Corrugated metal wood fasteners have been a staple in construction and woodworking for over a century, with their origins tracing back to the late 19th and early 20th centuries. Initially developed to address the need for durable and reliable connections between metal and wood, these fasteners gained widespread use during the industrial revolution as building techniques evolved. By the mid-20th century, they became essential in applications ranging from roofing and siding to framing and structural supports. Today, corrugated metal wood fasteners remain a trusted solution, combining strength, versatility, and longevity, making them indispensable in both traditional and modern construction projects. Their enduring presence highlights their effectiveness and adaptability over generations of building innovation.

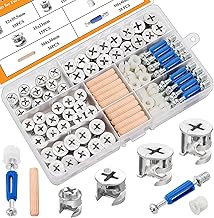

Explore related products

What You'll Learn

- History of Corrugated Metal Fasteners: Origins and early uses in construction and woodworking industries

- Material Evolution: Transition from traditional materials to modern corrugated metal for durability

- Manufacturing Process: Techniques and advancements in producing corrugated metal wood fasteners

- Applications Over Time: How usage has expanded across residential, commercial, and industrial projects

- Lifespan and Maintenance: Durability, longevity, and care tips for corrugated metal fasteners

History of Corrugated Metal Fasteners: Origins and early uses in construction and woodworking industries

Corrugated metal fasteners, often overlooked yet indispensable, have a history deeply intertwined with the evolution of construction and woodworking. Emerging in the mid-19th century, these fasteners were a response to the growing demand for durable, lightweight materials in industrializing societies. Early versions were rudimentary, crafted from galvanized steel to resist corrosion, and featured a corrugated design that enhanced grip and load-bearing capacity. Their initial use was primarily in roofing and siding, where they provided a cost-effective solution for securing corrugated metal sheets to wooden frames. This innovation marked a significant shift from traditional nails and spikes, offering greater strength and longevity in harsh environmental conditions.

The adoption of corrugated metal fasteners in woodworking came later, as craftsmen recognized their potential beyond construction. By the late 1800s, these fasteners were being used to join wooden structures in applications requiring both flexibility and durability, such as crates, pallets, and temporary frameworks. Their corrugated design allowed for better distribution of stress, reducing the risk of wood splitting compared to flat-headed nails. This made them particularly valuable in industries like shipping and agriculture, where materials needed to withstand rough handling and exposure to the elements. The fasteners’ versatility also extended to DIY projects, where their ease of use and reliability made them a staple in early woodworking kits.

A key factor in the early success of corrugated metal fasteners was their adaptability to mass production techniques. As the Industrial Revolution advanced, manufacturers began producing these fasteners in large quantities, making them widely accessible and affordable. This democratization of the technology accelerated their adoption across industries, from large-scale construction projects to small-scale woodworking shops. Innovations in metallurgy during this period further improved their performance, with advancements in galvanization and alloy composition enhancing their resistance to rust and wear. By the early 20th century, corrugated metal fasteners had become a standard component in both construction and woodworking toolkits.

Despite their widespread use, the early history of corrugated metal fasteners is often overshadowed by more glamorous innovations of the era. Yet, their impact on building practices and material efficiency cannot be overstated. For instance, their role in the construction of temporary shelters during wartime and in the rapid expansion of railroads highlights their importance in addressing urgent infrastructural needs. In woodworking, they enabled the creation of more robust and lightweight designs, influencing the development of modern furniture and packaging. Today, while newer materials and technologies have emerged, corrugated metal fasteners remain a testament to the enduring value of simple, well-engineered solutions.

Understanding the origins and early uses of corrugated metal fasteners offers valuable insights for contemporary applications. For modern woodworkers and builders, these fasteners serve as a reminder of the importance of combining strength, durability, and practicality. When selecting fasteners for projects, consider the environmental conditions and load requirements, as early users did. For restoration projects involving historic structures, using corrugated metal fasteners can maintain authenticity while ensuring structural integrity. Additionally, their history underscores the importance of innovation in addressing everyday challenges, inspiring current designers to rethink traditional materials and methods. By studying their past, we can better appreciate their role in shaping the industries we rely on today.

Spider Wood Durability: Lifespan in Aquascaping Explained

You may want to see also

Explore related products

Material Evolution: Transition from traditional materials to modern corrugated metal for durability

The evolution of construction materials reflects humanity's relentless pursuit of durability, efficiency, and adaptability. Traditional wood fasteners, while functional, often succumbed to environmental stressors like moisture, pests, and temperature fluctuations. Enter corrugated metal fasteners—a modern solution engineered to address these vulnerabilities. Their introduction marked a pivotal shift, combining the strength of metal with the flexibility of corrugated design to enhance structural integrity. But how long have these fasteners been in use, and what drove their adoption?

Historically, corrugated metal itself dates back to the early 19th century, initially used for roofing and siding due to its lightweight yet robust nature. Fasteners, however, evolved more gradually. By the mid-20th century, corrugated metal fasteners emerged as a response to the limitations of wooden alternatives, particularly in industrial and agricultural settings. These early iterations were rudimentary, often requiring manual installation and lacking the precision of today’s designs. Despite their simplicity, they demonstrated the potential of metal to outlast traditional materials in harsh conditions.

The transition to corrugated metal fasteners gained momentum in the late 20th century with advancements in manufacturing technology. High-tensile steel and galvanized coatings became standard, offering corrosion resistance and longevity. For instance, galvanized corrugated metal fasteners can withstand up to 50 years of exposure to saltwater environments, a feat unattainable with wood. This durability made them indispensable in coastal construction and outdoor applications. Additionally, the corrugated design provided better grip and load distribution, reducing the risk of material failure under stress.

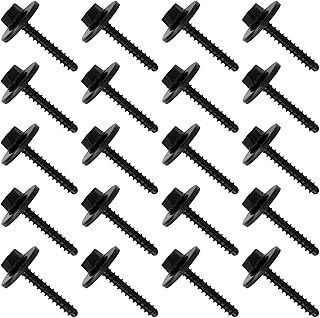

Today, corrugated metal fasteners are a staple in both residential and commercial construction. Their adoption is driven not only by durability but also by sustainability. Unlike wood, metal fasteners are recyclable, aligning with modern eco-conscious practices. Installation has also become more user-friendly, with self-drilling screws and pre-drilled holes streamlining the process. For DIY enthusiasts, a pro tip is to use a #3 Phillips bit for most corrugated metal fasteners to avoid stripping the screw head. This blend of innovation and practicality underscores why corrugated metal has become the material of choice for long-lasting structures.

In comparing traditional and modern fasteners, the advantages of corrugated metal are clear. While wooden fasteners may cost less upfront, their maintenance and replacement expenses over time often exceed those of metal alternatives. For example, a study found that corrugated metal fasteners reduced repair costs by 30% in agricultural buildings over a 20-year period. This economic efficiency, coupled with superior performance, cements their role in material evolution. As construction demands continue to grow, corrugated metal fasteners stand as a testament to the power of innovation in enhancing durability and sustainability.

Maximizing Traeger Wood Pellet Lifespan: Storage Tips and Burn Time

You may want to see also

Explore related products

Manufacturing Process: Techniques and advancements in producing corrugated metal wood fasteners

Corrugated metal wood fasteners, often referred to as corrugated fasteners or "wiggle wires," have been in use for over a century, with early patents dating back to the late 1800s. These versatile fasteners, characterized by their zigzag or corrugated design, were initially crafted through manual bending and cutting of metal strips. While the concept has remained consistent, the manufacturing process has evolved significantly, driven by advancements in technology and materials science.

From Hand Tools to Automated Machinery:

The earliest production methods relied on simple hand tools, where workers would manually bend metal strips into the corrugated shape and trim them to size. This labor-intensive process was time-consuming and limited production capacity. The introduction of mechanical presses in the early 20th century marked a turning point, enabling mass production with greater precision. Modern manufacturing now employs computer-controlled machines that cut, corrugate, and shape metal sheets in a single automated process, reducing waste and increasing efficiency. For example, high-speed stamping machines can produce thousands of fasteners per hour, a stark contrast to the dozens produced daily by hand.

Material Innovations: Strength and Durability:

Traditionally, corrugated fasteners were made from mild steel, which was prone to rust and corrosion. The development of galvanized steel and stainless steel in the mid-20th century revolutionized the industry, offering enhanced durability and resistance to environmental factors. Today, manufacturers often use pre-coated or galvanized steel sheets, which are fed into machines to create fasteners with a protective layer already in place. This eliminates the need for post-production treatments, saving time and resources. For outdoor applications, stainless steel fasteners are recommended, as they can withstand harsh weather conditions without degradation.

Precision Engineering: The Role of CAD and CNC:

The integration of Computer-Aided Design (CAD) and Computer Numerical Control (CNC) technology has further refined the manufacturing process. Engineers use CAD software to design fasteners with exacting tolerances, ensuring a perfect fit for specific applications. CNC machines then translate these designs into physical products, achieving consistency and accuracy that manual methods could never match. This precision is particularly critical in industries like construction and woodworking, where fasteners must align seamlessly with pre-drilled holes or slots.

Sustainability in Production: Reducing Environmental Impact:

As environmental concerns grow, manufacturers are adopting greener practices in corrugated fastener production. Recycling scrap metal from the cutting process has become standard, minimizing waste. Additionally, energy-efficient machinery and water-based coatings are being used to reduce the carbon footprint. Some companies are even experimenting with biodegradable materials for non-structural applications, though metal remains the industry standard for its strength and longevity.

Future Trends: Smart Fasteners and Customization:

Looking ahead, the corrugated fastener industry is poised for further innovation. The rise of "smart" fasteners, embedded with sensors to monitor structural integrity, is on the horizon. Customization is also gaining traction, with manufacturers offering fasteners in various lengths, thicknesses, and coatings to meet specific project needs. For instance, a contractor might order fasteners with a specific corrosion-resistant coating for a coastal construction project, ensuring longevity in a salty environment.

In summary, the manufacturing of corrugated metal wood fasteners has transformed from a manual craft to a high-tech, sustainable process. These advancements not only improve efficiency and durability but also open doors to new applications and customization options, ensuring the continued relevance of this century-old innovation.

Wood Green to Heathrow: Travel Time and Best Routes Explained

You may want to see also

Explore related products

Applications Over Time: How usage has expanded across residential, commercial, and industrial projects

Corrugated metal wood fasteners, often referred to as metal connectors or brackets, have been integral to construction for over a century. Initially designed for structural reinforcement in industrial settings, their applications have diversified dramatically. Today, these fasteners are ubiquitous across residential, commercial, and industrial projects, each sector leveraging their durability, versatility, and cost-effectiveness in unique ways.

Residential Projects: From Utility to Aesthetics

In the early 20th century, corrugated metal fasteners were primarily used in residential construction for structural framing, securing beams and joists in barns and homes. By the mid-1900s, their application expanded to include roofing and siding, particularly in rural areas where metal was favored for its longevity. Modern residential projects now incorporate these fasteners in both functional and decorative roles. For instance, metal brackets are used in open-concept designs to support exposed beams, blending industrial aesthetics with contemporary style. DIY enthusiasts also utilize smaller versions for shelving and furniture, combining strength with a rustic or modern look. A practical tip: when using these fasteners for visible applications, opt for galvanized or powder-coated finishes to prevent rust and enhance visual appeal.

Commercial Construction: Scaling Up Efficiency

Commercial projects began adopting corrugated metal fasteners in the mid-20th century, driven by the need for rapid, cost-effective construction. These fasteners became essential in building large-scale structures like warehouses and retail spaces, where they secured metal roofing, wall panels, and structural frameworks. Today, their use extends to modular construction, where pre-fabricated components rely on metal connectors for quick assembly. For example, a typical commercial roofing project might use over 1,000 fasteners per 1,000 square feet, ensuring wind and weather resistance. Architects and contractors should prioritize corrosion-resistant materials, such as stainless steel or zinc-coated fasteners, to withstand environmental stressors in commercial settings.

Industrial Applications: The Backbone of Heavy-Duty Construction

Industrial projects have long been the primary domain of corrugated metal fasteners, where their strength and reliability are non-negotiable. From the early days of factory construction to modern power plants and manufacturing facilities, these fasteners secure critical components like trusses, purlins, and heavy machinery mounts. In industrial settings, the focus is on load-bearing capacity and safety. For instance, high-tensile steel fasteners are often specified for applications requiring support of 500+ pounds per connection. A cautionary note: always consult engineering specifications and local building codes when using these fasteners in industrial projects, as improper installation can lead to catastrophic failures.

Cross-Sector Innovations: Bridging Gaps in Design and Function

The 21st century has seen corrugated metal fasteners evolve beyond their traditional roles, thanks to advancements in materials and design. Hybrid applications, such as combining wood and metal in mixed-use buildings, are now common. For example, a commercial-residential complex might use metal fasteners to secure timber framing in residential units while integrating them into the steel framework of commercial spaces. This cross-sector innovation highlights the fasteners’ adaptability. A takeaway: when planning multi-use projects, consider standardized fastener systems that comply with both residential and commercial building codes, streamlining procurement and installation.

Future Trends: Sustainability and Smart Construction

As construction trends shift toward sustainability, corrugated metal fasteners are poised to play a key role. Their longevity reduces the need for frequent replacements, while recyclable materials like aluminum are gaining popularity. Additionally, smart construction technologies, such as pre-drilled panels and self-tapping fasteners, are simplifying installation across all sectors. For instance, a residential builder might save 20% on labor costs by using pre-fabricated metal-framed wall systems. To stay ahead, professionals should explore eco-friendly options and invest in training for emerging fastening technologies.

In summary, the journey of corrugated metal wood fasteners from industrial necessity to versatile construction staple reflects their enduring utility. By understanding their evolving applications, builders and designers can maximize their potential across residential, commercial, and industrial projects.

Understanding Wood Dust Settling Time: Factors and Practical Tips

You may want to see also

Explore related products

Lifespan and Maintenance: Durability, longevity, and care tips for corrugated metal fasteners

Corrugated metal fasteners, often used in roofing and siding applications, have been a staple in construction for over a century. Their durability and versatility make them a preferred choice for securing corrugated metal sheets to wood structures. Understanding their lifespan and maintenance requirements is crucial for maximizing their performance and longevity.

Material Composition and Durability

Corrugated metal fasteners are typically made from galvanized steel or stainless steel, both of which offer exceptional resistance to corrosion and weathering. Galvanized steel fasteners, coated with a zinc layer, can last 20–50 years depending on environmental conditions. Stainless steel, while more expensive, provides superior longevity, often exceeding 50 years in moderate climates. The key to their durability lies in the material’s ability to withstand rust, UV exposure, and temperature fluctuations. However, in coastal or highly humid areas, even these robust materials may require additional protective coatings or more frequent inspections.

Factors Affecting Longevity

Several factors influence how long corrugated metal fasteners remain effective. Exposure to saltwater or industrial pollutants accelerates corrosion, reducing lifespan by up to 30%. Poor installation, such as over-tightening or using mismatched fasteners, can cause metal fatigue or damage the wood substrate. Additionally, thermal expansion and contraction of the metal sheets can loosen fasteners over time. Regular inspections, particularly after extreme weather events, are essential to identify and address these issues early.

Maintenance and Care Tips

To ensure optimal performance, inspect fasteners annually for signs of rust, loosening, or damage. Tighten any loose fasteners with a wrench, being careful not to overtighten, as this can strip the threads or warp the metal. For galvanized fasteners showing early signs of corrosion, apply a zinc-rich primer or paint to extend their life. In high-corrosion environments, consider replacing galvanized fasteners with stainless steel ones every 15–20 years. Keep the surrounding area clean to prevent debris buildup, which can trap moisture and accelerate deterioration.

Comparative Analysis: Fastener Types

While traditional corrugated metal fasteners dominate the market, modern alternatives like coated screws and self-drilling fasteners offer unique advantages. Coated screws, often featuring ceramic or polymer coatings, provide enhanced corrosion resistance and can last up to 40 years in harsh conditions. Self-drilling fasteners reduce installation time but may be less durable in long-term applications. For most residential projects, galvanized or stainless steel fasteners remain the most cost-effective and reliable option, balancing durability with affordability.

Practical Takeaway

The lifespan of corrugated metal fasteners hinges on material quality, environmental conditions, and maintenance practices. By selecting the right material, ensuring proper installation, and conducting regular inspections, you can extend their life significantly. For example, in a coastal home, investing in stainless steel fasteners and inspecting them biannually can save thousands in replacement costs over decades. With thoughtful care, these unassuming components can outlast many other elements of a building’s exterior.

Charlie Woods' Driver Distance: Unveiling the Young Golfer's Power

You may want to see also

Frequently asked questions

Corrugated metal wood fasteners, also known as corrugated fasteners or "wiggle wires," have been in use for over a century, with their origins dating back to the late 19th century.

Originally, corrugated metal wood fasteners were designed for securing corrugated metal roofing and siding to wooden structures, providing a durable and weather-resistant connection.

Yes, while the basic design remains similar, modern versions have improved materials and coatings to enhance corrosion resistance and longevity.

Yes, they are still widely used in construction, particularly for roofing, fencing, and agricultural applications, due to their simplicity, affordability, and effectiveness.

While newer fastening methods exist, corrugated metal wood fasteners remain popular for their ease of installation, low cost, and proven reliability in traditional and rustic construction projects.