Bending wood is a technique often used in woodworking to create curved shapes and intricate designs. One popular method involves soaking wood in ammonia to make it more pliable. The duration of the ammonia soak depends on several factors, including the type of wood, its thickness, and the desired bend. Generally, hardwoods require a longer soak time, ranging from 4 to 8 hours, while softer woods may only need 2 to 4 hours. It’s crucial to monitor the wood during the process, as over-soaking can weaken the material. After soaking, the wood must be bent immediately and clamped in place until it dries, ensuring it retains the desired shape. Always work in a well-ventilated area and wear protective gear, as ammonia fumes can be harmful.

| Characteristics | Values |

|---|---|

| Soaking Time | 4-7 days (varies based on wood thickness and type) |

| Ammonia Type | Household ammonia (5-10% concentration) |

| Wood Type | Best for hardwoods (e.g., oak, maple); softwoods may require less time |

| Temperature | Room temperature (68-77°F or 20-25°C) |

| Container Material | Plastic or glass (avoid metal due to corrosion) |

| Ammonia-to-Water Ratio | 1:1 (equal parts ammonia and water) |

| Wood Thickness | Thicker wood requires longer soaking time |

| Bending Time After Soaking | Immediately after removal from ammonia solution |

| Drying Time After Bending | 24-48 hours in a well-ventilated area |

| Safety Precautions | Wear gloves, goggles, and work in a ventilated area |

| Environmental Impact | Ammonia is toxic; dispose of solution properly |

| Alternative Methods | Steam bending or using vinegar (less effective than ammonia) |

| Effect on Wood | May lighten wood color; does not significantly weaken wood |

Explore related products

What You'll Learn

Ammonia type for wood bending

The type of ammonia used for wood bending is a critical factor in the process, as it directly influences the effectiveness and safety of the treatment. Household ammonia, typically a 5-10% solution of ammonium hydroxide in water, is the most commonly recommended type for this purpose. Its mild concentration allows for controlled softening of the wood fibers without causing excessive damage or weakening the material. Stronger industrial-grade ammonia, often found in concentrations of 25% or higher, is generally discouraged due to its corrosive nature and potential to degrade the wood’s structural integrity. For optimal results, use clear, unscented household ammonia, avoiding any additives or dyes that could interfere with the process.

When preparing the ammonia solution, dilution is rarely necessary, as the standard household concentration is already ideal for wood bending. However, if using a stronger solution, dilute it with water to achieve a 5-10% concentration. The soaking time, typically ranging from 30 minutes to 2 hours, depends on the wood species and thickness. Harder woods like oak or maple may require closer to 2 hours, while softer woods like pine may only need 30-45 minutes. Always test a small piece of wood first to determine the ideal soaking duration for your specific project.

Safety precautions are paramount when working with ammonia. The fumes can be irritating to the eyes, skin, and respiratory system, so always work in a well-ventilated area or outdoors. Wear gloves, safety goggles, and a mask to protect yourself from direct exposure. After soaking, rinse the wood thoroughly with water to remove any residual ammonia, which can affect finishing or gluing processes later. Proper disposal of the ammonia solution is also essential; neutralize it with vinegar before pouring it down the drain to prevent environmental harm.

Comparing ammonia to other wood-bending methods, such as steaming, highlights its accessibility and simplicity. While steaming requires specialized equipment and more time, ammonia soaking can be done with common household items and yields results in a fraction of the time. However, ammonia is less forgiving than steam, as over-soaking can lead to irreversible damage. For this reason, precise timing and careful monitoring are crucial when using ammonia for wood bending.

In practice, the choice of ammonia type and its application can make or break a wood-bending project. By selecting the right household ammonia, adhering to safety guidelines, and carefully controlling the soaking time, craftsmen can achieve beautifully curved wooden pieces with minimal risk. Whether creating furniture, musical instruments, or decorative elements, understanding the nuances of ammonia type and usage ensures both success and safety in the wood-bending process.

How Long Does Wood Last Before Requiring Stripping?

You may want to see also

Explore related products

Ideal soaking time for wood

The ideal soaking time for wood in ammonia to achieve optimal bending flexibility hinges on a delicate balance between species, thickness, and desired curvature. Harder woods like oak or maple demand longer immersion—up to 24 hours—while softer varieties such as pine or cedar may soften sufficiently within 8–12 hours. Thicker pieces require additional time; a 1-inch board might need twice as long as a ½-inch counterpart. Always test a scrap piece first to calibrate timing for your specific project.

Ammonia concentration plays a critical role in this process. A 10% solution (household ammonia diluted with water) is typically effective without causing excessive degradation. Stronger concentrations accelerate softening but risk weakening the wood’s structural integrity. Submerge the wood completely, ensuring even exposure, and maintain a consistent temperature—warmer environments (70–80°F) expedite the process but require vigilant monitoring to prevent over-softening.

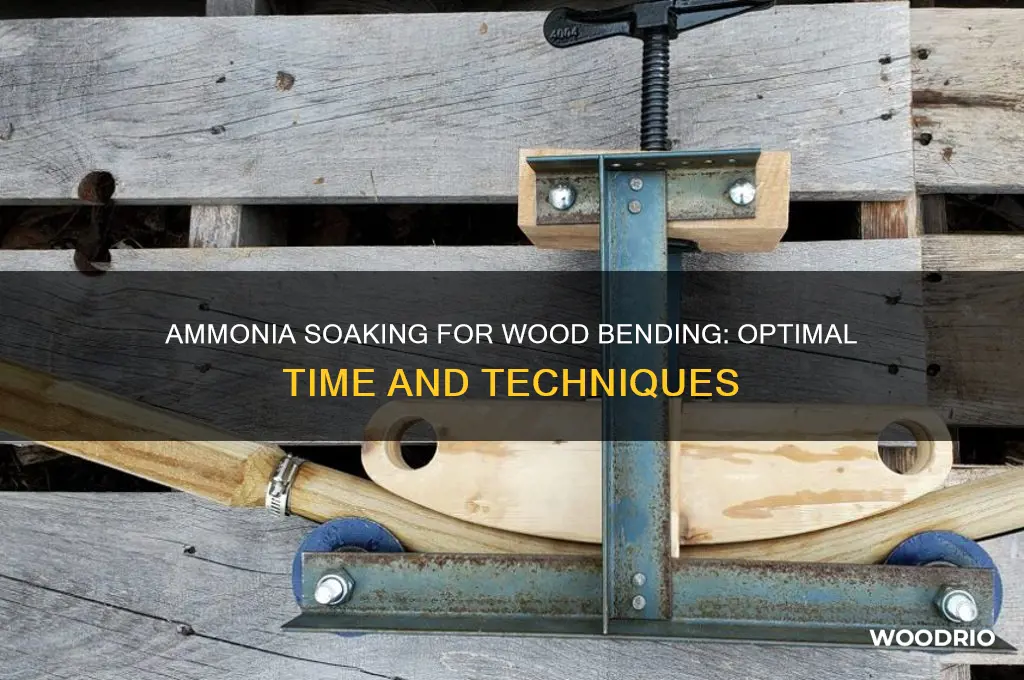

The bending window is fleeting, lasting only 1–2 hours after removal from the ammonia bath. Work swiftly but deliberately, as the wood will stiffen rapidly once exposed to air. Steam application immediately before bending can extend this window, providing additional pliability. Secure the wood in its bent shape using clamps or molds, and allow it to dry thoroughly—a process that may take several days—to retain the new form permanently.

Caution is paramount when handling ammonia. Always work in a well-ventilated area, wear gloves and safety goggles, and avoid inhaling fumes. Neutralize the wood post-soaking by rinsing it with a vinegar-water solution to prevent chemical residue. While ammonia soaking is a proven method, it’s not suitable for all projects; consider alternatives like steam bending or kerf-cutting for delicate or high-stakes pieces. Mastery of this technique requires patience, experimentation, and respect for the material’s limits.

Wood Decay Timeline: Factors Affecting Decomposition and Breakdown Process

You may want to see also

Explore related products

Wood species and ammonia reaction

The reaction between wood species and ammonia during the bending process is a delicate interplay of chemistry and material science. Different wood species exhibit varying levels of susceptibility to ammonia, which directly impacts the soaking time required for successful bending. For instance, hardwoods like oak and maple generally require longer soaking times—up to 48 hours—due to their dense cellular structure. In contrast, softer woods such as pine or cedar may only need 12 to 24 hours to achieve the necessary flexibility. Understanding these differences is crucial for achieving precise bends without compromising the wood’s integrity.

When selecting ammonia for wood bending, the concentration matters significantly. A common recommendation is a 10% to 20% ammonia solution, which strikes a balance between effectiveness and safety. Higher concentrations can accelerate the process but risk damaging the wood fibers, particularly in softer species. For hardwoods, a 15% solution is often ideal, while softer woods may respond better to a 10% mixture. Always test a small sample of the wood species before committing to a full-scale project to ensure compatibility and avoid costly mistakes.

The age and moisture content of the wood also play a pivotal role in its reaction to ammonia. Freshly cut, or "green," wood typically absorbs ammonia more readily than seasoned wood, which may require additional soaking time. Ideally, wood should have a moisture content of 12% to 15% before soaking, as this range optimizes the ammonia’s ability to break down lignin, the compound responsible for wood rigidity. If working with seasoned wood, consider rehydrating it by soaking in water for 24 hours prior to the ammonia treatment to enhance absorption.

Practical tips can further refine the bending process. After soaking, the wood should be bent immediately while still pliable, as it will begin to stiffen once exposed to air. Applying heat—such as from a steam box or heat gun—can complement the ammonia treatment, particularly for stubborn hardwoods. Additionally, sealing the wood in a plastic bag during soaking ensures even ammonia distribution and minimizes waste. Always work in a well-ventilated area and wear protective gear, as ammonia fumes can be hazardous.

In conclusion, mastering the wood species and ammonia reaction requires a blend of scientific understanding and practical experimentation. By tailoring the soaking time, ammonia concentration, and wood preparation to the specific species, craftsmen can achieve precise, durable bends. This nuanced approach not only enhances the quality of the final product but also deepens the appreciation for the intricate relationship between materials and processes in woodworking.

Spalting Wood: Understanding the Timeframe for Unique Artistic Results

You may want to see also

Explore related products

Safety precautions during soaking

Ammonia fumes are toxic and can cause severe respiratory issues, eye irritation, and chemical burns. Always soak wood in a well-ventilated area, preferably outdoors or in a space with powerful exhaust systems. If working indoors, open windows and use fans to maintain airflow. Wear a respirator with ammonia-rated cartridges, not just a dust mask, to protect your lungs. Eye protection, such as goggles, is essential to prevent splashes from causing harm. Nitrile gloves and long sleeves shield skin from prolonged exposure, as ammonia can cause dermatitis.

The concentration of ammonia solution matters significantly. Household ammonia (5-10% concentration) is commonly used for wood bending, but stronger solutions increase toxicity risks. Dilute concentrated ammonia with water if necessary, but always add ammonia to water, never the reverse, to avoid a violent chemical reaction. Limit soaking time to 4-8 hours for most woods, as longer exposure may weaken the wood fibers or intensify fume release. Monitor the process closely, and never leave ammonia-soaked wood unattended, especially in enclosed spaces.

Children and pets must be kept away from the soaking area due to the high risk of accidental ingestion or inhalation. Store ammonia in its original container, clearly labeled and out of reach, in a cool, dry place. Clean up spills immediately with baking soda to neutralize the ammonia, followed by thorough rinsing with water. Dispose of used ammonia solution responsibly, following local hazardous waste guidelines, as improper disposal can harm the environment.

After soaking, handle the wood with care, as it will be more pliable but also fragile. Rinse the wood thoroughly with water to remove ammonia residue before bending, as residual chemicals can cause skin irritation or affect finishing processes. Dry the wood completely in a well-ventilated area before applying heat for bending, as moisture can lead to steam buildup and uneven results. Always prioritize safety over expediency, as the consequences of ammonia exposure can be severe and long-lasting.

Mastering Hickory Wood Seasoning: Optimal Time for Perfect Flavor

You may want to see also

Explore related products

Post-soaking wood bending techniques

Ammonia soaking softens wood fibers, making them pliable for bending, but the real craftsmanship lies in what happens after the soak. Post-soaking techniques determine whether your bent wood retains its shape, cracks, or warps. The first critical step is controlled drying. Rapid drying can cause the wood to revert to its original stiffness or even split. Instead, allow the wood to air-dry gradually in a warm, low-humidity environment. Covering the wood with a damp cloth or plastic wrap can slow the drying process, giving the fibers time to set in their new shape.

Once dried, the bent wood must be stabilized to prevent it from springing back. Clamping is essential during this phase. Use clamps or a form to hold the wood in its desired shape until fully cured. For larger projects, such as chair legs or curved panels, consider using a jig or mold to maintain consistent pressure. The clamping time varies depending on the wood species and thickness but typically ranges from 24 to 72 hours. Hardwoods like oak or maple may require longer clamping periods compared to softer woods like pine or cedar.

Heat application can further enhance the bending process post-soak. Applying heat while the wood is still pliable can help set the fibers in their new position. A heat gun or steam can be used, but caution is necessary to avoid scorching or over-drying the wood. For steam bending, rehydrate the wood slightly by misting it with water before applying heat. This method is particularly effective for tight curves or intricate shapes.

Finally, post-bending treatment is crucial for longevity. Seal the wood with a finish to protect it from moisture fluctuations, which can cause warping or cracking. Oil-based finishes or polyurethane are excellent choices, as they penetrate the wood fibers and provide a durable barrier. Sanding the bent wood gently before finishing ensures a smooth surface and removes any residual ammonia.

Mastering post-soaking techniques transforms ammonia-soaked wood from a temporary bend into a permanent, functional piece. Patience, precision, and attention to detail during drying, clamping, heat application, and finishing will yield professional results. Whether crafting furniture, musical instruments, or decorative elements, these methods ensure your bent wood retains its shape and beauty for years to come.

Spider Wood Aquarium Lifespan: Durability and Maintenance Tips Revealed

You may want to see also

Frequently asked questions

Wood typically needs to be soaked in ammonia for 4 to 8 hours to become pliable enough for bending, depending on the wood species and thickness.

Yes, denser hardwoods like oak or maple may require longer soaking times (up to 8 hours), while softer woods like pine may only need 4 to 6 hours.

Leaving wood in ammonia overnight (8–12 hours) is generally safe and can make it more pliable, but avoid exceeding 24 hours, as prolonged exposure may weaken the wood.

Yes, it’s recommended to dilute household ammonia with an equal amount of water (1:1 ratio) to reduce its strength while still effectively softening the wood.

The wood is ready when it feels flexible and can be bent without cracking or breaking. Test a small piece first to ensure it’s sufficiently softened.

![Ziruma Non-Toxic Wood Wax - Natural Wood Conditioner for Butcher Blocks, Wooden Utensils & Bowls – No Mineral Oil, No Petroleum - Pure Beeswax, Lemon & Flaxseed Oil [7 oz]](https://m.media-amazon.com/images/I/61jR838SaKL._AC_UL320_.jpg)