When gluing wood panels, the duration for keeping clamps on is a critical factor in ensuring a strong and durable bond. The clamping time largely depends on the type of glue used, the wood species, and the environmental conditions such as temperature and humidity. Typically, for common wood glues like PVA (polyvinyl acetate), clamps should remain in place for at least 30 minutes to an hour to allow the glue to set initially. However, for a fully cured bond, it’s recommended to leave the clamps on for 24 hours or longer, especially for larger or load-bearing panels. Always refer to the glue manufacturer’s instructions for specific guidelines, as some epoxy or specialized glues may require different clamping times. Proper clamping pressure and duration are essential to prevent gaps, warping, or joint failure, ensuring a professional and long-lasting result.

| Characteristics | Values |

|---|---|

| Clamp Time for Wood Panels | Typically 30 minutes to 24 hours, depending on glue type and wood species. |

| Glue Type (PVA/Wood Glue) | 30 minutes to 1 hour for initial set; 24 hours for full cure. |

| Epoxy Glue | 4 to 8 hours for initial set; 24 hours for full cure. |

| Polyurethane Glue | 30 minutes to 1 hour for initial set; 24 hours for full cure. |

| Temperature Influence | Higher temperatures reduce clamp time; lower temperatures extend it. |

| Humidity Influence | Higher humidity can speed up drying; low humidity may slow it down. |

| Wood Species | Dense woods (e.g., oak) may require longer clamping than softwoods (e.g., pine). |

| Panel Thickness | Thicker panels may require longer clamping for even glue distribution. |

| Clamp Pressure | Consistent pressure is crucial; typically 100-200 PSI for wood panels. |

| Initial Set Time | Time until the glue is firm enough to handle without shifting (varies by glue). |

| Full Cure Time | Time until the glue reaches maximum strength (typically 24 hours). |

| Manufacturer Recommendations | Always follow glue manufacturer guidelines for specific clamp times. |

| Safety Precautions | Avoid over-tightening clamps to prevent wood damage. |

| Post-Clamping Handling | Avoid stressing the joint for at least 24 hours after removing clamps. |

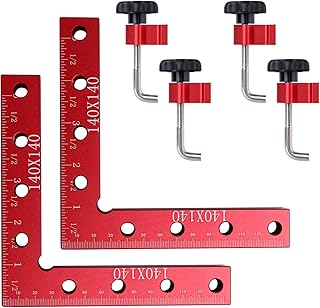

Explore related products

What You'll Learn

Clamp Pressure Requirements

Applying adequate clamp pressure is critical when gluing wood panels, as it ensures a strong, gap-free bond. The force exerted by clamps must be sufficient to compress the glue line evenly, eliminating air pockets and excess adhesive. However, excessive pressure can distort the wood or squeeze out too much glue, weakening the joint. Finding the right balance requires understanding the wood’s properties, the glue’s characteristics, and the panel’s dimensions. For most hardwoods, a clamp pressure of 100–200 psi is recommended, while softer woods may require less to avoid damage. Always refer to the glue manufacturer’s guidelines for specific pressure requirements.

The thickness and width of the wood panels directly influence the number and placement of clamps needed. As a rule of thumb, position clamps every 6–12 inches along the joint for even pressure distribution. Thicker panels may require more clamps or higher pressure to ensure the entire surface is bonded securely. For example, a 1-inch thick panel might need clamps spaced closer together than a ½-inch panel. Use a clamp calculator or trial and error to determine the optimal setup for your project. Remember, consistency is key—irregular pressure can lead to weak spots or visible gaps in the finished piece.

While clamp pressure is essential, it’s equally important to consider the type of clamps used. F-clamps and bar clamps are ideal for larger panels, providing strong, even force across the joint. Quick-grip clamps are convenient for smaller projects but may not offer the same sustained pressure. Pipe clamps, with their long reach and adjustable length, are versatile for various panel sizes. Always ensure clamps are perpendicular to the joint to avoid twisting or uneven pressure. Investing in high-quality clamps with reliable pressure mechanisms can make a significant difference in the outcome of your gluing process.

A common mistake is over-tightening clamps, which can warp the wood or create an uneven glue line. To avoid this, tighten clamps gradually, checking for resistance as you go. A good practice is to tighten until you see a thin, consistent bead of glue squeeze out along the joint—this indicates the glue line is fully compressed. If using a slow-setting glue like epoxy, you may have more time to adjust clamps, but fast-drying options like PVA require quick, precise application. Always monitor the clamps during the initial curing phase, as wood movement or settling can alter the pressure.

Finally, the duration of clamping depends heavily on the glue’s curing time and the clamp pressure applied. Most wood glues require clamps to remain in place for at least 30 minutes to an hour, but thicker panels or slower-curing glues may need 24 hours or more. Always follow the glue manufacturer’s instructions for curing times. Once the glue has fully cured, remove the clamps carefully to avoid stressing the joint. Proper clamp pressure, combined with patience, ensures a durable bond that will withstand the test of time and use.

Tom Ford Oud Wood Longevity: How Long Does It Last?

You may want to see also

Explore related products

Glue Drying Time Factors

Clamps should remain on wood panels until the glue reaches a safe minimum strength, typically 30 minutes to 2 hours for most wood glues, but this is just the beginning of the drying process. The full cure time, when the glue achieves maximum strength, can range from 24 hours to several days, depending on various factors. Understanding these factors is crucial for ensuring a strong, durable bond.

Glue Type and Formulation: Different wood glues have distinct drying times. Polyvinyl acetate (PVA) glues, commonly used for woodworking, generally dry within 30 minutes to an hour but require 24 hours for a full cure. Epoxy resins, known for their superior strength, can take up to 24 hours to set and several days to reach maximum hardness. Cyanoacrylate (super glue) sets almost instantly but may need additional time for a complete bond. Always refer to the manufacturer's instructions for specific drying times.

Environmental Conditions: Temperature and humidity significantly impact glue drying. Higher temperatures accelerate drying, but excessive heat can weaken the bond. Ideal temperatures for most wood glues range between 60°F and 80°F (15°C and 27°C). Humidity affects water-based glues more than solvent-based ones. In humid conditions, water-based glues may take longer to dry, while solvent-based glues are less affected. Proper ventilation is essential to prevent moisture buildup and ensure even drying.

Wood Species and Joint Design: The type of wood and joint design influence drying time. Dense hardwoods like oak or maple may slow down the drying process compared to softer woods like pine. Additionally, the joint’s surface area and clamping pressure play a role. Larger surface areas and adequate clamping pressure ensure even glue distribution and faster drying. For example, a simple butt joint may dry quicker than a complex dovetail joint due to the latter’s intricate design.

Practical Tips for Optimal Results: To ensure a strong bond, keep clamps on for at least the minimum recommended time, then test the joint gently before removing them. Avoid stressing the joint until the glue is fully cured. For critical projects, extend clamping time beyond the minimum to allow for any variability in conditions. Always store glue in a cool, dry place to maintain its effectiveness. By considering these factors, you can achieve a reliable and long-lasting bond in your wood panel projects.

Wood Filler Drying Time: Factors Affecting Cure and Hardening Process

You may want to see also

Explore related products

Wood Type Considerations

Different wood types react uniquely to clamping pressures and glue adhesion, making species selection a critical factor in determining clamp duration. Softwoods like pine or cedar, with their lower density, require less clamping time—typically 30 minutes to an hour—as their porous structure allows glue to penetrate and cure faster. Conversely, hardwoods such as oak or maple, with denser fibers, demand longer clamping periods, often 2 to 4 hours, to ensure the glue fully bonds under pressure. Always refer to the glue manufacturer’s guidelines for wood-specific recommendations, as some adhesives are formulated for particular densities.

When working with exotic or engineered woods, additional considerations arise. Tropical hardwoods like teak or mahogany, known for their natural oils, may repel water-based glues, necessitating longer clamping times—up to 6 hours—to achieve a strong bond. Engineered woods, such as plywood or MDF, have layered structures that can absorb moisture unevenly, potentially causing warping if clamps are removed too soon. For these materials, maintain clamping pressure for at least 4 hours, and inspect the panel for flatness before releasing.

Grain orientation also plays a role in clamping strategy. End-grain joints, where wood fibers are perpendicular to the glue line, are inherently weaker and require extended clamping—often overnight—to ensure the glue fully cures. Edge-grain or face-grain joints, where fibers run parallel to the glue line, bond more readily and typically need only 2 to 3 hours under clamps. Always apply even pressure across the joint, using cauls or scrap wood to distribute force evenly and prevent indentations.

Moisture content in the wood is another critical factor. Freshly milled or damp wood can prolong curing times, as excess moisture dilutes the glue and slows its setting. For best results, ensure wood panels are acclimated to your workshop’s humidity and have a moisture content of 8–12%. If working with damp wood, extend clamping time by 50% and consider using a waterproof glue to mitigate risks.

Finally, consider the wood’s natural movement. Species with high shrinkage or expansion rates, like walnut or cherry, may require longer clamping to stabilize the joint under pressure. After releasing clamps, allow the panel to rest for 24 hours before sanding or finishing, as this minimizes the risk of joint failure due to residual stress. By tailoring clamping duration to the wood’s characteristics, you ensure a durable, professional-grade bond.

Measuring Wood Length: Understanding Standard Sizes and Custom Cuts

You may want to see also

Explore related products

Panel Thickness Impact

Thicker panels demand longer clamping times. This fundamental principle stems from the basic physics of glue curing. As panel thickness increases, the distance the adhesive must penetrate and bond across grows proportionally. A ¾-inch panel, for instance, requires significantly more time for the glue to fully cure and develop maximum strength compared to a ¼-inch panel. Rushing this process risks weak joints prone to failure under stress.

Understanding this relationship is crucial for anyone gluing wood panels, whether crafting furniture, cabinetry, or structural components.

The specific clamping time for a given panel thickness depends on several factors. Glue type plays a major role, with slower-curing adhesives like polyurethane requiring longer clamping periods than fast-setting epoxies. Environmental conditions also matter; higher temperatures generally accelerate curing, while humidity can affect drying times for water-based glues. As a general guideline, for a ¾-inch panel using a standard wood glue, a minimum of 24 hours clamping time is recommended. Thicker panels, exceeding 1 inch, may necessitate 48 hours or more.

Always refer to the manufacturer's instructions for specific recommendations regarding your chosen adhesive.

While longer clamping times are essential for thicker panels, it's important to avoid excessive pressure. Over-clamping can lead to panel distortion, particularly with softer woods. Use enough clamps to distribute pressure evenly across the joint, but avoid over-tightening. A good rule of thumb is to tighten clamps until you feel slight resistance, ensuring the panels are firmly held together without causing undue stress.

Ultimately, the key to successful panel gluing lies in understanding the interplay between panel thickness, glue type, and environmental factors. By respecting the curing time required for the adhesive to fully bond across the panel's thickness, you'll ensure strong, durable joints that withstand the test of time. Remember, patience is paramount when gluing wood panels – rushing the process compromises the integrity of your project.

Understanding Natural Wood Off-Gassing: Duration and Factors Explained

You may want to see also

Explore related products

Environmental Conditions Effect

Humidity levels significantly influence the clamping duration required for gluing wood panels. In high-humidity environments (above 60%), moisture in the air can slow the curing process of most wood glues, particularly polyvinyl acetate (PVA) types. This necessitates extending clamping time by 20–30% to ensure a robust bond. Conversely, in dry conditions (below 30% humidity), the glue may cure faster but risks drying too quickly on the surface, creating a weak bond. Use a hygrometer to monitor humidity and adjust clamping time accordingly, adding 1–2 hours in high humidity or reducing by 30 minutes in dry conditions.

Temperature plays a critical role in glue curing dynamics. Most wood glues perform optimally between 60°F and 80°F (15°C–27°C). Below 50°F (10°C), curing slows dramatically, potentially doubling the required clamping time. Above 90°F (32°C), the glue may set too rapidly, compromising penetration into the wood fibers. For cold environments, preheat the wood panels to room temperature before gluing, and maintain a consistent workspace temperature using heaters or insulation. In hot conditions, apply glue in thin, even layers and clamp immediately to prevent premature drying.

Airflow directly impacts surface drying and curing uniformity. In windy or drafty conditions, the outer layer of glue can dry faster than the interior, leading to a brittle bond. To counteract this, shield the glued panels from direct airflow using plastic sheeting or cardboard barriers. In controlled environments, such as workshops, use fans strategically to maintain gentle, even airflow without accelerating surface drying. For outdoor projects, schedule gluing during calm periods or create a temporary windbreak with tarps.

Direct sunlight can degrade glue performance, particularly for UV-sensitive adhesives like PVA. Prolonged exposure to sunlight raises the surface temperature of wood panels, causing uneven curing and potential warping. When working outdoors, position panels in shaded areas or use reflective shields to block direct sunlight. If indoor lighting is necessary, avoid UV-emitting bulbs and opt for LED or incandescent lights. Always store glue in a cool, dark place to preserve its efficacy, and discard any product that appears discolored or thickened due to heat exposure.

Altitude affects atmospheric pressure, which subtly influences glue curing. At elevations above 5,000 feet (1,500 meters), lower air pressure can cause some glues to off-gas more rapidly, reducing their bonding strength. To compensate, increase clamping pressure by 10–15% and extend clamping time by 1 hour. Additionally, use epoxy or polyurethane glues, which are less affected by altitude, for high-elevation projects. Always test glue performance at your specific altitude before committing to large-scale panel bonding.

Wood Turtles in Captivity: Understanding Their Lifespan and Care

You may want to see also

Frequently asked questions

Clamps should typically remain on wood panels for at least 30 minutes to 1 hour, depending on the type of glue used and the manufacturer's instructions.

While some glues dry quickly, it’s best to keep clamps on for the full recommended time (usually 30 minutes to 1 hour) to ensure a strong bond and prevent shifting.

Follow the glue manufacturer’s curing time guidelines. Most wood glues are clamp-safe after 30 minutes to 1 hour but may take 24 hours to fully cure.

Removing clamps too early can cause the panels to shift or separate, resulting in a weak joint or glue failure. Always wait the recommended clamping time.

![Right Angle Clamp, Housolution [4 PACK] Single Handle 90° Aluminum Alloy Corner Clamp, Clamps for Woodworking Adjustable Swing Jaw, Woodworking Tools Photo Frame Vise Holder, Gifts for Men Dad](https://m.media-amazon.com/images/I/71xNSiBOZ+L._AC_UL320_.jpg)

![Housolution Right Angle Clamp, [2 PACK] Single Handle 90° Aluminum Alloy Corner Clamp, Clamps for Woodworking Adjustable Swing Jaw, Woodworking Tools Photo Frame Vise Holder, Gifts for Men Dad](https://m.media-amazon.com/images/I/71nW-qkVwnL._AC_UL320_.jpg)