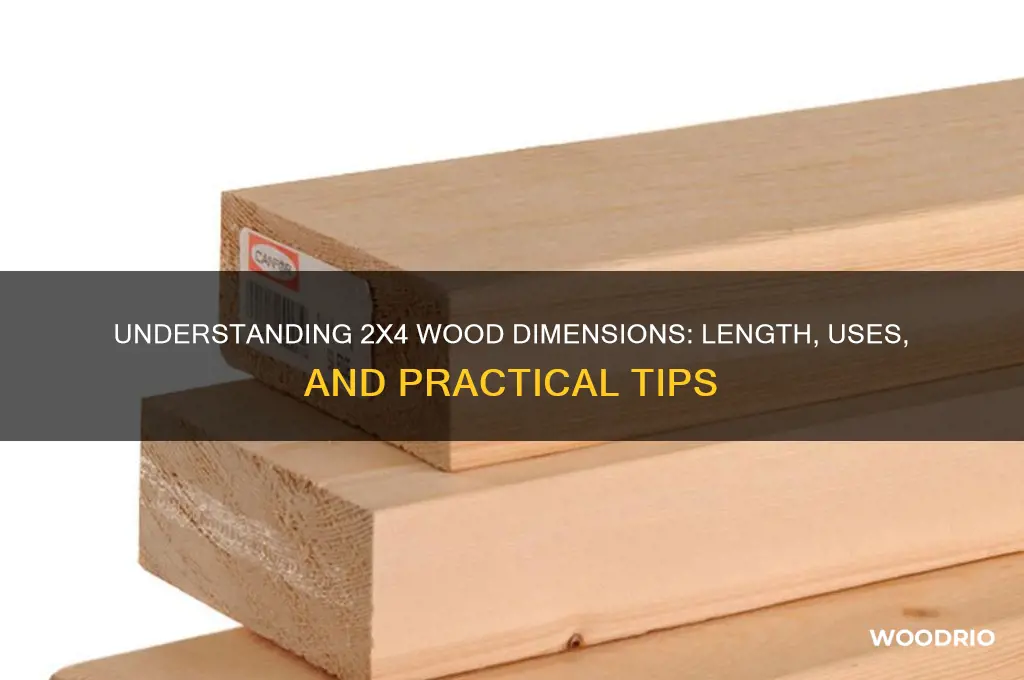

When discussing the dimensions of 2 by 4 wood, it’s important to note that the actual measurements differ from the nominal size due to drying and planing processes. A standard 2x4 piece of lumber, commonly used in construction and woodworking, typically measures approximately 1.5 inches by 3.5 inches in its finished form. The length, however, varies depending on the intended use and can range from 8 feet to 16 feet or more. Understanding these dimensions is crucial for accurate planning, material estimation, and ensuring structural integrity in projects.

| Characteristics | Values |

|---|---|

| Nominal Size | 2 inches x 4 inches |

| Actual Size | 1.5 inches x 3.5 inches |

| Standard Lengths | 8 feet, 10 feet, 12 feet, 14 feet, 16 feet, 20 feet |

| Material | Typically softwood (e.g., pine, fir, spruce) or hardwood (less common) |

| Weight (per 8-foot length) | ~9 lbs (softwood), varies with moisture content and species |

| Common Uses | Framing, furniture, shelving, DIY projects |

| Moisture Content | Typically kiln-dried to 19% or less |

| Grade | Varies (e.g., Select Structural, #2, #3), affecting strength and appearance |

| Finish | Usually unfinished, can be painted, stained, or treated |

| Strength | Depends on species and grade; softwoods like SPF (Spruce-Pine-Fir) are common for structural use |

| Cost (per board) | $3–$10 (varies by length, species, and market conditions) |

Explore related products

$29.99 $35.99

What You'll Learn

Standard Lengths of 2x4 Wood

The nominal dimensions of a 2x4 board are 2 inches by 4 inches, but its actual measurements are slightly smaller due to drying and planing processes. However, the length of a 2x4 is where standardization truly comes into play. Typically, 2x4 wood is sold in even-foot increments, with the most common lengths being 8 feet, 10 feet, and 12 feet. These lengths are widely available at hardware stores and lumberyards, making them the go-to choices for most construction and DIY projects. Understanding these standard lengths is crucial for planning material needs and minimizing waste.

When selecting the right length of 2x4 wood, consider the scale of your project and the structural requirements. For framing walls or building small structures like sheds, 8-foot lengths are often sufficient and easier to handle. However, for larger projects such as decks or room additions, 10-foot or 12-foot boards may be more practical, as they reduce the number of joints needed. Keep in mind that longer boards are heavier and more cumbersome, so factor in transportation and handling when making your choice.

While 8, 10, and 12 feet are the most common lengths, 2x4 wood can also be found in 14-foot and 16-foot lengths, though these are less frequently stocked and may require special ordering. These longer boards are ideal for spanning greater distances without additional support, such as in ceiling joists or roof trusses. If your project demands non-standard lengths, many lumber suppliers offer cutting services to ensure you get the exact size needed, though this may incur additional costs.

For those working on custom or intricate projects, understanding the standard lengths of 2x4 wood allows for smarter design decisions. For example, if you’re building furniture, aligning your dimensions with standard board lengths can reduce the need for complex cuts and minimize material waste. Additionally, knowing the availability of longer boards can open up possibilities for more ambitious designs, such as built-in shelving or expansive outdoor structures.

Finally, while standard lengths are convenient, they aren’t the only factor to consider. Always account for the actual dimensions of the wood, which are slightly smaller than the nominal size, and plan for any additional material needed for cuts or mistakes. By mastering the standard lengths of 2x4 wood and how they apply to your project, you can streamline your workflow, save money, and achieve professional results.

The Making of Night in the Woods: Development Timeline Revealed

You may want to see also

Explore related products

Common Uses for 2x4 Lumber

2x4 lumber, a staple in construction and DIY projects, is incredibly versatile due to its strength, affordability, and availability. While its actual dimensions are 1.5 inches by 3.5 inches (due to drying and planing), its uses extend far beyond framing. One of its most common applications is in structural framing, where it forms the skeleton of walls, floors, and roofs in residential and commercial buildings. Its strength-to-weight ratio makes it ideal for supporting heavy loads, ensuring stability and durability in construction projects.

For those leaning toward furniture making, 2x4s offer a cost-effective and sturdy base material. From rustic farmhouse tables to minimalist bookshelves, the lumber’s thickness and width provide a solid foundation. A practical tip: sand the edges thoroughly to avoid splinters, and consider staining or painting to enhance durability and aesthetics. For outdoor furniture, treat the wood with a weather-resistant sealant to prevent rot and warping.

In landscaping and outdoor projects, 2x4s shine as a go-to material for raised garden beds, retaining walls, and even simple benches. Their affordability allows for large-scale projects without breaking the bank. When building raised beds, line the interior with landscape fabric to prevent soil erosion and extend the wood’s lifespan. For retaining walls, stagger the boards and secure them with galvanized screws to ensure stability on uneven ground.

DIY enthusiasts often turn to 2x4s for organizational solutions, such as garage shelving or closet systems. A simple design involves cutting boards to length, attaching them to wall studs, and adding plywood shelves for a robust storage system. Pro tip: use a Kreg Jig to create pocket holes for cleaner joints and added strength. For heavier items, reinforce the shelves with metal brackets to distribute weight evenly.

Finally, 2x4s are a favorite for crafts and decorative projects, offering a blank canvas for creativity. From holiday yard decorations to custom picture frames, their simplicity allows for endless customization. For seasonal projects, consider using a jigsaw to cut intricate shapes, then prime and paint to match your theme. For a polished finish, sand between coats and seal with a clear topcoat to protect against wear and tear.

In every application, the key to maximizing 2x4 lumber’s potential lies in understanding its limitations and strengths. Whether for heavy-duty construction or lightweight crafts, this versatile material proves time and again that it’s a builder’s best friend.

Understanding Water Damage: How Long Does Wood Take to Recover?

You may want to see also

Explore related products

Actual vs. Nominal Dimensions Explained

A trip to the lumber aisle reveals a curious discrepancy: that "2x4" board isn’t actually 2 inches by 4 inches. This disconnect between what’s labeled (the nominal dimension) and what you measure (the actual dimension) is a cornerstone of the lumber industry. Understanding this difference is crucial for anyone tackling a woodworking project, as it directly impacts material calculations, structural integrity, and overall fit.

Nominal dimensions are a legacy of historical milling practices and green lumber dimensions. When freshly cut, a 2x4 is indeed close to its stated size. However, during the drying process, wood shrinks, and further planning smooths the surface, reducing its final dimensions. This shrinkage is intentional, ensuring the wood is stable and less prone to warping.

The actual dimensions of a 2x4 are typically 1.5 inches by 3.5 inches. This discrepancy isn’t a trick; it’s a standardized convention. The lumber industry uses nominal sizes for convenience and historical continuity, while actual sizes reflect the reality of the material after processing. This system, while potentially confusing at first, allows for consistent communication and planning within the industry.

This size difference has practical implications. For instance, when framing a wall, using nominal dimensions for calculations would result in gaps and misalignments. Accurate measurements based on actual dimensions are essential for a sturdy and precise build. Understanding this distinction empowers DIYers and professionals alike to make informed decisions, ensuring projects are both structurally sound and aesthetically pleasing.

Durability of Wood Frame Futons: Lifespan and Maintenance Tips

You may want to see also

Explore related products

Cutting 2x4 Wood to Size

A standard 2x4 board, despite its name, doesn't actually measure 2 inches by 4 inches. Nominally sized, it's closer to 1.5 inches by 3.5 inches due to drying and planning during manufacturing. This discrepancy is crucial when cutting 2x4s to size, as relying solely on the nominal dimensions will result in inaccurate cuts.

Understanding this size variation is the first step in ensuring your 2x4 cuts are precise.

Cutting 2x4s accurately requires the right tools. A circular saw, miter saw, or hand saw are all viable options, each with its own advantages. Circular saws offer portability and versatility, miter saws excel at making precise angled cuts, and hand saws are ideal for occasional cuts or tight spaces. Regardless of the tool, a sharp blade is essential for clean, splinter-free cuts. Dull blades can cause tearing and splintering, compromising the integrity of your project.

Remember, safety is paramount. Always wear safety glasses and ear protection when operating power tools. Secure the wood firmly before cutting and maintain a steady hand for accurate results.

Measuring twice and cutting once is a golden rule in woodworking, and it's especially crucial when working with 2x4s. Mark your cut lines clearly using a straight edge and a pencil. For added precision, consider using a speed square to ensure your lines are perfectly perpendicular to the edge of the board. If you're making multiple cuts of the same length, consider creating a cutting template from scrap wood. This ensures consistency and saves time.

When cutting, let the saw do the work. Apply steady pressure without forcing the blade. For crosscuts (cuts across the grain), support the offcut piece to prevent it from falling and potentially binding the blade.

While cutting 2x4s is a fundamental woodworking skill, there are common pitfalls to avoid. One mistake is neglecting to account for the kerf, the width of the saw blade. This can result in cuts that are slightly shorter than intended. To compensate, measure from the inside edge of your cut line to ensure accuracy. Another common error is rushing the cut, leading to uneven or jagged edges. Take your time and maintain a steady pace for clean, professional results. Finally, be mindful of the wood grain direction. Cutting against the grain can cause splintering. Whenever possible, cut with the grain for a smoother finish.

Durability of Wooden Gravel Boards: Lifespan and Maintenance Tips

You may want to see also

Explore related products

Weight and Density of 2x4 Wood

The weight of a 2x4 wood board is a critical factor in construction and DIY projects, influencing structural integrity, transportation, and cost. A standard 8-foot long 2x4 made of Douglas fir or pine typically weighs between 9 to 12 pounds, depending on moisture content and specific gravity. For longer boards, such as 10 or 12 feet, the weight increases proportionally, reaching up to 15 or 18 pounds. Understanding these weight variations is essential for planning projects, especially when handling multiple boards or working at heights.

Density plays a pivotal role in determining the weight of 2x4 wood, with denser species like oak or cedar weighing significantly more than lighter options like spruce or pine. For instance, an 8-foot oak 2x4 can weigh upwards of 15 pounds, compared to a spruce board of the same length weighing around 8 pounds. This density difference affects not only weight but also durability, strength, and resistance to moisture. When selecting wood for a project, consider the trade-offs between weight and performance to ensure the material meets your needs without unnecessary strain.

To estimate the weight of a 2x4 board accurately, use the formula: Weight (lbs) = Length (ft) × Density (lbs/ft³). For example, Douglas fir has a density of approximately 32 lbs/ft³, so an 8-foot board would weigh 8 ft × 32 lbs/ft³ / 12 (linear feet per board foot) = 21.3 lbs. However, this calculation assumes fully dry wood, which is rare in practice. For practical purposes, refer to standard weight ranges or consult supplier specifications, especially when working with exotic or treated wood.

Transporting and handling 2x4 wood requires awareness of its weight to prevent injury and damage. For DIY enthusiasts, stacking boards on a flat surface or using a cart can reduce strain, while professionals may employ forklifts or team lifts for bulk quantities. Always distribute weight evenly when loading vehicles to avoid exceeding weight limits or causing imbalance. Additionally, store wood in a dry, well-ventilated area to minimize moisture absorption, which can increase weight and compromise structural integrity over time.

In summary, the weight and density of 2x4 wood are interlinked properties that impact project feasibility and safety. By understanding species-specific densities, using estimation formulas, and adopting safe handling practices, you can optimize material selection and execution. Whether building a frame, deck, or furniture, this knowledge ensures your project stands strong without being weighed down—literally or metaphorically.

Durability of Wood Mowing Strips: Lifespan and Maintenance Tips

You may want to see also

Frequently asked questions

A standard 2 by 4 piece of wood is typically 8 feet long, which is equivalent to 96 inches or 2.44 meters.

No, due to drying and planing during manufacturing, a 2 by 4 is actually about 1.5 inches by 3.5 inches in size.

Yes, 2 by 4 wood is commonly available in various lengths, such as 10 feet, 12 feet, and 16 feet, depending on the supplier.

The weight of an 8-foot 2 by 4 piece of wood varies by wood type, but it typically weighs between 9 to 12 pounds (4 to 5.5 kilograms).