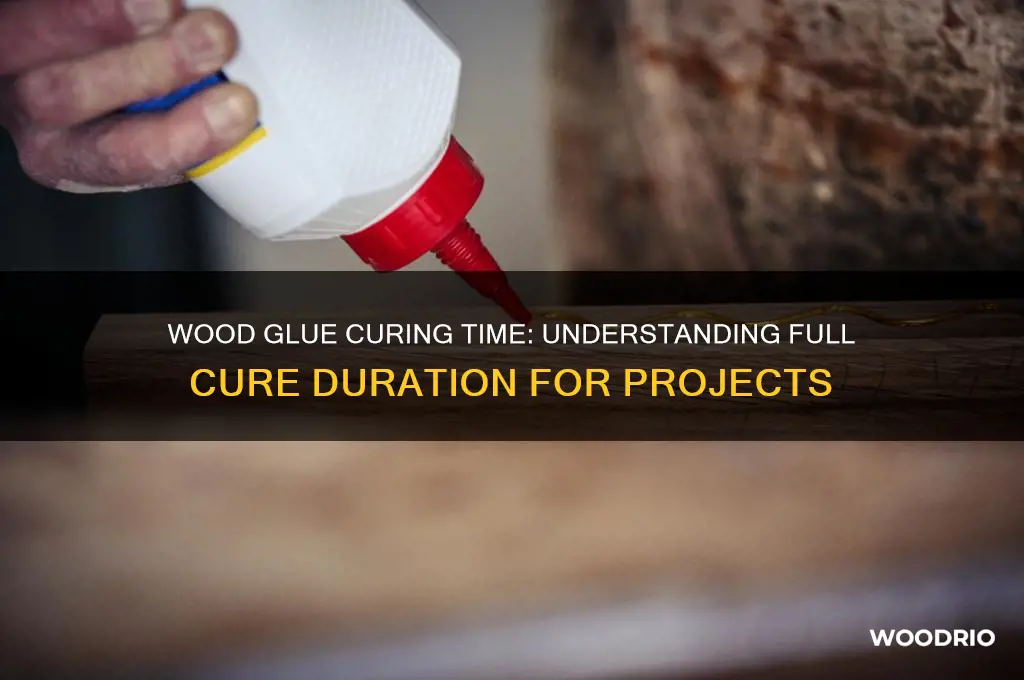

Wood glue curing time is a critical factor in woodworking projects, as it directly impacts the strength and durability of the bonded materials. Typically, wood glue takes about 24 hours to reach its initial cure, allowing for handling and light use, but it can take up to 72 hours or more to fully cure, depending on factors such as glue type, wood species, humidity, and temperature. For instance, PVA (polyvinyl acetate) glues, commonly used in woodworking, may take longer to cure in cold or damp conditions, while epoxy-based glues often cure faster but require precise mixing and application. Understanding these variables ensures optimal bond strength and project success.

| Characteristics | Values |

|---|---|

| Initial Clamp Time | 30 minutes to 1 hour (varies by glue type and conditions) |

| Handling Strength Time | 2 to 6 hours (glue is strong enough for light handling) |

| Full Cure Time (Room Temperature) | 24 hours (for most PVA wood glues) |

| Full Cure Time (Optimal Conditions) | 24 to 48 hours (70°F/21°C and 50% humidity) |

| Full Cure Time (Cold/Humid Conditions) | Up to 72 hours or longer |

| Maximum Strength Achievement | 7 to 14 days (for complete curing and maximum bond strength) |

| Accelerated Curing Methods | Warm, dry environment or using a glue with faster curing properties |

| Factors Affecting Cure Time | Temperature, humidity, glue type, wood density, and clamp pressure |

| Recommended Clamp Pressure | 100 to 200 psi (varies by application) |

| Glue Types | PVA (white/yellow glue), epoxy, polyurethane, and cyanoacrylate (CA) |

| Shelf Life of Glue | 1 to 2 years (unopened); 6 months to 1 year (opened) |

Explore related products

What You'll Learn

- Factors Affecting Cure Time: Temperature, humidity, glue type, and wood porosity influence drying duration

- Standard Cure Times: Most wood glues take 24 hours for initial strength, 72 hours to fully cure

- Accelerating Cure Time: Using clamps, warm environments, or specialized glues can speed up curing

- Testing Bond Strength: Apply gentle pressure after 24 hours to check if glue is fully set

- Extended Cure for Large Projects: Thick glue layers or dense wood may require up to 7 days

Factors Affecting Cure Time: Temperature, humidity, glue type, and wood porosity influence drying duration

Wood glue cure times aren’t set in stone. While product labels often suggest 24 hours for initial strength, full curing—the point where the bond reaches maximum durability—can take days or even weeks. This variability hinges on four key factors: temperature, humidity, glue type, and wood porosity. Understanding their interplay empowers woodworkers to optimize drying times and ensure robust joints.

Temperature acts as a catalyst, accelerating curing in most glues. Polyvinyl acetate (PVA) glues, the workhorses of woodworking, cure fastest between 65°F and 80°F (18°C and 27°C). Below 50°F (10°C), curing slows dramatically, while temperatures above 90°F (32°C) can cause the glue to dry too quickly, leading to weak bonds. Epoxy resins, on the other hand, often require specific temperature ranges for proper hardening, typically around 70°F to 80°F (21°C to 27°C). For optimal results, control the environment by working in a temperature-stable space or using heating pads for cold conditions.

Humidity plays a dual role, affecting both the glue and the wood. High humidity slows PVA glue curing by preventing water evaporation, a critical step in its hardening process. Conversely, low humidity can cause the wood to dry out, leading to shrinkage and weakened joints. Aim for a relative humidity of 50% to 70% for balanced curing. In dry climates, misting the wood lightly before gluing or using a humidifier can help maintain moisture levels.

Glue type dictates the curing timeline and environmental needs. PVA glues typically reach full strength within 24 to 48 hours, while epoxy resins may require 8 to 24 hours, depending on the formulation. Cyanoacrylate (super glue) bonds almost instantly but lacks the strength of PVA or epoxy for structural joints. Always follow manufacturer guidelines for specific curing times and conditions, as these can vary widely between products.

Wood porosity determines how the glue interacts with the material. Dense hardwoods like maple or oak absorb glue slowly, extending curing times. Softwoods like pine, with their larger pores, allow for faster absorption and quicker initial bonding. To enhance adhesion, lightly sand the wood surfaces to increase porosity and ensure a clean, even application. For extremely dense woods, consider using a thinner glue or applying slight pressure during clamping to promote penetration.

By mastering these factors, woodworkers can predict and manipulate cure times effectively. Whether crafting fine furniture or simple joints, tailoring the environment and materials to the glue’s needs ensures strong, lasting bonds. Patience and precision, coupled with an understanding of these variables, transform waiting into a strategic part of the woodworking process.

Wood Pellets Lifespan: How Long Do They Last and Stay Effective?

You may want to see also

Explore related products

Standard Cure Times: Most wood glues take 24 hours for initial strength, 72 hours to fully cure

Wood glue cure times are a critical factor in any woodworking project, ensuring the structural integrity and longevity of your creation. The standard cure time for most wood glues follows a predictable pattern: 24 hours for initial strength and 72 hours to fully cure. This timeline is not arbitrary but rooted in the chemical processes that occur as the adhesive bonds wood fibers together. During the first 24 hours, the glue undergoes rapid polymerization, forming a strong but still flexible bond. By the 72-hour mark, the adhesive reaches its maximum hardness and durability, making it ready for heavy use or finishing.

Understanding this timeline is essential for planning your workflow. For instance, if you’re assembling a piece of furniture, you can handle and move it after 24 hours, but avoid applying stress or weight until the full 72 hours have passed. This staged curing process allows you to work efficiently without compromising the final result. However, factors like humidity, temperature, and wood porosity can influence these times, so always check the manufacturer’s guidelines for specific recommendations.

To optimize curing, maintain a consistent environment. Ideal conditions include a temperature range of 65°F to 80°F (18°C to 27°C) and moderate humidity levels. Avoid extreme cold or heat, as these can slow down or disrupt the curing process. For example, if you’re working in a garage during winter, consider using a space heater to keep the temperature stable. Similarly, in humid climates, ensure proper ventilation to prevent moisture from interfering with the adhesive’s performance.

Practical tips can further enhance your results. Clamping pressure is crucial during the initial 24 hours, as it ensures even distribution and maximizes bond strength. Use clamps rated for the size and type of wood you’re working with, and apply enough pressure to create a thin glue line without squeezing excess adhesive out. Once clamped, resist the temptation to check the bond prematurely, as this can weaken the joint. Patience is key—allow the glue to cure undisturbed for the full 72 hours for optimal results.

Finally, consider the type of wood glue you’re using, as formulations can vary. Polyvinyl acetate (PVA) glues, the most common type, adhere closely to the 24/72-hour rule. However, epoxy or polyurethane glues may have different curing times and requirements. Always read the label for specific instructions, as some products may cure faster or slower depending on their composition. By respecting these standard cure times and adjusting for environmental factors, you’ll ensure strong, lasting bonds in your woodworking projects.

Stardew Valley Wood Fence Lifespan: Durability and Maintenance Tips

You may want to see also

Explore related products

Accelerating Cure Time: Using clamps, warm environments, or specialized glues can speed up curing

Wood glue cure times vary widely, typically ranging from 24 hours to several days, depending on factors like glue type, wood density, and environmental conditions. However, when deadlines loom or projects demand urgency, accelerating this process becomes essential. Three effective methods stand out: applying clamps, utilizing warm environments, and opting for specialized glues. Each approach targets specific aspects of the curing process, offering a tailored solution to reduce waiting time without compromising bond strength.

Applying Clamps: The Mechanical Advantage

Clamps are not just for holding pieces together; they actively enhance curing by ensuring even pressure distribution across the joint. This pressure minimizes gaps and maximizes glue-to-wood contact, allowing for faster moisture evaporation and polymerization. For optimal results, use F-style or bar clamps, applying 100–200 psi of pressure. Avoid over-tightening, as excessive force can squeeze out too much glue, weakening the bond. Aim for a consistent, firm hold, and leave clamps in place for at least 30 minutes to an hour before removing them, even if the glue feels set. This initial clamp time ensures the joint stabilizes before the curing process completes.

Warm Environments: The Thermal Catalyst

Heat accelerates chemical reactions, and wood glue curing is no exception. Increasing the ambient temperature to 70–80°F (21–27°C) can halve curing time, while temperatures up to 100°F (38°C) can expedite it further. Use a space heater, heat lamp, or even an oven set to low heat, ensuring the wood doesn’t warp or dry too quickly. For small projects, placing the glued piece in a warm, dry room or near a radiator works well. Avoid direct heat sources that could scorch the wood or glue. Pairing warmth with proper ventilation prevents moisture buildup, which can otherwise prolong curing.

Specialized Glues: The Chemical Shortcut

Not all wood glues are created equal. Fast-curing formulations, such as epoxy or polyurethane-based glues, can set in as little as 5–30 minutes and fully cure within 2–6 hours. For instance, Titebond III offers a 24-hour cure time but achieves initial strength in just 30 minutes. When selecting a specialized glue, consider the project’s requirements: waterproof glues like polyurethane expand as they cure, filling gaps, while cyanoacrylate (super glue) bonds instantly but lacks flexibility. Always follow manufacturer instructions, as these glues often require precise application techniques and may have specific temperature or humidity needs.

Practical Tips for Success

Combine these methods for maximum efficiency. For example, use clamps to ensure a tight joint, place the project in a warm environment, and opt for a fast-curing glue. Prep wood surfaces by sanding to remove dust and oils, ensuring better adhesion. Test glue on scrap wood to confirm compatibility and curing behavior. Finally, plan ahead: while accelerating cure time is possible, rushing the process can lead to weak bonds or damaged materials. Patience, paired with these strategies, ensures both speed and strength in your woodworking projects.

Perfect Plank Prep: Soaking Wood for Salmon Smoking Success

You may want to see also

Explore related products

Testing Bond Strength: Apply gentle pressure after 24 hours to check if glue is fully set

After 24 hours, wood glue has typically reached a stage where it feels solid to the touch, but is it truly ready for heavy-duty use? Testing bond strength at this point is crucial to ensure the glue has fully set. Apply gentle, even pressure to the joint—enough to simulate real-world stress but not so much that you risk damaging the bond. For example, if you’ve glued a tabletop, press down firmly along the seam, or if it’s a chair leg, try to wiggle it slightly. The goal is to detect any give or movement, which would indicate the glue hasn’t fully cured. This simple test is a practical way to avoid premature use of the piece, preventing potential failure under stress.

The 24-hour mark is often cited as the point when wood glue is "dry to the touch," but full curing is a different matter. Most wood glues, such as PVA (polyvinyl acetate) varieties, take 24 hours to develop initial strength but require up to 72 hours for maximum bond strength. Testing at 24 hours serves as a checkpoint, not a final verdict. If the bond holds firm under gentle pressure, it’s a good sign, but avoid subjecting the piece to heavy loads or moisture until the full curing time has elapsed. This staged approach ensures you’re not overestimating the glue’s readiness, which could lead to costly mistakes.

When testing bond strength, consider the type of wood and environmental conditions, as these factors influence curing time. Hardwoods like oak or maple may bond faster than softer woods like pine due to their denser grain structure. Humidity and temperature also play a role—higher humidity can slow curing, while warmer temperatures (around 70°F or 21°C) accelerate it. For instance, a joint glued in a humid basement may need more than 24 hours to pass the pressure test, whereas one in a temperature-controlled workshop might be ready sooner. Always account for these variables when interpreting your test results.

A practical tip for testing is to mark the glued area with a small, discreet indicator, such as a piece of tape or a light pencil mark, before applying pressure. This helps you focus on the joint and ensures you’re testing the same spot consistently. If the bond feels weak or shifts, resist the urge to reapply glue immediately. Instead, clamp the joint again and allow additional curing time. This methodical approach not only ensures a strong bond but also builds your understanding of how wood glue behaves under different conditions, making future projects more predictable and successful.

Solid Core Engineered Wood Acclimation: Essential Timeframe for Optimal Installation

You may want to see also

Explore related products

Extended Cure for Large Projects: Thick glue layers or dense wood may require up to 7 days

Thick glue layers and dense wood species can significantly extend the curing time of wood glue, often requiring up to 7 days for full strength. This extended cure period is crucial for large projects where structural integrity is paramount. Unlike thin glue lines in smaller joints, thicker applications trap more moisture, slowing evaporation and hindering the cross-linking process essential for curing. Similarly, dense woods like teak or mahogany absorb moisture more slowly, delaying the glue’s ability to bond effectively. Ignoring this extended timeline can result in weak joints prone to failure under stress.

To ensure optimal bonding in such scenarios, follow these steps: first, apply glue in thin, even coats rather than a single thick layer, as this promotes faster moisture release. Second, clamp the joint firmly but avoid excessive pressure, which can squeeze out too much glue, leaving insufficient material for bonding. Third, maintain a consistent temperature and humidity level during curing; fluctuations can disrupt the process. For dense woods, pre-drilling small holes along the joint can facilitate moisture escape, reducing cure time.

A comparative analysis highlights the difference between standard and extended curing. While most wood glues achieve initial strength within 24 hours, full curing for thick layers or dense wood requires patience. For instance, a dovetail joint in pine might cure fully in 2 days, but the same joint in mahogany could take the full 7 days. This disparity underscores the importance of tailoring your approach to the project’s specifics.

Practical tips can further enhance success. Use a moisture meter to monitor wood moisture content before gluing, aiming for 8–12% for optimal results. If time is a constraint, consider using epoxy resins, which cure faster in thick layers but are more expensive and less flexible. Finally, always test a small sample joint to confirm curing time and bond strength before committing to the full project.

In conclusion, extended curing for large projects with thick glue layers or dense wood is not just a recommendation—it’s a necessity. By understanding the factors at play and adjusting your techniques, you can ensure durable, long-lasting bonds that stand the test of time. Patience and precision are your greatest tools in this process.

Exploring Muir Woods: Ideal Time to Experience Its Majestic Beauty

You may want to see also

Frequently asked questions

Wood glue generally takes 24 hours to fully cure under ideal conditions (room temperature and humidity). However, it may take up to 48 hours for maximum strength, depending on the type of glue and environmental factors.

Yes, temperature significantly impacts curing time. Warmer temperatures (around 70°F or 21°C) accelerate curing, while colder temperatures slow it down. Avoid extreme heat or cold, as it can weaken the bond.

Yes, you can speed up curing by applying gentle heat (e.g., using a heat lamp or hairdryer) or increasing airflow around the glued area. However, avoid excessive heat, as it may damage the wood or glue. Clamping the joint firmly also helps ensure a strong bond while curing.