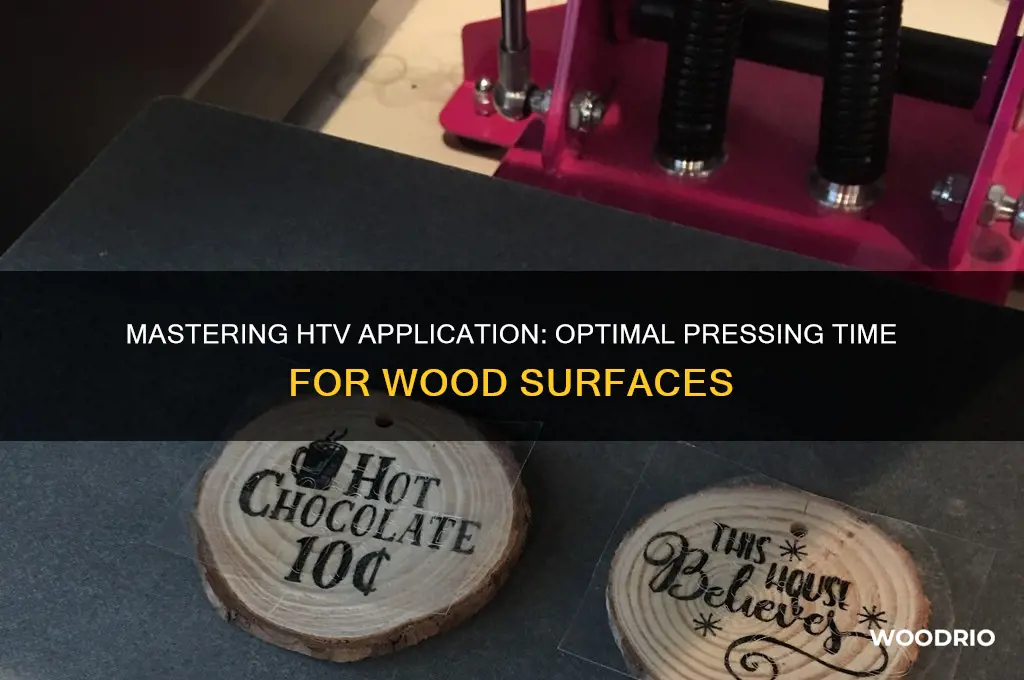

Heat Transfer Vinyl (HTV) is a popular choice for customizing wood surfaces, offering a durable and professional finish. However, achieving the perfect application requires precise timing when pressing the HTV onto the wood. The duration of the press depends on factors such as the type of HTV, the heat press or iron used, and the wood’s surface texture. Generally, HTV on wood requires pressing for 15 to 30 seconds at a temperature between 305°F to 320°F (152°C to 160°C). It’s crucial to follow the manufacturer’s guidelines and perform a test press to ensure the HTV adheres properly without damaging the wood. Proper timing ensures a long-lasting bond and a smooth, professional result.

| Characteristics | Values |

|---|---|

| Press Time | 15-30 seconds |

| Temperature | 305°F (152°C) |

| Pressure | Medium to firm pressure |

| Peeling | Cold peel (peel immediately after pressing) |

| Wood Type | Works best on smooth, non-porous wood surfaces |

| HTV Type | Regular HTV (not specialty types like glitter or holographic) |

| Additional Notes | Preheat wood for 10-15 seconds before applying HTV; ensure surface is clean and dry |

Explore related products

What You'll Learn

- Ideal temperature settings for HTV application on wood surfaces

- Recommended pressing time for different wood types and HTV brands

- Using a heat press vs. household iron for wood HTV projects

- Layering HTV on wood: additional pressing time and precautions

- Troubleshooting common issues: peeling, bubbling, or incomplete adhesion on wood

Ideal temperature settings for HTV application on wood surfaces

Heat transfer vinyl (HTV) application on wood surfaces requires precise temperature control to ensure adhesion without damaging the material. Wood, being a natural and often porous substrate, reacts differently to heat compared to fabrics or plastics. The ideal temperature range for most HTV applications on wood falls between 300°F to 325°F (149°C to 163°C). This range balances the need for heat activation of the adhesive with the risk of scorching or warping the wood. Always consult the manufacturer’s guidelines for your specific HTV brand, as variations exist.

The duration of heat application is equally critical, typically ranging from 15 to 20 seconds. However, temperature and time are interdependent—higher temperatures may require shorter press times, while lower temperatures may necessitate longer durations. For example, pressing at 300°F for 20 seconds is a common starting point, but if using a darker wood or thicker HTV, reducing the temperature to 285°F and extending the press time to 25 seconds may yield better results. Experimentation with scrap wood is recommended to fine-tune settings for your specific project.

One often-overlooked factor is the type of wood being used. Hardwoods like oak or maple can withstand higher temperatures and longer press times compared to softer woods like pine, which may scorch or dent more easily. Additionally, the moisture content of the wood plays a role—drier wood is less prone to warping under heat. If working with unfinished wood, ensure it’s smooth and free of debris to avoid imperfections in the HTV transfer.

To optimize adhesion, preheating the wood surface for 2-3 seconds before applying the HTV can help remove moisture and improve bond strength. Use a Teflon sheet or parchment paper between the heat press and the HTV to prevent scorching and ensure even heat distribution. After pressing, allow the wood to cool completely before peeling the carrier sheet to avoid lifting the vinyl.

In summary, achieving the ideal temperature for HTV on wood involves balancing heat, time, and material properties. Start within the 300°F to 325°F range, adjust based on wood type and HTV thickness, and always test on scrap material. Proper preparation and post-press care will ensure a durable, professional finish.

Durability of Wooden Hammock Stands: Lifespan and Maintenance Tips

You may want to see also

Explore related products

Recommended pressing time for different wood types and HTV brands

Pressing heat transfer vinyl (HTV) onto wood requires precision, as different wood types and HTV brands demand specific time and temperature settings. For instance, softer woods like pine or cedar absorb heat more quickly, often requiring shorter press times (10–15 seconds) at lower temperatures (285°F–300°F) to avoid scorching. Harder woods like oak or maple, however, may need longer press times (20–25 seconds) at slightly higher temperatures (305°F–320°F) to ensure proper adhesion. Always test a small area first to fine-tune your settings.

Among HTV brands, Siser EasyWeed stands out for its versatility, typically adhering well to wood within 15–20 seconds at 305°F. Cricut Everyday Iron-On, on the other hand, may require a slightly longer press time of 20–25 seconds at the same temperature to achieve optimal results. Specialty HTVs, like glitter or holographic varieties, often need additional time (up to 30 seconds) due to their thicker composition. Always refer to the manufacturer’s guidelines, but be prepared to adjust based on your wood type and heat press efficiency.

For best results, consider the wood’s moisture content and finish. Unsealed or raw wood may absorb heat unevenly, necessitating a pre-press (5–10 seconds) to remove moisture before applying HTV. Sealed or painted wood surfaces, however, may require a firmer press and slightly higher temperature to penetrate the protective layer. Use a Teflon sheet or parchment paper to protect both the HTV and wood surface during pressing, ensuring even heat distribution and preventing scorch marks.

A comparative analysis reveals that while pressing times vary, consistency in pressure is equally critical. Insufficient pressure can lead to incomplete adhesion, while excessive pressure may damage the wood or HTV. Aim for medium, even pressure across the entire surface. For intricate designs or small wood pieces, a handheld heat press or iron with firm, circular motions can yield better results than a flat press, which may not conform to uneven surfaces.

In conclusion, mastering HTV application on wood hinges on understanding the interplay between wood type, HTV brand, and pressing conditions. Start with the recommended settings, then adjust incrementally based on your specific materials and equipment. Patience and experimentation are key—rush the process, and you risk poor adhesion or wood damage; take your time, and you’ll achieve professional, long-lasting results. Always document your successful settings for future reference, as consistency is the hallmark of expertise in this craft.

Perfect Campfire Wood: Seasoning Time for Safe, Efficient Burning

You may want to see also

Explore related products

Using a heat press vs. household iron for wood HTV projects

Heat transfer vinyl (HTV) on wood projects demands precision, especially when considering the pressing tool. While both heat presses and household irons can apply HTV to wood, their performance and outcomes differ significantly. A heat press offers consistent temperature and pressure, crucial for even adhesion on wood’s uneven surface. Household irons, though accessible, require more skill to maintain steady heat and pressure, often leading to uneven results. Understanding these differences ensures your wood HTV project succeeds, regardless of the tool you choose.

Steps for Using a Heat Press on Wood HTV Projects

Set your heat press to 305°F (150°C), the recommended temperature for most HTV brands. Preheat the press for 1-2 minutes to ensure even heat distribution. Place the wood surface on the press, position the HTV design, and cover it with a Teflon sheet or parchment paper. Press for 15-20 seconds, applying firm pressure. Allow the wood to cool completely before peeling the carrier sheet. This method guarantees professional results with minimal effort, making it ideal for intricate designs or bulk projects.

Cautions When Using a Household Iron

Household irons lack the precision of heat presses, requiring careful technique. Avoid irons with steam settings or temperature controls that fluctuate. To press HTV on wood with an iron, set it to the cotton or linen setting (typically medium-high heat). Place the HTV design on the wood, cover with parchment paper, and apply firm, circular pressure for 20-30 seconds per section. Move the iron constantly to prevent scorching. This method is more labor-intensive and less reliable for large or detailed designs but remains a viable option for small-scale projects.

Comparative Analysis: Heat Press vs. Iron

A heat press excels in consistency and efficiency, making it the superior choice for professional or repetitive wood HTV projects. Its even heat and pressure ensure long-lasting adhesion, even on textured wood surfaces. Conversely, a household iron demands more attention and skill, with results varying based on technique and iron quality. While an iron is budget-friendly and accessible, it’s better suited for beginners or one-off projects where perfection isn’t critical.

Practical Tips for Success

Regardless of the tool, prepare your wood surface by sanding it smooth and cleaning it of dust or debris. Use a Teflon sheet or parchment paper to protect both the HTV and your pressing tool. For curved or uneven wood pieces, apply gentle, even pressure with your iron or use a heat press with adjustable pressure settings. Always test a small area first to ensure compatibility between the HTV, wood, and pressing tool. With the right approach, both heat presses and irons can yield impressive wood HTV results.

Understanding Water Damage: How Long Does Wood Take to Recover?

You may want to see also

Explore related products

Layering HTV on wood: additional pressing time and precautions

Layering Heat Transfer Vinyl (HTV) on wood can elevate your projects with depth and complexity, but it demands precision and patience. Each additional layer requires extra pressing time to ensure proper adhesion without damaging the material. For instance, a single layer of HTV typically needs 10-15 seconds of pressing, but adding a second layer extends this to 15-20 seconds per layer. This incremental increase accounts for the cumulative heat absorption of the wood and vinyl, ensuring each layer bonds securely without scorching.

The type of wood and HTV used significantly impacts the process. Softer woods like pine absorb heat more readily, necessitating lower temperatures (around 305°F) and shorter press times. Harder woods like oak or walnut can withstand higher temperatures (up to 320°F) but still require careful monitoring. Glossy or specialty HTVs may also need adjustments—for example, glitter HTV often requires 10-15 additional seconds per layer due to its thicker composition. Always refer to the manufacturer’s guidelines for specific recommendations.

Precautions are critical when layering HTV on wood. Overheating can cause the wood to burn or the vinyl to melt, while insufficient heat results in peeling. Use a Teflon sheet or parchment paper between the heat press and the vinyl to distribute heat evenly and protect the surface. Allow each layer to cool completely before applying the next to prevent shifting or bubbling. For intricate designs, consider pre-cutting and weeding each layer separately to ensure precise alignment.

A practical tip for multi-layered projects is to test on a scrap piece of wood first. This allows you to fine-tune temperature, pressure, and timing without risking your final piece. If using a Cricut EasyPress or similar tool, apply firm, even pressure and use a timer to avoid overexposure. For larger projects, work in sections to maintain control over heat distribution. Remember, layering HTV on wood is as much an art as a science—practice and experimentation yield the best results.

Gel Medium Drying Time on Wood: A Comprehensive Guide

You may want to see also

Explore related products

Troubleshooting common issues: peeling, bubbling, or incomplete adhesion on wood

Peeling, bubbling, or incomplete adhesion of HTV on wood often stems from improper surface preparation. Wood’s natural texture and oils can create barriers to adhesion, even if the surface feels smooth. Sanding the wood with 220-grit sandpaper removes rough patches and opens pores, while wiping with rubbing alcohol eliminates oils and debris. Skip this step, and your HTV will likely fail to bond uniformly, regardless of pressing time or temperature.

Temperature and pressure inconsistencies are another culprit. HTV requires precise heat to activate its adhesive properties, typically between 305°F and 315°F for wood. Too low, and the adhesive won’t melt; too high, and it can scorch the wood or HTV. Use a heat gun or press with a reliable thermometer to ensure accuracy. Pressure must be firm but even—a Cricut EasyPress or household iron with firm, circular motions works better than a light, quick press. Incomplete coverage leads to bubbling or lifting edges.

Moisture in the wood, though unseen, can sabotage adhesion. Wood stored in humid environments absorbs moisture, which evaporates during pressing, creating bubbles or gaps. Always acclimate wood to your workspace for 24–48 hours before application. For humid climates, consider sealing the wood with a thin coat of shellac or sanding sealer, allowing it to dry completely before applying HTV. This creates a moisture barrier without compromising adhesion.

Layering HTV or using incompatible materials exacerbates adhesion issues. Each layer adds thickness, reducing heat penetration and increasing the risk of peeling. If layering is necessary, preheat the wood for 10–15 seconds to remove moisture, apply the first layer, and let it cool before adding the next. Avoid mixing HTV types (e.g., regular HTV with puff or glitter HTV) unless explicitly stated as compatible by the manufacturer.

Finally, rushing the cooling process can undo your efforts. Peeling HTV too soon or exposing it to sudden temperature changes (e.g., placing it near a fan or window) weakens the bond. Let the HTV cool naturally under the carrier sheet for at least 1–2 minutes. For wood, which retains heat longer than fabrics, err on the side of caution—wait 5 minutes before removing the carrier sheet. Patience here ensures the adhesive sets fully, preventing edges from lifting later.

Tacky Glue Drying Time on Wood: Quick Tips for Crafters

You may want to see also

Frequently asked questions

The recommended time to press HTV on wood is typically 10-15 seconds, depending on the type of HTV and the heat press or iron used. Always refer to the manufacturer’s instructions for specific guidelines.

Pressing HTV on wood for longer than 15 seconds is not recommended, as it can cause the wood to scorch or the HTV to melt and lose its adhesive properties. Stick to the suggested time for best results.

Yes, temperature plays a crucial role. Most HTV requires a temperature of 305°F to 320°F (152°C to 160°C) for wood. Adjust the pressing time slightly if using a lower or higher temperature, but avoid exceeding the recommended range to prevent damage.

![Cricut EasyPress Mat, Protective Heat-Resistant Mat for Heat Press Machines and HTV and Iron On Projects, [12" x 12"] (2004475)](https://m.media-amazon.com/images/I/71RB90WvdzL._AC_UL320_.jpg)