Installing wood decking is a popular home improvement project that can enhance outdoor living spaces, but the time required varies significantly based on several factors. The size of the deck, the complexity of the design, the type of wood used, and the skill level of the installer all play crucial roles in determining the duration. On average, a small, straightforward deck (around 10x10 feet) can take a DIY enthusiast with moderate experience about 2 to 3 days to complete, while larger or more intricate designs may require a week or more. Professional installation typically speeds up the process, often completing the job in 1 to 3 days, depending on the scope. Additionally, factors like weather conditions, site preparation, and the need for permits can further influence the timeline. Proper planning and understanding these variables are essential for a successful and efficient decking project.

| Characteristics | Values |

|---|---|

| Average Installation Time | 1-3 days for a small deck (100-300 sq. ft), 3-7 days for a large deck (500+ sq. ft) |

| Preparation Time | 1-2 days (includes planning, permits, and site preparation) |

| Framing Time | 1-2 days (depends on deck size and complexity) |

| Decking Board Installation Time | 1-2 days for a small deck, 2-4 days for a large deck |

| Railing & Stairs Installation | 1-2 days (if included) |

| Finishing & Cleanup | 1 day (includes staining, sealing, and site cleanup) |

| Drying Time for Finishes | 24-48 hours (if staining or sealing is applied) |

| Weather Impact | Can add 1-3 days if weather delays occur |

| Professional vs. DIY | Professionals: 50-75% faster than DIY |

| Material Complexity | Exotic hardwoods or intricate designs may add 1-2 days |

| Site Accessibility | Difficult access can add 1 day or more |

| Permit Processing Time | 1-4 weeks (varies by location, not included in installation time) |

Explore related products

What You'll Learn

Preparation and Planning Time

Before the first board is laid, the success of your wood decking project hinges on meticulous preparation and planning. This phase, often underestimated, can consume 20-40% of your total project timeline, depending on complexity. For a standard 200-square-foot deck, expect to dedicate 2-4 days to this stage. Begin by assessing your site: check local building codes, ensure compliance with zoning laws, and verify if permits are required—a step that alone can add weeks if overlooked. Soil testing is critical for larger decks; unstable ground may necessitate additional footings or ground reinforcement, extending prep time by 3-5 days.

Analyzing your material needs is equally vital. Calculate the exact quantity of decking boards, joists, screws, and fasteners, factoring in a 10% waste allowance for cuts and errors. For exotic hardwoods or specialty finishes, lead times for material delivery can stretch to 2-4 weeks, particularly during peak construction seasons. Use digital tools like deck calculators to streamline this process, but always double-check measurements manually. A miscalculation here can derail your timeline and budget, turning a weekend project into a month-long ordeal.

Persuasive planning extends beyond logistics to design considerations. Sketching a detailed layout or using 3D modeling software can save hours of on-site adjustments. Incorporate features like built-in benches, lighting, or multi-level designs early to avoid mid-project revisions. For example, integrating a pergola requires additional post placements and structural support, adding 1-2 days to prep time. Engage with professionals for complex designs; a structural engineer’s consultation, though costing $300-$500, can prevent costly mistakes and ensure safety compliance.

Comparatively, DIY enthusiasts often rush through this phase, lured by the promise of quick results. However, professional contractors allocate 30-50% more time to preparation, recognizing its impact on efficiency and longevity. For instance, pre-treating wood with sealants or stains before installation—a step many skip—can add a day but extends the deck’s lifespan by 5-10 years. Similarly, renting specialized tools like post-hole diggers or laser levels upfront prevents delays caused by manual labor or inaccurate measurements.

Descriptively, envision your workspace: clear the area of debris, mark utility lines to avoid hazardous strikes, and establish a staging zone for materials. For elevated decks, ensure scaffolding or ladders are available and comply with safety standards. Weatherproofing your plan is crucial; rain can halt excavation or staining, so monitor forecasts and schedule flexible buffer days. By treating preparation as a project in itself, you transform potential obstacles into manageable tasks, setting a foundation for a seamless installation process.

How Long Does It Take for Large Wood to Sink in an Aquarium?

You may want to see also

Explore related products

Material Gathering Duration

The time required to gather materials for a wood decking project is a critical phase that can significantly impact the overall timeline. On average, this stage takes 1 to 3 weeks, depending on factors like material availability, supplier lead times, and project complexity. For instance, standard pressure-treated lumber is often readily available at local hardware stores, while exotic hardwoods like Ipe or Tigerwood may require special orders with lead times of 2–4 weeks. Planning ahead is essential; start by creating a detailed material list, including decking boards, joists, screws, and fasteners, ensuring quantities are accurate to avoid delays.

Analyzing the supply chain reveals that seasonal demand can affect material availability. During peak construction seasons (spring and summer), suppliers may experience shortages or longer lead times, especially for popular wood species like cedar or redwood. To mitigate this, consider ordering materials 4–6 weeks in advance or exploring alternative suppliers. Additionally, bulk orders often qualify for discounts but require more storage space, so weigh the cost savings against logistical challenges. For smaller projects, pre-cut decking kits can reduce gathering time to just a few days, though customization options may be limited.

A persuasive argument for investing time in material gathering is the long-term durability and aesthetic appeal of high-quality wood. Opting for premium materials like composite decking or sustainably sourced hardwoods may extend the gathering phase but can result in a deck that lasts 25+ years with minimal maintenance. Conversely, rushing this stage to save time might lead to settling for lower-quality materials, increasing the risk of warping, splintering, or rot. Prioritize suppliers with a reputation for reliability and transparency, even if it means waiting longer for delivery.

Comparatively, DIY enthusiasts often underestimate the complexity of material sourcing. While professional contractors have established relationships with suppliers and access to wholesale pricing, homeowners may face challenges like mismatched inventory or hidden shipping fees. To streamline the process, use online calculators to estimate material needs and leverage local contractor networks for recommendations. For example, a 200 sq. ft. deck typically requires 250–300 linear feet of decking boards, 100–150 screws, and 50–75 joist hangers, so precision in ordering is key.

Descriptively, the material gathering phase is a blend of research, negotiation, and logistics. Picture visiting a lumberyard, running your hand over smooth cedar planks, and discussing grain patterns with a knowledgeable salesperson. Alternatively, imagine scrolling through online catalogs, comparing prices, and calculating shipping costs to stay within budget. Practical tips include requesting material samples to assess color and texture, verifying supplier return policies, and scheduling deliveries to coincide with the start of installation. By treating this phase as a strategic step rather than a mere errand, you set the foundation for a seamless decking project.

How Long Do Wood Stakes Support Trees? A Durability Guide

You may want to see also

Explore related products

Framing Installation Steps

The foundation of any wood decking project lies in its framing, a critical phase that demands precision and adherence to best practices. Begin by laying out the perimeter of your deck, ensuring it aligns with your design plans and local building codes. Use batter boards and mason lines to establish straight, square lines, a step that can take anywhere from 1 to 3 hours depending on the deck’s complexity. This initial setup is crucial, as it dictates the accuracy of the entire framing process.

Once the layout is complete, focus on installing the ledger board, which secures the deck to the house. This step involves attaching a treated 2x8 or 2x10 board to the house’s exterior wall, ensuring it’s level and securely fastened with appropriate hardware. Allow 2 to 4 hours for this task, factoring in time for flashing installation to prevent water damage. Proper ledger installation is non-negotiable, as it bears a significant portion of the deck’s weight and ensures structural integrity.

Next, tackle the beam and joist system, the backbone of your deck’s framing. Position beams perpendicular to the ledger, using posts and footings for support. Joists, typically 2x8 or 2x10 treated lumber, run parallel to the ledger and are spaced 16 inches on center for standard decking. This phase can consume 6 to 8 hours, depending on the deck’s size and the complexity of the post-and-beam setup. Double-check joist hangers and beam connections to ensure they meet load requirements and local codes.

Finally, install blocking and bracing to stabilize the frame. Add 2x4 blocks between joists every 4 to 6 feet to prevent lateral movement and provide nailing surfaces for decking boards. This step, often overlooked, takes 1 to 2 hours but significantly enhances the deck’s durability. Once complete, inspect the entire frame for plumb, level, and square alignment before proceeding to decking installation. A well-executed frame not only speeds up subsequent steps but also ensures a long-lasting, safe deck.

Durability of Wooden Bed Frames: Lifespan and Maintenance Tips

You may want to see also

Explore related products

Deck Board Laying Process

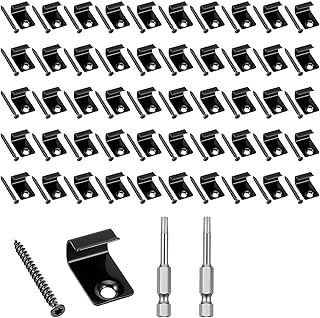

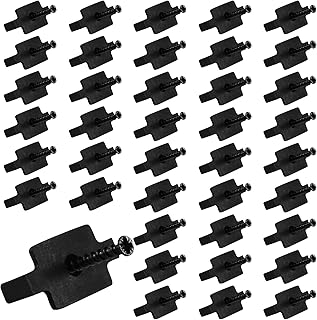

The deck board laying process is a critical phase in wood decking installation, demanding precision and patience. Begin by ensuring your joists are level and spaced no more than 16 inches apart for standard 5/4 decking boards. This spacing prevents sagging and ensures structural integrity. Use a chalk line to mark the starting point, aligning the first board perpendicular to the joists. Secure it with corrosion-resistant screws or nails, leaving a 1/8-inch gap between boards for expansion. This initial setup sets the tone for the entire project, so take your time to get it right.

Once the first board is in place, the real challenge begins: maintaining straight lines and consistent spacing. A hidden fastener system can streamline this process, offering a cleaner look and reducing the risk of splintering. Alternatively, face-screwing with stainless steel screws provides a durable, cost-effective solution. For curved or angled decks, pre-drilling holes and using shorter boards can prevent splitting. Remember, the goal is not just aesthetics but also longevity—properly laid boards resist warping and moisture damage.

Efficiency in this stage hinges on preparation and tools. A pneumatic nailer or screw gun can cut installation time by half compared to manual methods, but accuracy remains paramount. For large decks, consider working in sections, completing one area before moving to the next. This approach minimizes errors and allows for adjustments without disrupting the entire layout. Keep a rubber mallet handy to nudge boards into place without damaging the wood.

Finally, the finishing touches elevate a good deck to a great one. Trim excess board lengths with a circular saw, ensuring clean edges. Fill any gaps or imperfections with wood filler, then sand the surface for a smooth finish. Apply a sealant or stain immediately after installation to protect against UV rays and moisture. This final step not only enhances appearance but also extends the deck’s lifespan, making the meticulous laying process well worth the effort.

Buddha's Forest Retreat: Unveiling the Duration of His Woodland Journey

You may want to see also

Explore related products

Finishing and Cleanup Phase

The final stretch of installing wood decking is the finishing and cleanup phase, a critical step that ensures longevity, safety, and aesthetic appeal. This stage typically takes 1-2 days, depending on the size of the deck and the complexity of the finish. It involves sanding, staining or sealing, and a thorough cleanup to prepare the space for use. Skipping or rushing this phase can lead to splintering, warping, or premature wear, undermining the entire project.

Sanding: The Foundation of a Smooth Finish

Begin by sanding the deck surface with 80-grit sandpaper to remove rough edges and splinters, followed by a pass with 120-grit for a smoother finish. Pay special attention to high-traffic areas and handrails. Use a pole sander for large, flat surfaces and a detail sander for corners and edges. Dust removal is crucial; use a shop vacuum or a tack cloth to ensure the surface is clean before applying any finish. This step alone can take 2-4 hours for a 200 sq. ft. deck, but it’s non-negotiable for professional results.

Staining or Sealing: Protection Meets Aesthetics

Choose a stain or sealant based on your climate and desired look. Semi-transparent stains enhance wood grain while providing UV protection, while solid stains offer more color options and better protection against moisture. Apply the product with a roller or brush, working in small sections to avoid lap marks. Follow the manufacturer’s instructions for drying time, typically 24-48 hours. A second coat may be necessary for deeper color or added protection. This step not only beautifies the deck but also shields it from weather damage, extending its lifespan by 5-10 years.

Cleanup: The Final Touch

Once the finish has dried, remove all tools, debris, and protective coverings. Sweep the deck thoroughly and inspect for any missed splinters or rough spots. Clean the surrounding area, including the yard and house exterior, to remove stains or debris. Dispose of rags, brushes, or leftover finish according to local regulations. A final rinse with a garden hose or pressure washer (on low setting) can remove residual dust, leaving the deck ready for furniture and foot traffic. This phase ensures the deck is not only functional but also safe and inviting.

Practical Tips for Efficiency

Work in the early morning or late afternoon to avoid direct sunlight, which can cause the finish to dry too quickly and unevenly. Keep a damp cloth handy to wipe up spills immediately. For larger decks, consider renting a floor sander to save time. Finally, plan this phase when the weather forecast is dry for at least 48 hours to ensure proper curing. With attention to detail and patience, the finishing and cleanup phase transforms a construction site into a stunning outdoor living space.

Understanding Dry Rot: Timeline for Wood Decay and Prevention Tips

You may want to see also

Frequently asked questions

The installation time for wood decking varies depending on the size and complexity of the project, but it typically takes 2 to 5 days for a standard 200-300 square foot deck.

Yes, the type of wood can impact installation time. Harder woods like Ipe may take longer to cut and fasten compared to softer woods like cedar or pressure-treated pine.

Absolutely. Rain, high winds, or extreme temperatures can halt or slow down the installation process, potentially adding days to the timeline.

Complex designs with features like built-in benches, curved edges, or multi-level structures can significantly increase installation time, often adding 1-3 days or more.

Yes, professional installers typically complete the job faster due to their experience, tools, and team size. DIY installations can take 2-3 times longer, depending on skill level.