When gluing wood pieces together, clamping time is a critical factor in ensuring a strong and durable bond. The duration for which wood should be clamped after applying glue depends on several variables, including the type of glue used, the wood species, and the environmental conditions such as temperature and humidity. Typically, common wood glues like PVA (polyvinyl acetate) require clamping for at least 30 minutes to an hour, but for maximum strength, it’s recommended to leave the clamps on for 24 hours or until the glue fully cures. Faster-setting glues may allow for shorter clamping times, but always refer to the manufacturer’s instructions for specific guidelines. Proper clamping pressure and adequate time ensure the glue sets evenly and securely, preventing gaps or weak spots in the joint.

| Characteristics | Values |

|---|---|

| Clamp Time (General) | 30 minutes to 24 hours (varies by glue type and wood species) |

| Glue Types | PVA (White/Yellow Glue): 30 mins - 1 hour; Epoxy: 2-24 hours; Polyurethane: 30 mins - 2 hours |

| Wood Species | Dense woods (e.g., oak, maple): Longer clamp time; Softwoods (e.g., pine): Shorter clamp time |

| Joint Type | Edge joints: 1-2 hours; Mitre joints: 2-4 hours; Larger assemblies: Up to 24 hours |

| Temperature | Ideal: 60-80°F (15-27°C); Higher temps reduce clamp time; Lower temps increase it |

| Humidity | Higher humidity can slow curing; Lower humidity speeds it up |

| Glue Application | Thin, even coat; Excess glue can extend clamp time |

| Clamp Pressure | 100-200 PSI (pounds per square inch) for optimal bonding |

| Cure Time (Full Strength) | 24-48 hours for most glues; 7 days for maximum strength |

| Accelerated Curing Methods | Warm environment, clamping with heat, using fast-setting glues |

| Safety Precautions | Avoid over-tightening clamps; ensure even pressure; follow glue instructions |

| Testing Bond Strength | Wait at least 24 hours before testing or stressing the joint |

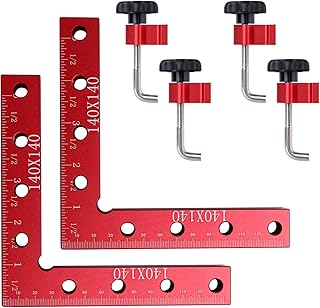

Explore related products

What You'll Learn

- Clamp Time for Different Glues: PVA, epoxy, polyurethane—varying clamp times based on glue type

- Wood Moisture Impact: Higher moisture content in wood may require longer clamping periods

- Joint Type Considerations: Edge, butt, or miter joints need specific clamping durations for strength

- Temperature Effects: Warmer temperatures speed up glue curing, reducing necessary clamp time

- Pressure Application: Consistent, even pressure ensures proper bonding during the clamping process

Clamp Time for Different Glues: PVA, epoxy, polyurethane—varying clamp times based on glue type

Clamping time is a critical factor in woodworking, and it varies significantly depending on the type of glue used. PVA (polyvinyl acetate), epoxy, and polyurethane glues each have distinct curing times and clamping requirements, which directly impact the strength and durability of the joint. Understanding these differences ensures that your wood pieces bond effectively without compromising the integrity of your project.

PVA Glue: The Quick-Clamp Option

PVA glue, commonly known as white or yellow wood glue, is a staple in woodworking due to its ease of use and strong bond. For most applications, PVA glue requires clamping for 30 minutes to 1 hour to achieve initial set. However, full curing takes 24 hours, during which the clamped joint should remain undisturbed. This glue is ideal for projects where quick assembly is needed, but it’s essential to maintain consistent pressure during the initial clamping period. For thinner applications or smaller joints, a shorter clamping time of 15–20 minutes may suffice, but always refer to the manufacturer’s guidelines for specific instructions.

Epoxy: Patience Pays Off

Epoxy glue is a two-part adhesive known for its exceptional strength and gap-filling properties. Unlike PVA, epoxy requires a longer clamping time, typically 4 to 6 hours, depending on the formulation. This extended period allows the epoxy to cure fully and reach its maximum bond strength. Epoxy is particularly useful for joints under stress or in humid environments, but it demands precision in mixing and application. Over-clamping can lead to squeeze-out, so use just enough pressure to close the joint without forcing excess glue out. Full curing can take up to 72 hours, so plan your workflow accordingly.

Polyurethane Glue: The Moisture-Activated Powerhouse

Polyurethane glue, such as Gorilla Glue, expands as it cures, creating a foam-like bond that fills gaps and provides incredible strength. Clamping time for polyurethane glue is relatively short, 1 to 2 hours, but it requires moisture to activate. Dampen the wood surfaces slightly before applying the glue to ensure proper curing. While the initial bond forms quickly, full curing takes 24 hours, during which the joint should remain clamped. This glue is excellent for rough or uneven surfaces but can be messy, so apply sparingly and clean up excess immediately.

Practical Tips for Optimal Clamping

Regardless of the glue type, ensure even clamping pressure to avoid weak spots or warping. Use clamps appropriate for the size and shape of the joint, and consider using cauls or scrap wood to distribute pressure evenly. For epoxy and polyurethane glues, work in a well-ventilated area and wear gloves to avoid skin contact. Always test the glue on scrap wood to confirm clamping times and bond strength before applying it to your project. By tailoring your clamping approach to the glue type, you’ll achieve professional-quality joints that stand the test of time.

Mastering Precision: Drilling Long, Straight Holes in Wood Effortlessly

You may want to see also

Explore related products

Wood Moisture Impact: Higher moisture content in wood may require longer clamping periods

Wood with higher moisture content can significantly alter the clamping time required for glued joints. Moisture acts as a barrier to glue penetration, slowing the curing process. When wood is damp, the adhesive takes longer to bond effectively because it must first displace the water within the cellular structure. This delay necessitates extended clamping periods to ensure a strong, durable joint. For instance, while dry wood might only need 30 minutes to an hour of clamping, wood with a moisture content above 12% could require up to 24 hours or more, depending on the glue type and environmental conditions.

Understanding the moisture content of your wood is crucial for determining clamping duration. A moisture meter, an inexpensive and widely available tool, can provide an accurate reading. Aim for wood with a moisture content between 8% and 12% for optimal gluing conditions. If the moisture level exceeds this range, consider kiln-drying or air-drying the wood before proceeding. Ignoring this step can lead to weak joints, as the glue may not fully cure or bond properly. Additionally, high moisture content increases the risk of warping or cracking as the wood dries post-gluing.

The type of glue used also interacts with wood moisture in distinct ways. Polyurethane glues, for example, are moisture-reactive and can actually benefit from slightly damp wood, curing faster as they interact with water. However, most common wood glues, such as PVA (white or yellow glue), require dry conditions to cure effectively. Epoxy resins are more forgiving but still perform best with wood at moderate moisture levels. Always consult the manufacturer’s guidelines for specific clamping times based on wood moisture content and glue type.

Practical tips can help mitigate the impact of moisture on clamping times. If working with damp wood, apply gentle heat (using a heat lamp or space heater) to accelerate evaporation without causing damage. Ensure proper ventilation to prevent moisture buildup in the workspace. For critical joints, consider using clamps with higher pressure capacity to maintain even contact during the extended curing period. Finally, always test the joint strength before removing clamps, especially when dealing with high-moisture wood, to avoid premature failure.

In summary, higher moisture content in wood demands careful consideration when clamping glued pieces. By measuring moisture levels, selecting appropriate glues, and employing practical techniques, woodworkers can ensure strong, lasting joints despite challenging conditions. Patience and attention to detail are key when working with damp wood, as rushing the process can compromise the integrity of the entire project.

Durability of Wooden Pencils: Lifespan and Longevity Explained

You may want to see also

Explore related products

Joint Type Considerations: Edge, butt, or miter joints need specific clamping durations for strength

Clamping duration isn’t one-size-fits-all—it hinges on the joint type. Edge joints, where wood pieces align side by side, typically require longer clamping times due to the larger glue surface area. For example, a 3/4-inch thick hardwood edge joint should be clamped for at least 30 minutes to an hour, but leaving it under pressure for 2–4 hours ensures maximum strength. Butt joints, where end grain meets face grain, are less forgiving. Since end grain absorbs glue poorly, clamping for 1–2 hours is essential, but even then, mechanical reinforcement like screws or biscuits is often recommended for durability. Miter joints, with their angled cuts, demand precision and patience. Clamping for 1–2 hours is standard, but complex mitered frames or boxes may need up to 24 hours to fully cure, especially when using slow-setting glues like epoxy.

Consider the glue type alongside joint type. Polyvinyl acetate (PVA) wood glue, the most common choice, sets in 30 minutes but needs 24 hours to reach full strength. Epoxy, while slower to set (6–24 hours), provides superior gap-filling and strength, making it ideal for miter joints. Cyanoacrylate (super glue) sets in seconds but lacks the bond depth for structural joints. For edge and butt joints, PVA is reliable, but for miter joints under stress, epoxy’s longer cure time and gap-bridging ability are critical. Always follow the manufacturer’s guidelines for clamping pressure and duration, as over-clamping can squeeze out excess glue, weakening the bond.

Practical tips can streamline the process. For edge joints, use cauls (sacrificial wood blocks) to distribute clamping pressure evenly and prevent bowing. Butt joints benefit from clamping at a slight angle to close gaps, but avoid over-tightening, which can split the wood. Miter joints require careful alignment—use tape or clamps with adjustable jaws to hold the joint together while applying pressure. In humid conditions, extend clamping times by 25–50%, as moisture slows glue curing. Conversely, in dry environments, cover the joint with plastic wrap to retain moisture and ensure proper curing.

The takeaway is clear: joint type dictates clamping strategy. Edge joints prioritize surface area and pressure distribution, butt joints rely on mechanical support and longer clamping, and miter joints demand precision and patience. Pairing the right glue with the joint type and environmental conditions ensures a bond that lasts. Ignore these specifics, and even the strongest glue won’t save a poorly clamped joint. Master these nuances, and your woodworking projects will stand the test of time.

Do Long Wood Pieces Break Easier Under Compression in Bridges?

You may want to see also

Explore related products

Temperature Effects: Warmer temperatures speed up glue curing, reducing necessary clamp time

Warmer temperatures act as a catalyst for wood glue curing, significantly reducing the time required to securely bond wooden pieces. This phenomenon is rooted in the chemistry of glue, where heat accelerates the molecular reactions responsible for hardening. For instance, common PVA (polyvinyl acetate) wood glues, which are water-based, cure faster at higher temperatures because the water evaporates more quickly, allowing the polymer chains to bond sooner. At 70°F (21°C), a typical clamp time might be 30 minutes to an hour, but at 90°F (32°C), this can drop to 15–20 minutes, provided the glue is evenly spread and the joint is properly aligned.

To leverage this effect, woodworkers can strategically manipulate their workspace temperature. Using a space heater or working in a naturally warmer environment can expedite the process, especially during colder months. However, caution is necessary: excessive heat, above 100°F (38°C), can cause the glue to set too quickly, leading to uneven bonding or surface imperfections. Additionally, rapid temperature changes can introduce stress into the wood, potentially causing warping or cracking. Thus, maintaining a consistent, moderately warm environment—ideally between 75°F and 90°F (24°C–32°C)—yields the best results.

For those working in cooler climates or during winter, pre-warming the wood pieces and glue can mitigate the effects of low temperatures. Placing the wood near a heat source for 15–20 minutes before gluing ensures both the material and adhesive are at an optimal temperature. Similarly, storing glue in a warm area rather than a cold garage or workshop can improve its flow and curing speed. These small adjustments can save time and enhance the strength of the bond, particularly in joints that bear significant stress, such as table legs or chair frames.

While warmer temperatures reduce clamp time, they do not eliminate the need for proper clamping pressure. Even with accelerated curing, maintaining consistent pressure ensures the glue spreads evenly and the joint remains aligned. Quick-setting glues or epoxy resins may require even more attention to clamping, as their rapid curing can lead to misalignment if not handled promptly. Therefore, combining temperature control with meticulous clamping techniques maximizes efficiency without sacrificing quality.

In summary, understanding the relationship between temperature and glue curing allows woodworkers to optimize their processes. By working within a warmer, controlled environment and pre-warming materials, clamp times can be significantly reduced without compromising bond strength. However, balance is key—avoiding extreme heat and maintaining proper clamping pressure ensures the final piece is both sturdy and aesthetically pleasing. This approach not only saves time but also enhances the overall craftsmanship of the project.

Durability of Wood Type: Lifespan, Factors, and Maintenance Tips

You may want to see also

Explore related products

Pressure Application: Consistent, even pressure ensures proper bonding during the clamping process

Applying consistent, even pressure is the linchpin of successful wood gluing. Uneven force can lead to gaps, weak bonds, or even warping, undermining the structural integrity of your project. Imagine a joint where one side is compressed more than the other—the glue starves in the over-clamped area, while excess adhesive squeezes out, leaving a messy, compromised bond. This imbalance is avoidable with careful attention to pressure distribution.

Achieving uniform pressure requires both technique and the right tools. Start by selecting clamps suited to the size and shape of your workpiece. For edge-gluing panels, use pipe or bar clamps spaced evenly along the joint, approximately every 6 to 8 inches. For smaller or curved pieces, consider spring clamps or band clamps, which distribute force more gently. Always pre-fit your pieces to ensure they align perfectly before applying glue, as misalignment can exacerbate pressure inconsistencies.

The force applied should be sufficient to close the joint without distorting the wood. A common rule of thumb is to tighten clamps until you see a thin, even bead of glue squeeze out along the entire joint. This indicates that the glue has been evenly distributed and that the pieces are fully seated. Over-tightening, however, can crush the wood fibers or force excess glue into the wood grain, weakening the bond. Aim for a pressure that feels firm but not excessive—think of it as a gentle embrace rather than a vise grip.

Layering cauls or scrap wood between the clamps and the workpiece can further enhance pressure consistency. Cauls distribute the clamping force over a larger area, reducing the risk of indentations and ensuring even contact across the joint. For wide panels, use multiple cauls spaced evenly to prevent the wood from bowing under pressure. This simple addition can make the difference between a professional-looking joint and one that fails under stress.

Finally, maintain consistent pressure throughout the entire clamping time, which varies depending on the glue type. For PVA (white or yellow) wood glue, this typically ranges from 30 minutes to 24 hours. Quick-setting glues may require only 15 minutes, while epoxy can take several hours. Avoid the temptation to release the clamps prematurely, as the glue may not have fully cured, leading to joint failure. Patience and steady pressure are your allies in achieving a bond that lasts a lifetime.

Chicken of the Woods Growth Timeline: How Long to Harvest?

You may want to see also

Frequently asked questions

Clamping time depends on the glue type, but most wood glues require clamping for at least 30 minutes to 1 hour for initial curing.

While 30 minutes is often sufficient for initial bonding, it’s best to leave clamps on for 24 hours to ensure the glue fully cures and achieves maximum strength.

Yes, different glues have varying curing times. PVA (white or yellow) glue typically requires 24 hours, while epoxy or polyurethane glues may need longer.

Removing clamps too early can result in weak joints, misalignment, or gaps, as the glue hasn’t fully cured and hardened.

Yes, clamping is essential for all glued wood joints, regardless of size, to ensure proper bonding, alignment, and strength.

![Right Angle Clamp, Housolution [4 PACK] Single Handle 90° Aluminum Alloy Corner Clamp, Clamps for Woodworking Adjustable Swing Jaw, Woodworking Tools Photo Frame Vise Holder, Gifts for Men Dad](https://m.media-amazon.com/images/I/71xNSiBOZ+L._AC_UL320_.jpg)

![Housolution Right Angle Clamp, [2 PACK] Single Handle 90° Aluminum Alloy Corner Clamp, Clamps for Woodworking Adjustable Swing Jaw, Woodworking Tools Photo Frame Vise Holder, Gifts for Men Dad](https://m.media-amazon.com/images/I/71nW-qkVwnL._AC_UL320_.jpg)