species |

| Ideal Humidity Range | 30-50% relative humidity (matches typical indoor conditions) |

| Temperature Range | 60-80°F (15-27°C) for optimal acclimation |

| Wood Moisture Content Goal | 6-9% moisture content (matches ambient conditions) |

| Storage Conditions | Flat, stacked with spacers, in a climate-controlled environment |

| Species Variability | Exotic or dense woods may require longer acclimation (e.g., 2 weeks) |

| Thickness Consideration | Thicker wood (e.g., ¾ inch or more) needs more time to acclimate |

| Installation Readiness | Moisture meter reading should match ambient conditions before install |

| Seasonal Adjustment | Longer acclimation in extreme humidity or temperature conditions |

| Manufacturer Guidelines | Follow specific recommendations from the wood supplier or manufacturer |

Explore related products

What You'll Learn

- Ideal Acclimation Duration: Recommended time for wood to adjust to environment before installation

- Humidity and Temperature: Optimal conditions for wood acclimation to prevent warping

- Wood Type Considerations: How different wood species affect acclimation time requirements

- Storage Best Practices: Proper methods for storing wood during the acclimation period

- Signs of Readiness: Indicators that wood is fully acclimated and ready for installation

Ideal Acclimation Duration: Recommended time for wood to adjust to environment before installation

Wood acclimation is a critical step often overlooked in installation processes, yet it directly impacts the material's performance and longevity. The ideal duration for acclimation varies based on wood type, environmental conditions, and project specifics. Hardwoods like oak or maple typically require 7 to 14 days to adjust to new humidity and temperature levels, while softer woods such as pine may need only 5 to 7 days. These timelines ensure the wood reaches equilibrium moisture content (EMC), reducing the risk of warping, cracking, or gapping post-installation.

Environmental factors play a decisive role in determining acclimation needs. In regions with high humidity (above 60%), wood may absorb excess moisture, necessitating longer acclimation periods. Conversely, dry climates (below 30% humidity) can cause wood to shrink, requiring careful monitoring during adjustment. Temperature fluctuations also matter; wood should acclimate in the same space where it will be installed, ideally at consistent temperatures between 60°F and 80°F. Ignoring these conditions can lead to costly repairs or replacements.

A practical approach to acclimation involves stacking wood in the installation area, allowing air circulation between planks, and avoiding direct contact with walls or floors. For flooring projects, open boxes and lay planks in staggered stacks to promote even moisture exchange. Use a moisture meter to test wood and subfloor humidity levels, aiming for a 2-4% moisture content difference between the two. If discrepancies exceed this range, extend the acclimation period until equilibrium is achieved.

Comparing acclimation practices across different wood applications reveals nuanced requirements. Engineered wood, for instance, acclimates faster (2-3 days) due to its layered construction, which resists dimensional changes. Solid wood, however, demands stricter adherence to acclimation guidelines. For furniture or cabinetry, shorter acclimation times (3-5 days) may suffice, but always consult manufacturer recommendations. The key is tailoring the duration to the wood’s end use and environmental exposure.

Ultimately, rushing acclimation undermines the wood’s stability and aesthetic appeal. While 7 to 14 days is a standard benchmark, treat this as a starting point, not a rigid rule. Monitor conditions, test moisture levels, and adjust timelines as needed. Proper acclimation is an investment in durability, ensuring wood retains its beauty and functionality for years to come.

Wood Pigeon Egg Incubation: Understanding Their Nesting Duration

You may want to see also

Explore related products

Humidity and Temperature: Optimal conditions for wood acclimation to prevent warping

Wood is hygroscopic, meaning it naturally absorbs and releases moisture in response to its environment. This characteristic makes humidity control critical during acclimation. The goal is to match the wood’s moisture content to the conditions where it will be installed, typically achieving equilibrium moisture content (EMC). For interior installations, aim for an EMC of 6–8% in dry climates and 9–11% in humid regions. Use a moisture meter to measure the wood’s moisture content and compare it to the EMC target. If the difference exceeds 2–4%, extend the acclimation period, as rapid changes in humidity can cause warping, cupping, or splitting.

Temperature plays a secondary but equally vital role in wood acclimation. Extreme temperature fluctuations can accelerate moisture exchange, leading to uneven drying or swelling. Store wood in a temperature-controlled environment between 60°F and 80°F (15°C–27°C) to ensure gradual acclimation. Avoid placing wood near heat sources like radiators or vents, as localized drying can create stress points. Similarly, cold temperatures can slow moisture movement, prolonging acclimation time. Consistency is key—maintain stable temperature conditions throughout the acclimation period to prevent thermal shock.

To optimize acclimation, stack wood properly to allow air circulation. Use stickers (spacers) between layers to promote even moisture distribution. For hardwoods, acclimate for 5–14 days, while softwoods may require 3–7 days. Monitor conditions daily, especially in climates with high humidity or seasonal changes. If installing in a new construction, allow the HVAC system to run for at least 3–5 days before acclimating wood to stabilize indoor humidity and temperature. This proactive approach minimizes the risk of post-installation issues.

Consider the wood species, as density and grain pattern influence acclimation needs. Dense hardwoods like oak or maple are more resistant to warping but require longer acclimation due to slower moisture absorption. Softwoods like pine acclimate faster but are more prone to distortion if conditions are not ideal. For exotic woods, consult supplier guidelines, as some species may need specific humidity ranges. Always cross-reference the wood’s origin moisture content with the installation environment to tailor the acclimation process.

Finally, document the acclimation process for future reference. Record initial and final moisture readings, humidity levels, and temperature ranges. This data helps refine acclimation protocols for subsequent projects. If warping occurs despite proper acclimation, reassess the installation environment for hidden moisture sources, such as leaks or inadequate ventilation. By prioritizing humidity and temperature control, you ensure wood remains stable, preserving both its structural integrity and aesthetic appeal.

Shellac Drying Time on Wood: Factors Affecting Cure and Finish

You may want to see also

Explore related products

Wood Type Considerations: How different wood species affect acclimation time requirements

Wood species vary widely in density, moisture absorption rates, and dimensional stability, directly influencing how long they need to acclimate before installation. For instance, dense hardwoods like oak or maple require longer acclimation periods—typically 7 to 14 days—due to their slower moisture exchange with the environment. In contrast, softer woods like pine or cedar acclimate faster, often within 3 to 5 days, because their cellular structure allows quicker moisture absorption or release. Understanding these differences is critical to prevent warping, cracking, or gaps after installation.

Consider the environment where the wood will be installed. Tropical hardwoods, such as teak or mahogany, are naturally more stable but still need 7 to 10 days to adjust to indoor humidity levels, especially in drier climates. Conversely, domestic species like hickory or walnut, known for their reactivity to moisture changes, may demand up to 21 days of acclimation in humid conditions. A rule of thumb: the higher the wood’s density and moisture content, the longer the acclimation period required.

Practical steps can streamline the acclimation process based on wood type. For dense hardwoods, stack planks in the installation room with spacers between boards to allow air circulation, and maintain a consistent humidity level of 30–50%. Softwoods, which are more forgiving, can be acclimated in bundles with minimal spacing, but ensure the room’s temperature remains stable (60–80°F). Always check the manufacturer’s guidelines, as engineered wood products, regardless of species, often acclimate faster—typically 48 to 72 hours—due to their layered construction.

A comparative analysis reveals that exotic woods, such as Brazilian cherry or ipe, often require the longest acclimation times—up to 30 days—due to their high density and natural oils, which slow moisture exchange. Domestic softwoods like fir or spruce, on the other hand, are ready for installation in as little as 2 days in controlled environments. The key takeaway: match the acclimation duration to the wood’s natural properties and the installation environment to ensure long-term performance.

Finally, ignore the myth that all wood acclimates the same. Each species has unique characteristics that dictate its needs. For example, bamboo, though technically a grass, behaves similarly to hardwoods and requires 7 to 14 days of acclimation. Always measure the wood’s moisture content before installation—ideally, it should match the subfloor’s moisture level within 2–4 percentage points. Investing time in proper acclimation, tailored to the wood type, pays off in a durable, flawless installation.

Understanding the Time It Takes for Wood to Petrify Naturally

You may want to see also

Explore related products

Storage Best Practices: Proper methods for storing wood during the acclimation period

Wood acclimation is a critical step before installation, but its success hinges on proper storage during this period. The goal is to allow the wood to adjust to the environment’s humidity and temperature, minimizing warping, cracking, or gaps post-installation. Improper storage can negate the acclimation process entirely, leading to costly repairs or replacements.

Location Matters: Choose the Right Environment

Store wood in the same space where it will be installed—whether it’s a living room, basement, or outdoor deck. This ensures the wood adapts to the specific conditions it will face. Avoid areas with extreme temperature fluctuations, such as garages or sheds, unless the installation site is similarly exposed. For indoor projects, maintain a consistent room temperature between 60°F and 80°F (15°C–27°C) and humidity levels between 30% and 50%.

Stacking Techniques: Promote Airflow and Stability

Stack wood planks or panels on sturdy, flat surfaces, using stickers (thin strips of wood) between layers to allow air circulation. Stickers should be placed every 16–24 inches along the stack to prevent sagging. Avoid piling wood directly on concrete floors, as moisture can wick up and cause warping. Instead, use pallets or a moisture barrier like plastic sheeting. For vertical storage, lean wood against a wall at a slight angle, securing it to prevent tipping.

Moisture Control: Prevent Warping and Mold

Wood is hygroscopic, meaning it absorbs and releases moisture based on its environment. Use a dehumidifier in humid climates to maintain optimal humidity levels. In dry environments, a humidifier can prevent the wood from drying out and cracking. Regularly inspect stored wood for signs of moisture damage, such as discoloration or mold. If detected, separate affected pieces and address the source of moisture immediately.

Duration and Monitoring: Patience Pays Off

Acclimation typically takes 5–30 days, depending on wood species, thickness, and environmental conditions. Hardwoods like oak or maple may require longer acclimation periods than softer woods like pine. Monitor the wood’s moisture content using a moisture meter, aiming for a reading within 2–4 percentage points of the installation site’s average moisture level. Rushing this process risks installation failures, so plan storage time accordingly.

By following these storage best practices, you ensure the wood acclimates effectively, setting the stage for a durable and visually appealing installation. Proper storage is not just a step—it’s an investment in the longevity of your project.

Killing Dry Wood: Understanding the Timeframe for Effective Treatment

You may want to see also

Explore related products

Signs of Readiness: Indicators that wood is fully acclimated and ready for installation

Wood acclimation is a critical step in ensuring the longevity and stability of your flooring or woodworking project. But how do you know when the wood has fully adjusted to its new environment? The answer lies in observing specific signs that indicate the material has reached equilibrium moisture content (EMC) with its surroundings. One of the most reliable indicators is the absence of noticeable changes in the wood's dimensions. After acclimating for the recommended period—typically 5 to 30 days depending on the wood species and climate—measure the planks or boards at multiple points. If there’s no further expansion, contraction, or warping, the wood is likely ready for installation.

Another key sign of readiness is the wood’s weight stability. Freshly delivered wood often contains excess moisture, making it heavier than acclimated material. To test this, weigh a sample piece at the start of the acclimation period and again after a few weeks. If the weight remains consistent, the wood has reached its optimal moisture level. This method is particularly useful in humid climates, where moisture absorption can be more pronounced. Pairing this with a moisture meter reading—ideally between 6% and 8% for most indoor installations—provides a definitive confirmation of readiness.

Visually inspecting the wood can also reveal its acclimation status. Look for gaps between boards or changes in grain pattern, which often indicate ongoing moisture movement. Fully acclimated wood will show uniform color and texture across all pieces. Additionally, run your hand along the surface to check for rough patches or raised edges, signs that the wood is still adjusting. Smooth, consistent surfaces suggest the material is stable and ready for use.

For those seeking a more scientific approach, monitoring the wood’s moisture content over time is essential. Use a pin-type or pinless moisture meter to measure the EMC at regular intervals. Once the readings stabilize and align with the recommended range for your specific wood type and environment, installation can proceed. Keep in mind that rapid changes in humidity or temperature can disrupt acclimation, so maintain consistent conditions during this period.

Finally, consider the practical test of flexibility. Wood that is still acclimating may feel stiff or brittle due to excess moisture or dryness. Gently bend a small offcut or apply slight pressure to observe its response. Fully acclimated wood will exhibit natural flexibility without cracking or splitting. This simple yet effective test complements other methods, ensuring you install wood that’s not only stable but also structurally sound. By recognizing these signs, you can confidently move forward with your project, knowing the wood is fully prepared for its new role.

Chris Wood's Supergirl Tenure: Exploring Mon-El's Time in the Series

You may want to see also

Frequently asked questions

Wood should typically acclimate for 5 to 14 days, depending on the type of wood, humidity, and temperature of the installation environment.

Yes, denser hardwoods like oak may require longer acclimation (7–14 days), while softer woods like pine may only need 5–7 days.

No, skipping acclimation can lead to warping, gaps, or buckling after installation due to moisture imbalance in the wood. Always allow proper acclimation time.