The question how long is a piece of wood? may seem straightforward, but it opens up a fascinating exploration into the variability and purpose of wood as a material. Wood lengths can range from mere inches, such as in small craft projects or kindling, to several feet or even meters for construction beams or furniture. The length of a piece of wood is often dictated by its intended use, the type of tree it comes from, and the manufacturing or cutting process. Understanding these factors not only sheds light on the practical aspects of woodworking and construction but also highlights the natural diversity and adaptability of this essential resource.

Explore related products

What You'll Learn

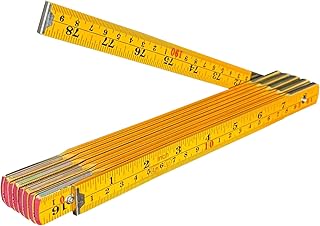

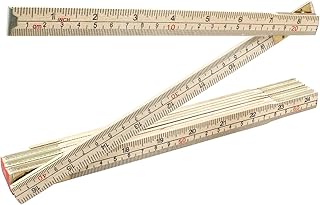

- Measuring wood length accurately using standard tools like tape measures or rulers

- Common wood lengths for construction, furniture, and DIY projects

- Factors affecting wood length, such as cutting, warping, or shrinkage

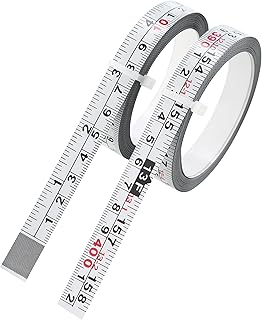

- Converting wood measurements between inches, feet, meters, and centimeters

- Determining wood length for specific applications like framing or crafting

Measuring wood length accurately using standard tools like tape measures or rulers

Accurate measurement of wood length is a fundamental skill in carpentry, woodworking, and DIY projects. The precision of your measurements directly impacts the fit, stability, and overall quality of your work. Whether you’re building furniture, framing a house, or crafting a simple shelf, knowing how to use standard tools like tape measures or rulers effectively is essential. These tools are ubiquitous, affordable, and versatile, making them the go-to choice for most woodworkers. However, their simplicity can be deceiving—proper technique is key to avoiding errors that could derail your project.

To measure wood length accurately, start by selecting the right tool for the job. A tape measure is ideal for longer pieces, offering flexibility and ease of use, while a ruler or straightedge is better suited for shorter, more precise measurements. Ensure the tool is clean and free of debris, as even small particles can throw off your reading. Place the zero end of the tape measure or ruler firmly against one end of the wood, aligning it with the edge for consistency. For longer pieces, it’s helpful to have a second person hold the wood steady to prevent shifting. Read the measurement at eye level to avoid parallax errors, which occur when the angle of viewing distorts the reading.

One common mistake is failing to account for the hook at the end of a tape measure. This hook, designed to grab edges, is calibrated to provide accurate measurements only when pulled out or pushed against a surface. If you’re measuring the inside length of a piece (e.g., the distance between two points), use the inner markings on the tape. Conversely, for outside measurements, rely on the outer edge of the hook. Always double-check your measurements by taking a second reading. If using a ruler, mark the length lightly with a pencil before cutting to ensure accuracy.

Environmental factors can also affect wood measurements. Wood expands and contracts with changes in humidity and temperature, so measure and cut wood in the same environment where it will be used. For example, wood intended for outdoor projects should be measured and cut in conditions similar to its final placement. Additionally, always measure from the longest point of irregular or bowed wood to ensure a proper fit. If precision is critical, consider using a digital caliper for measurements under 6 inches, as they offer accuracy to the nearest hundredth of an inch.

In conclusion, measuring wood length accurately with standard tools requires attention to detail, the right technique, and awareness of potential pitfalls. By choosing the appropriate tool, aligning it correctly, and accounting for environmental factors, you can achieve reliable results. Practice makes perfect—the more you measure, the more intuitive the process becomes. With these skills, you’ll ensure your woodworking projects are not only functional but also professionally finished.

Durability of Wooden Fences in the UK: Lifespan and Maintenance Tips

You may want to see also

Explore related products

$16.99 $20.99

Common wood lengths for construction, furniture, and DIY projects

Wood lengths vary widely depending on the application, but construction projects typically rely on standardized dimensions for efficiency and compatibility. Common lengths for structural lumber include 8, 10, 12, 14, 16, and 20 feet, with 8 and 16 feet being the most prevalent. These lengths align with standard wall heights and spacing in residential framing, reducing waste and simplifying planning. For instance, a 16-foot 2x4 is ideal for top and bottom plates in an 8-foot-tall wall, while 8-foot studs are often cut to fit between them. Always verify local building codes, as some regions mandate specific lengths for load-bearing structures.

Furniture projects demand precision and often use shorter, more manageable lengths. Common dimensions include 6, 7, and 8 feet for tabletops, shelving, and casework. For example, a standard dining table might require a 6-foot-long hardwood board, while a bookshelf could use 7-foot pine boards for vertical dividers. When sourcing wood, consider the grain direction and potential for warping—longer boards are more prone to twisting, so opt for lengths that minimize waste while maintaining stability. Pre-cut furniture kits often include 4- to 6-foot sections to simplify assembly for DIYers.

DIY projects benefit from versatility, and shorter lengths are frequently preferred for ease of handling. Common lengths for small-scale projects range from 2 to 6 feet, with 4-foot sections being particularly popular for crafts, shelving, and decorative elements. For example, a 4-foot 1x6 board is perfect for a floating shelf, while 2-foot lengths are ideal for picture frames or planter boxes. When working with plywood, 4x8 feet is the standard sheet size, but many suppliers offer pre-cut halves (2x8 feet) or quarters (2x4 feet) for smaller projects. Always measure twice and cut once to avoid costly mistakes.

Comparing construction, furniture, and DIY applications highlights the importance of matching wood length to project scale. While construction prioritizes long, standardized lengths for structural integrity, furniture and DIY projects favor shorter, more customizable dimensions. For instance, a 20-foot 2x10 beam might support a second-story floor, but a 5-foot hardwood plank is better suited for a coffee table. When selecting wood, consider not only the length but also the thickness and species, as these factors influence both cost and performance. Pro tip: Buy slightly longer boards than needed to account for cutting errors or future adjustments.

Mahogany Wood Durability: Lifespan, Care, and Longevity Explained

You may want to see also

Explore related products

Factors affecting wood length, such as cutting, warping, or shrinkage

Wood length is not a fixed attribute but a dynamic characteristic influenced by various factors, each leaving its mark on the final measurement. Cutting, for instance, is the most immediate and controllable factor. The precision of the cut determines the length of the wood piece. A miter saw can achieve an accuracy of ±1 millimeter, while a handheld circular saw may vary by up to ±3 millimeters. For projects requiring tight tolerances, such as cabinetry, investing in a high-precision tool and using a sharp blade is essential. Dull blades can cause splintering or uneven cuts, adding variability to the length.

Warping introduces unpredictability into wood length, often due to moisture imbalance. Wood is hygroscopic, meaning it absorbs or releases moisture depending on the surrounding humidity. A 2-inch-thick hardwood board can warp by as much as 1/4 inch if one side dries faster than the other. To mitigate this, acclimate wood to the environment where it will be used. For example, store lumber in a workshop for at least two weeks before cutting to allow it to reach equilibrium moisture content (EMC), typically around 6-8% for indoor projects. Additionally, seal all sides of the wood with a moisture-resistant finish to minimize warping after cutting.

Shrinkage is another critical factor, particularly for green wood or wood stored in humid conditions. As wood dries, it can shrink by 1-2% in length, depending on the species. For instance, a 10-foot piece of oak might lose up to 2 inches as it dries. To account for shrinkage, cut wood slightly longer than the final desired length and allow it to dry completely before making final adjustments. For structural applications, such as framing, use kiln-dried lumber, which has been dried to a consistent moisture level, reducing the risk of significant shrinkage post-installation.

Understanding these factors allows for better planning and execution of woodworking projects. For example, when building a wooden table, cut the legs 1/8 inch longer than needed to account for potential shrinkage and sanding. Regularly inspect wood for signs of warping during the drying process, and use clamps or weights to correct minor distortions. By anticipating how cutting, warping, and shrinkage affect wood length, craftsmen can achieve more precise and durable results, ensuring that the final piece meets both functional and aesthetic requirements.

How Quickly Does Mold Grow on Wet Wood? A Timeline

You may want to see also

Explore related products

Converting wood measurements between inches, feet, meters, and centimeters

Wood measurements often vary by region, trade, and application, making conversions between inches, feet, meters, and centimeters a practical necessity. In the United States, wood lengths are typically measured in inches and feet, with common sizes like 2x4s or 8-foot planks. In contrast, most of the world uses the metric system, where wood might be sold in meters or centimeters. Understanding these conversions ensures accuracy in purchasing, cutting, and construction. For instance, a standard 8-foot board is 96 inches, which converts to approximately 2.44 meters or 244 centimeters.

To convert wood measurements effectively, start by mastering the basic ratios. One foot equals 12 inches, and one inch is 2.54 centimeters. To convert feet to meters, multiply by 0.3048. For example, a 10-foot piece of wood is 10 × 0.3048 = 3.048 meters. Conversely, to convert meters to feet, divide by 0.3048. A 2-meter board is 2 ÷ 0.3048 ≈ 6.56 feet. These calculations are straightforward but require attention to detail, especially when dealing with fractional measurements common in woodworking.

Practical tips can streamline the conversion process. For quick estimates, remember that 1 meter is roughly 39.37 inches, and 1 foot is about 30 centimeters. When working with lumber, round measurements to the nearest quarter-inch or half-centimeter for simplicity. Use digital tools like smartphone apps or online converters for precision, especially in critical projects. Labeling wood with both imperial and metric measurements can also prevent errors on the job site.

Cautions are necessary when converting measurements, particularly in mixed-system environments. Double-check units before cutting wood, as a mistake in conversion can lead to wasted material. For example, confusing inches with centimeters could result in a board being cut 2.54 times shorter than intended. Always verify the source of the measurement—whether it’s from a U.S. supplier (likely in feet/inches) or a metric-based supplier (meters/centimeters). Consistency in units throughout a project is key to avoiding costly errors.

In conclusion, converting wood measurements between inches, feet, meters, and centimeters is a skill that bridges regional and professional divides. By understanding the ratios, employing practical tips, and exercising caution, woodworkers and builders can ensure accuracy and efficiency. Whether crafting furniture or framing a house, mastering these conversions transforms a piece of wood from a raw material into a precisely measured component of a larger creation.

Drying Green Wood: Essential Tips for Optimal Time and Techniques

You may want to see also

Explore related products

$29.59 $31.19

Determining wood length for specific applications like framing or crafting

Wood length is not a one-size-fits-all measurement; it varies dramatically based on the application. For framing, standard stud lengths in residential construction are 8, 9, or 10 feet, chosen to align with common ceiling heights and minimize waste. Crafting, however, demands precision tailored to the project—a wooden spoon might require a 12-inch handle, while a furniture leg could need a 24-inch piece. Understanding these application-specific needs is the first step in determining the right wood length.

In framing, the rule of thumb is to match wood length to structural requirements. For example, a wall with a 9-foot ceiling typically uses 92 ⅝-inch studs to account for bottom and top plates, ensuring stability and code compliance. Deviating from these standards can compromise integrity or lead to unnecessary material costs. Always measure twice and consider load-bearing needs before cutting.

Crafting, on the other hand, thrives on creativity but still requires careful planning. A wooden toy car might need a 6-inch base, while a custom picture frame could demand lengths proportional to the artwork. Here, flexibility is key—use a miter saw for precise cuts and sand edges to ensure safety and aesthetics. Keep a sketch or template handy to avoid errors.

Comparing framing and crafting highlights the importance of context. While framing prioritizes uniformity and structural safety, crafting emphasizes individuality and detail. For instance, a framer might bulk-order 2x4s in 8-foot lengths, while a crafter may repurpose scrap wood for a unique project. Both applications benefit from understanding wood dimensions but apply that knowledge differently.

To streamline the process, start by listing project requirements, then source wood lengths accordingly. For framing, consult building plans or industry standards; for crafting, let design dictate dimensions. Always factor in material waste and consider purchasing slightly longer pieces to allow for adjustments. Whether building a house or a birdhouse, the right wood length begins with purpose-driven planning.

Wood Gorilla Glue Drying Time: Quick Guide to Perfect Bonding

You may want to see also

Frequently asked questions

The length of a piece of wood varies depending on its purpose and source. Common lengths include 8 feet, 10 feet, and 12 feet for lumber, but custom lengths are also available.

Yes, in construction and woodworking, standard lengths for lumber are typically 8 feet, 10 feet, 12 feet, and 16 feet, though this can vary by region and supplier.

Use a tape measure or ruler to measure from one end of the wood to the other along its longest dimension, ensuring the tool is straight for an accurate reading.

Yes, wood can be cut to any desired length, though standard lengths are more common and cost-effective. Custom lengths may require special ordering or cutting.