Boiling wood to permanently enlarge it is a technique rooted in traditional woodworking practices, though its effectiveness and permanence are often debated. The process involves submerging wood in boiling water for an extended period, typically ranging from 30 minutes to several hours, depending on the wood type and desired expansion. The idea is that the heat and moisture cause the wood fibers to swell, potentially increasing the material's size. However, this method is generally considered temporary, as the wood tends to shrink back to its original dimensions once it dries. For more permanent enlargement, alternative methods like laminating or using moisture-resistant treatments are often recommended. Understanding the limitations and proper techniques is essential for achieving the desired results in woodworking projects.

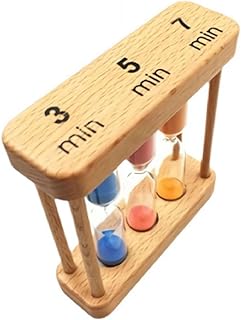

Explore related products

What You'll Learn

Boiling Time for Wood Expansion

Boiling wood to permanently enlarge it is a technique rooted in the natural properties of wood fibers and their interaction with water. When submerged in boiling water, wood absorbs moisture, causing the cellulose and lignin structures to expand. This process, known as hydration, can increase the wood’s volume by up to 10%. However, the key to permanent enlargement lies not just in boiling but in controlled drying afterward, which locks the expanded state in place. The boiling time required varies depending on the wood species, density, and desired expansion level, typically ranging from 30 minutes to 2 hours.

Analyzing the process reveals that softer woods like pine or cedar respond more quickly to boiling, often reaching maximum expansion within 45 minutes. Harder woods, such as oak or maple, may require closer to 2 hours due to their denser structure. Temperature consistency is critical; water must remain at a rolling boil to ensure even moisture penetration. A common mistake is underestimating the importance of gradual cooling after boiling. Rapid temperature changes can cause the wood to crack or warp, negating the expansion effect. Instead, allow the wood to cool slowly in the water for at least 30 minutes before removing it.

For practical application, start by cutting the wood to the desired size, as boiling will enlarge it uniformly. Submerge the wood in a pot large enough to prevent overcrowding, ensuring all surfaces are exposed to the water. After boiling, transfer the wood to a dry, well-ventilated area for air drying. Alternatively, use a low-heat oven (150°F) to accelerate drying while minimizing shrinkage. For projects requiring precise dimensions, measure the wood post-boiling and pre-drying to account for the expanded size. This method is particularly useful for crafting wooden joints, handles, or decorative pieces where a snug fit or unique texture is desired.

Comparing boiling to other wood expansion methods, such as steam bending or chemical treatments, highlights its simplicity and accessibility. While steam bending offers more control over shape, boiling is ideal for uniform enlargement without specialized equipment. Chemical treatments, though effective, often involve toxic substances and require safety precautions. Boiling, on the other hand, uses only water and heat, making it a safer, eco-friendly option for hobbyists and professionals alike. However, it’s less suitable for large-scale projects or intricate designs, where precision tools are necessary.

In conclusion, mastering the boiling time for wood expansion requires understanding the interplay between wood type, boiling duration, and drying techniques. By experimenting with different woods and times, craftsmen can achieve permanent enlargement tailored to their needs. Whether for functional or artistic purposes, this method offers a natural, cost-effective way to transform wood into a more voluminous and versatile material. With patience and attention to detail, boiling wood becomes a valuable skill in any woodworking repertoire.

How Long Does It Take for Wood to Weather Gray?

You may want to see also

Explore related products

$13.09

Types of Wood and Boiling Durations

Boiling wood to permanently enlarge it is a technique rooted in traditional craftsmanship, but not all woods respond the same way. Hardwoods like oak and maple, known for their dense fibers, require longer boiling times—typically 2 to 4 hours—to achieve noticeable expansion. Softer woods, such as pine or cedar, expand more quickly, often within 30 minutes to an hour. The key lies in the wood’s cellular structure: denser woods need more time for heat to penetrate and cause the cells to swell irreversibly.

Consider the process as a delicate balance between time and temperature. For example, boiling a hardwood plank at 212°F (100°C) for 3 hours can increase its thickness by up to 10%, while the same duration might cause a softer wood to crack or warp. Always pre-soak the wood in cold water for 30 minutes before boiling to minimize surface shock. Use a large pot or container to ensure even heat distribution, and monitor the water level to avoid scorching.

The type of enlargement you seek also dictates boiling duration. For subtle, uniform expansion—ideal for furniture joints or musical instruments—shorter boiling times (1–2 hours) suffice. Dramatic, textured effects, often used in decorative pieces, require longer exposure, up to 6 hours. Experiment with small samples first to gauge the wood’s response. Remember, once enlarged, the wood cannot shrink back, so precision is critical.

Comparing woods reveals fascinating differences. Tropical hardwoods like teak or mahogany, prized for their durability, resist expansion even after prolonged boiling, making them unsuitable for this technique. In contrast, balsa wood, though lightweight, expands dramatically but lacks structural integrity post-boiling. For practical applications, mid-density woods like ash or cherry strike the best balance, offering noticeable enlargement without compromising strength.

Finally, post-boiling care is essential. After removing the wood from the water, let it air-dry slowly in a controlled environment to prevent warping. Applying a light coat of wood sealant can preserve the enlarged shape and protect against moisture loss. While boiling wood to enlarge it is a niche technique, understanding the interplay between wood type and boiling duration unlocks its potential for both functional and artistic projects.

Seasoning Wood for Barrels: Optimal Time for Perfect Aging Results

You may want to see also

Explore related products

Safety Precautions During Boiling

Boiling wood to permanently enlarge it is a process that requires careful attention to safety, as it involves handling hot liquids and potentially hazardous materials. One of the most critical precautions is using a well-ventilated area to avoid inhaling steam or fumes from the wood or any added substances. Boiling wood often requires large pots or containers, and the steam produced can quickly fill a confined space, leading to respiratory discomfort or dizziness. If working indoors, open windows or use a fume hood to maintain air circulation. For outdoor setups, ensure the area is free from flammable materials and sheltered from wind to prevent accidental spills.

Another essential safety measure is wearing appropriate protective gear. Heat-resistant gloves are a must to handle hot containers and wood safely, as accidental contact with boiling water can cause severe burns. Safety goggles are equally important to protect your eyes from splashes or steam. Additionally, consider wearing long sleeves and pants made from natural fibers, which are less likely to melt or stick to the skin if exposed to heat. While it may seem excessive, these precautions significantly reduce the risk of injury during the boiling process.

Monitoring the boiling duration and temperature is crucial to prevent accidents and ensure the process is effective. Most wood enlargement methods involve boiling for 30 minutes to 2 hours, depending on the wood type and desired outcome. However, prolonged exposure to heat can weaken the wood or cause it to crack. Use a thermometer to keep the water temperature consistent, typically between 180°F and 212°F (82°C to 100°C). Avoid leaving the setup unattended, as boiling water can overflow or evaporate too quickly, leading to dry heat that damages both the wood and the container.

Finally, proper disposal of materials after boiling is often overlooked but equally important. The water used for boiling may contain chemicals or wood residues that are harmful to the environment. Allow the water to cool completely before disposing of it, and avoid pouring it down drains or into natural water sources. Instead, discard it in accordance with local hazardous waste guidelines. Clean all equipment thoroughly to remove any residue, as leftover particles can contaminate future projects or pose health risks. By taking these precautions, you can safely and effectively boil wood for enlargement while minimizing risks to yourself and the environment.

Wood Glue Curing Time: Understanding Full Cure Duration for Projects

You may want to see also

Explore related products

Effectiveness of Boiling for Permanent Enlargement

Boiling wood to achieve permanent enlargement is a concept rooted in traditional practices and artisanal techniques, but its effectiveness is often misunderstood. The process involves submerging wood in boiling water for extended periods, purportedly to alter its cellular structure and increase its size. However, scientific scrutiny reveals that boiling primarily affects the wood’s moisture content, causing temporary swelling rather than permanent enlargement. For instance, hardwoods like oak or maple may expand by up to 10% when boiled, but this effect diminishes as the wood dries, returning it to its original dimensions. Thus, while boiling can temporarily alter wood’s size, it does not yield lasting results without additional treatments.

To explore this further, consider the steps involved in boiling wood for enlargement. First, select a suitable wood type—softwoods like pine are less effective due to their lower density. Submerge the wood in boiling water for 30 minutes to 2 hours, depending on thickness; thicker pieces require longer exposure. After boiling, the wood must be compressed under heavy weights while drying to maintain the enlarged shape. This method, known as "hydro-compression," is labor-intensive and requires precise timing. For example, a 1-inch thick wooden plank might need 1 hour of boiling followed by 24–48 hours of weighted drying. Despite these efforts, the results are often inconsistent, making this technique impractical for large-scale applications.

A comparative analysis highlights why boiling falls short as a permanent solution. Unlike chemical treatments or mechanical processes, boiling does not alter the wood’s fundamental structure. Chemical methods, such as acetylation, permanently modify wood cells by introducing acetyl groups, reducing moisture absorption and increasing dimensional stability. Mechanical processes, like laminating or carving, physically reshape the wood. Boiling, in contrast, relies on water absorption, a reversible process. For artisans seeking permanent enlargement, combining boiling with chemical treatments or mechanical techniques may yield better results, but this requires advanced knowledge and resources.

From a practical standpoint, boiling wood for enlargement is best suited for small-scale, experimental projects rather than functional applications. For hobbyists, boiling can be a low-cost way to explore wood manipulation, but expectations should be tempered. To enhance effectiveness, pre-treat the wood by sealing its ends with wax to prevent excessive moisture absorption, and use a moisture meter to monitor hydration levels during drying. Additionally, applying heat gradually during the boiling process can reduce the risk of cracking. While these tips improve outcomes, they underscore the limitations of boiling as a standalone method for permanent wood enlargement.

Cedar vs Pressure Treated Wood: Which Fence Lasts Longer?

You may want to see also

Explore related products

Alternatives to Boiling for Wood Enlargement

Boiling wood to permanently enlarge it is a method shrouded in myth and misinformation. While some claim it works, scientific evidence is lacking, and the process can damage the wood’s structure. Fortunately, safer and more effective alternatives exist for those seeking to alter wood dimensions or properties.

One method gaining traction is steam bending, a technique used for centuries in woodworking. By exposing wood to steam at temperatures around 212°F (100°C) for 30 minutes to several hours, depending on thickness and species, the cellulose fibers soften, allowing the wood to be bent into new shapes. This method doesn't permanently enlarge the wood but allows for controlled manipulation, ideal for crafting curved furniture pieces or musical instruments.

Chemical treatments offer another avenue. Soaking wood in solutions like polyethylene glycol (PEG) or glycerin can cause the wood to absorb moisture, leading to temporary swelling. PEG, typically used in concentrations of 50-100%, is applied over several weeks, gradually enlarging the wood. However, this method is time-consuming and requires careful monitoring to prevent over-swelling or cracking.

For a more immediate, though less permanent, solution, consider mechanical methods. Compressing wood with clamps or weights can force it to expand slightly. This technique is best suited for thin pieces and requires careful application to avoid splitting. Alternatively, lamination involves gluing multiple thin layers of wood together, effectively increasing thickness without altering the individual layers' dimensions.

Heat and moisture control are crucial for any wood enlargement method. Kiln drying, a process used to remove moisture from wood, can be reversed by carefully reintroducing moisture. This controlled rehydration can lead to slight expansion, but precision is key to avoid warping or cracking.

While boiling wood may seem like a simple solution, its effectiveness is questionable and risks damaging the material. Exploring alternatives like steam bending, chemical treatments, mechanical methods, and controlled moisture manipulation offers woodworkers safer and more reliable ways to achieve desired dimensional changes. Each method has its own advantages and limitations, requiring careful consideration of the project's specific needs and the wood species involved.

Durability of Wood Gazebos: Lifespan and Maintenance Tips

You may want to see also

Frequently asked questions

No, boiling wood does not permanently enlarge it. Boiling may cause temporary swelling due to water absorption, but the wood will shrink back to its original size as it dries.

Boiling wood for any length of time will not result in permanent enlargement. The process is ineffective and can damage the wood’s structure.

The type of wood does not impact the outcome, as boiling does not permanently enlarge any wood species.

Permanent enlargement of wood is not possible through boiling or other simple methods. Wood dimensions are determined by its natural properties and cannot be altered permanently without significant structural changes.

Prolonged boiling can weaken the wood, cause it to crack, warp, or degrade, and may lead to permanent damage. It will not result in enlargement.