Charcoal production from wood, a process known as carbonization, involves heating wood in a low-oxygen environment to remove volatile compounds and leave behind a carbon-rich material. The time required to char wood varies depending on factors such as the type of wood, the size of the wood pieces, the temperature of the kiln or retort, and the desired level of carbonization. Generally, the process can take anywhere from a few hours to several days. Hardwoods like oak or maple typically take longer to char than softwoods like pine due to their denser structure. Additionally, smaller wood pieces char more quickly than larger logs. Understanding these variables is crucial for achieving the desired quality and efficiency in charcoal production.

| Characteristics | Values |

|---|---|

| Time to Char Wood | Varies based on method and desired char level; typically 1-4 hours |

| Temperature Range | 200°C to 400°C (392°F to 752°F) |

| Methods | Open flame, kiln, oven, or specialized charring tools |

| Wood Types | Hardwoods (e.g., oak, maple) are preferred for durability |

| Char Depth | Surface char (1-2 mm) to deep char (5-10 mm) |

| Purpose | Enhance wood aesthetics, improve weather resistance, or pest control |

| Safety Precautions | Wear protective gear; ensure proper ventilation; avoid open flames indoors |

| Post-Charring Care | Seal with oil or varnish to preserve the charred surface |

| Environmental Impact | Minimal if using sustainable wood sources and efficient methods |

| Cost | Low to moderate, depending on tools and scale of the project |

Explore related products

What You'll Learn

Ideal Wood Types for Charring

The density and resin content of wood significantly influence how it chars, making certain species more ideal than others. Hardwoods like oak and maple, with their tight grain structure, char evenly and retain structural integrity, ideal for techniques requiring precision like shou sugi ban. Conversely, softwoods such as pine or cedar, rich in resins, char quickly but can become brittle or uneven, better suited for short-duration charring or decorative purposes where durability is less critical.

Selecting the right wood type is as crucial as timing when charring. For deep, long-lasting char (up to 20 minutes of exposure), choose dense hardwoods like walnut or hickory, which develop a robust carbonized layer without compromising strength. For lighter, aesthetic charring (5–10 minutes), softer woods like birch or poplar offer a subtle contrast between charred and natural surfaces. Always consider the wood’s moisture content—seasoned wood (below 20% moisture) chars more predictably than green wood, which can steam and warp under heat.

If durability is your priority, avoid woods with high sap content, such as fir or spruce, as their resins can create uneven charring and reduce longevity. Instead, opt for teak or mahogany, which char beautifully while maintaining resistance to decay. For outdoor applications, pair charred hardwoods with a protective finish like linseed oil to enhance weather resistance. Remember, the ideal wood type aligns with both the desired aesthetic and functional demands of your project.

Experimenting with wood types allows for creative control over texture and color. For instance, cherry wood develops a rich, reddish-brown char, while ash produces a lighter, silvery tone. Test small samples to observe how different woods react to varying charring times (e.g., 2 minutes for a light toast, 15 minutes for a deep black). This hands-on approach ensures you achieve the exact look and performance needed for your project, whether it’s a charred wood accent wall or a weather-resistant outdoor feature.

Hickory Wood Durability: Does It Truly Last Forever?

You may want to see also

Explore related products

Time Based on Wood Density

Wood density plays a pivotal role in determining how long it takes to char, with denser woods requiring more time and heat to achieve the desired depth of carbonization. Hardwoods like oak or maple, with their tightly packed fibers, resist heat penetration, often needing 30 to 60 minutes per inch of thickness to char fully. In contrast, softwoods such as pine or cedar, with their looser structure, char more quickly, typically within 15 to 30 minutes per inch. This disparity underscores the importance of selecting the right wood for your project and adjusting your technique accordingly.

To illustrate, consider the process of creating a charred wood finish for outdoor siding. If using dense tropical hardwood like ipe, plan for a longer charring time—up to 2 hours for a 1-inch thick board—to ensure the heat penetrates deeply enough to create a durable, weather-resistant surface. Conversely, a softer wood like spruce might only need 45 minutes to achieve the same effect. Always test a small sample first to fine-tune your timing and avoid over-charring, which can compromise the wood’s structural integrity.

For those using a blowtorch or controlled flame, the technique must adapt to the wood’s density. With dense woods, maintain a steady, even heat across the surface, moving the torch slowly to allow the heat to permeate. For softer woods, a quicker, more dynamic motion prevents scorching the surface before the interior chars adequately. A moisture meter can be a useful tool here; denser woods should reach a moisture content below 12% before charring to ensure even heat distribution.

Practical tips include pre-drying the wood to reduce moisture content, which accelerates the charring process regardless of density. For dense woods, consider preheating the surface with a heat gun before applying the torch to jumpstart the process. Softwoods benefit from a light sanding beforehand to remove resins that can burn unevenly. Always work in a well-ventilated area and keep a fire extinguisher nearby, as denser woods can smolder longer after charring.

In conclusion, understanding wood density allows for precise control over the charring process, ensuring both aesthetic appeal and functional durability. Whether crafting furniture, cladding, or artistic pieces, tailoring your approach to the wood’s inherent properties yields superior results. By respecting the material’s characteristics and adjusting time and technique, you can master the art of charring wood with confidence and precision.

How Long Does Spider Wood Take to Sink in Aquariums?

You may want to see also

Explore related products

Tools and Techniques for Charring

Charring wood is an art that demands precision, the right tools, and a mastery of technique. The duration of charring depends heavily on the method chosen, with each approach offering distinct advantages and challenges. For instance, traditional open-flame charring can take anywhere from 30 seconds to 5 minutes per side, depending on the wood’s density and desired depth of char. Modern tools like blowtorches or propane burners accelerate this process, often halving the time while providing more control over the intensity of the burn.

Analytical Perspective:

The choice of tool directly influences the charring time and outcome. A blowtorch, operating at temperatures up to 2,500°F, can char a 1-inch thick piece of oak in under 2 minutes, creating a deep, even burn. In contrast, a wood-fired oven or grill may take 5–10 minutes to achieve a similar effect but imparts a smoky flavor ideal for culinary applications. The key is matching the tool to the purpose: quick, high-heat tools for structural projects, and slower, lower-heat methods for flavor enhancement in cooking.

Instructive Steps:

To char wood effectively, start by selecting the appropriate tool. For small-scale projects, a culinary blowtorch (1,500–2,500°F) is ideal, while larger pieces may require a propane burner or a controlled fire pit. Prepare the wood by sanding it smooth and ensuring it’s dry (moisture prolongs charring time). Hold the flame 2–4 inches from the surface, moving steadily to avoid uneven burns. For deeper charring, repeat the process in layers, allowing the wood to cool between passes. Always work in a well-ventilated area and keep a fire extinguisher nearby.

Comparative Insight:

While traditional methods like open-flame charring rely on ambient heat and take longer, modern techniques prioritize efficiency. For example, the Japanese *shou sugi ban* method involves torching wood until it chars, then cooling it with water—a process that takes 5–10 minutes per board. In contrast, a DIY enthusiast using a blowtorch can achieve a similar aesthetic in half the time. However, the slower methods often yield richer patinas and deeper penetration, making them preferable for long-lasting outdoor applications.

Descriptive Takeaway:

The beauty of charred wood lies in its texture and durability, but achieving this requires a balance of speed and precision. Whether you’re using a high-powered torch for quick results or embracing the slow burn of a fire pit, the goal is to control the heat’s interaction with the wood. Too little time, and the char won’t penetrate; too much, and the wood risks structural damage. By understanding your tools and adjusting your technique, you can master the art of charring, transforming ordinary wood into a striking, resilient material.

Unveiling the Distance: How Far Can a 7 Wood Travel?

You may want to see also

Explore related products

Safety Precautions During Charring

Charring wood, while a transformative process, demands respect for its inherent risks. Open flames, intense heat, and toxic fumes create a hazardous environment if proper precautions aren't taken. Understanding these dangers is the first step towards safe charring.

Fire, the primary tool in charring, is unpredictable. A single spark can ignite nearby combustibles, leading to uncontrolled blazes. Hot embers, easily carried by wind, pose a similar threat. Additionally, the charring process releases carbon monoxide, a colorless, odorless gas that can be fatal in enclosed spaces.

Protective Gear: Your First Line of Defense

Before igniting any wood, equip yourself with essential protective gear. Heat-resistant gloves shield your hands from burns, while long sleeves and pants made from natural fibers (cotton or wool) minimize skin exposure. Safety goggles are crucial to protect your eyes from flying embers and ash. For respiratory protection, a respirator with organic vapor cartridges is recommended, especially in poorly ventilated areas.

Remember, this gear isn't optional; it's a necessity for your safety.

Controlling the Blaze: Location and Containment

Choose your charring location wisely. Opt for an open, outdoor area away from flammable structures, dry vegetation, and overhanging branches. A fire pit or designated burn area with a non-flammable base (like gravel or sand) provides a controlled environment. Never char wood indoors or in enclosed spaces.

Fuel and Fire Management: A Delicate Balance

Use dry, seasoned hardwood for charring. Wet or green wood produces excessive smoke and can be difficult to control. Start with a small fire, gradually increasing the heat as needed. Avoid using accelerants like gasoline or lighter fluid, as they significantly increase the risk of flare-ups and explosions. Keep a fire extinguisher or a bucket of water nearby for immediate fire suppression.

Regularly monitor the fire, ensuring it remains contained and under control.

Post-Charring Precautions: Don't Let Your Guard Down

Even after the charring process is complete, dangers persist. Allow the charred wood to cool completely before handling. Residual heat can cause burns. Dispose of ashes safely, ensuring they are completely extinguished before disposal. Store charred wood in a dry, well-ventilated area, away from flammable materials.

By following these safety precautions, you can minimize risks and enjoy the benefits of charring wood while prioritizing your well-being. Remember, safety should always be the top priority in any wood-charring endeavor.

How Long Does Wood Take to Sink: Factors and Timeframe

You may want to see also

Explore related products

Applications of Charred Wood

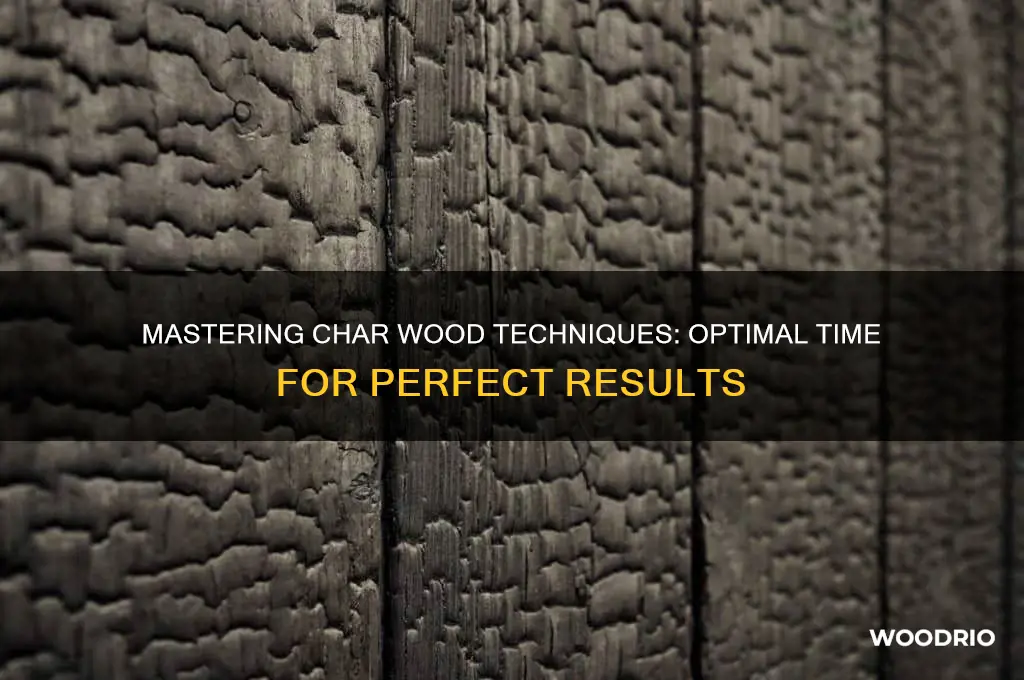

Charred wood, often referred to as shou sugi ban in Japanese tradition, is a material that has been transformed through a precise burning process. This technique not only enhances its aesthetic appeal but also significantly improves its durability and resistance to elements. The duration of charring typically ranges from 5 to 30 minutes, depending on the desired depth of char and the wood species. For instance, softer woods like pine may require less time compared to denser hardwoods like oak. The key is to monitor the process closely to achieve the right balance between charring and preserving the wood’s structural integrity.

One of the most compelling applications of charred wood is in exterior cladding. The charred layer acts as a natural barrier against moisture, pests, and UV radiation, extending the lifespan of the wood by decades. Architects and builders often prefer this method for its low maintenance and eco-friendly nature, as it eliminates the need for chemical treatments. For optimal results, char the wood for 10–15 minutes, ensuring the surface is evenly blackened but not overly brittle. After charring, brush off loose carbon and seal the wood with a natural oil to enhance its water resistance.

In interior design, charred wood adds a unique, rustic elegance to spaces. It is commonly used for accent walls, furniture, and decorative panels. The deep, textured finish creates a striking visual contrast, especially when paired with modern materials like glass or metal. To achieve a refined look, char the wood for 5–8 minutes, allowing some of the natural grain to remain visible beneath the char. Sand the surface lightly after cooling to smooth sharp edges while preserving the texture. This technique is particularly effective in contemporary homes and commercial spaces seeking a blend of tradition and innovation.

Another innovative application is in landscaping and outdoor structures. Charred wood is ideal for garden borders, fences, and pergolas due to its natural resilience. For outdoor projects, char the wood for 12–18 minutes to ensure maximum durability. After charring, apply a protective finish to guard against weathering. This method not only enhances the wood’s longevity but also provides a distinctive, weathered appearance that complements natural surroundings. Additionally, the charring process can reduce the wood’s flammability, making it a safer choice for fire-prone areas.

Finally, charred wood is gaining popularity in sustainable construction practices. Its longevity reduces the need for frequent replacements, minimizing waste and resource consumption. By charring locally sourced wood, builders can also lower the carbon footprint associated with transportation. For structural applications, char the wood for 15–20 minutes to ensure it retains sufficient strength. Always test a small sample before treating large batches to ensure the desired outcome. With its blend of functionality and beauty, charred wood stands as a testament to the timeless synergy between craftsmanship and nature.

Stardew Valley Wood Fence Durability: Lifespan and Maintenance Tips

You may want to see also

Frequently asked questions

Charring wood for smoking typically takes 1-3 hours, depending on the type of wood, its moisture content, and the desired level of char. Harder woods like oak or hickory may take longer than softer woods like pine.

For crafting or artistic purposes, charring wood usually takes 15-30 minutes using a torch or heat gun. The goal is to create a surface char without compromising the wood’s structural integrity.

In the Shou Sugi Ban technique, wood is charred for 5-10 minutes per side, depending on the wood thickness and desired finish. The process involves controlled burning followed by cooling and brushing to achieve a durable, weather-resistant surface.