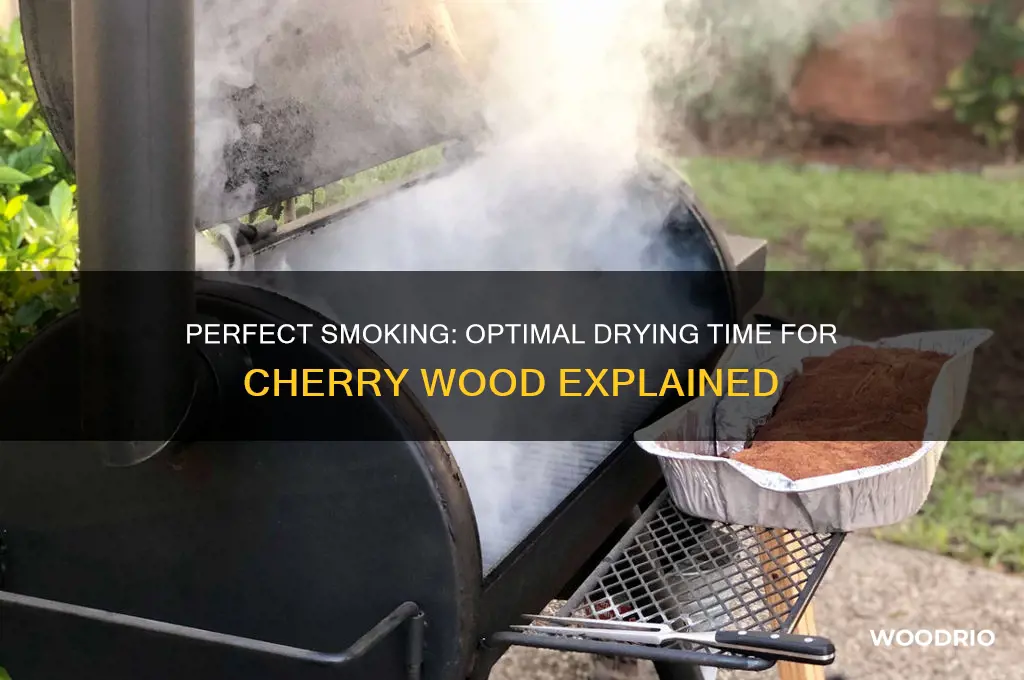

Drying cherry wood for smoking is a crucial step in ensuring it burns efficiently and imparts the desired flavor to your food. The drying process, also known as seasoning, involves removing moisture from the wood to achieve an optimal moisture content, typically around 20-25%. Freshly cut cherry wood can take anywhere from 6 months to 2 years to dry properly, depending on factors such as the wood's thickness, humidity levels, and storage conditions. Properly dried cherry wood will be lighter in weight, have cracks at the ends, and produce a sharp, clear sound when struck together, indicating it's ready for use in your smoker.

| Characteristics | Values |

|---|---|

| Drying Time (Air Drying) | 6 months to 1 year (depending on humidity, temperature, and wood thickness) |

| Moisture Content Goal | 20% or less for optimal smoking |

| Seasoning Method | Air drying or kiln drying |

| Ideal Conditions for Air Drying | Well-ventilated area, protected from rain, and direct sunlight |

| Kiln Drying Time | 2-4 weeks (faster but requires specialized equipment) |

| Wood Thickness Impact | Thicker pieces take longer to dry than thinner pieces |

| Humidity Impact | Higher humidity prolongs drying time |

| Temperature Impact | Warmer temperatures accelerate drying |

| Splitting Risk | Higher if dried too quickly; gradual drying reduces risk |

| Storage After Drying | Store in a dry, cool place, off the ground, and covered |

| Readiness Test | Wood should feel light, sound hollow when tapped, and show cracks |

| Use for Smoking | Once properly dried, cherry wood imparts a mild, sweet, fruity flavor |

Explore related products

What You'll Learn

Ideal moisture content for cherry wood smoking

Cherry wood, prized for its sweet, fruity smoke that enhances meats like pork, poultry, and beef, demands precise moisture management for optimal flavor. The ideal moisture content for smoking lies between 15% and 20%. Below 15%, the wood burns too quickly, producing ash rather than smoke. Above 20%, excess moisture creates steam, diluting the smoke’s flavor and potentially imparting a bitter or creosote taste to the food. Achieving this range ensures a clean, consistent burn that maximizes the wood’s aromatic qualities.

Reaching the ideal moisture content requires proper drying, a process influenced by humidity, temperature, and wood thickness. Air-drying cherry wood typically takes 6 to 12 months, depending on these factors. For faster results, kiln-drying reduces the timeline to 2 to 4 weeks, but this method requires specialized equipment. Regardless of the method, monitoring moisture levels with a wood moisture meter is essential. Readings above 20% indicate the wood needs more time to dry, while readings below 15% suggest it’s ready for immediate use or should be stored in a humid environment to prevent further drying.

Comparing cherry wood to other smoking woods highlights its unique drying needs. Hickory, for instance, is denser and can tolerate a slightly higher moisture content (up to 25%) without compromising performance. Cherry wood, however, is more sensitive due to its softer texture and higher sugar content, which can caramelize or burn if the wood is too dry. This distinction underscores the importance of tailoring the drying process to the specific wood type, ensuring cherry wood retains its signature flavor profile.

Practical tips for drying cherry wood include splitting logs into 2- to 4-inch thicknesses to expedite moisture evaporation and stacking them in a well-ventilated, shaded area. Covering the stack with a tarp protects the wood from rain while allowing airflow. For those in humid climates, elevating the wood off the ground with pallets prevents moisture absorption from the soil. Regularly rotating the stack ensures even drying and minimizes the risk of mold or insect infestation.

In conclusion, mastering the ideal moisture content for cherry wood smoking is a balance of patience, precision, and technique. By targeting the 15% to 20% range and employing proper drying methods, smokers can unlock the full potential of cherry wood’s sweet, fruity essence. Whether air-drying or kiln-drying, consistent monitoring and thoughtful storage practices guarantee a superior smoking experience every time.

Drying Time for Wood Subfloors: What to Expect and How to Speed It Up

You may want to see also

Explore related products

Air-drying vs. kiln-drying cherry wood methods

Cherry wood, prized for its sweet, fruity smoke flavor, requires proper drying to unlock its full potential for smoking meats and cheeses. The drying method—air-drying or kiln-drying—significantly impacts the wood’s moisture content, flavor profile, and usability. Air-drying, a traditional method, relies on natural elements like sunlight, wind, and time to reduce moisture levels. Kiln-drying, on the other hand, uses controlled heat and humidity in a specialized chamber to expedite the process. Both methods have distinct advantages and trade-offs, making the choice between them a matter of priorities: time, flavor, cost, and environmental impact.

Air-drying cherry wood is a patient process, typically taking 6 to 12 months, depending on climate and wood thickness. Stack the split logs in a dry, well-ventilated area, ensuring gaps between pieces for airflow. Cover the pile with a tarp to protect from rain while allowing moisture to escape. This method preserves the wood’s natural oils and sugars, resulting in a richer, more complex smoke flavor. However, it requires ample space, consistent weather conditions, and vigilance against mold or insect infestation. For hobbyists or those prioritizing flavor authenticity, air-drying is ideal, though it demands commitment and planning.

Kiln-drying, in contrast, reduces drying time to 2 to 4 weeks by using precise temperature and humidity controls. A kiln can process larger volumes of wood uniformly, making it efficient for commercial operations. Temperatures are gradually increased from 120°F to 180°F, while humidity is monitored to prevent cracking or warping. While kiln-dried cherry wood is ready for immediate use, the rapid drying process can reduce the concentration of volatile compounds responsible for its signature flavor. This method is best for those needing quick turnaround or consistent results, but it may sacrifice some of the wood’s natural character.

Comparing the two methods, air-drying is cost-effective and environmentally friendly, requiring minimal energy input. Kiln-drying, however, offers predictability and speed, crucial for large-scale production. For smoking, air-dried cherry wood is often preferred for its deeper flavor, while kiln-dried wood is more convenient for frequent use. A practical compromise is to air-dry wood for 3–4 months, then finish it in a kiln to stabilize moisture levels without fully compromising flavor.

Practical tips: If air-drying, split logs into 2–4 inch pieces to accelerate moisture loss. For kiln-drying, monitor moisture content with a wood moisture meter, aiming for 15–20% for smoking. Store dried wood in a cool, dry place to maintain quality. Ultimately, the choice between air-drying and kiln-drying depends on your goals: embrace air-drying for superior flavor, or opt for kiln-drying when time and consistency are paramount.

How Long Does It Take for Spider Wood to Sink?

You may want to see also

Explore related products

Time required for cherry wood to season

Cherry wood, prized for its sweet, fruity smoke flavor, requires proper seasoning before it’s ready for smoking meats or other foods. The time needed to dry cherry wood depends heavily on environmental conditions and the method chosen. Air drying, the most common approach, typically takes 6 to 12 months in a temperate climate with moderate humidity. Stacking split logs in a dry, well-ventilated area allows moisture to gradually escape, ensuring the wood burns cleanly and imparts the desired flavor. For those in humid regions, extending this period to 18 months may be necessary to achieve the ideal moisture content of 20% or less.

For a faster alternative, kiln drying can reduce seasoning time to 2 to 4 weeks, though this method requires specialized equipment and precise temperature control. Kiln drying at 120°F to 140°F accelerates moisture evaporation while minimizing the risk of cracking or warping. However, this approach is less accessible for hobbyists and may alter the wood’s natural aroma slightly. If time is a constraint, purchasing pre-seasoned cherry wood chunks or chips is a reliable option, though it sacrifices the satisfaction of preparing the wood yourself.

A critical factor in seasoning cherry wood is proper splitting and storage. Logs should be split into 2 to 4-inch pieces, exposing more surface area to air. Stack these pieces off the ground, using pallets or racks, and cover the pile with a tarp to protect from rain while allowing airflow. Regularly rotating the stack ensures even drying and prevents mold or insect infestations. Patience is key; rushing the process can result in wood that smolders instead of smokes, ruining the flavor of your food.

Comparing cherry wood to other smoking woods highlights its unique requirements. While hardwoods like oak or hickory can season in 6 to 9 months, cherry’s higher moisture content and denser grain often demand additional time. Fruitwoods, including apple and peach, share similar drying timelines but may require slightly less due to their lighter density. Understanding these differences helps smokers tailor their seasoning approach to the wood type, ensuring optimal results for each culinary application.

Ultimately, the time required to season cherry wood is an investment in flavor. Properly dried wood enhances the smoking process, delivering a consistent, sweet aroma that complements pork, poultry, and beef. Whether air drying for a year or kiln drying in weeks, the goal remains the same: achieving wood with a moisture content low enough to burn efficiently but high enough to retain its natural oils. With careful attention to splitting, stacking, and storage, smokers can unlock the full potential of cherry wood, elevating their craft one piece at a time.

Durability of Wooden Conservatories: Lifespan and Maintenance Tips

You may want to see also

Explore related products

Effects of humidity on drying duration

Humidity plays a pivotal role in determining how long cherry wood takes to dry for smoking, acting as both a catalyst and a hindrance depending on its levels. At its core, drying wood is about moisture evaporation, a process significantly slowed in high-humidity environments. For instance, in regions with relative humidity above 70%, cherry wood can take upwards of 12 months to reach the ideal moisture content of 20-25% for smoking. Conversely, in drier climates with humidity below 50%, the same wood might dry in as little as 6 months. This disparity underscores the need to monitor local humidity conditions closely when planning the drying process.

To mitigate the effects of high humidity, woodworkers often employ strategic stacking and ventilation techniques. Stacking cherry logs or splits in a crisscross pattern allows air to circulate, while elevating the pile off the ground prevents moisture absorption from the soil. Additionally, covering the wood with a breathable tarp shields it from rain while still permitting airflow. For those in particularly humid areas, investing in a dehumidifier or moving the wood to a controlled indoor environment can drastically reduce drying time. These methods, while requiring effort, ensure the wood dries uniformly and efficiently.

A comparative analysis reveals that humidity’s impact on drying duration is not linear but exponential. For every 10% increase in relative humidity, drying time can extend by 20-30%. This relationship highlights why coastal or tropical regions face greater challenges in drying wood compared to arid climates. For example, cherry wood drying in a Mediterranean climate (average humidity 50-60%) might achieve readiness in 8-10 months, whereas the same wood in a tropical climate (average humidity 80-90%) could require 18-24 months. Understanding this exponential effect is crucial for setting realistic expectations and timelines.

Persuasively, controlling humidity isn’t just about speeding up the process—it’s about ensuring the wood’s quality for smoking. Prolonged exposure to high humidity can lead to mold growth, insect infestation, or uneven drying, all of which compromise the wood’s flavor and burn characteristics. By actively managing humidity, whether through environmental adjustments or protective measures, smokers can safeguard the integrity of their cherry wood. This proactive approach not only saves time but also enhances the end product, delivering a cleaner, more consistent smoke.

Finally, a practical takeaway is to use moisture meters as a tool to navigate humidity challenges. Regularly testing the wood’s moisture content allows for informed decisions about when to adjust drying conditions. For instance, if humidity spikes during a rainy season, moving the wood indoors or increasing ventilation can prevent moisture levels from rising above 25%. Conversely, in dry conditions, occasional misting or covering the wood to slow drying can prevent cracking. By combining humidity awareness with precise monitoring, smokers can optimize the drying process, ensuring cherry wood is ready for smoking at its peak condition.

Understanding 2x4 Wood Dimensions: Length, Uses, and Practical Tips

You may want to see also

Explore related products

Storing cherry wood post-drying for optimal use

Proper storage of dried cherry wood is crucial for maintaining its quality and ensuring it performs optimally when used for smoking. After the wood has been air-dried for the recommended 6 to 12 months—depending on climate and moisture content—it’s essential to store it in a controlled environment. Exposure to excessive humidity can cause the wood to reabsorb moisture, leading to mold or uneven burning. Conversely, overly dry conditions may cause the wood to become brittle, reducing its smoke output. The ideal storage area should have a consistent humidity level between 30% and 50% and a temperature range of 50°F to 70°F.

To store cherry wood effectively, stack the pieces off the ground using pallets or racks to prevent moisture absorption from concrete or soil. Cover the stack with a breathable material like burlap or a tarp, ensuring it’s shielded from rain while still allowing air circulation. Avoid plastic wraps, as they trap moisture and promote mold growth. For smaller quantities, store the wood in a dry shed, garage, or basement, ensuring the space is well-ventilated. If using a basement, consider a dehumidifier to maintain optimal conditions, especially in humid climates.

For long-term storage, consider seasoning the wood further by splitting it into smaller pieces, which reduces density and accelerates moisture release. Kiln-drying is another option, though it’s more resource-intensive and typically reserved for commercial operations. Once stored, periodically inspect the wood for signs of mold, pests, or warping. If mold appears, remove affected pieces and improve ventilation. For added protection, treat the storage area with natural pest deterrents like cedar blocks or diatomaceous earth to keep insects at bay.

The ultimate goal of proper storage is to preserve the wood’s natural sugars and oils, which contribute to its distinctive sweet, fruity smoke flavor. Poorly stored cherry wood can lose these qualities, resulting in a bland or acrid smoke. By investing time in thoughtful storage, you ensure that the wood remains ready for use whenever you need it, delivering consistent results for smoking meats, cheeses, or vegetables. Think of it as aging fine wine—patience and care yield a superior product.

Understanding Wood Absorption: How Long Does Water Soak In?

You may want to see also

Frequently asked questions

Cherry wood typically takes 6 to 12 months to air dry properly for smoking, depending on humidity, temperature, and the thickness of the wood pieces.

Yes, you can speed up drying by splitting the wood into smaller pieces, storing it in a well-ventilated area, and using a kiln, though air drying is preferred for better flavor retention.

Cherry wood is fully dried when its moisture content is below 20%. You can test this using a moisture meter, or by checking if the wood feels light, cracks when struck, and has a dull sound when tapped.

Using undried cherry wood can result in excessive smoke, creosote buildup, and a bitter flavor. Always ensure the wood is properly dried before using it for smoking.

Yes, drying times vary by wood type. Cherry wood dries at a moderate pace compared to denser woods like oak (longer drying time) or softer woods like alder (shorter drying time).