Curing eucalyptus wood is a crucial process that ensures its durability, stability, and resistance to warping or cracking. Eucalyptus, known for its strength and natural oils, requires proper curing to maximize its potential for use in furniture, flooring, or construction. The curing time for eucalyptus wood typically ranges from 3 to 6 months, depending on factors such as the wood’s thickness, moisture content, and environmental conditions like humidity and temperature. During this period, the wood is allowed to air-dry slowly, reducing its moisture levels to match the surrounding environment. Properly cured eucalyptus wood not only enhances its structural integrity but also preserves its natural beauty and longevity, making it a valuable material for various applications.

| Characteristics | Values |

|---|---|

| Curing Time (Air Drying) | 6 months to 2 years, depending on thickness and climate conditions |

| Optimal Moisture Content | 12-15% for most applications |

| Kiln Drying Time | 2-4 weeks, significantly faster than air drying |

| Ideal Curing Environment | Well-ventilated, shaded area with low humidity (40-60%) |

| Wood Thickness Impact | Thicker pieces take longer to cure (e.g., 4/4 lumber: 1-2 years) |

| Species Variation | Some eucalyptus species cure faster due to lower density |

| Cracking/Warping Risk | Higher if dried too quickly; proper stacking and spacing are essential |

| Stability Post-Curing | Highly stable and durable once properly cured |

| Recommended Practices | Seal ends with wax or paint to prevent moisture loss |

| Post-Curing Treatment | Sanding and finishing to enhance appearance and longevity |

Explore related products

What You'll Learn

- Ideal Drying Conditions: Proper airflow, temperature, and humidity levels for effective eucalyptus wood curing

- Curing Timeframe: Typical duration for eucalyptus wood to cure fully, varying by thickness

- Moisture Content Goals: Target moisture levels to ensure wood stability and prevent warping

- Kiln Drying vs. Air Drying: Comparison of methods and their impact on curing time

- Signs of Fully Cured Wood: Indicators like weight stability and lack of cracks

Ideal Drying Conditions: Proper airflow, temperature, and humidity levels for effective eucalyptus wood curing

Eucalyptus wood, prized for its durability and rich grain, demands precise drying conditions to prevent warping, cracking, or decay. Proper airflow, temperature, and humidity levels are the trifecta of effective curing, each playing a distinct role in transforming raw timber into a stable, usable material.

Airflow: The Unseen Catalyst

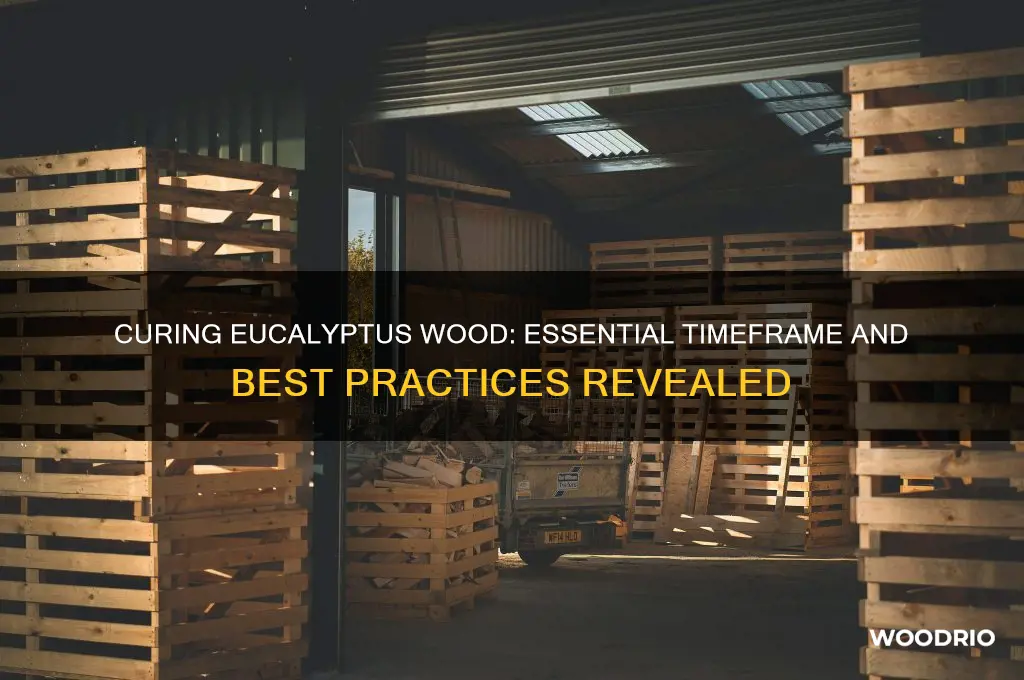

Adequate airflow is non-negotiable. Stagnant air traps moisture, breeding mold and uneven drying. For optimal results, stack eucalyptus planks or logs with 1–2 inches of space between them, allowing air to circulate freely. In industrial settings, fans or dehumidifiers can enhance airflow, but natural ventilation often suffices for smaller-scale projects. Aim for a consistent breeze, not a draft, to avoid surface checking.

Temperature: The Balancing Act

Temperature directly influences drying speed and wood integrity. Eucalyptus thrives in temperatures between 60°F and 90°F (15°C–32°C). Below 60°F, drying stalls; above 90°F, the wood risks case-hardening, where the exterior dries faster than the interior, leading to internal stresses. For accelerated drying, solar kilns or heated sheds can maintain ideal temperatures, but monitor closely to avoid overheating.

Humidity: The Moisture Meter

Humidity control is the linchpin of curing. Eucalyptus should dry to a moisture content (MC) of 12–15% for indoor use, or 18–20% for outdoor applications. In regions with high ambient humidity (above 70%), dehumidifiers or kiln drying are essential. Conversely, in arid climates, cover the wood to slow moisture loss. Use a moisture meter to track progress, testing at the core and surface to ensure uniformity.

Practical Tips for Success

Start curing eucalyptus in the shade to prevent rapid surface drying. Rotate stacks weekly to promote even moisture loss. For larger pieces, seal the ends with wax or paint to minimize end grain absorption. Patience is paramount—eucalyptus typically takes 6–12 months to air-dry naturally, though kiln drying can reduce this to 2–4 weeks. Always acclimate cured wood to its final environment for 2–3 weeks before use to prevent post-installation issues.

Mastering these conditions transforms eucalyptus curing from guesswork into science. With proper airflow, temperature, and humidity management, the wood’s natural strength and beauty are preserved, ensuring a product that stands the test of time.

Perfect Boston Butt: Wood Pellet Grill Cooking Time Guide

You may want to see also

Explore related products

Curing Timeframe: Typical duration for eucalyptus wood to cure fully, varying by thickness

Eucalyptus wood, prized for its durability and rich grain, requires careful curing to reach its full potential. The curing timeframe hinges critically on thickness, with denser pieces demanding more patience. For instance, a 1-inch thick board typically needs 6 to 12 months to cure adequately, while a 4-inch slab can take 2 to 3 years or more. This disparity underscores the importance of planning ahead when working with eucalyptus, as rushing the process risks warping, cracking, or instability in the final product.

To optimize curing, consider environmental factors. Eucalyptus wood cures best in a controlled, well-ventilated space with consistent humidity levels (ideally 50-60%) and moderate temperatures (60-80°F). Storing wood in a shed or garage with airflow but minimal direct sunlight prevents uneven drying. For thicker pieces, stacking with spacers allows air circulation, reducing the risk of mold or rot. Regularly flipping the wood every few months ensures even moisture loss on all sides.

A comparative analysis reveals that eucalyptus cures faster than hardwoods like oak or maple but slower than softwoods like pine. Its dense, oily nature resists decay but slows moisture evaporation. Thinner eucalyptus pieces (under 1 inch) can be kiln-dried in 3 to 6 weeks, significantly reducing wait time, though this method may compromise the wood’s natural luster. Air-drying, while slower, preserves the wood’s inherent beauty and structural integrity, making it the preferred method for fine woodworking.

Practical tips can expedite the curing process without sacrificing quality. For thicker pieces, sealing the ends with a wax or commercial end-grain sealer minimizes moisture loss from these vulnerable areas, reducing the risk of splits. Monitoring moisture content with a wood moisture meter (targeting 12-15% for indoor use) ensures the wood is ready for use. If time is a constraint, combining air-drying with periodic kiln treatment can strike a balance between speed and preservation.

Ultimately, curing eucalyptus wood is an exercise in patience and precision. While thickness dictates the baseline timeframe, proactive measures—like controlled storage, end sealing, and moisture monitoring—can refine the process. Whether crafting furniture, flooring, or decorative pieces, respecting the wood’s natural curing rhythm ensures a durable, stunning result that stands the test of time.

Glo Ring Secret Wood Durability: How Long Does It Last?

You may want to see also

Explore related products

$19.99

Moisture Content Goals: Target moisture levels to ensure wood stability and prevent warping

Eucalyptus wood, prized for its durability and versatility, demands precise moisture management to ensure stability and prevent warping. The ideal moisture content (MC) for eucalyptus typically ranges between 8% and 12%, aligning with the average equilibrium moisture content (EMC) of its intended environment. For indoor use, aim for 10% MC, while outdoor applications may tolerate slightly higher levels, around 12–14%, to account for humidity fluctuations. Achieving these targets requires careful monitoring and controlled drying processes, as eucalyptus’ natural density and resin content can complicate moisture release.

To reach these moisture content goals, start by air-drying freshly cut eucalyptus logs in a well-ventilated area, stacking them with spacers to promote airflow. This initial phase can take 3–6 months, depending on climate conditions. For faster and more uniform results, kiln-drying is recommended, reducing the curing time to 2–4 weeks. Kiln schedules should begin at low temperatures (40–50°C) to avoid surface checking, gradually increasing to 70–80°C as the wood dries. Regularly measure MC using a pin-type or pinless moisture meter, ensuring readings stabilize within the target range before proceeding with milling or construction.

Warping and cracking occur when moisture gradients develop within the wood, causing uneven shrinkage. To prevent this, maintain consistent drying conditions and avoid exposing eucalyptus to direct sunlight or rapid temperature changes during curing. If warping does occur, corrective measures such as reconditioning in a controlled humidity environment or light planing can help restore flatness. However, prevention through meticulous moisture management remains the most effective strategy, saving time and material in the long run.

Comparatively, eucalyptus dries more slowly than softer woods like pine due to its higher density and natural oils, which act as barriers to moisture escape. This necessitates patience and vigilance during the curing process. For instance, while pine might reach 10% MC in 2–3 weeks of kiln-drying, eucalyptus could take twice as long. Understanding these differences allows woodworkers to tailor their approach, ensuring eucalyptus achieves optimal moisture levels without compromising its structural integrity.

In practice, achieving moisture content goals for eucalyptus wood is a blend of science and craftsmanship. Begin with proper log selection, favoring defect-free timber to minimize internal stresses. Use moisture meters regularly, taking readings from multiple depths and locations to ensure uniformity. For large-scale projects, invest in a kiln or collaborate with a professional drying service to expedite the process. Finally, acclimate the dried wood to its final environment for at least 2 weeks before use, allowing it to equilibrate with local humidity conditions. By prioritizing moisture control, you safeguard eucalyptus’s natural beauty and longevity, ensuring it performs flawlessly in any application.

Drying Wood Boards: Essential Tips for Optimal Moisture Removal

You may want to see also

Explore related products

Kiln Drying vs. Air Drying: Comparison of methods and their impact on curing time

Eucalyptus wood, prized for its durability and versatility, requires careful curing to achieve optimal stability and performance. Two primary methods dominate this process: kiln drying and air drying. Each has distinct advantages, drawbacks, and impacts on curing time, making the choice between them critical for woodworkers and manufacturers.

Kiln drying accelerates the curing process through controlled heat and humidity. This method involves placing eucalyptus wood in a kiln, where temperature and moisture levels are meticulously regulated. A typical kiln drying cycle for eucalyptus ranges from 2 to 6 weeks, depending on thickness and initial moisture content. For instance, 1-inch thick boards may dry in 2–3 weeks at temperatures between 120°F and 160°F, while 2-inch thick planks could require 4–6 weeks. The precision of kiln drying minimizes warping and cracking, ensuring uniform moisture distribution. However, the energy costs and initial investment in kiln equipment can be prohibitive for small-scale operations.

Air drying, in contrast, relies on natural conditions and patience. Eucalyptus logs or planks are stacked with spacers to allow airflow, often under a covered but open-air structure. This method can take 6 months to 2 years, depending on climate, wood thickness, and desired moisture content. For example, in a temperate climate, 1-inch boards might air dry in 6–12 months, while 4-inch planks could require up to 2 years. Air drying is cost-effective and environmentally friendly but carries a higher risk of defects like checking or uneven drying. Proper stacking techniques, such as using stickers and ensuring good ventilation, are essential to mitigate these risks.

The choice between kiln and air drying hinges on time constraints, budget, and desired wood quality. Kiln drying is ideal for projects requiring quick turnaround or high precision, such as furniture making or flooring. Air drying suits long-term projects or those prioritizing sustainability and cost savings. For instance, a small woodworking shop might opt for air drying to minimize expenses, while a large manufacturer might invest in kiln drying to meet tight production schedules.

Practical tips can optimize both methods. For kiln drying, monitor moisture content regularly using a moisture meter to prevent overdrying. In air drying, stack wood in a north-south orientation to minimize sun exposure and rotate stacks periodically to ensure even drying. Regardless of the method, understanding eucalyptus’s unique properties—such as its natural oils and density—is crucial for achieving the best results. By weighing the pros and cons of kiln and air drying, woodworkers can select the most effective approach for their specific needs.

Corona on Wood: Understanding the Survival Duration of the Virus

You may want to see also

Explore related products

Signs of Fully Cured Wood: Indicators like weight stability and lack of cracks

Eucalyptus wood, prized for its durability and versatility, requires careful curing to reach its full potential. Determining when it’s fully cured isn’t guesswork—specific signs indicate readiness for use. Weight stability is a primary indicator. Freshly cut eucalyptus can lose up to 20% of its weight during the drying process as moisture evaporates. A fully cured piece will feel lighter than its green state but maintain a consistent weight over time, unaffected by humidity fluctuations. If you’ve monitored its weight weekly and noticed no significant changes for at least two consecutive weeks, it’s a strong sign the wood has stabilized.

Another critical sign is the absence of cracks or checks. Eucalyptus, with its dense grain, is less prone to splitting than softer woods, but improper curing can still lead to surface or internal fissures. Inspect the wood closely: run your hand along its surface and examine the ends for any visible cracks. Fully cured eucalyptus will have a smooth, even texture, with no signs of warping or splitting. If you notice hairline cracks, it’s a red flag—the wood may need more time to dry or was dried too quickly.

For those curing eucalyptus at home, patience is key. Air-drying, the most common method, typically takes 6 to 12 months, depending on climate and wood thickness. Kiln-drying accelerates this to 2–4 weeks but requires precise temperature and humidity control. A practical tip: use a moisture meter to confirm the wood’s moisture content is below 12%, the ideal range for most applications. If you lack a meter, the “knock test” can help—a sharp, resonant sound when tapped indicates dryness, while a dull thud suggests residual moisture.

Comparing eucalyptus to other hardwoods highlights its unique curing behavior. Unlike oak or maple, eucalyptus has a higher natural oil content, which aids in moisture resistance but can slow drying. This makes weight stability an even more reliable indicator for eucalyptus. Additionally, its density means it’s less forgiving of rapid drying methods, making cracks a more significant concern. Understanding these nuances ensures you don’t mistake partially cured wood for fully cured, which could lead to warping or decay in finished projects.

In conclusion, fully cured eucalyptus wood is marked by weight stability and a crack-free surface. Monitor its weight, inspect for defects, and use tools like moisture meters to confirm readiness. Whether air-drying or kiln-drying, respect the wood’s natural timeline and characteristics. Properly cured eucalyptus will reward you with strength, beauty, and longevity in any project.

BBQ Wood Pellets Lifespan: How Long Do They Really Last?

You may want to see also

Frequently asked questions

Eucalyptus wood typically takes 6 to 12 months to cure properly, depending on factors like humidity, temperature, and thickness of the wood.

Yes, curing can be expedited by storing the wood in a dry, well-ventilated area with consistent airflow and moderate temperatures, but it should not be rushed to avoid cracking or warping.

Cured eucalyptus wood should have a moisture content of 12-15% for optimal stability and durability in most applications.

Yes, different eucalyptus species may have slightly different curing times due to variations in density and natural oils, but the general range remains 6 to 12 months.

Fully cured eucalyptus wood will feel dry to the touch, have minimal cracks or warping, and its weight will stabilize, indicating it has reached the desired moisture content.