When preparing wood for staining or finishing, applying a pre-conditioner is a crucial step to ensure even absorption and a professional finish. However, the duration for leaving pre-conditioner on wood varies depending on the type of wood and the product used. Generally, softwoods like pine may only require 5-10 minutes, while denser hardwoods such as oak or maple can benefit from 10-15 minutes. Always follow the manufacturer’s instructions, as some pre-conditioners may recommend specific times to achieve optimal results. Over-application can lead to blotching or uneven color, so timing is key for a smooth and consistent finish.

| Characteristics | Values |

|---|---|

| Recommended Dwell Time | 10-15 minutes for most pre-conditioners |

| Factors Affecting Dwell Time | Wood type, humidity, temperature, product instructions |

| Softwoods (e.g., Pine, Cedar) | Typically require shorter dwell times (5-10 minutes) |

| Hardwoods (e.g., Oak, Maple) | May require longer dwell times (10-15 minutes) |

| High Humidity Conditions | May reduce dwell time slightly (8-12 minutes) |

| Low Humidity Conditions | May require slightly longer dwell time (12-15 minutes) |

| Temperature Range | Optimal application between 50°F and 90°F (10°C and 32°C) |

| Product-Specific Instructions | Always follow manufacturer guidelines for exact dwell time |

| Over-Application Risks | Can lead to uneven staining, raised grain, or prolonged drying time |

| Under-Application Risks | May result in poor stain absorption or uneven color |

| Testing on Scrap Wood | Recommended to determine optimal dwell time for specific conditions |

| Cleaning After Application | Wipe off excess pre-conditioner after dwell time to avoid residue |

Explore related products

What You'll Learn

Pre-conditioner types and absorption rates

Wood pre-conditioners are not one-size-fits-all. Their effectiveness hinges on the type of pre-conditioner and the wood’s absorption rate, which varies by species, age, and moisture content. Oil-based pre-conditioners, for instance, penetrate denser hardwoods like oak or maple more slowly than water-based formulas. Softwoods like pine, with larger pores, absorb both types more rapidly but may require additional coats for even coverage. Understanding these dynamics ensures optimal preparation for staining, preventing blotching or uneven color absorption.

Analyzing Types and Rates: Water-based pre-conditioners are fast-acting, typically left on wood for 5–10 minutes before wiping off excess. They’re ideal for softwoods or when quick turnaround is needed. Oil-based pre-conditioners, however, demand patience—leave them on for 30–60 minutes, allowing deeper penetration into hardwoods. Gel formulas strike a balance, offering moderate absorption times (15–30 minutes) and reduced risk of drips, making them suitable for vertical surfaces like doors or cabinets.

Practical Application Tips: Always test absorption rates on a scrap piece of the same wood species. For oil-based pre-conditioners, apply a thin, even coat using a brush or cloth, ensuring full coverage without pooling. Water-based formulas can be applied more liberally but require prompt wiping to avoid drying residue. Temperature and humidity play a role too—warmer, drier conditions accelerate absorption, while cooler environments may necessitate extended application times.

Cautions and Considerations: Over-application of pre-conditioner can lead to a greasy finish or interfere with stain adhesion. Conversely, insufficient absorption leaves wood unprepared for staining. For aged or weathered wood, lightly sand the surface before application to enhance pre-conditioner penetration. Always follow manufacturer guidelines for specific products, as some may require unique application techniques or drying times.

How Long Do Germs Survive on Wood Surfaces? A Guide

You may want to see also

Explore related products

Wood species and porosity impact

Wood species and porosity are critical factors that dictate how long a pre-conditioner should remain on the surface before staining or finishing. Dense woods like maple or cherry have tighter grain structures, absorbing conditioners slowly and requiring shorter dwell times—typically 5 to 10 minutes. In contrast, porous woods such as pine or oak soak up conditioners rapidly, often needing 15 to 20 minutes to ensure even penetration. Ignoring these differences risks uneven absorption, leading to blotchy finishes or surface residue. Always test a small area first to gauge absorption rates and adjust timing accordingly.

Analyzing porosity reveals why one-size-fits-all approaches fail. Softwoods like cedar or fir, with their open cell structures, act like sponges, demanding longer conditioning times to prevent the wood from pulling stain unevenly. Hardwoods, with their denser fibers, require precision—leave the conditioner on too long, and excess product can pool, causing sticky surfaces or finish adhesion issues. For example, walnut benefits from a 10-minute application, while ash may only need 7 minutes. Understanding these nuances ensures the conditioner works effectively without over-saturating the wood.

Practical application tips further refine the process. For highly porous woods, apply the conditioner in thin, even coats, allowing each layer to penetrate before adding more. Use a clean cloth to wipe away excess after the recommended time, ensuring no residue remains. In humid conditions, reduce dwell times by 2–3 minutes to account for slower evaporation. Conversely, in dry climates, extend the time slightly to compensate for quicker absorption. These adjustments bridge the gap between theory and practice, delivering consistent results across wood types.

Comparing wood species highlights the need for tailored approaches. Tropical hardwoods like teak or mahogany, known for natural oils and density, may not require pre-conditioning at all, as their inherent properties resist uneven staining. Meanwhile, engineered woods or plywood often have inconsistent porosity, necessitating longer conditioning times—up to 30 minutes—to address variations in layers. By categorizing woods based on porosity and natural oils, craftsmen can predict behavior and optimize conditioning strategies for each project.

In conclusion, mastering the interplay between wood species and porosity transforms pre-conditioning from guesswork into science. Dense woods demand brevity, porous woods require patience, and every species in between calls for observation and adaptation. Armed with this knowledge, woodworkers can achieve uniform, professional finishes, ensuring the natural beauty of the material shines through without flaws. Test, observe, and adjust—these principles elevate every project, regardless of the wood’s characteristics.

John Wood Water Heater Lifespan: What to Expect and How to Extend It

You may want to see also

Explore related products

Environmental factors: humidity and temperature

Humidity levels significantly influence how wood absorbs pre-conditioner, dictating both application time and effectiveness. In high-humidity environments (above 60%), wood fibers swell with moisture, reducing their ability to absorb oils or conditioners. This saturation acts as a barrier, slowing penetration and necessitating longer drying times—often 8–12 hours. Conversely, in low-humidity conditions (below 30%), wood becomes dry and porous, absorbing pre-conditioner rapidly. Here, 2–4 hours may suffice, but over-absorption risks uneven finish or oil pooling. Optimal humidity for application is 40–50%, balancing absorption efficiency and drying speed.

Temperature accelerates or decelerates the chemical reactions within pre-conditioners, directly impacting drying time. In warm climates (75°F–85°F), the product penetrates wood faster due to increased molecular activity, typically requiring 4–6 hours. Cooler temperatures (50°F–65°F) slow this process, extending drying time to 6–10 hours. Below 50°F, pre-conditioners may remain tacky indefinitely, as cold inhibits proper curing. For best results, apply in a temperature-controlled space, avoiding extremes. If working outdoors, schedule applications during mild weather and monitor conditions closely.

The interplay of humidity and temperature creates unique challenges. For instance, a warm, humid day (80°F, 70% humidity) risks surface oiliness due to slow evaporation, while a cool, dry day (60°F, 20% humidity) may cause rapid absorption but uneven distribution. To mitigate this, adjust application thickness: use lighter coats in high heat/humidity and heavier coats in cooler, drier conditions. Always test a small area first to gauge absorption and drying behavior.

Professionals often use dehumidifiers or heaters to create ideal conditions, but DIYers can achieve similar results with practical hacks. In humid areas, run a fan or open windows to improve air circulation. In dry, cool spaces, pre-warm the wood slightly with a hairdryer (on low heat) to enhance absorption. Regardless of environment, avoid direct sunlight, which can cause uneven drying and discoloration.

Understanding these environmental factors transforms pre-conditioning from guesswork into precision. By tailoring application time and technique to humidity and temperature, you ensure optimal wood preparation—whether for staining, sealing, or finishing. This proactive approach not only saves time but also enhances the longevity and appearance of the final product.

Treated Wood Fence Lifespan: Factors Affecting Durability and Longevity

You may want to see also

Explore related products

Desired finish depth and intensity

The desired finish depth and intensity of your wood project hinges on how long you leave the pre-conditioner to work its magic. Think of it as a marinade for your wood – too little time, and the wood won't absorb enough product, resulting in a shallow, uneven finish. Too long, and you risk oversaturation, leading to a sticky, blotchy surface.

Pre-conditioners are designed to prepare the wood by opening its pores, allowing stain or finish to penetrate more deeply and evenly. This is crucial for achieving a rich, consistent color and highlighting the wood's natural grain.

Finding the Sweet Spot:

Most pre-conditioners recommend application times ranging from 5 to 15 minutes. However, this is a general guideline, not a hard and fast rule. Several factors influence the ideal dwell time:

- Wood Type: Dense hardwoods like oak or maple require longer conditioning times (closer to 15 minutes) compared to softer woods like pine or cedar (5-10 minutes).

- Desired Intensity: For a deeper, more pronounced color, err on the longer side of the recommended time. For a subtler effect, shorten the dwell time.

- Environmental Conditions: Warmer temperatures and lower humidity accelerate absorption, potentially requiring shorter conditioning times.

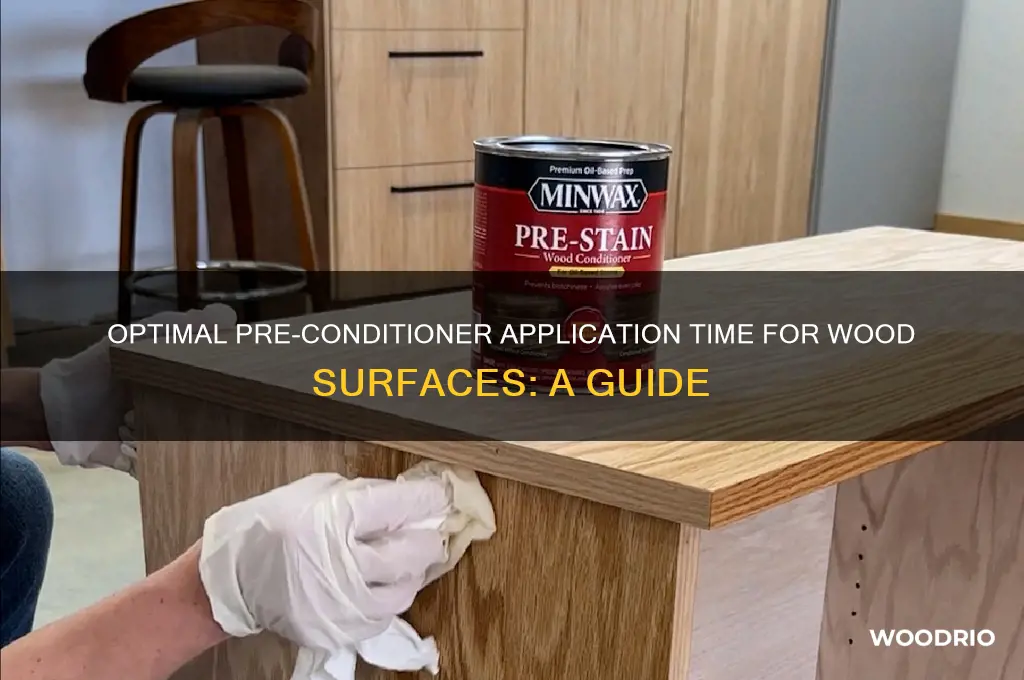

Observing the Process:

The key to success lies in careful observation. After applying the pre-conditioner, watch for the wood's surface to appear slightly darker and more uniform. This indicates that the pores are opening and the product is being absorbed. Once this effect plateaus (usually within the recommended time frame), it's time to wipe away the excess.

Pro Tip: Test the pre-conditioner on a scrap piece of the same wood species to determine the optimal dwell time for your specific project.

Avoiding Common Pitfalls:

Leaving the pre-conditioner on too long can lead to a gummy residue that interferes with stain adhesion. If this happens, gently sand the surface with fine-grit sandpaper before proceeding. Conversely, insufficient conditioning time results in patchy stain absorption and an uneven finish. Remember, patience is key – rushing the process will compromise the final result.

Maine Winter Wood Supply: How Long Does a Cord Last?

You may want to see also

Explore related products

Manufacturer guidelines and recommendations

Manufacturers of wood pre-conditioners provide specific guidelines to ensure optimal results, and these instructions are crucial for achieving the desired wood finish. The recommended dwell time, or the duration the pre-conditioner should remain on the wood surface, varies significantly across brands and product types. For instance, a popular water-based pre-conditioner from Brand X suggests a 10-15 minute application time for softwoods like pine, while hardwoods such as oak may require up to 30 minutes. This variation highlights the importance of consulting the manufacturer's instructions, as each product is formulated with unique ingredients and intended for specific wood types.

In the realm of oil-based pre-conditioners, the guidelines often emphasize longer dwell times. Brand Y's premium oil pre-conditioner, for example, recommends a minimum of 2 hours for absorption, with the option to extend this period for denser wood species. This extended duration allows the oil to penetrate deeply, enhancing the wood's natural grain and providing a more durable base for subsequent finishes. It is essential to note that these longer application times are not merely suggestions but critical steps to achieve the manufacturer's promised results, including improved stain absorption and a more uniform finish.

##

The instructions often include specific application techniques to maximize the pre-conditioner's effectiveness. Some manufacturers advise applying the product with a brush, ensuring an even coat, while others recommend using a cloth for better control and to avoid raising the wood grain. For instance, Brand Z's eco-friendly pre-conditioner line provides a detailed guide on the optimal amount to use, suggesting 100-150 ml per square meter for the first coat, with a second coat applied after 4 hours, but only if the wood appears to have absorbed the initial application completely. This precision in dosage and technique underscores the manufacturer's role in guiding users toward the best outcomes.

A comparative analysis of various manufacturer guidelines reveals a common emphasis on wood preparation. Before applying the pre-conditioner, most brands insist on sanding the wood surface to a specific grit, typically ranging from 120 to 220, depending on the wood type and desired finish. This preparation step ensures the wood is ready to receive the pre-conditioner, allowing for better absorption and a more consistent result. Following these guidelines not only ensures the product performs as advertised but also helps users avoid common pitfalls, such as uneven staining or poor finish adhesion.

In summary, manufacturer guidelines are not mere suggestions but essential instructions tailored to each pre-conditioner's unique formulation and intended use. By following these recommendations, woodworkers and DIY enthusiasts can achieve professional-quality results, ensuring the wood is properly prepared for staining or finishing. From specific dwell times and application techniques to precise dosage instructions, these guidelines provide a roadmap to success, highlighting the manufacturer's expertise and commitment to product performance. Adhering to these instructions is a critical step in any wood finishing project, ensuring the final result meets, if not exceeds, expectations.

Wood Sealant Drying Time: Essential Tips for Perfect Application and Results

You may want to see also

Frequently asked questions

Leave pre-conditioner on wood for 5–15 minutes, depending on the product instructions and wood type.

No, leaving pre-conditioner on wood overnight is not recommended, as it can lead to uneven absorption and affect the final finish.

Pre-conditioner typically dries within 15–30 minutes, but check the product label for specific drying times.

Yes, wipe off any excess pre-conditioner with a clean cloth after the recommended dwell time to ensure proper stain absorption.

Leaving pre-conditioner on too long can cause blotching, uneven color, or interfere with the stain’s ability to penetrate the wood properly.