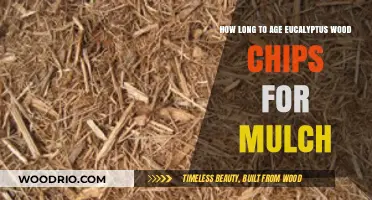

Aging wood is a process that enhances its appearance, durability, and character, making it a sought-after material for furniture, flooring, and decorative elements. The time required to age wood varies depending on the desired outcome, the type of wood, and the method used. Natural aging can take decades, as wood exposed to the elements gradually develops a weathered patina, while accelerated techniques like heat treatment, chemical processes, or wire brushing can achieve similar effects in weeks or months. Understanding the factors influencing wood aging helps crafters, builders, and enthusiasts choose the best approach to achieve their desired aesthetic and functional results.

| Characteristics | Values |

|---|---|

| Minimum Aging Time for Most Woods | 6 months to 1 year |

| Ideal Aging Time for Hardwoods (e.g., Oak, Maple) | 1 to 2 years |

| Ideal Aging Time for Softwoods (e.g., Pine, Cedar) | 6 months to 1 year |

| Moisture Content Goal for Aged Wood | 8-12% (depending on local climate) |

| Optimal Aging Conditions | Covered, well-ventilated area, off the ground |

| Aging Method for Faster Results | Kiln drying (reduces time to weeks) |

| Purpose of Aging Wood | Stabilizes moisture content, reduces warping/cracking |

| Signs of Properly Aged Wood | Consistent weight, no visible moisture, straight grain |

| Effect of Aging on Wood Strength | Increases durability and workability |

| Environmental Factors Affecting Aging | Humidity, temperature, airflow |

| Maximum Aging Time (Practical) | 2-3 years (beyond this, minimal additional benefit) |

| Cost Impact of Aging | Increases cost due to storage time and space |

| Alternative to Aging | Air drying or using pre-dried lumber |

Explore related products

$24.95 $24.95

What You'll Learn

Factors Affecting Aging Time

Wood aging is a delicate balance of science and art, influenced by a myriad of factors that determine the final product's quality and character. One critical aspect is the wood species itself, as different types age at varying rates due to their unique cellular structures and natural oils. For instance, oak, a popular choice for aging, can take anywhere from 6 months to 2 years to develop its signature flavor and aroma profiles, depending on the desired outcome. In contrast, softer woods like pine or cedar may age more rapidly but are less commonly used for extended aging processes.

The environment in which the wood is aged plays a pivotal role in determining the aging time. Humidity, temperature, and air circulation are key variables that can accelerate or decelerate the aging process. A controlled environment with consistent humidity levels between 60-70% and temperatures around 60-70°F is ideal for most wood aging applications. In such conditions, wood can age more predictably, allowing for better planning and quality control. However, natural aging in outdoor environments can also yield unique results, albeit with less control over the process. For example, wood aged in a dry, sunny climate may develop a distinct flavor profile compared to the same wood aged in a cool, damp environment.

The size and shape of the wood also impact aging time, with smaller pieces or shavings aging more quickly than larger logs or planks. This is due to the increased surface area-to-volume ratio, allowing for more efficient moisture exchange and chemical reactions. As a general rule, wood shavings or chips can age in as little as 3-6 months, while larger barrels or casks may require 1-2 years or more to achieve the desired effect. Furthermore, the intended use of the aged wood should be considered when determining aging time. Wood used for smoking meats or aging spirits may require different aging profiles than wood used for furniture or construction, where structural integrity and appearance are paramount.

Aging techniques, such as toasting or charring, can also influence the aging process. Toasting wood at specific temperatures (e.g., 350-450°F for medium toast) can accelerate the release of desirable compounds, reducing aging time by up to 30%. Charring, on the other hand, creates a deeper, more complex flavor profile but may require additional aging time to mellow out harsh notes. It is essential to monitor the wood's progress throughout the aging process, using sensory evaluation and, if necessary, laboratory analysis to ensure the desired outcome is achieved. By understanding these factors and their interactions, one can fine-tune the aging process to produce wood with the perfect balance of flavor, aroma, and texture for its intended application.

In practice, achieving optimal aging times requires a combination of art and science. For instance, a whiskey distiller might experiment with different wood species, toasting levels, and aging durations to create a unique flavor profile. A furniture maker, on the other hand, might prioritize wood stability and appearance, opting for longer aging times to reduce the risk of warping or cracking. By considering the specific requirements of each application and adjusting aging parameters accordingly, it is possible to harness the full potential of aged wood. Ultimately, the key to successful wood aging lies in understanding the intricate relationships between wood properties, environmental conditions, and desired outcomes, allowing for informed decision-making and precise control over the aging process.

Oxalic Acid Wood Bleaching: Timeframe for Effective Results Revealed

You may want to see also

Explore related products

Indoor vs. Outdoor Aging Methods

Aging wood indoors offers precise control over environmental factors, making it ideal for projects requiring consistency. By regulating temperature, humidity, and airflow, you can accelerate or slow the aging process to achieve specific textures and colors. For instance, maintaining a humidity level of 60–70% and a temperature of 70–80°F can mimic natural aging conditions, but in a fraction of the time. Use fans to circulate air evenly, preventing mold or uneven drying. This method is particularly effective for smaller pieces like furniture or decorative panels, where uniformity is key.

Outdoor aging, on the other hand, relies on natural elements—sunlight, rain, and temperature fluctuations—to weather wood organically. This method is hands-off but unpredictable, with results varying based on climate. For example, wood exposed to direct sunlight in arid regions will gray faster due to UV degradation, while humid environments may encourage deeper checking (cracks) and fungal growth. To mitigate risks, elevate wood off the ground to prevent rot and rotate pieces periodically for even exposure. Outdoor aging is best suited for larger projects like fencing or outdoor furniture, where a rustic, varied appearance is desirable.

The choice between indoor and outdoor aging hinges on your desired outcome and timeline. Indoor methods can produce aged wood in as little as 2–4 weeks, while outdoor aging typically takes 6–12 months for noticeable results. However, outdoor aging imparts a unique, authentic character that’s hard to replicate indoors. If you’re short on time but crave the look of naturally weathered wood, consider a hybrid approach: start outdoors for initial weathering, then finish indoors to refine the texture and color.

Practical tips for both methods include selecting dense hardwoods like oak or teak, which age more gracefully than softwoods. For indoor aging, experiment with vinegar or tea solutions to enhance color before exposing the wood to controlled conditions. Outdoors, apply a thin coat of linseed oil to protect against excessive moisture while still allowing natural weathering. Whichever method you choose, patience and observation are key—regularly inspect your wood to ensure it’s aging as intended, not deteriorating.

Mastering Wood Oven Preheating: Time, Tips, and Techniques Explained

You may want to see also

Explore related products

Accelerated Aging Techniques

Aging wood naturally can take years, even decades, to achieve the desired patina and character. However, for those seeking a quicker transformation, accelerated aging techniques offer a viable solution. These methods mimic the effects of time, weather, and wear, compressing years of aging into a matter of days or weeks. By understanding and applying these techniques, woodworkers, artisans, and DIY enthusiasts can achieve authentic, aged aesthetics without the wait.

One of the most effective accelerated aging techniques involves chemical treatments. A popular method is using a mixture of vinegar, steel wool, and hydrogen peroxide. Start by soaking fine-grade steel wool (0000) in white vinegar for 24 hours to create an iron acetate solution. Apply this solution to the wood surface, allowing it to react with the natural tannins in the wood. Follow this by lightly spraying or brushing on 3% hydrogen peroxide, which will deepen the color and create a weathered appearance. This process can be repeated in layers to achieve varying degrees of aging, from subtly rustic to deeply distressed.

Another technique leverages physical distressing combined with heat. Use tools like wire brushes, sandpaper, or even chains to scratch, dent, and roughen the wood surface. For a more pronounced aged effect, apply heat with a torch or heat gun, being careful not to scorch the wood. The heat will raise the grain and create natural-looking cracks and splits. Afterward, neutralize the wood with a damp cloth to stop the heating process and seal it with a matte finish to preserve the texture. This method is particularly effective for furniture or decorative pieces where tactile authenticity is desired.

For those seeking a more controlled and uniform aged look, wire brushing and graying agents are ideal. Wire brushing removes the softer wood fibers, leaving behind a textured, weathered surface. Pair this with a commercial wood graying product, which typically contains oxalic acid or other mild chemicals to neutralize the wood’s natural color. Apply the graying agent according to the manufacturer’s instructions, often diluting it with water for a subtler effect. This technique is especially useful for outdoor projects like fencing or siding, where a consistent, aged appearance is needed across large surfaces.

While accelerated aging techniques offer speed and control, they require precision and experimentation. Over-application of chemicals or excessive physical distressing can damage the wood, so always test on a small, inconspicuous area first. Additionally, consider the type of wood you’re working with, as denser woods like oak or maple may react differently than softer woods like pine. With practice and attention to detail, these techniques allow you to bypass time’s slow hand, crafting aged wood that tells a story in a fraction of the time.

Durability of Wood Doors: Lifespan, Maintenance, and Longevity Factors

You may want to see also

Explore related products

Wood Type and Grain Impact

The density and porosity of wood species significantly influence how they age. Hardwoods like oak and maple, with their tight grain patterns, resist moisture absorption, making them slower to develop patina but more durable over centuries. Softwoods such as pine, with looser grain structures, age faster due to quicker moisture penetration, yet they’re more prone to warping or cracking. For instance, oak beams in medieval buildings have darkened gracefully over 500 years, while pine furniture often shows distressing within decades. Choose wood type based on desired aging speed and structural longevity.

Grain direction plays a pivotal role in how wood weathers. End grain, the exposed cross-section of wood fibers, absorbs moisture and finishes unevenly, leading to rapid aging effects like checking or spalling. Quarter-sawn or rift-sawn boards, where grain runs vertically, resist cupping and twist, aging more uniformly. Flat-sawn wood, with its cathedral-like grain pattern, ages dramatically with pronounced color variations due to uneven UV exposure. To control aging, orient grain direction strategically: use end grain for rustic posts, quarter-sawn for stable panels, and flat-sawn for dynamic visual effects.

Aging wood isn’t just about time—it’s about managing environmental stressors. Tropical woods like teak or ipe contain natural oils that slow aging, even when exposed to harsh climates, making them ideal for outdoor applications. Conversely, domestic woods like cherry or walnut develop richer patinas when shielded from direct sunlight, which can bleach their natural hues. Apply finishes sparingly to accelerate or preserve aging: linseed oil enhances depth in hardwoods, while polyurethanes lock in softness in softwoods. Tailor your approach to the wood’s inherent traits and intended use.

For those seeking accelerated aging, species with open grain structures like ash or hickory respond well to techniques like wire brushing or vinegar-steel wool solutions, which darken wood within hours. Dense woods like ebony or rosewood require months of controlled humidity exposure to mimic centuries of aging. Experiment with small samples to calibrate effects: apply heat to soften grain, then sand to reveal layered tones. Remember, forced aging can compromise structural integrity—balance aesthetics with functionality, especially in load-bearing applications.

Xavier Woods' Injury Timeline: How Long Has He Been Sidelined?

You may want to see also

Explore related products

$11.33 $26.99

Signs of Properly Aged Wood

The patina of properly aged wood is a symphony of subtle cues, each note signaling maturity and stability. Look for a uniform, muted tone that replaces the raw, vibrant hues of fresh lumber. This color shift isn’t arbitrary—it’s the result of cellular breakdown and oxidation, processes that take years to perfect. For instance, oak transitions from a golden tan to a rich, honeyed brown, while cedar deepens from reddish-brown to a silvery gray. These changes aren’t just aesthetic; they indicate reduced moisture content and increased durability, hallmarks of wood ready for fine craftsmanship.

Beyond color, texture tells a story. Run your hand over the surface—properly aged wood feels smoother, its grain softened by time and exposure. This isn’t wear from handling but a natural settling of fibers as internal stresses dissipate. For example, air-dried wood aged 2–5 years will show less splintering and more even grain patterns compared to its green counterpart. However, beware of over-aging; wood left too long can become brittle or develop cracks, particularly in harsh climates. The sweet spot varies by species: hardwoods like walnut may need 8–10 years, while softwoods like pine stabilize in 3–5.

Weight is another critical indicator. Aged wood is lighter due to moisture loss, a process that slows dramatically after the first year. A simple test: compare a freshly cut board to one aged for 3 years—the latter should feel noticeably less dense. This reduction in moisture content (ideally below 12% for indoor use) minimizes warping and splitting, making the wood more predictable for joinery. However, don’t rely on weight alone; use a moisture meter to confirm, especially in humid regions where drying times extend.

Finally, listen to the wood. Tap a piece of aged lumber, and it emits a clear, resonant sound, unlike the dull thud of green wood. This acoustic change reflects reduced internal moisture and increased structural integrity. Carpenters often use this method to assess readiness for projects like flooring or instruments. Pair this test with visual and tactile inspections for a comprehensive evaluation. Properly aged wood isn’t just material—it’s a testament to patience, transformed by time into something stronger, more beautiful, and infinitely more useful.

The Ancient Process: How Long Does Petrified Wood Formation Take?

You may want to see also

Frequently asked questions

Natural wood aging can take anywhere from 5 to 20 years or more, depending on the species, climate, and desired level of patina. Exposure to sunlight, moisture, and temperature fluctuations accelerates the process.

Yes, wood can be aged artificially using techniques like wire brushing, vinegar and steel wool, or heat treatment. Artificial aging typically takes a few hours to a few days, depending on the method used.

Yes, different wood species age at varying rates. Softwoods like pine age faster, while hardwoods like oak or walnut may take longer to develop a weathered appearance due to their denser grain structure.