When working with glued wood, knowing how long to keep clamps on is crucial for ensuring a strong and durable bond. The clamping time depends on several factors, including the type of glue used, the wood species, and the environmental conditions such as temperature and humidity. Typically, fast-setting wood glues may require clamping for as little as 30 minutes to an hour, while slower-drying options like polyurethane or epoxy glues might need clamping for several hours or even overnight. It’s essential to follow the manufacturer’s recommendations for the specific glue being used, as improper clamping time can result in weak joints or glue failure. Additionally, maintaining consistent pressure during the clamping period is vital to achieving a tight and even bond. Always allow the glue to cure fully before removing clamps and subjecting the joint to stress.

| Characteristics | Values |

|---|---|

| Clamp Time for Wood Glue | 30 minutes to 1 hour (for most common wood glues like PVA) |

| Clamp Time for Epoxy Glue | 4 to 24 hours (depending on epoxy type and manufacturer instructions) |

| Clamp Time for Polyurethane Glue | 30 minutes to 2 hours (expands and foams during curing) |

| Clamp Time for Hide Glue | 15 to 30 minutes (natural glue with shorter open time) |

| Clamp Pressure | 100-150 PSI (pounds per square inch) for optimal bonding |

| Minimum Clamp Time | 30 minutes (even if glue sets faster, clamping ensures proper alignment) |

| Cure Time Before Stress | 24 hours (avoid stressing the joint until fully cured) |

| Environmental Factors | Higher humidity/temperature speeds up curing; lower slows it down |

| Wood Type Impact | Dense hardwoods may require longer clamping than softwoods |

| Joint Type Impact | Edge-to-edge joints may need less time than complex joints |

| Glue Brand Variability | Always follow manufacturer instructions for specific clamp/cure times |

| Safety Precautions | Avoid over-tightening clamps to prevent wood damage |

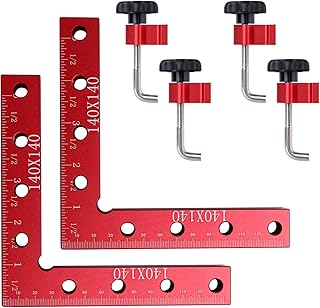

Explore related products

What You'll Learn

Clamping Time for Different Glues

The clamping time for glued wood hinges on the adhesive’s chemistry and curing mechanism. Polyvinyl acetate (PVA) glues, commonly known as white or yellow wood glues, typically require 30 minutes to 1 hour of clamping under moderate pressure for initial set. However, full curing takes 24 hours, during which clamps should remain in place to ensure bond integrity. Epoxy resins, on the other hand, demand a different approach. Most two-part epoxies achieve handling strength within 6 to 8 hours but need 24 to 48 hours for complete curing. Clamps must stay on until the epoxy reaches its specified cure time, as premature removal risks joint failure. Understanding these timelines ensures optimal adhesion and structural stability.

For cyanoacrylate (super glue), the clamping strategy shifts dramatically. This adhesive sets in seconds to minutes, depending on the formulation. While initial bonding occurs rapidly, clamps should remain for at least 10 minutes to prevent shifting. Full strength is achieved within an hour, but thin applications may cure faster. Super glue’s speed makes it ideal for small joints or quick repairs, but its brittleness limits use in high-stress applications. Always apply sparingly to avoid runoff and ensure even clamping pressure to maximize bond effectiveness.

Hide glue, a traditional adhesive, requires precise temperature control and clamping discipline. Liquid hide glue sets within 15 to 30 minutes when applied warm (120°F to 140°F), but clamps must stay on for at least 2 hours to ensure proper bonding. Hot hide glue, applied at 160°F to 180°F, sets almost instantly but still needs 1 to 2 hours under clamps. This adhesive’s reversibility—it can be softened with heat for adjustments—makes it valuable for fine woodworking. However, its sensitivity to moisture and temperature demands careful handling and extended clamping to avoid joint weakness.

Polyurethane glue, such as Gorilla Glue, expands as it cures, creating a foam-like bond. Clamping time varies based on humidity and wood density, but initial set occurs within 1 to 2 hours. Clamps should remain for at least 6 hours, with full curing taking 24 hours. This adhesive’s expansion properties require careful application—use sparingly to prevent excess foam from compromising the joint. Over-clamping can distort the wood, so apply moderate, even pressure. Ideal for indoor projects, polyurethane glue’s water resistance and strong bond make it a versatile choice, but its clamping requirements must be respected for best results.

In summary, clamping times are not one-size-fits-all. PVA glues need 24 hours under clamps for full strength, while epoxies demand up to 48 hours. Super glue’s rapid set allows clamp removal in minutes, and hide glue requires 1 to 2 hours with temperature considerations. Polyurethane glue’s 6-hour clamping period accommodates its unique expansion. Each adhesive’s curing profile dictates clamping duration, and adhering to these guidelines ensures durable, reliable wood joints. Always consult manufacturer instructions for specific products, as formulations and environmental factors can influence performance.

Wood Glue Drying Time: When Can You Safely Start Sawing?

You may want to see also

Explore related products

Ideal Pressure for Wood Clamps

Applying excessive pressure when clamping glued wood can lead to joint failure, while insufficient pressure results in weak bonds. The ideal clamping pressure depends on the wood species, glue type, and joint design. Hardwoods like oak and maple require more pressure (100–150 psi) than softwoods like pine (50–75 psi) due to their denser cell structure. Epoxy and polyurethane glues, which cure under pressure, demand higher clamping force (150–200 psi) compared to PVA wood glues (75–125 psi). Always refer to the glue manufacturer’s recommendations for precise pressure values.

To achieve consistent pressure, use a clamp pressure gauge or follow the "nickel test." Place a nickel between the wood pieces and tighten the clamp until the coin is flattened but not torn. This ensures even distribution without crushing the wood fibers. For larger projects, distribute clamps every 6–8 inches along the joint to maintain uniform pressure. Avoid over-tightening by using a torque wrench or tightening clamps incrementally, allowing the glue to flow evenly into the joint.

The duration of clamping is directly tied to the pressure applied. Insufficient pressure prolongs curing time, while excessive pressure can squeeze out too much glue, weakening the bond. For PVA glues, maintain ideal pressure for at least 30 minutes to 1 hour, depending on humidity and temperature. Epoxy and polyurethane glues may require 2–4 hours under consistent pressure. Always allow the glue to cure fully before removing clamps, even if the joint feels solid.

Advanced techniques, such as using cauls or sacrificial boards, help distribute pressure more evenly, especially for curved or irregular joints. Cauls, made from hardwood or plastic, conform to the wood’s shape and prevent indentation. For edge-gluing panels, apply clamps at a slight angle (15–20 degrees) to the joint to maximize pressure along the glue line. Regularly inspect clamps for wear and replace damaged components to ensure accurate pressure application.

In summary, ideal clamping pressure is a balance of force, time, and technique. Tailor pressure to the wood and glue type, use tools to monitor consistency, and allow sufficient curing time. Mastering this balance ensures strong, durable joints that withstand the test of time and use.

Mastering Smoking: Optimal Wood Chip Soaking Time for Perfect Flavor

You may want to see also

Explore related products

Glue Drying Time Factors

The time required to keep clamps on glued wood isn’t a one-size-fits-all answer. Glue drying time hinges on several interrelated factors, each playing a critical role in determining how long your clamps need to stay in place. Understanding these variables ensures a strong, durable bond and prevents premature joint failure.

Let’s break down the key factors influencing glue drying time:

Glue Type: Different glues have distinct curing mechanisms and drying times. Polyvinyl acetate (PVA) glues, commonly used for woodworking, typically require clamping for 30 minutes to an hour for initial tack, but full cure times can range from 18 to 24 hours. Epoxy resins, known for their superior strength, often demand longer clamping times, sometimes up to 24 hours, with full curing taking several days. Cyanoacrylate (super glue) sets rapidly, often within seconds to minutes, but clamping for a few minutes ensures proper bonding. Always refer to the manufacturer’s instructions for specific drying times and clamping recommendations.

Wood Species and Moisture Content: Wood density and moisture content significantly impact glue drying. Denser woods like oak or maple absorb moisture more slowly, potentially extending drying time. Conversely, softer woods like pine may allow for faster curing. High moisture content in the wood can dilute the glue, slowing down the drying process. Ideally, wood should be kiln-dried to a moisture content of 6-8% for optimal glue performance.

Environmental Conditions: Temperature and humidity play a crucial role in glue drying. Most wood glues cure best at room temperature (65-80°F or 18-27°C). Higher temperatures can accelerate drying, but excessive heat can weaken the bond. Conversely, cold temperatures slow down curing. Humidity levels also matter; high humidity can prolong drying time, while low humidity can cause the glue to dry too quickly, potentially leading to a weak bond. Aim for a controlled environment with moderate temperature and humidity for best results.

Clamp Pressure and Joint Fit: Adequate clamping pressure is essential for a strong bond. Insufficient pressure can result in gaps or weak spots. As a general rule, apply enough pressure to close the joint completely without forcing the wood pieces apart. The joint fit also matters; a tight, well-fitted joint allows for better glue distribution and faster drying.

Project Requirements: The intended use of the glued piece dictates the necessary drying time. For structural applications, such as furniture or cabinetry, allow for the full recommended curing time to ensure maximum strength. For less critical projects, like decorative items, shorter clamping times may suffice. Always prioritize safety and durability, especially for load-bearing structures.

Ronnie Wood's Enduring Journey with The Rolling Stones: Timeline

You may want to see also

Explore related products

Removing Clamps Safely

The timing of clamp removal is a delicate balance between ensuring a strong bond and avoiding joint failure. While glue manufacturers provide curing time guidelines, the real challenge lies in understanding when the glue has reached sufficient strength to withstand the stress of clamp removal. This critical point varies depending on factors like glue type, wood species, joint design, and environmental conditions.

Rushing to remove clamps before the glue is fully cured can lead to joint separation, compromising the integrity of your project. Conversely, leaving clamps on for too long can cause unnecessary stress on the wood fibers, potentially leading to warping or cracking.

Understanding Glue Curing Times:

Different glues have distinct curing times. Epoxy resins, for example, typically require 24 hours for initial curing and up to 72 hours for full strength. Polyurethane glues cure faster, often reaching full strength within 6-8 hours. PVA (white) glues generally need 30 minutes to an hour for initial tack, but full curing can take 24 hours or more. Always refer to the manufacturer's instructions for specific curing times.

Factors Influencing Clamp Removal Time:

Beyond glue type, several factors influence when it's safe to remove clamps:

- Wood Species: Dense hardwoods like oak or maple require longer clamping times compared to softer woods like pine or cedar.

- Joint Design: Complex joints with more glue surface area need more time to cure than simple butt joints.

- Environmental Conditions: Warmer temperatures accelerate curing, while colder temperatures slow it down. High humidity can also affect curing time.

Safe Clamp Removal Techniques:

Once you've determined the appropriate clamping time, follow these steps for safe removal:

- Gradual Release: Don't abruptly remove all clamps at once. Loosen one clamp at a time, allowing the joint to adjust gradually to the release of pressure.

- Inspect the Joint: After removing a clamp, carefully inspect the joint for any signs of movement or separation. If the joint feels loose or shows gaps, reapply the clamp and allow more curing time.

- Support the Workpiece: As you remove clamps, support the workpiece to prevent it from shifting or warping under its own weight.

- Clean Excess Glue: Once all clamps are removed, carefully clean any excess glue squeeze-out with a damp cloth. Allow the glue to fully cure before sanding or finishing.

Remember: Patience is key when it comes to removing clamps from glued wood. By understanding the factors influencing curing time and employing safe removal techniques, you can ensure strong, durable joints that will stand the test of time.

Wood Roach Lifespan: How Long Until They Perish Naturally?

You may want to see also

Explore related products

Effects of Wood Type on Clamping

The density and porosity of wood significantly influence how long clamps should remain on glued joints. Hardwoods like oak or maple, with their tight grain structure, require longer clamping times—typically 24 to 48 hours—to ensure the adhesive penetrates and cures fully. Softer woods like pine or cedar, being more porous, allow glue to wick quickly, often needing only 12 to 24 hours. Ignoring these differences risks weak joints or glue starvation, where the adhesive is drawn into the wood instead of bonding surfaces effectively.

Consider the moisture content of the wood, as it directly affects clamping duration. Green or freshly milled wood, with higher moisture levels, can cause glue to cure unevenly or swell, compromising the joint. For such cases, extend clamping time by 50% to account for moisture migration. Kiln-dried or well-seasoned wood, with stable moisture content, adheres to standard clamping times. Always measure moisture levels with a wood moisture meter to ensure optimal conditions for gluing.

Exotic woods like teak or mahogany introduce additional challenges due to natural oils or resins. These substances can repel water-based glues, necessitating longer clamping times—up to 72 hours—to ensure proper adhesion. For best results, lightly sand the mating surfaces to remove oils and use a solvent-based adhesive. Clamping pressure must also be higher to counteract the wood’s natural resistance, but avoid over-tightening to prevent crushing the fibers.

Finally, the grain orientation of the wood impacts clamping strategy. End-grain joints, where wood fibers are perpendicular to the glue line, require significantly more clamping time—often double that of edge or face grain joints. This is because end grain absorbs glue rapidly, leaving less adhesive for bonding. Use thicker glue applications and maintain pressure for at least 36 hours to compensate. For critical joints, consider mechanical fasteners as a supplement to ensure long-term stability.

Ideal Wooden Fence Post Length for Corner Posts: A Comprehensive Guide

You may want to see also

Frequently asked questions

Keep clamps on glued wood for at least 30 minutes to 2 hours, depending on the type of glue used. Follow the glue manufacturer’s instructions for best results.

No, even if the glue feels dry to the touch, it’s essential to keep the clamps on for the recommended time to ensure a strong bond and proper curing.

The type of wood doesn’t significantly impact clamping time, but denser woods may require more pressure. Always follow the glue’s instructions regardless of the wood type.

Removing clamps too early can result in a weak bond, gaps, or misalignment in the joint, as the glue may not have fully cured or set properly.

For larger or thicker pieces, it’s often recommended to keep clamps on for the full curing time of the glue, which can be up to 24 hours for some types of adhesive. Always check the glue’s instructions.

![Right Angle Clamp, Housolution [4 PACK] Single Handle 90° Aluminum Alloy Corner Clamp, Clamps for Woodworking Adjustable Swing Jaw, Woodworking Tools Photo Frame Vise Holder, Gifts for Men Dad](https://m.media-amazon.com/images/I/71xNSiBOZ+L._AC_UL320_.jpg)