Drying wood boards is a critical process in woodworking and construction, as it ensures the material’s stability, durability, and resistance to warping or cracking. The time required for a wood board to dry depends on several factors, including the wood species, initial moisture content, thickness of the board, environmental conditions such as humidity and temperature, and the drying method used (air drying or kiln drying). For instance, air drying can take anywhere from several months to over a year for thicker hardwoods, while kiln drying significantly reduces this time to days or weeks. Understanding these variables is essential for achieving optimal results and preventing issues caused by improperly dried wood.

Explore related products

What You'll Learn

- Initial Moisture Content: Determines drying time based on wood's starting wetness level

- Wood Species: Denser woods dry slower than lighter, less dense types

- Drying Methods: Air drying vs. kiln drying affects speed and quality

- Environmental Factors: Humidity, temperature, and airflow influence drying duration

- Thickness of Board: Thicker boards take significantly longer to dry completely

Initial Moisture Content: Determines drying time based on wood's starting wetness level

The initial moisture content of wood is a critical factor in determining how long it will take for a board to dry. Freshly cut timber, known as green wood, can have a moisture content of up to 200% (meaning it holds twice its weight in water). For practical use, wood must be dried to a moisture content of 6–12%, depending on its intended application. This drastic reduction in moisture is a slow process, influenced heavily by the wood’s starting point. For instance, a board with an initial moisture content of 150% will take significantly longer to dry than one starting at 50%, even under identical conditions. Understanding this relationship allows for more accurate predictions of drying time and better planning in woodworking projects.

Analyzing the drying process reveals why initial moisture content is so pivotal. Wood dries in two phases: the first involves the evaporation of free water from cell cavities, which occurs relatively quickly. The second phase, where bound water is released from cell walls, is far slower and more dependent on the wood’s initial wetness. For example, a board with 100% initial moisture content may spend weeks in the first phase, while a board starting at 30% could bypass it entirely. This distinction highlights the importance of measuring moisture content early—a simple moisture meter can provide this data, allowing woodworkers to estimate drying times more precisely. Without this measurement, drying schedules remain guesswork, risking either over-drying or insufficient drying.

From a practical standpoint, reducing initial moisture content before drying can expedite the process. Air-drying wood outdoors for several months, under a shed to protect it from rain, can lower moisture levels by 30–50%. For faster results, kiln-drying can be employed, but even this method is more efficient when the wood starts at a lower moisture content. A tip for small-scale woodworkers: stack boards with stickers (spacers) between them to promote airflow, and store them in a well-ventilated area with moderate humidity. This simple step can shave weeks off drying time by addressing surface moisture early.

Comparing woods with different initial moisture contents underscores the variability in drying times. Softwoods like pine, often harvested with higher moisture levels, can take 6–12 months to air-dry to usable levels. Hardwoods like oak, which may start with slightly lower moisture, still require 9–18 months. However, exotic woods with extremely high initial moisture, such as teak, can take up to 2 years. This comparison illustrates why wood species and their typical moisture profiles must be considered alongside initial measurements. Ignoring these differences can lead to warping, cracking, or mold growth during drying.

In conclusion, initial moisture content is not just a starting point—it’s a determinant of the entire drying timeline. By measuring it accurately, understanding its role in the drying phases, and taking proactive steps to reduce it, woodworkers can streamline the process. Whether air-drying or kiln-drying, this knowledge ensures wood reaches the desired moisture level efficiently, preserving its quality for long-term use. Treat initial moisture content as the cornerstone of your drying strategy, and the rest of the process will fall into place.

Mastering Chopping Wood in BDO: Time-Saving Tips and Tricks

You may want to see also

Explore related products

Wood Species: Denser woods dry slower than lighter, less dense types

The density of wood plays a pivotal role in determining how long it takes for a board to dry. Denser woods, such as oak or maple, have more tightly packed fibers, which restrict moisture movement and slow down the drying process. In contrast, lighter woods like pine or balsa have larger cell cavities, allowing moisture to escape more freely. This fundamental difference in structure means that a 1-inch thick oak board might take twice as long to dry as a similarly sized pine board under the same conditions. Understanding this relationship is crucial for woodworkers and craftsmen who need to plan for drying times to avoid warping, cracking, or other defects.

To illustrate, consider the drying time for a 4/4 (1-inch thick) board of red oak versus a 4/4 board of white pine. Red oak, with a density of around 45 pounds per cubic foot, can take upwards of 6 to 12 months to air-dry to a moisture content of 12%, suitable for indoor use. White pine, with a density of approximately 25 pounds per cubic foot, typically reaches the same moisture level in 3 to 6 months. Kiln drying accelerates this process but still follows the same principle: denser woods require longer kiln cycles. For instance, a kiln schedule for oak might run at 120°F for 4 weeks, while pine could be dried at 140°F for just 2 weeks.

For practical application, woodworkers should select species based on both the desired aesthetic and the time available for drying. If a project requires a dense, durable wood like teak but is time-sensitive, consider using pre-dried lumber or opting for a less dense alternative like cedar. Additionally, monitoring moisture content with a wood moisture meter is essential, as denser woods may retain hidden moisture pockets even after surface drying. Aim for a moisture content of 6-8% for outdoor projects and 8-12% for indoor use, adjusting drying times accordingly.

A comparative analysis reveals that while denser woods offer superior strength and durability, their slower drying times can be a drawback for time-constrained projects. Lighter woods, though less robust, provide a quicker turnaround and are often more forgiving for beginners. For example, a novice woodworker might start with pine for a practice piece, allowing them to complete the project within weeks rather than months. However, for long-term investments like furniture or structural elements, the patience required for denser woods pays off in longevity and stability.

In conclusion, the density of wood is a critical factor in drying times, influencing both the method and duration required to achieve optimal moisture content. By understanding this relationship, craftsmen can make informed decisions about species selection, drying methods, and project timelines. Whether air-drying, kiln-drying, or using pre-dried lumber, accounting for wood density ensures the final product is both functional and durable. Always plan ahead, measure moisture content regularly, and match the wood species to the project’s needs for the best results.

Exploring Muir Woods: Average Visitor Time and Tips for Your Trip

You may want to see also

Explore related products

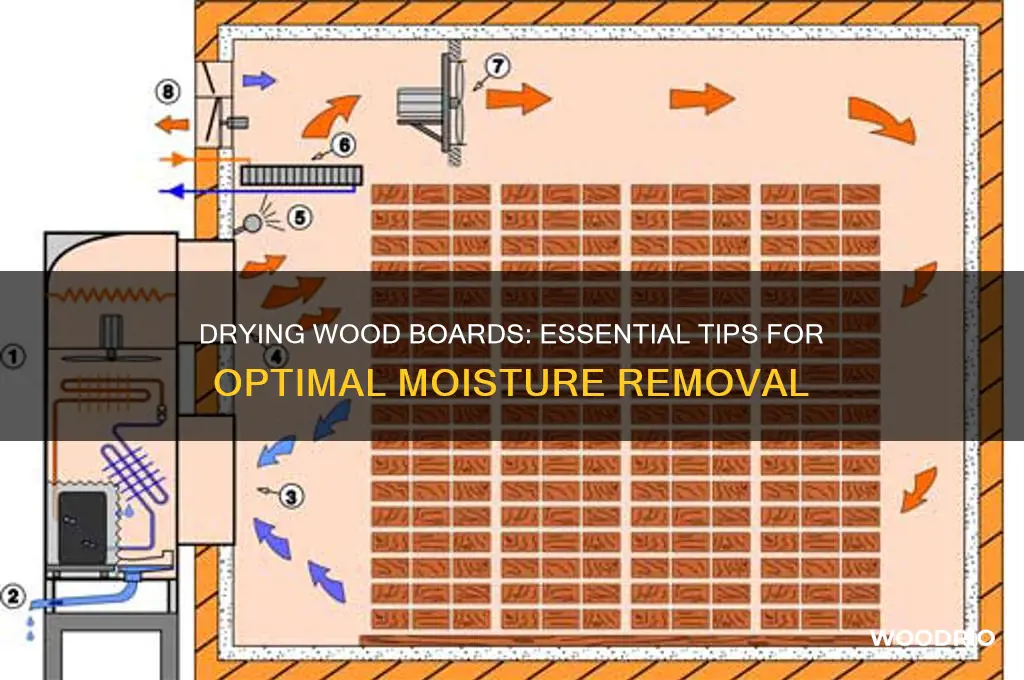

Drying Methods: Air drying vs. kiln drying affects speed and quality

The time it takes for a wood board to dry depends heavily on the method chosen: air drying or kiln drying. Air drying, a traditional approach, relies on natural conditions—ambient temperature, humidity, and airflow. While cost-effective, it’s slow, often requiring 1–3 years for hardwoods like oak or maple to reach a moisture content of 12–15%. Softwoods like pine dry faster, typically within 6–12 months. However, air drying is unpredictable; improper stacking or high humidity can lead to warping, cracking, or fungal growth. For those with patience and space, it’s a viable option, but quality control remains a challenge.

Kiln drying, on the other hand, is a controlled process that accelerates drying time to mere days or weeks. By regulating temperature and humidity in a kiln, wood can achieve the same 12–15% moisture content in as little as 2–4 weeks for softwoods and 4–8 weeks for hardwoods. This method minimizes defects like checking or honeycombing, as the drying rate is carefully monitored. However, it requires significant energy input, making it more expensive. Kiln drying is ideal for commercial operations or projects requiring consistent, high-quality wood with precise moisture levels.

Choosing between air and kiln drying involves balancing speed, cost, and quality. Air drying suits hobbyists or small-scale projects where time isn’t critical, while kiln drying is essential for large-scale production or time-sensitive applications. For instance, furniture makers often prefer kiln-dried wood for its stability, whereas a DIY enthusiast might opt for air-dried lumber to save costs. Understanding these trade-offs ensures the right method is selected for the specific needs of the project.

Practical tips can optimize both methods. For air drying, stack wood stickers (spacers) between boards to allow airflow, and cover the pile to protect it from rain while permitting ventilation. Kiln operators should gradually increase temperature to avoid case hardening, where the outer layer dries too quickly, trapping moisture inside. Regularly monitor moisture content with a meter to ensure uniformity. Whether air or kiln drying, the goal is to achieve stable, usable wood—the method chosen should align with the project’s timeline, budget, and quality requirements.

Drying Wood Slices: Timeframe, Techniques, and Tips for Perfect Results

You may want to see also

Explore related products

Environmental Factors: Humidity, temperature, and airflow influence drying duration

Wood drying is a delicate balance of science and patience, where environmental factors play a pivotal role. Among these, humidity, temperature, and airflow are the triumvirate that dictates how long a wood board takes to dry. High humidity levels slow down the process, as moisture in the air competes with the wood's internal moisture, hindering evaporation. For instance, in regions with 70% relative humidity or higher, drying times can extend by 50% compared to drier climates. Conversely, low humidity accelerates drying but risks uneven moisture loss, leading to cracks or warping. Understanding these dynamics is crucial for anyone working with wood, whether in construction, craftsmanship, or hobbyist projects.

Temperature acts as a catalyst in the drying process, directly influencing the rate of moisture evaporation. Optimal drying occurs between 70°F and 90°F (21°C to 32°C), where warmth encourages water molecules to escape without causing stress to the wood fibers. Below 50°F (10°C), drying stalls, as cold air holds less moisture and reduces the wood's ability to release it. Above 100°F (38°C), the wood risks drying too rapidly, leading to internal stresses and structural weaknesses. For example, kiln drying, a controlled environment method, often maintains temperatures around 140°F (60°C) to expedite drying while minimizing defects, but this requires precise monitoring to avoid damage.

Airflow is the unsung hero of wood drying, facilitating the movement of moisture from the wood into the surrounding air. Stagnant air traps humidity around the wood, slowing evaporation, while consistent airflow accelerates it. In practical terms, stacking wood boards with spacers to allow air circulation can reduce drying time by up to 30%. Industrial settings often use fans or dehumidifiers to enhance airflow, ensuring uniform drying. For DIY enthusiasts, positioning wood in a well-ventilated area, such as a garage with open windows or a shed with gaps for air exchange, can yield better results than a closed, damp space.

The interplay of these factors creates a complex equation for drying wood. For instance, a wood board in a warm, dry environment with good airflow might dry in 6–8 weeks, while the same board in a cool, humid space with poor ventilation could take 6 months or more. To optimize drying, consider the wood’s initial moisture content (MC), typically measured with a moisture meter. Aim for a final MC of 12–15% for indoor use, adjusting environmental conditions accordingly. For example, if humidity is high, use a dehumidifier; if airflow is poor, rearrange the stack or introduce fans.

In conclusion, mastering the environmental factors of humidity, temperature, and airflow is key to efficient wood drying. By manipulating these variables, whether through natural means or controlled environments, one can significantly reduce drying times while preserving the wood’s integrity. Practical steps include monitoring humidity levels, maintaining optimal temperatures, and ensuring consistent airflow. For those seeking precision, investing in tools like hygrometers, thermometers, and moisture meters can provide data-driven insights, turning the drying process from an art into a science.

Clearcoat Drying Time on Wood: Factors Affecting Cure and Finish

You may want to see also

Explore related products

Thickness of Board: Thicker boards take significantly longer to dry completely

The drying time of a wood board is directly proportional to its thickness, a principle rooted in the physics of moisture movement. As water migrates from the core to the surface of the wood, thicker boards present a longer path for this process, slowing evaporation. For instance, a 4/4 (1-inch thick) board may air-dry in 6 to 12 months in optimal conditions, while an 8/4 (2-inch thick) board could require 2 to 4 years. This disparity underscores the importance of planning for thickness when managing wood drying schedules.

To expedite drying, woodworkers often opt for kiln drying, which uses controlled heat and humidity to accelerate moisture removal. However, even in kilns, thicker boards demand longer cycles to prevent internal stress and cracking. A 1-inch board might dry in 2 to 4 weeks, whereas a 2-inch board could take 6 to 8 weeks under the same conditions. Monitoring moisture content with a meter is crucial, as thicker boards retain moisture in their core long after the surface feels dry.

For those air-drying thicker boards, strategic stacking and spacing are essential. Stickers (small strips of wood) placed between boards allow air circulation, but thicker boards require wider spacing to accommodate slower drying. Additionally, rotating stacks periodically ensures even drying and prevents warping. Patience is key, as rushing the process risks defects like checks or honeycombing, which compromise the wood’s structural integrity.

Comparatively, thinner boards offer a quicker turnaround but may lack the dimensional stability of thicker, slower-dried wood. For projects requiring immediate use, thinner stock is practical, but for long-term durability, thicker boards—despite their longer drying time—are often superior. Understanding this trade-off helps woodworkers balance time constraints with material quality.

In conclusion, the thickness of a wood board is a critical factor in its drying timeline, influencing both method and duration. Whether air-drying or kiln-drying, thicker boards demand careful management to achieve optimal results. By respecting the natural pace of moisture movement, woodworkers can produce high-quality, stable lumber that stands the test of time.

Mastering Wood Carving: Timeframe for Crafting a Detailed Wooden Head

You may want to see also

Frequently asked questions

Air drying time for wood boards varies depending on the wood species, thickness, and environmental conditions, but it generally takes 1 to 2 years for a 1-inch thick board to dry sufficiently.

Yes, kiln drying can significantly reduce drying time, typically taking 2 to 10 weeks, depending on the wood type and kiln settings, compared to air drying.

Higher temperatures and lower humidity accelerate drying, while cold, damp conditions slow it down. Ideal drying conditions are warm temperatures (70–90°F) and low humidity (below 60%).

Yes, drying wood too quickly can cause cracking, warping, or splitting. Gradual drying is essential to maintain the wood’s structural integrity and prevent defects.